Rapidly-opened spanner

A wrench, fast technology, applied in the direction of wrench, manufacturing tools, wrench, etc., can solve the problems of unfavorable resource saving, hex nut damage, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

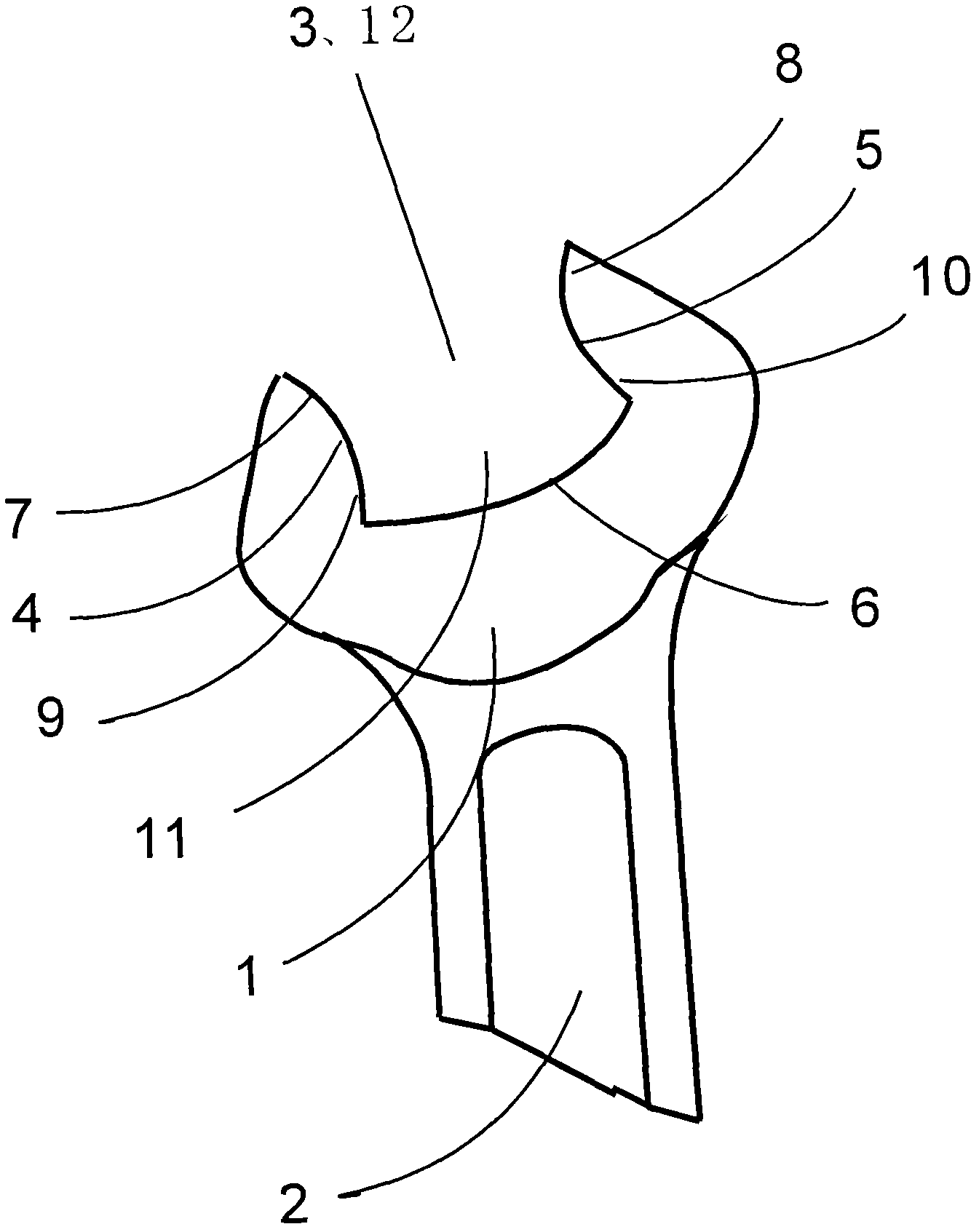

[0012] figure 2 Among them, the arc-shaped working surfaces 4 and 5 in the opening 3 are in contact with the planes on both sides of the hex nut. When operating clockwise, due to the idle position (11) in the opening 3 of the present invention, what the arc-shaped working surface 5 contacts is The lower part of the plane on the right side of the hexagonal nut, the working arc surface 4 is in contact with the upper part of the plane on the left side of the hexagonal nut, thereby increasing the rotational torque to the hexagonal nut and avoiding the direct transmission of torque to the corners of the hexagonal nut.

