Design method of direct-current ice melting device with special converter transformer

A converter transformer, DC ice melting technology, applied in overhead installation, cable installation, flexible AC transmission system and other directions, can solve the problem of no design method and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

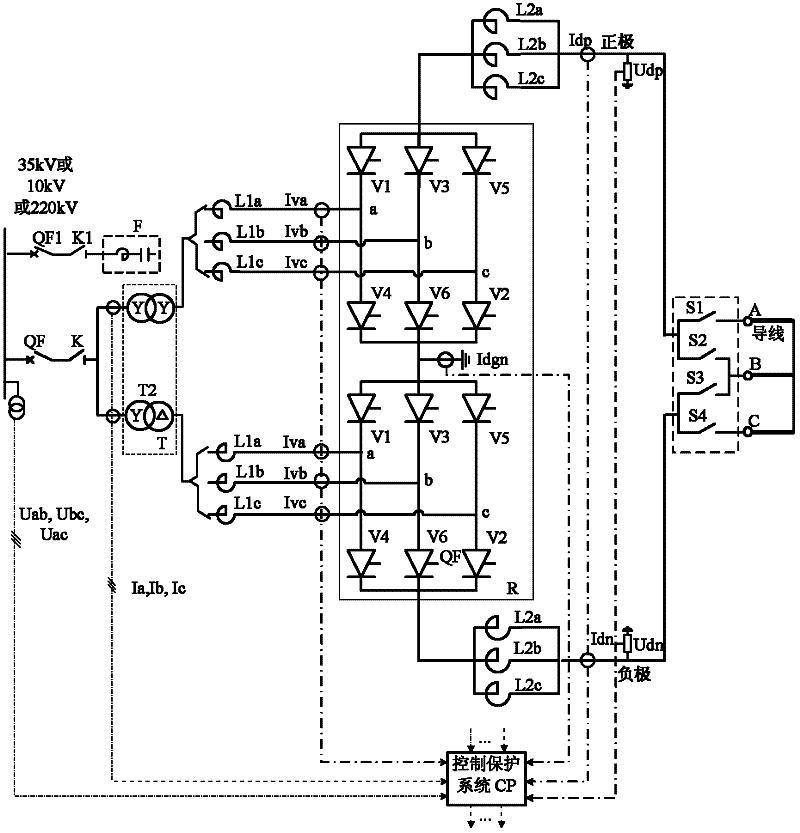

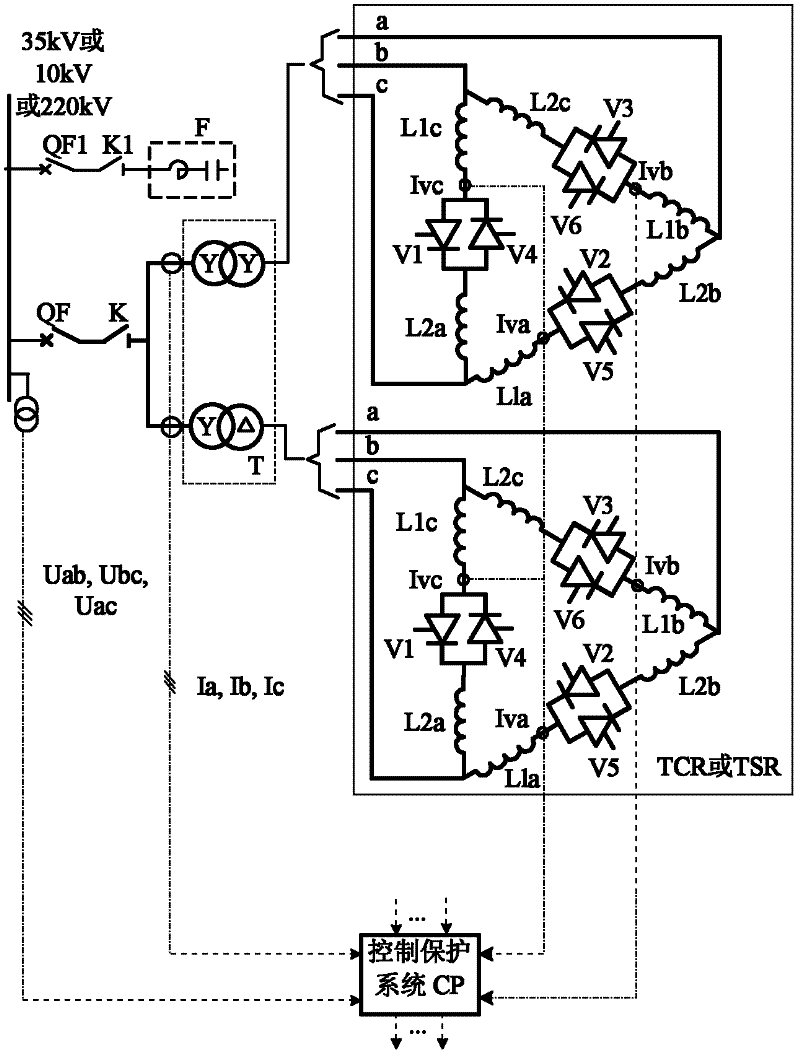

[0106] The structural diagram of the 12-pulse DC ice-melting and reactive power compensation device with special converter transformer of the present invention is as follows: figure 1 , 2As shown, in this embodiment, there are two dedicated converter transformers T (one is Y / Y connection, the other is Y / Δ connection), two groups of reactors L1a, L1b, L1c, two groups of six-pulse Converter R, two sets of reactors L2a, L2b, L2c, knife switches S1, S2, S3, S4, control and protection system CP, AC filter bank F, reactors L1a, L1b, L1c are The commutation reactance is a part of the thyristor controlled reactor TCR or the thyristor switching reactor TSR in the reactive power compensation mode, and the reactors L2a, L2b, and L2c are all connected in parallel as smoothing reactors in the DC deicing mode. In the power compensation mode, it is a part of the thyristor controlled reactor TCR or the thyristor switching reactor TSR; The DC transformer T is connected to form a twelve-pulse...

