All-gear automotive automatic transmission

A technology for automatic transmissions and gears, applied to gear transmissions, belts/chains/gears, transmissions, etc., to achieve the effects of not being easily damaged, reducing failures, and expanding the torque range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

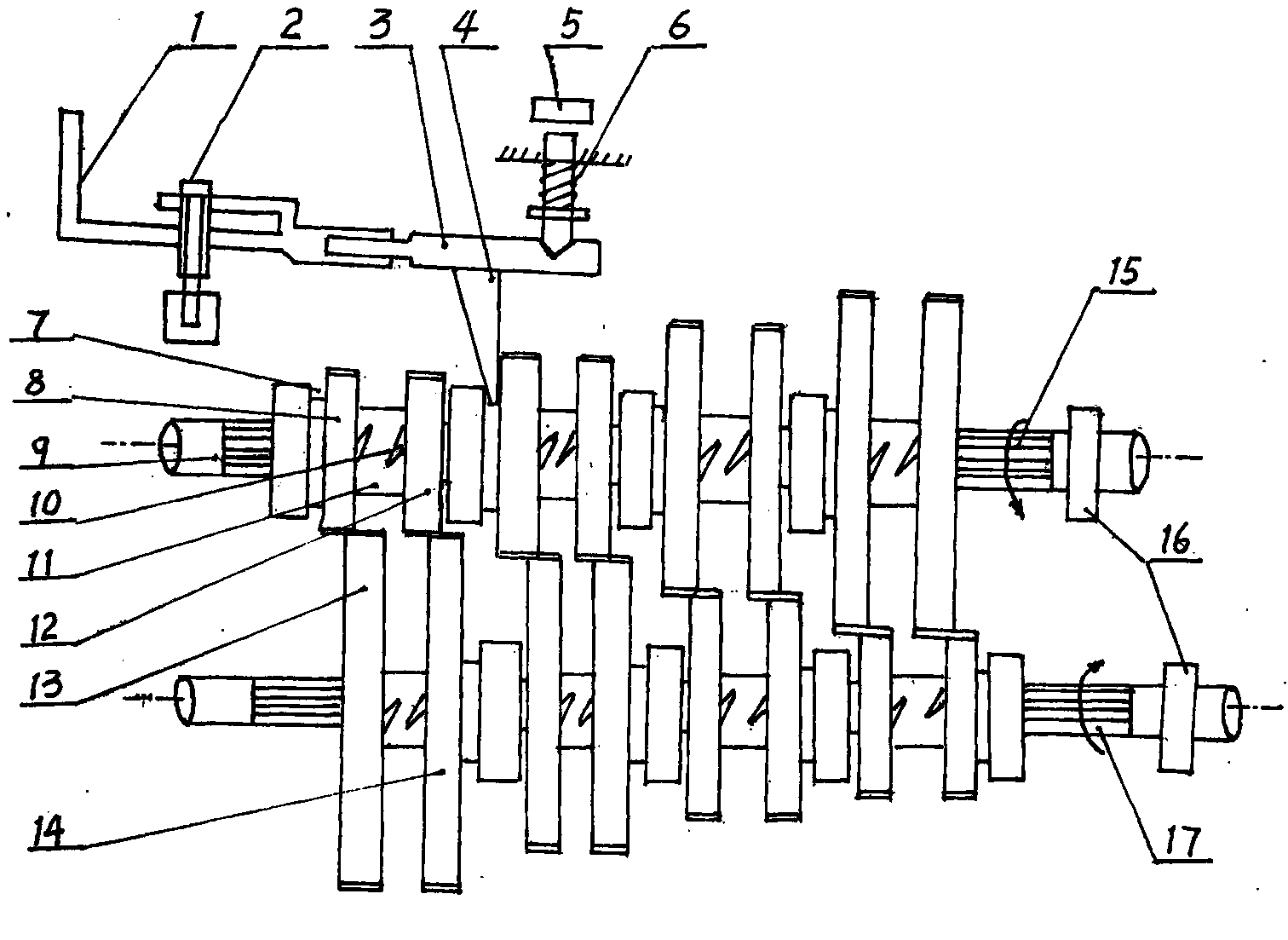

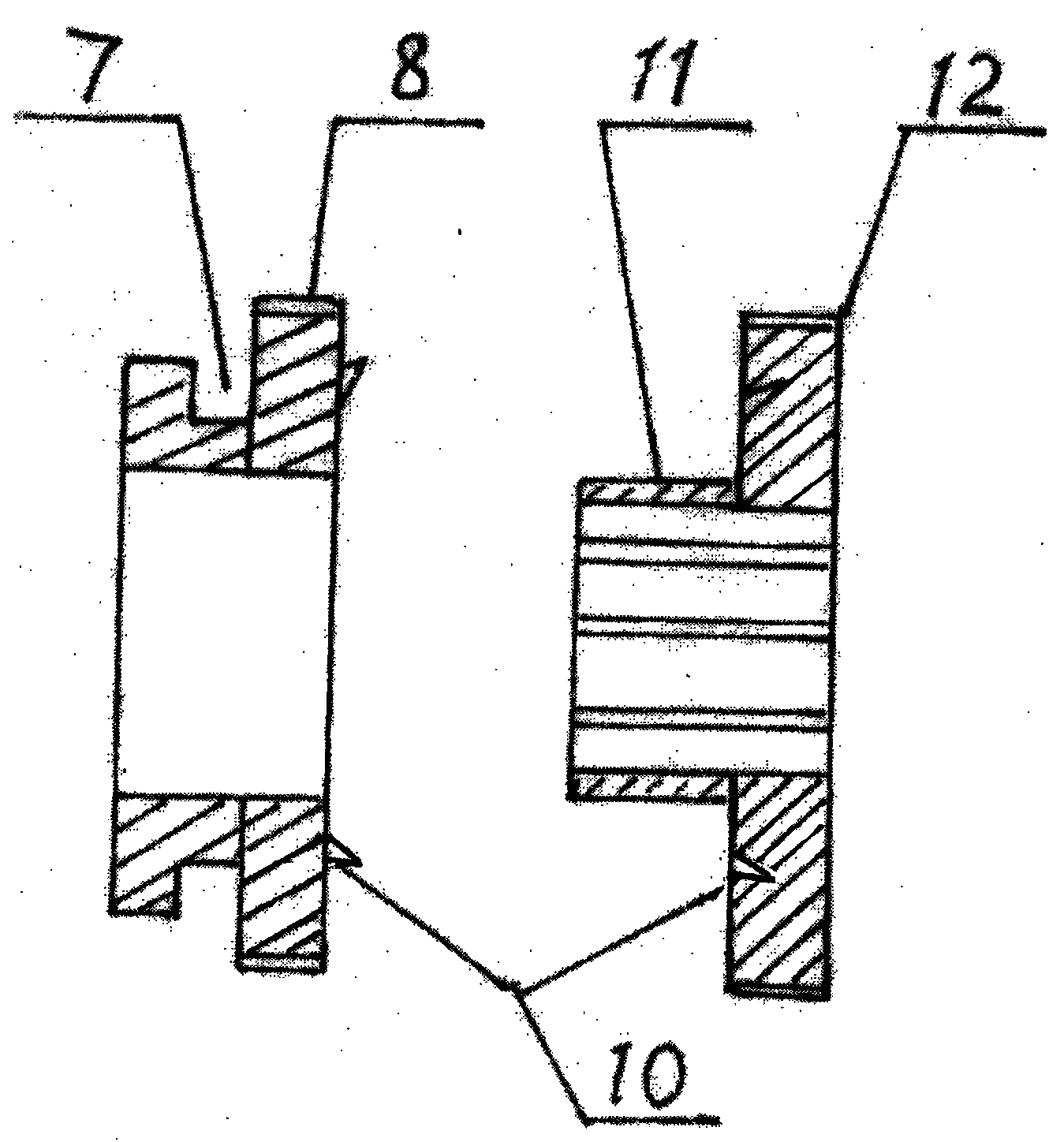

[0016] In conjunction with the drawings and embodiments, the specific structure and working principle of the present invention will be further described, and its features and advantages will be clearer.

[0017] Full gear automobile automatic transmission embodiment 1 of the present invention, see figure 1 , figure 2 , its structure includes: a hydraulic power mechanism and different gear sets, a gear handle 4 and a latch 6 are set on the output rod 3 of the hydraulic power mechanism, and different gear sets for each gear use A gear 8 and B gear with the same number of teeth and the same diameter 12. A gear 8 is slipped on one side of the sleeve 11 of the B gear 12, and the inner wall of the sleeve 11 of the B gear 12 is provided with an axial groove (see figure 2 ), the ratchet teeth and the corresponding ratchet slots 10 that are tightly combined with the rotation of the A gear and the B gear are respectively arranged on the opposite inner disk surfaces of the A gear 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com