Vehicle bumper beam and manufacturing method thereof

A technology for bumpers and beams, applied to bumpers and other directions, can solve problems such as shear damage, improve impact absorption characteristics, realize miniaturization, and achieve lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

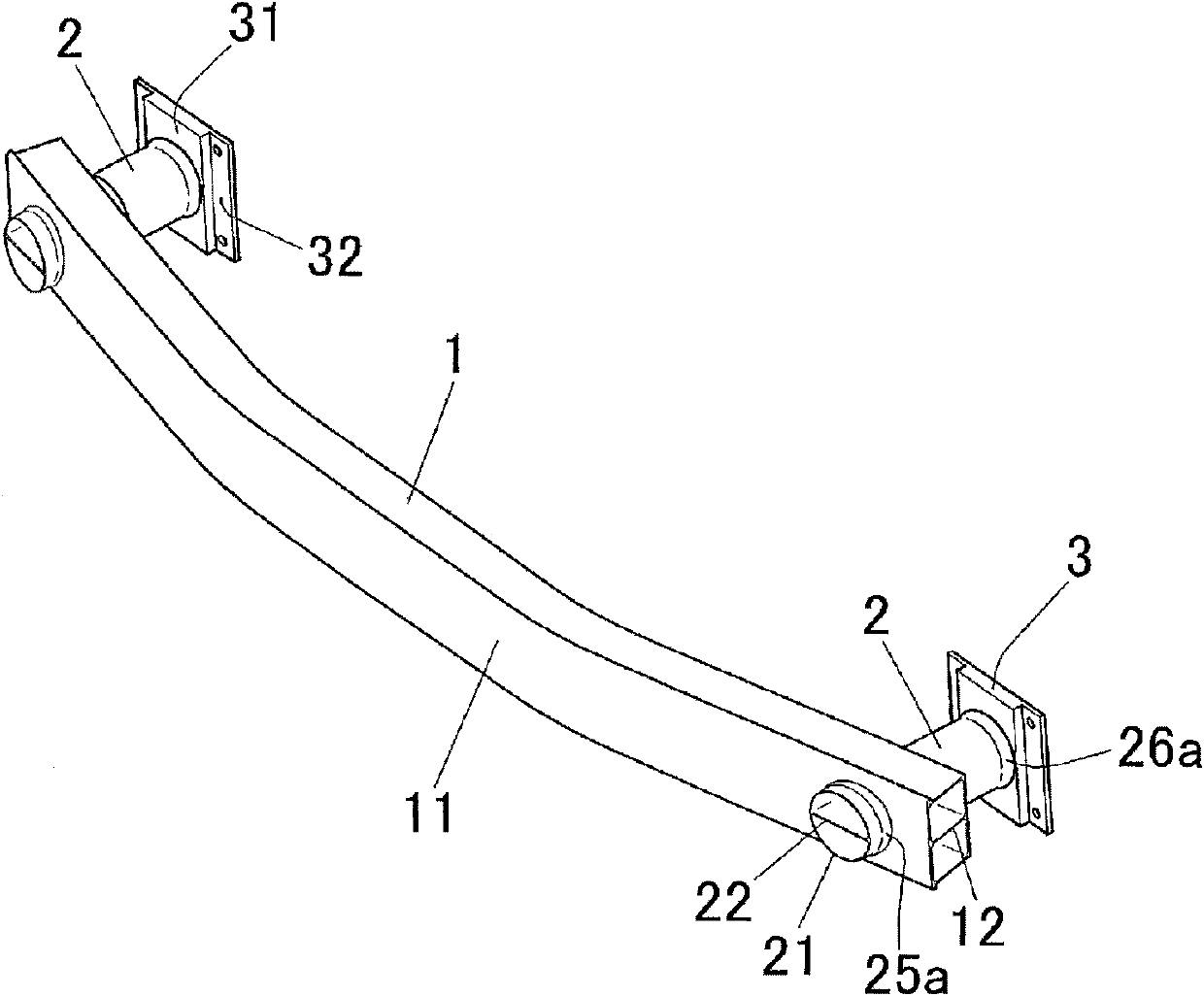

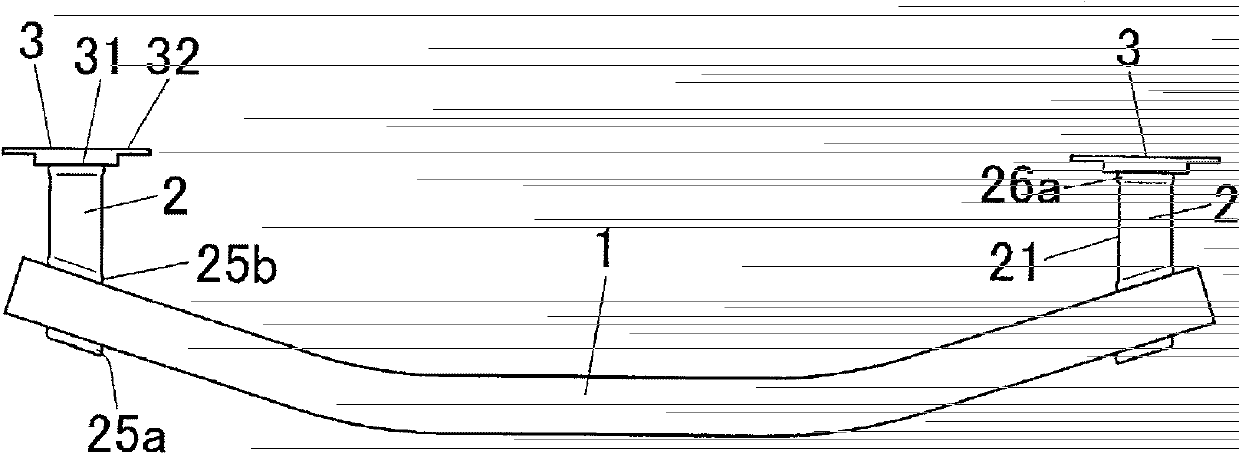

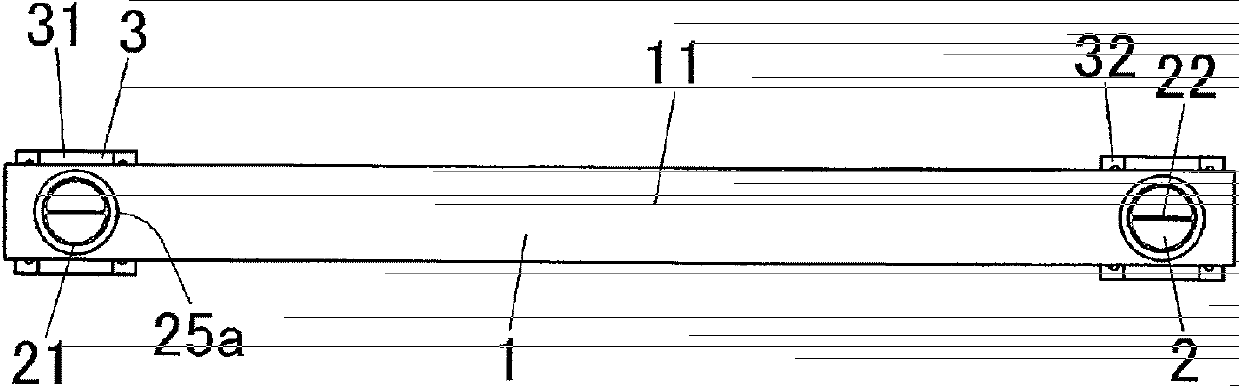

[0070] figure 1 It is a perspective view showing a vehicle bumper beam according to a first embodiment of the present invention. figure 2 It is a plan view showing the vehicle bumper beam according to the first embodiment. image 3 It is a front view showing the vehicle bumper beam according to the first embodiment. Figure 4 It is a side view showing the vehicle bumper beam according to the first embodiment. Figure 5 It is a horizontal sectional view showing the vehicle bumper beam according to the first embodiment. Figure 6 It is an enlarged perspective view showing a side portion of the vehicle bumper beam according to the first embodiment. Figure 7 It is an enlarged horizontal cross-sectional view showing a side portion of the vehicle bumper beam according to the first embodiment.

[0071] As shown in these figures, the bumper beam is provided at the front end of the vehicle for impact absorption at the time of collision. The bumper beam includes: a bumper reinfor...

no. 2 approach

[0107] Figure 9 It is a perspective view showing a vehicle bumper beam according to a second embodiment of the present invention. Figure 10 It is an enlarged perspective view showing a side portion of the vehicle bumper beam according to the second embodiment. Figure 11 It is an enlarged horizontal cross-sectional view showing a side portion of the vehicle bumper beam according to the second embodiment.

[0108] As shown in these figures, in this bumper beam, at an intermediate position in the longitudinal direction (axial direction) of the crush can 2, a single protrusion 27 for a starting point of deformation is formed continuously in the circumferential direction by pipe expansion processing. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com