Embodiment 2

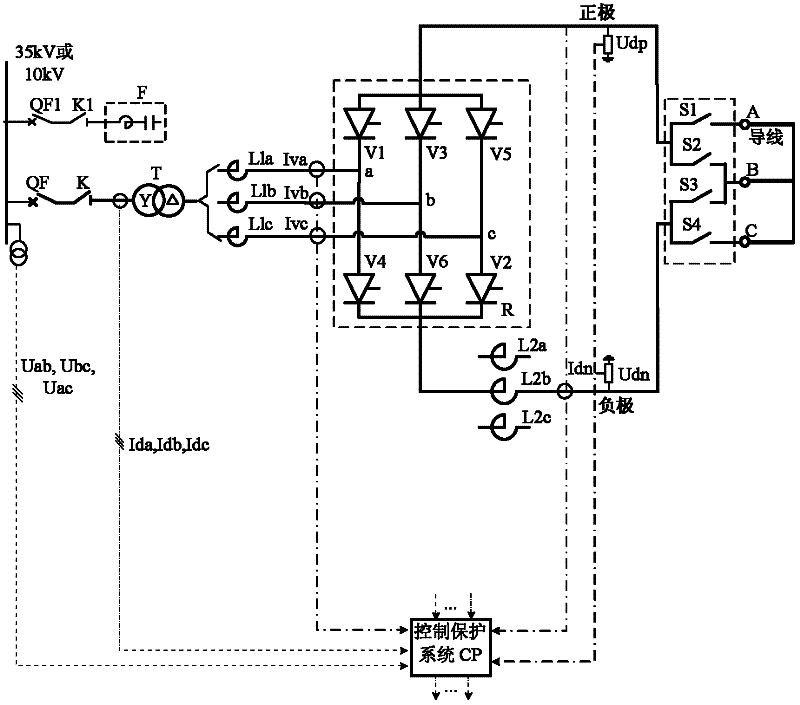

[0174] The structural diagram of the six-pulse DC ice-melting and reactive power compensation device with special converter transformer of the present invention is as follows: image 3 , 4 As shown, in this embodiment, a dedicated converter transformer T (Y / Δ connection), a set of reactors L1a, L1b, L1c, a set of six-pulse converter R, a set of reactors L2a, L2b, L2c, knife switch S1, S2, S3, S4, control and protection system CP, AC filter bank F, reactors L1a, L1b, L1c are commutation reactors in DC ice melting mode, and thyristor control in reactive power compensation mode Reactor TCR or a part of thyristor switching reactor TSR, reactors L2a, L2b, L2c are all smoothing reactors in the next phase of DC ice melting mode, and are thyristor controlled reactors TCR or thyristor switching in reactive power compensation mode Cut off part of the reactor TSR; in the DC ice-melting mode, the AC side of the six-pulse converter R is connected to the dedicated converter transformer T t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com