Anti-falling brake-buffer system for mining express elevator

A high-speed elevator and buffer system technology, which is applied in elevators, transportation and packaging, etc., can solve the problems of no mine-used high-speed elevator anti-fall braking buffer system and large car braking deceleration, so as to solve the buffer force setting Difficult to overcome, easy to loosen, and the effect of constant buffer force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

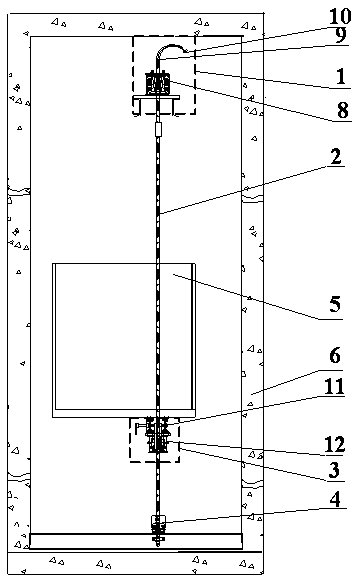

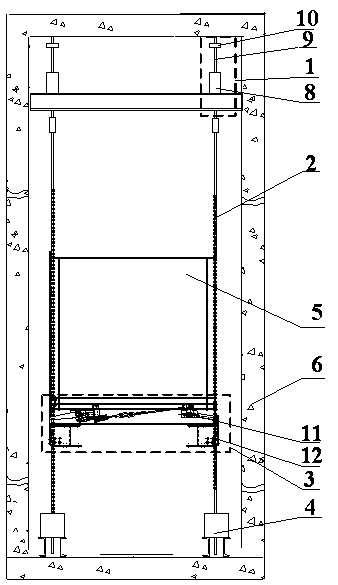

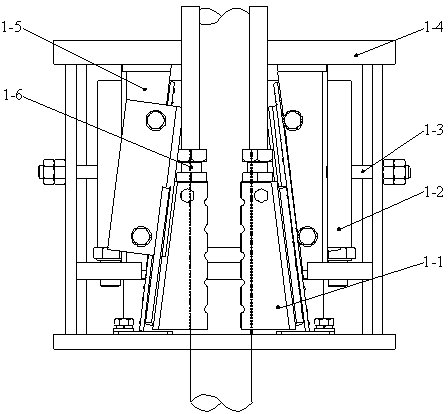

[0023] Such as figure 1 , 2 As shown, the mine high-speed elevator anti-fall brake buffer system of the present invention mainly consists of a buffer 1, a brake rope 2, a brake rope safety gear 3, a tensioning connector 4, a brake rope progressive safety gear 8, Buffer rope 9, buffer rope rope clip 10, linkage mechanism 11, instantaneous brake rope safety gear-12 constitute. The brake rope 2 is fixed on both sides of the car 5, one end of the brake rope 2 is fixed on the top of the shaft 6, the other end is fixed on the bottom of the shaft 6, the linkage mechanism 11 is set at the bottom of the car 5, and the buffer 1 is set on the The top of the brake rope 2, the tension connector 4 is located at the bottom of the brake rope 2, and the bottom of the car 5 is provided with a brake rope safety pliers 3 fixed on the brake rope 2 and connected with the linka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com