Special round thread highly-torque-resistant oil casing coupling

A technology for connecting joints and round threads, which is applied in the field of special round thread high-torque oil casing connection joints, can solve the problems of unsatisfactory use effect, weak bending resistance, leakage of threaded connections, etc. Good buckle performance, not easy to buckle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

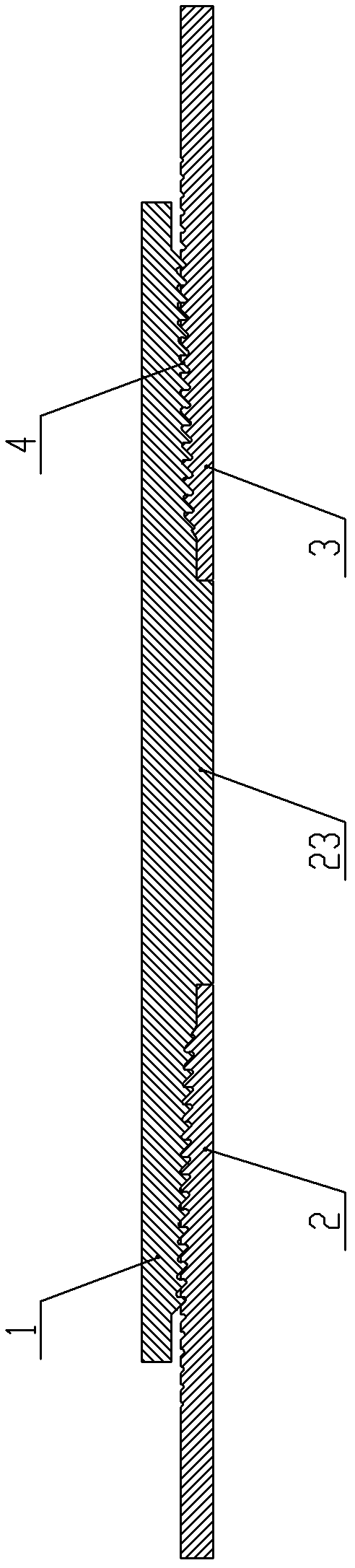

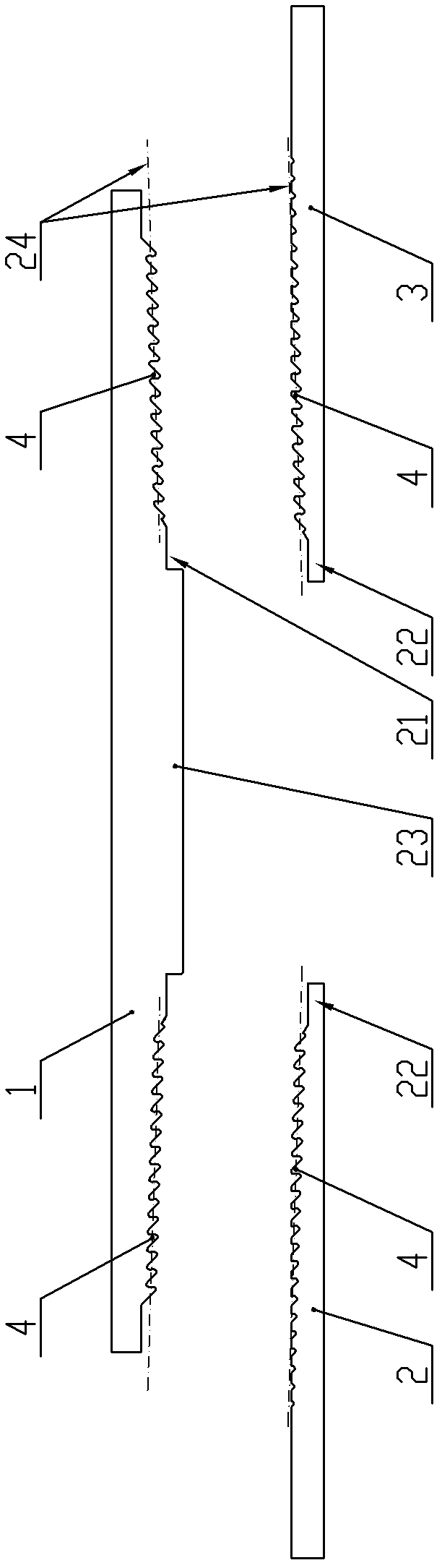

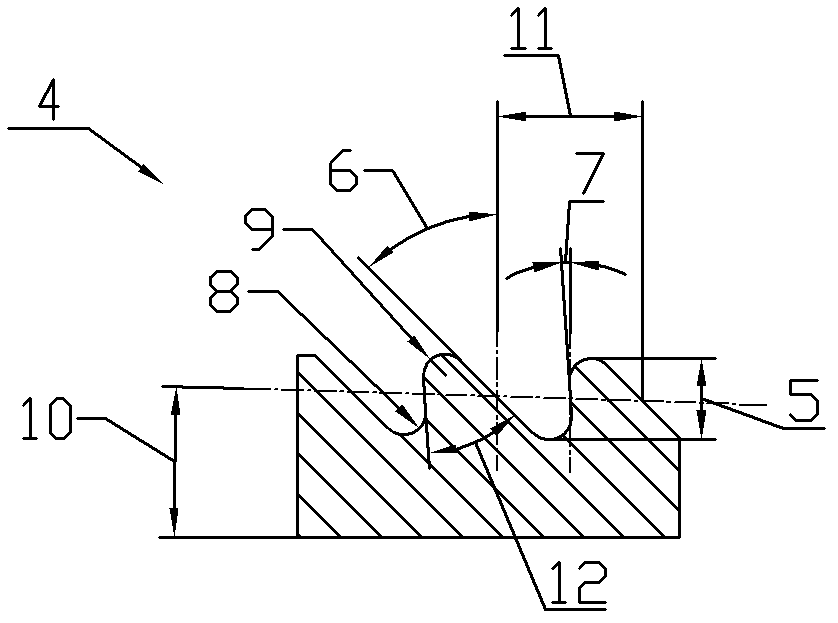

[0020] Figure 1~Figure 5 Among them, including coupling 1, pipe body 2, pipe body 3, thread 4, tooth height 5, guide surface flank angle 6, bearing surface flank angle 7, tooth bottom arc 8, tooth top arc 9, Taper 10, pitch 11, tooth angle 12, outer seal cylinder 13, inner seal cylinder 14, outer seal end face 15, inner seal end face 16, outer end fillet 17, inner end fillet 18, outer end inner Fillet 19, inner end face outer fillet 20, inner sealing surface 21, outer sealing surface 22, middle cylindrical surface 23, middle diameter line 24, etc.

[0021] Such as figure 1 , figure 2 As shown, the present invention is a special round thread high-torque oil-casing connection joint, which includes a coupling 1 connected by a thread 4 and pipe bodies 2 and 3 . The coupling 1 and the pipe body 2 are closely matched based on the virtual pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com