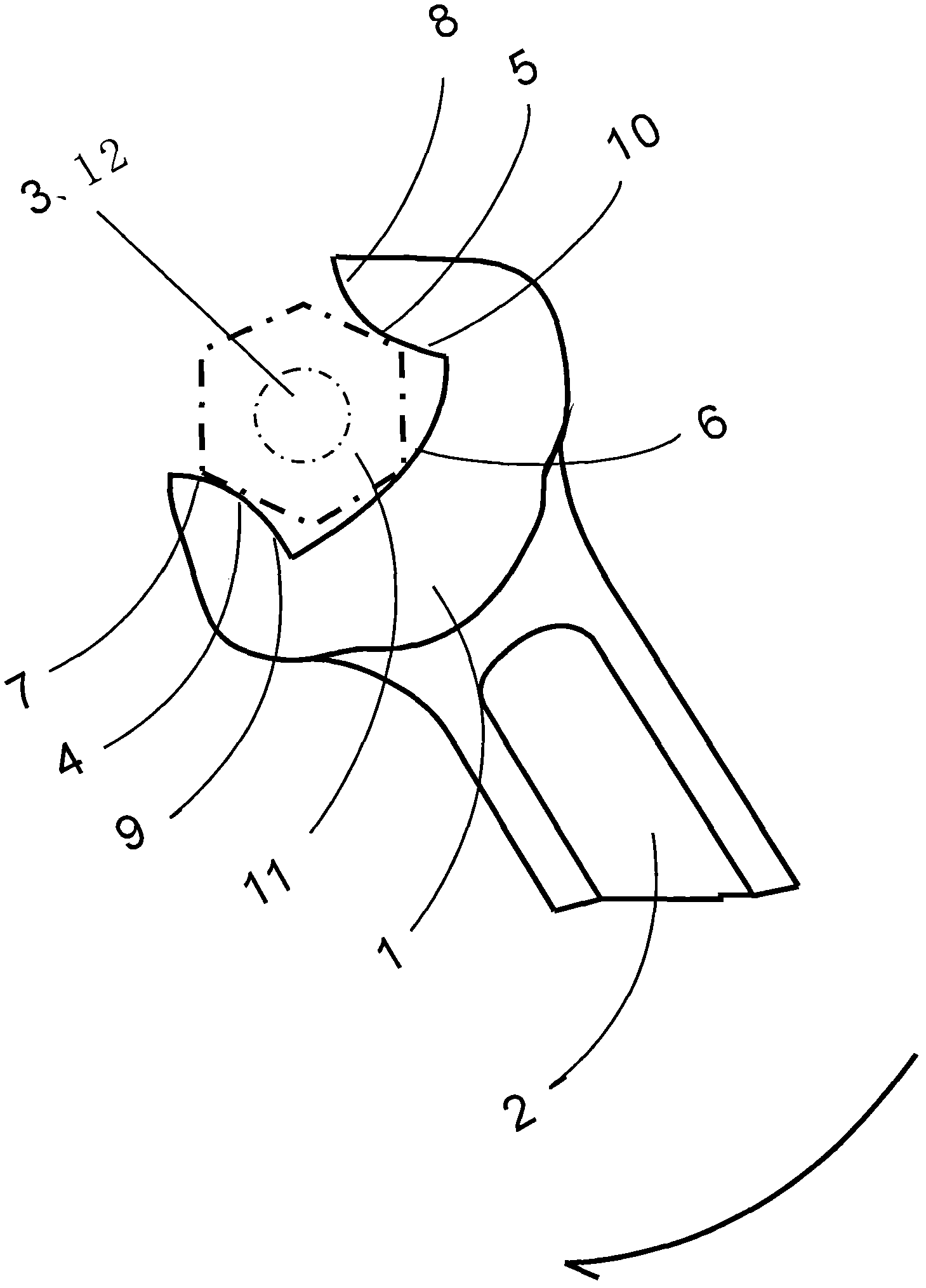

[0013] image 3 During the counterclockwise abdication operation, keep the arc-shaped working surface 5 in contact with the plane on the right side of the nut, and you can back out empty.

