Internal stress detection mechanism for shock absorber and using method thereof

A detection mechanism and shock absorber technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve problems such as inability to guarantee accuracy, and achieve the effect of avoiding economic losses and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

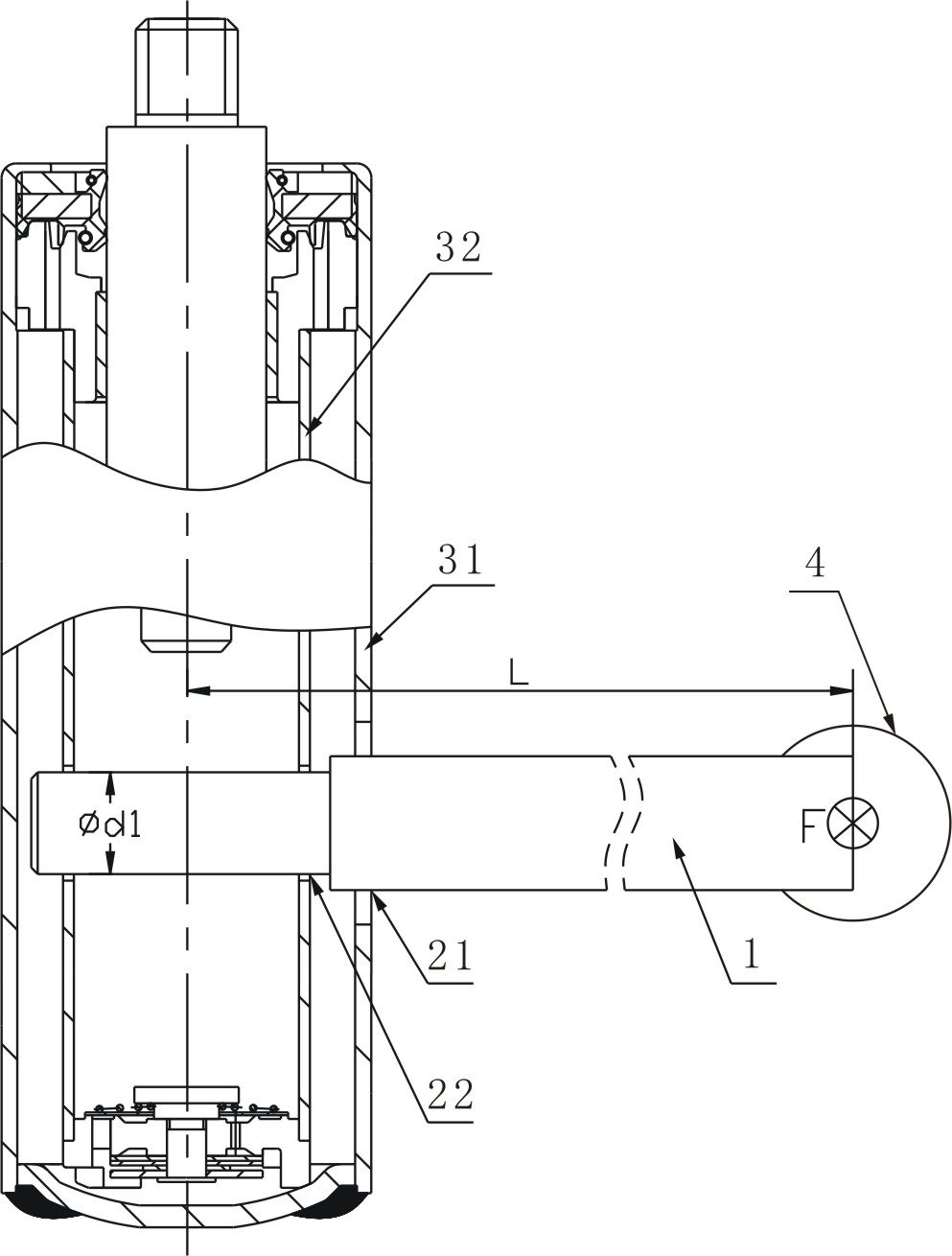

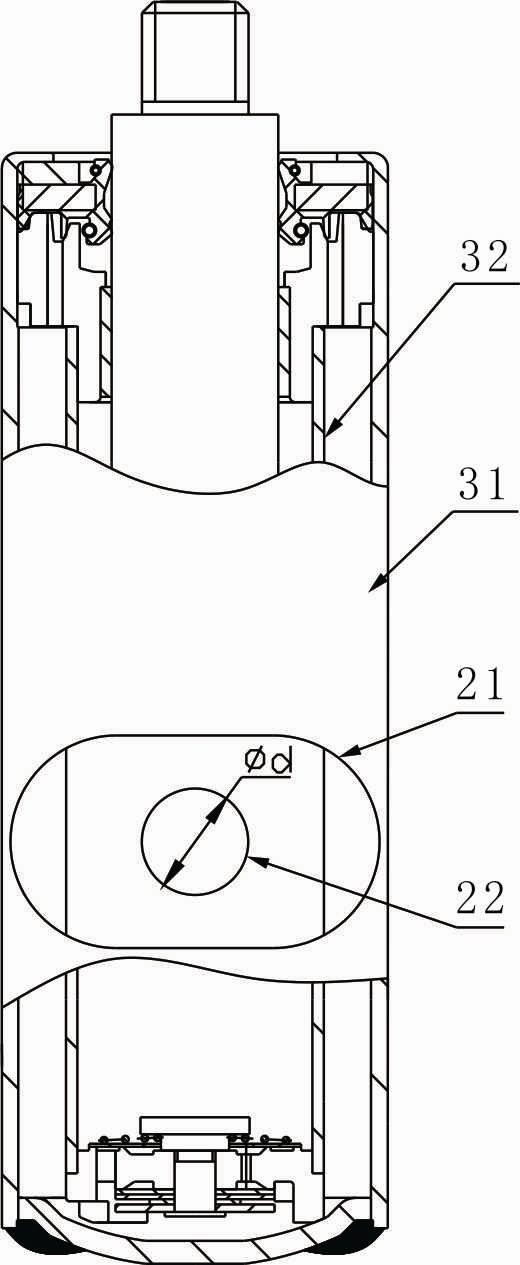

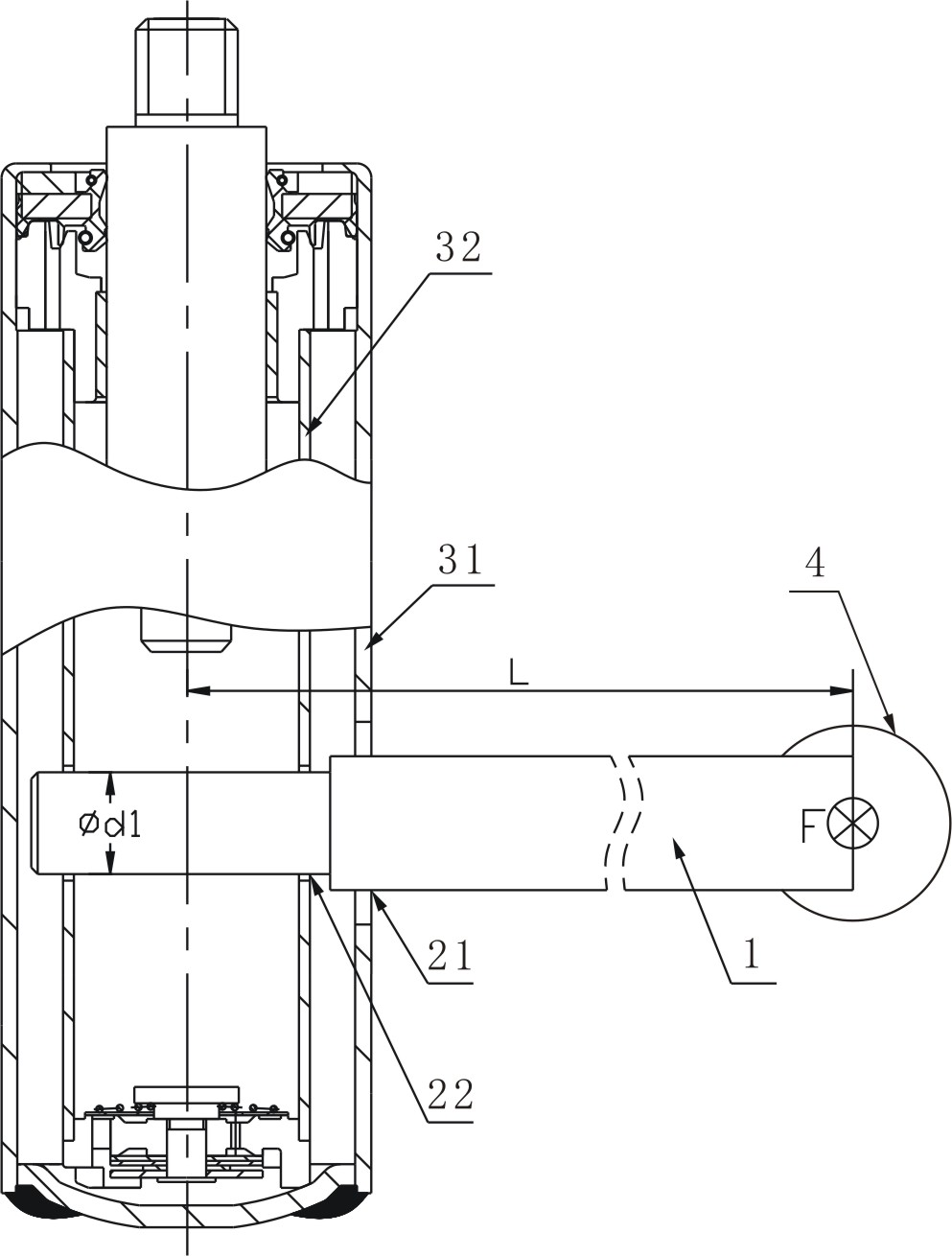

[0020] In order to solve the abnormal sound of the shock absorber during the working process due to the inappropriate pre-tightening force after spinning, we have designed a detection method for internal stress after spinning. The use of the detection method can effectively control the manufacturing process of the spinning closing process, so as to solve the abnormal sound of the shock absorber caused by the spinning pretightening force not meeting the requirements. The structure will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement the present invention.

[0021] like figure 1 , 2 shown. The detection mechanism is composed of a tooling rod 1, a U-shaped detection gap 21 arranged on the cylinder 31, a through hole 22 arranged on the working cylinder 32 and passing through the working cylinder 32, and a spring balance 4; during detection, the tooling rod 1 One end of the spring scale (4) is hooked into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com