Substrate backing device and substrate thermocompression bonding device

A backing plate and substrate technology, applied in the direction of workpiece clamping devices, electrical components, manufacturing tools, etc., can solve the problems of rising equipment costs and difficulty in ensuring connection quality, so as to ensure connection quality, stabilize connection quality, and improve followability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

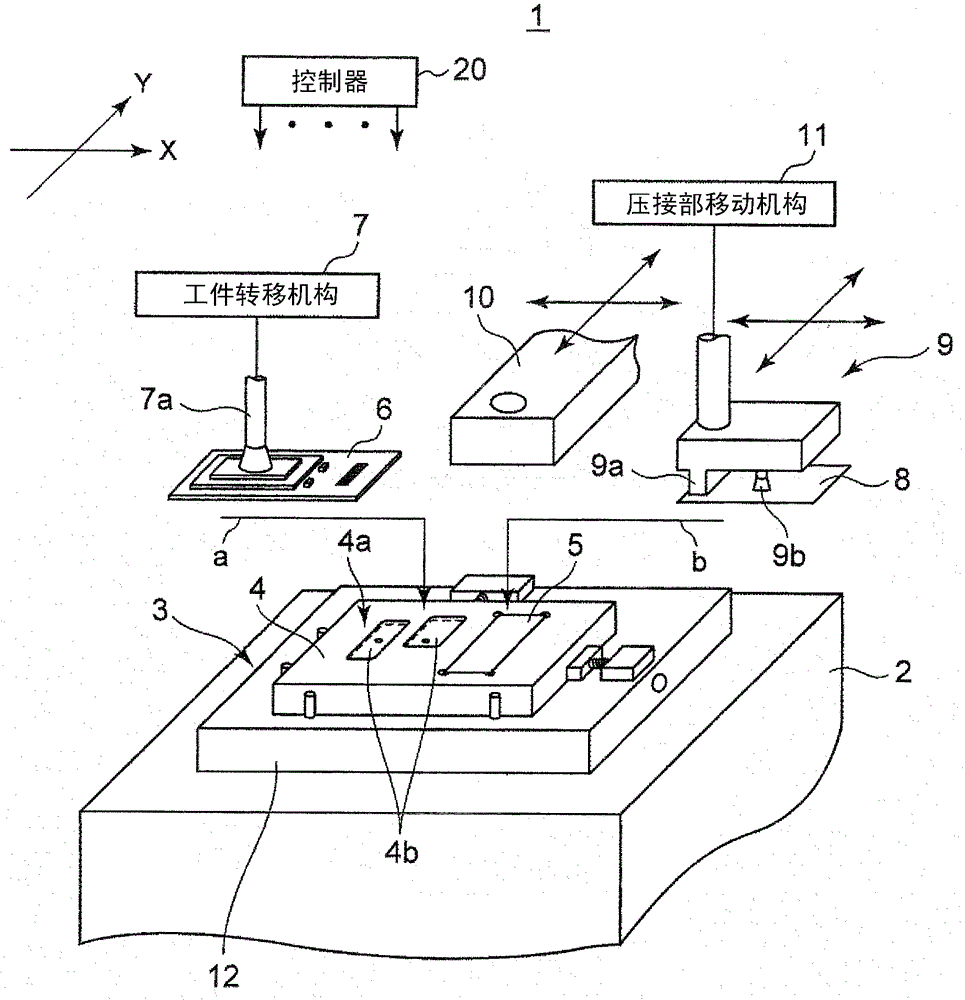

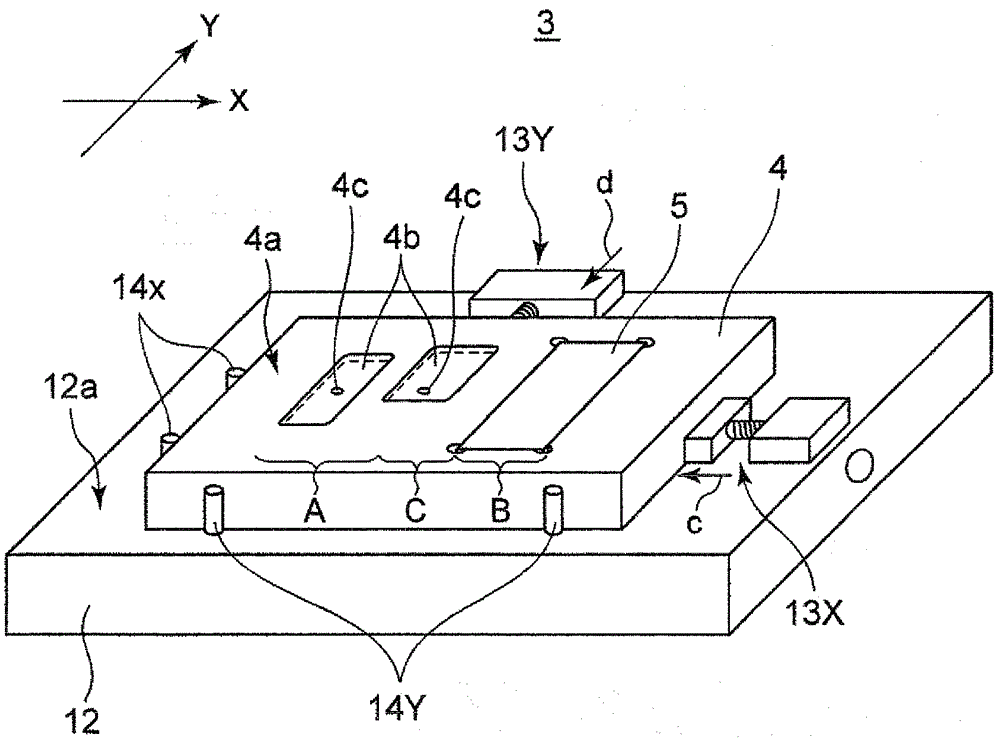

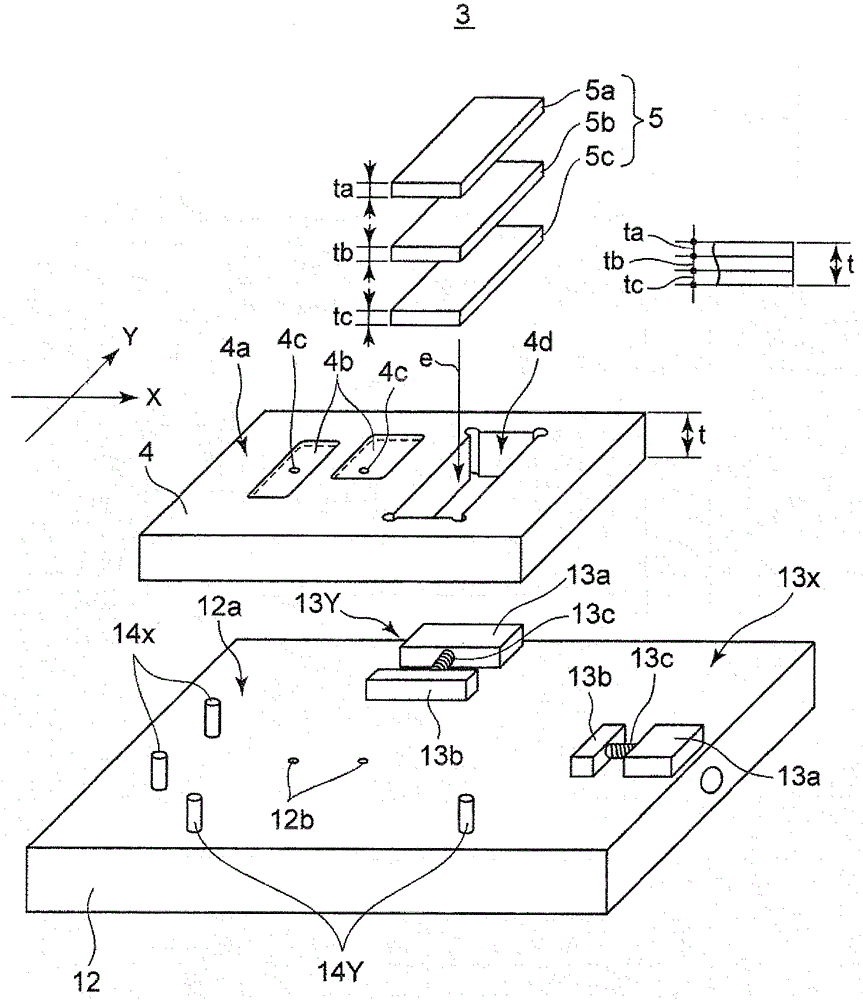

[0050] First, refer to figure 1 Next, the configuration and functions of the substrate thermocompression bonding device 1 provided with the substrate backing device 3 according to the first embodiment of the present invention will be described. The substrate thermocompression bonding apparatus 1 has a function of pressing a flexible substrate 8 that is a flexible second substrate to an edge portion of a rigid substrate 6 that is a hard first substrate to perform thermocompression bonding. The thermocompression bonding apparatus 1 in this embodiment includes a workpiece transfer device 7 , a crimping unit 9 , an imaging unit 10 , and a crimping movement mechanism 11 in addition to the substrate backing device 3 . Furthermore, the thermocompression bonding apparatus 1 includes a controller 20 that controls the operation of the entire apparatus including the substrate backing apparatus 3 , the workpiece transfer apparatus 6 , the imaging unit 10 , and the pressure bonding movemen...

no. 2 Embodiment approach

[0084] Figure 10 The configuration of the receiving member 21 of the second embodiment shown is different from that of the first embodiment. Specifically, as Figure 11 As shown, the receiving member 21 in this embodiment includes a single rebound member 21a. The rebounding member 21 is made of elastic body such as resin or rubber, sponge, felt, etc., which can freely expand and contract by external force, generate a predetermined rebound force according to the degree of compression, and return to the original shape when the external force is removed. A plurality of slits 22a, 22b are provided in the substantially flat rectangular parallelepiped rebounding member 21a from the upper surface toward the lower surface. Specifically, the slits 22a are straight lines extending in the width direction in the drawing, and are arranged at equal intervals from each other. In addition, the slits 22b are straight lines extending in the depth direction in the figure, and are arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com