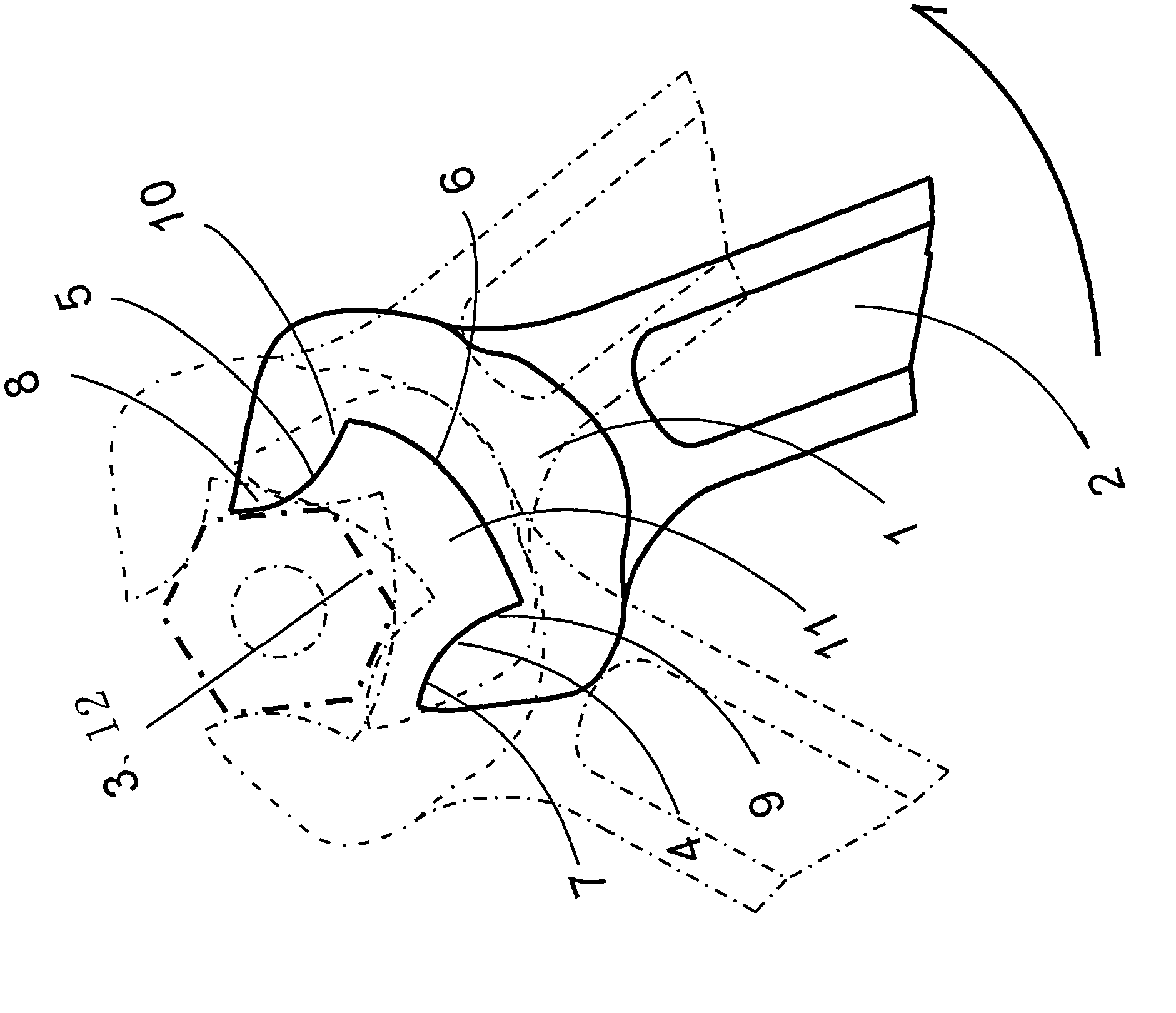

[0014] Figure 4 Among them, because there is a 15 or 18 degree idling spare position 11 in the opening 3, when the present invention operates in a narrow dead angle range, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com