Monitor mounting and fixing device

A fixing device and monitor technology, applied in the electronic field, can solve problems such as complicated operation and easily damaged ceiling, and achieve the effects of convenient operation, prevention of rotation and displacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

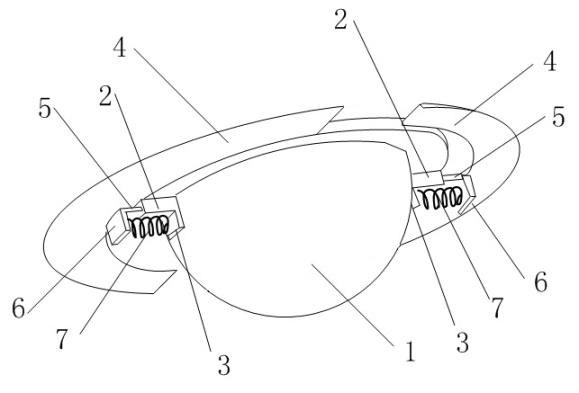

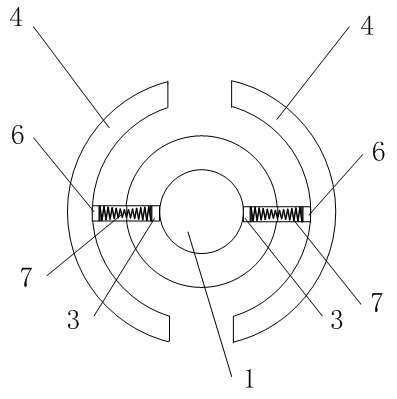

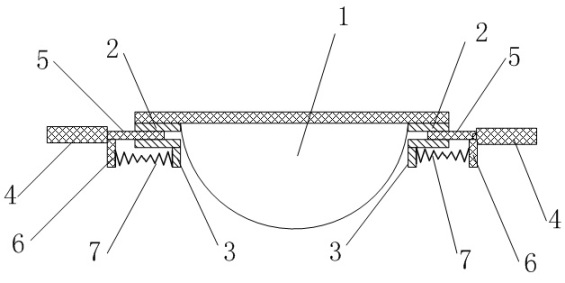

[0023] In this embodiment, a monitor installation and fixing device is used to install the monitor on the installation panel, such as Figure 1~Figure 3 As shown, it includes a hemispherical monitor body 1. The bottom edge of the monitor body 1 is provided with two evenly distributed horizontal chute 2, and each chute 2 is vertically provided with a main stop near one end of the monitor body 1. Block 3; chute 2 and main block 3 are integrally formed. It also includes a telescopic bracket 4. The telescopic bracket 4 is composed of two arc-shaped airfoils surrounding the bottom edge of the monitor main body 1. Each airfoil is integrally provided with a chute 2 extending toward the center of the monitor body 1. The slide rail 5 that slides relatively in the center; the joint between the slide rail 5 and the telescopic support 4 is vertically provided with a secondary stopper 6 corresponding to the main stopper, and the slide rail 5 and the secondary stopper 6 are integrally forme...

Embodiment 2

[0027] This embodiment is similar in structure to Embodiment 1, as Figure 4~Figure 5 As shown, the difference is that a screw hole 8 is provided at both ends of the airfoil of the telescopic support 4 respectively; The perforation 10, the bolt passes through the perforation 10 and the installation panel, and is screwed into the screw hole 8, so that the monitor installation fixture is fixed on the installation panel. Before the bolts are tightened and fixed, the round and rotatable characteristics of the monitor installation and fixture can be used to rotate the angle of the monitor. After tightening, it can be fixed on the installation panel to prevent its rotation and displacement, which is simple and convenient.

Embodiment 3

[0029] This embodiment is similar in structure to Embodiment 1, as Figure 6 As shown, the difference is that the airfoil of the telescopic support 4 is integrally formed with a fixing part 9, and the fixing part 9 and the airfoil are combined to form a clamping part 11, and the cross section of the clamping part 11 is U-shaped. The direction of the opening is outward, and the size of the opening is at least the same as the thickness of the mounting panel. Four pairs of screw holes 8 and perforations 10 are provided at the corresponding positions of the airfoil of the clamping part 11 and the fixing part 9. The bolts pass through the perforations 10 and the mounting panel, and are screwed into the screw holes 8 to fix the monitor installation fixture on the installation panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com