Conveying device

A technology of conveying device and conveying mechanism, which is applied in the direction of conveyer objects, transportation and packaging, etc., can solve the problems of wasting man-hours and high labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

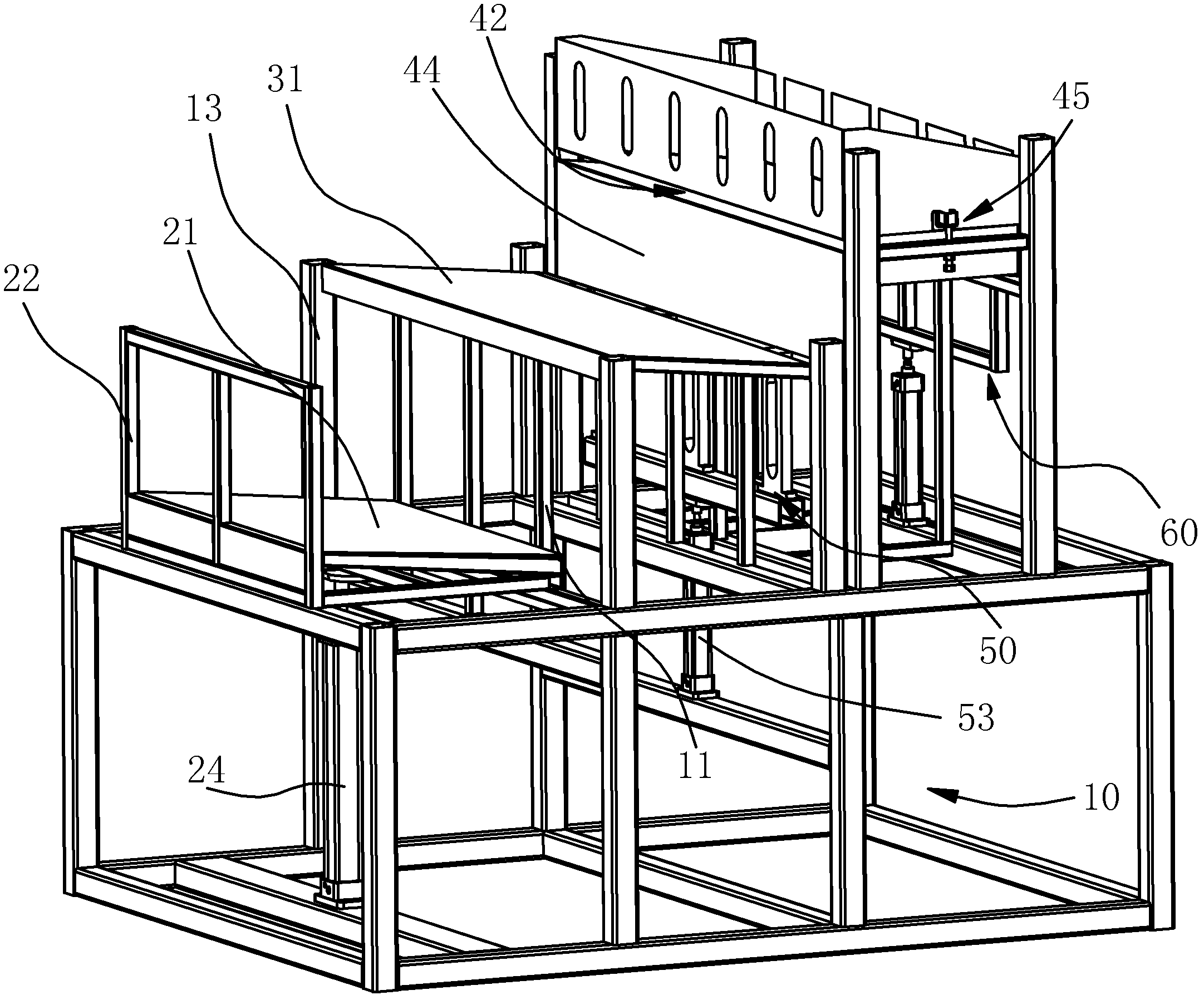

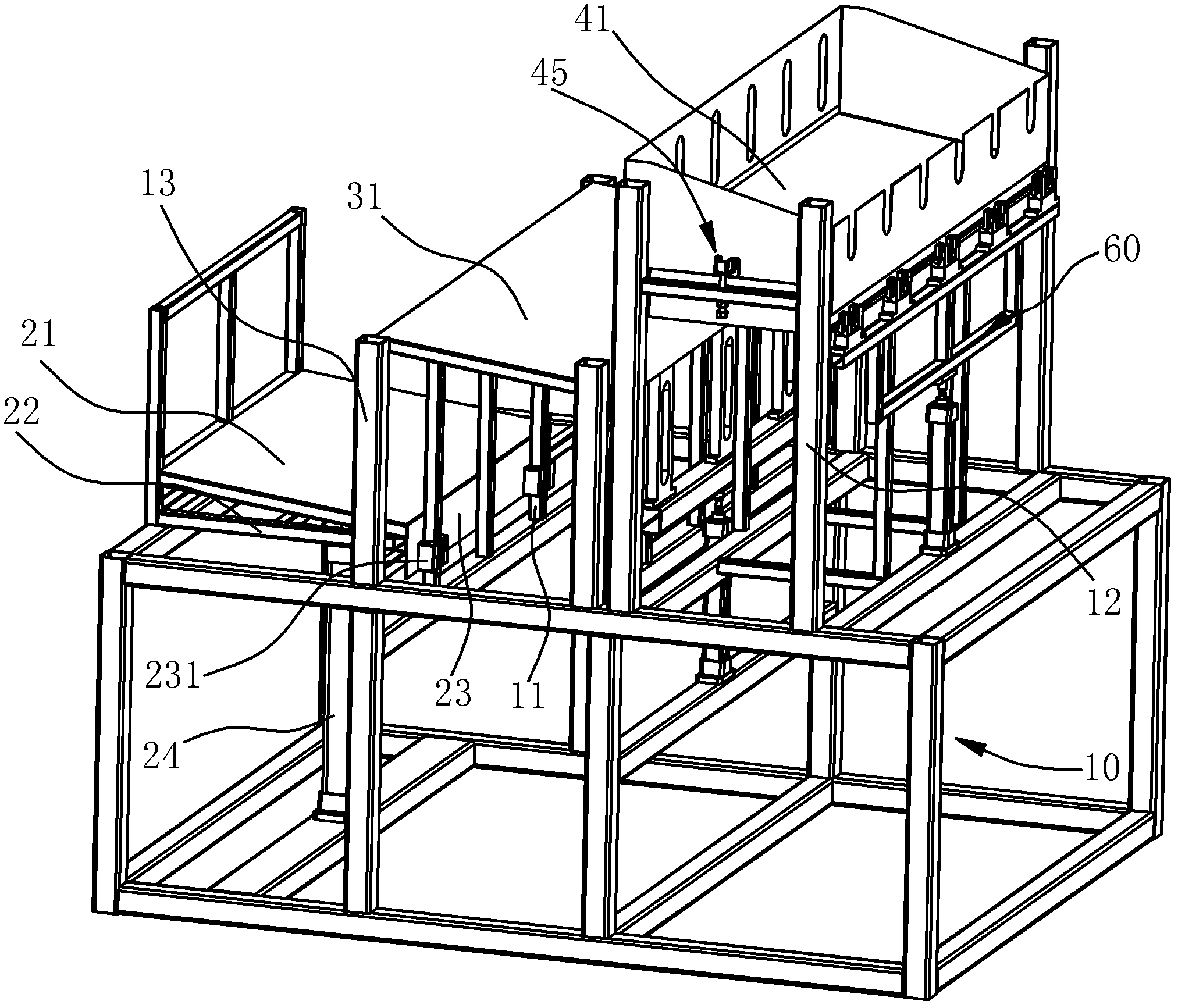

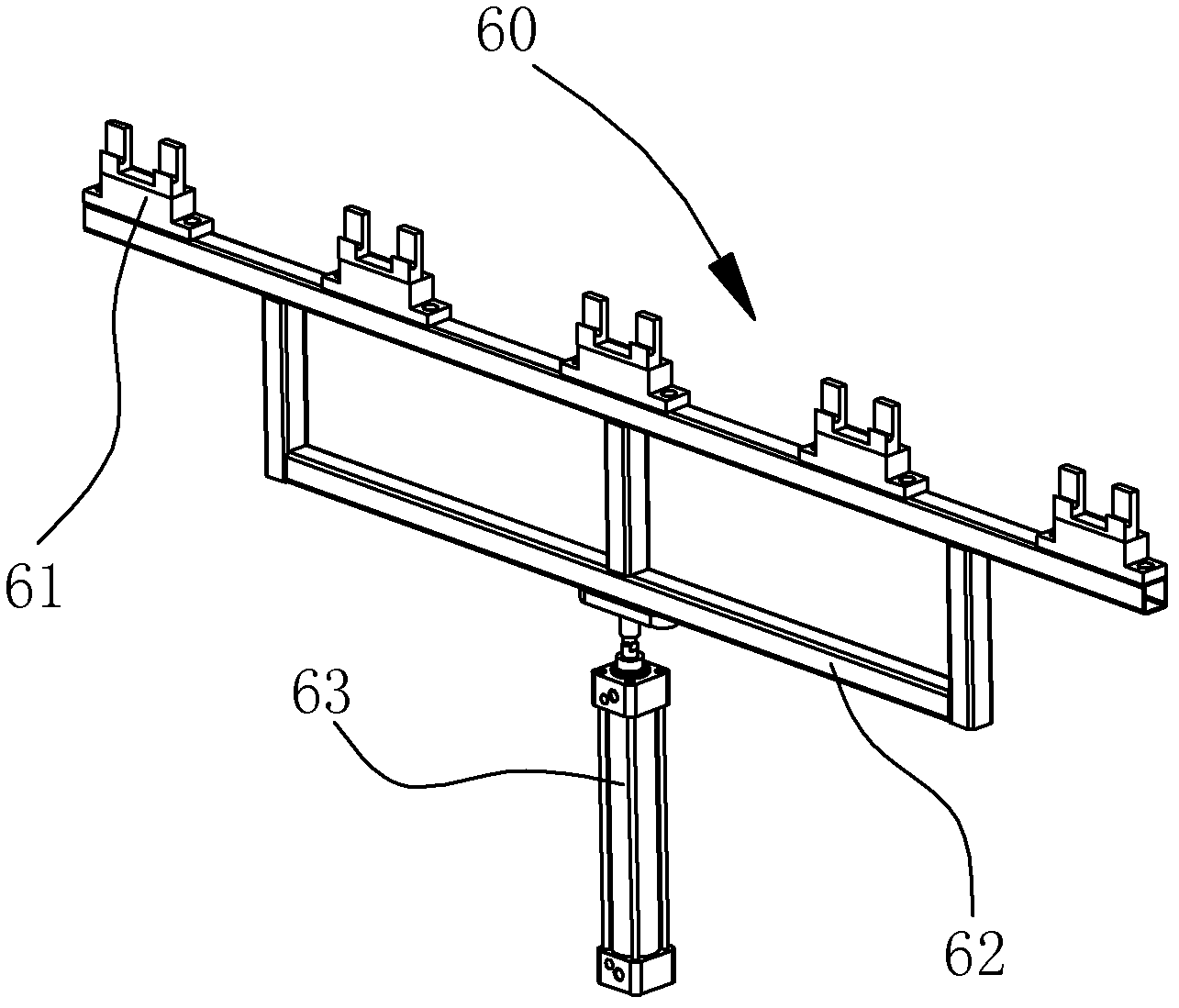

[0012] The problem to be solved by the present invention is to solve the problem that pipe fittings or processed materials between adjacent processes need to be effectively, continuously and quickly transported at high and low positions. The technical solution adopted is: a transport device, which is characterized in that: The first supporting plate 21 of the holder and the conveying mechanism for transporting the pipes on the first supporting plate 21 to the high position / low position, the first supporting plate 21 is fixed on the frame 10, and the conveying The mechanism is connected to a power source. The present invention arranges the first material support plate 21 and the discharge port of the previous process correspondingly through the provided first material support plate 21, so that the pipe fittings from the previous process can directly fall to the first material support plate 21, The conveying mechanism then transports the pipe fittings on the first supporting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com