One-piece type welding-fixation disposal blood taking needle

A one-time, one-piece technology, applied in the field of medical devices, can solve the problems of low strength, failure to meet the shelf life requirements, and difficulty in ensuring assembly quality, and achieve small welding deformation and residual stress, which is conducive to mechanized die-casting and assembly , Simplify the effect of aligning and closing the assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

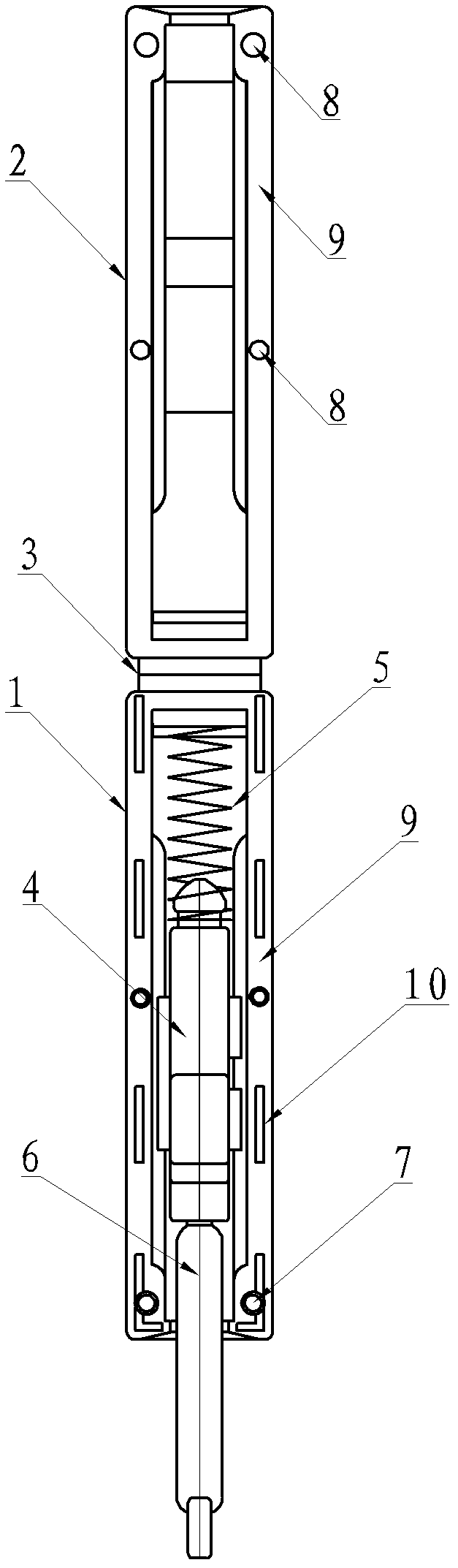

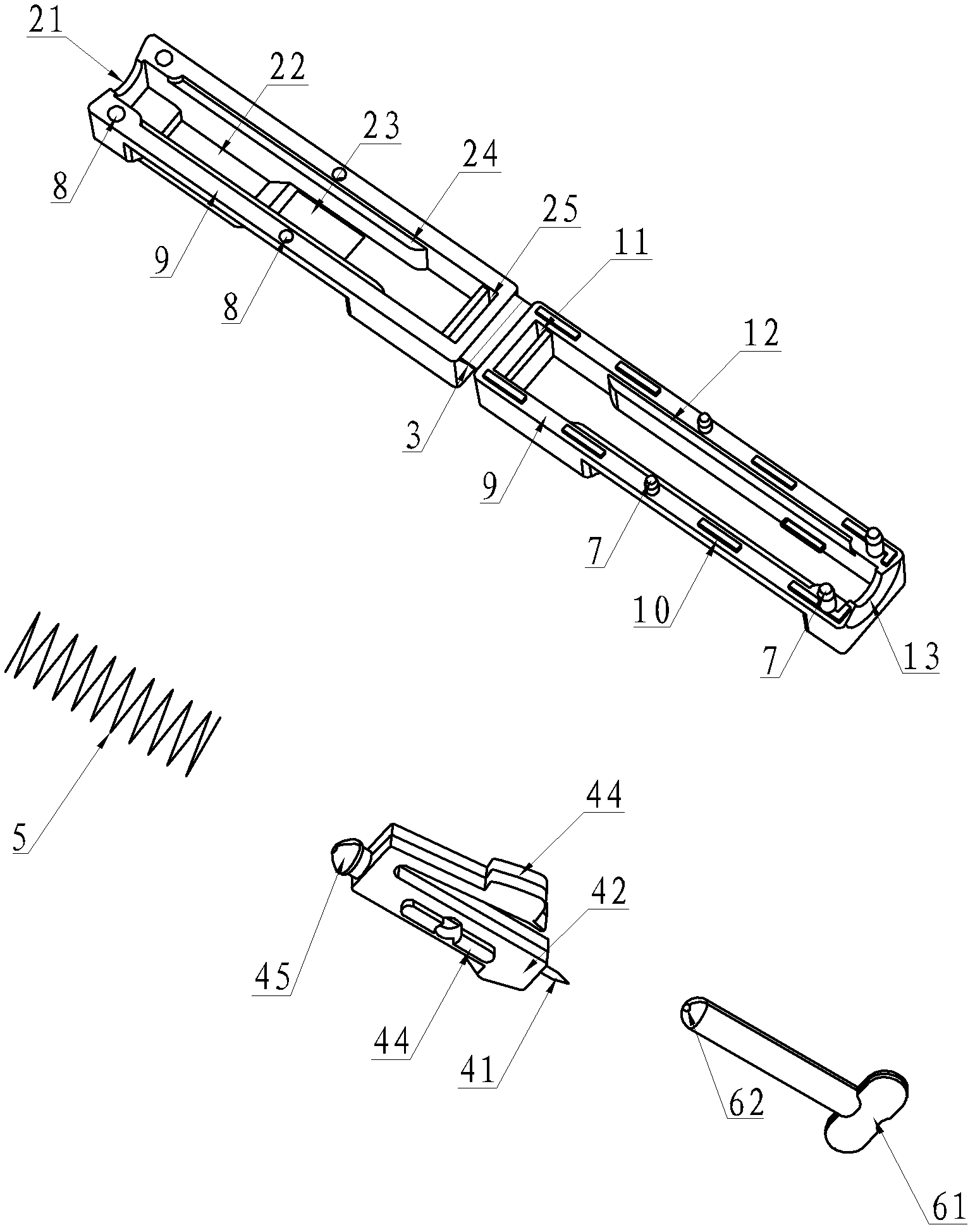

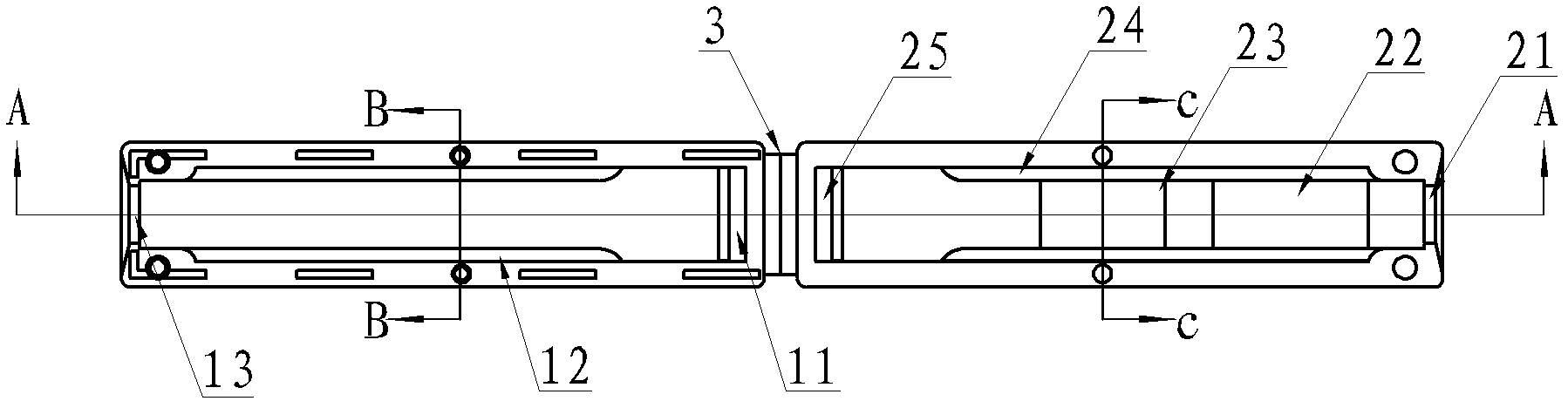

[0027] Embodiment 1: A one-piece welded fixed disposable blood collection needle, such as figure 1 , 2 As shown, it consists of lower housing 1, upper housing 2, connecting belt 3, sliding needle block 4, return spring 5 and needle point cap 6, as image 3 , 4 , 5, and 6, the lower case 1 and the upper case 2 are connected as a whole through the connecting band 3, and the connecting band 3 is arranged on the opposite end of the lower case 1 and the upper case 2 where the pinhole end is provided, and the upper case 2 Turn over 180 degrees to cover the upper end of the lower casing 1, and the joint surface 9 of the two is fixedly connected by welding with the same material. The lower casing 1 includes the lower part of the spring clamping groove 11, the lower rail 12 and the lower part of the needle hole 13, and the spring clamping The lower part 11 of the groove is arranged at one end of the inner cavity of the lower casing 1, the sliding rails 12 are respectively arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com