Internal warp uniformizing system suitable for fiberglass yarn weaving

A glass fiber yarn and loom technology, which is applied to auxiliary equipment for weaving, textiles, papermaking, and textiles, etc., can solve the problems of large equipment area, large number of rollers, and complicated mechanism, so as to reduce contact links and prevent Glass fiber fluff, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

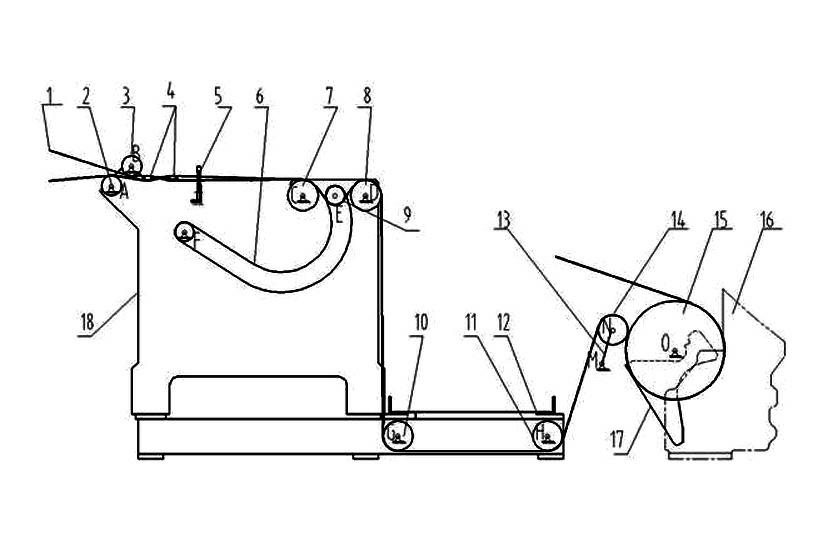

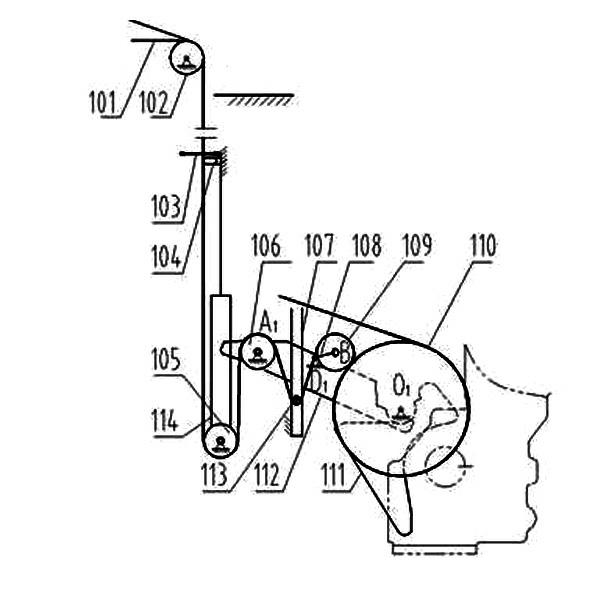

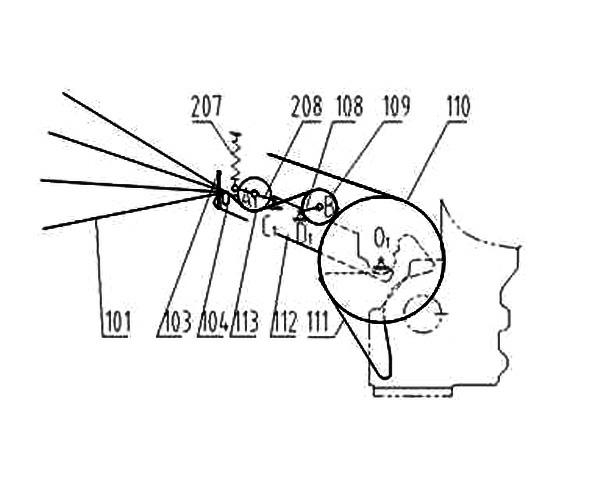

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings: the warp leveling system in the machine suitable for glass fiber yarn weaving according to the present invention includes a splitting reed 103 for the yarn that is unwound from the creel to pass through, and a main A warp leveling mechanism composed of tension roller 113, warp beam pressure roll 109, warp yarn one-way limit roller 203 or intermediate transition roll 106, a false warp beam 110 that can drive warp yarns into the weaving area to participate in weaving; Mechanism is fixed on an inclined support plate 112 that is fixedly connected with the loom wallboard.

[0016] figure 2 As shown, the creel is placed above a floor, and the loom is placed below the floor. An upper transition roller 102 for turning the yarn is arranged above the floor, and an upper transition roller 102 is arranged below the floor. 102 and the lower transition roller 105 on the same v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com