Ultrasonic detachment of glass substrates from the carrier

An ultrasonic and substrate technology, which is used in the manufacture of semiconductor devices, electric solid state devices, and semiconductor/solid state devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

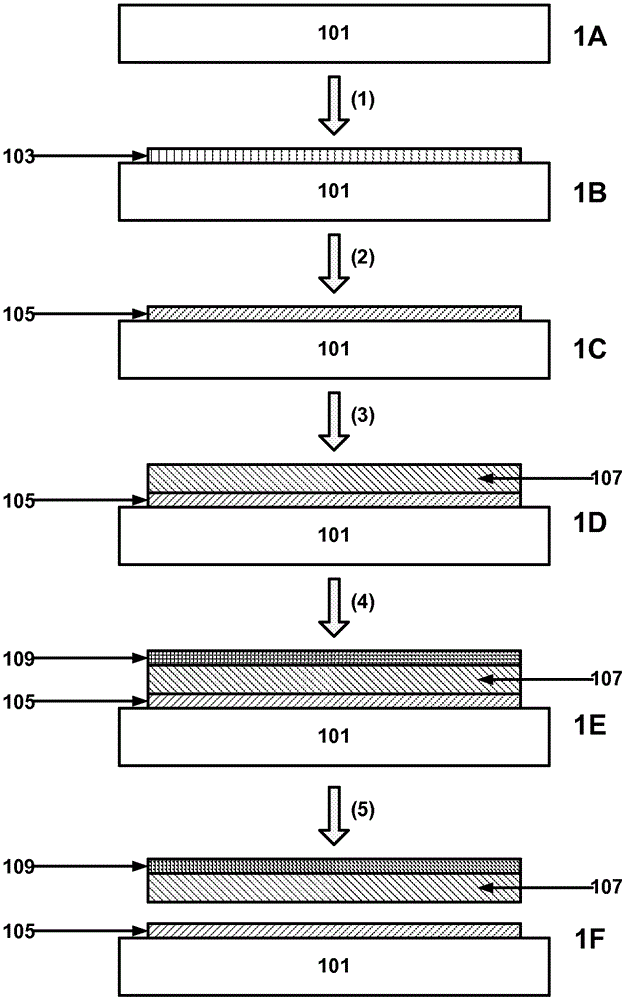

Method used

Image

Examples

Embodiment 1

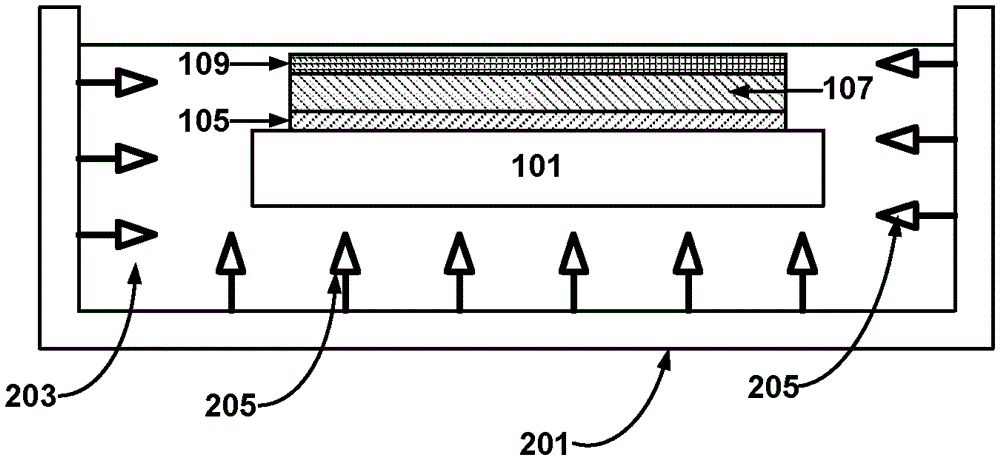

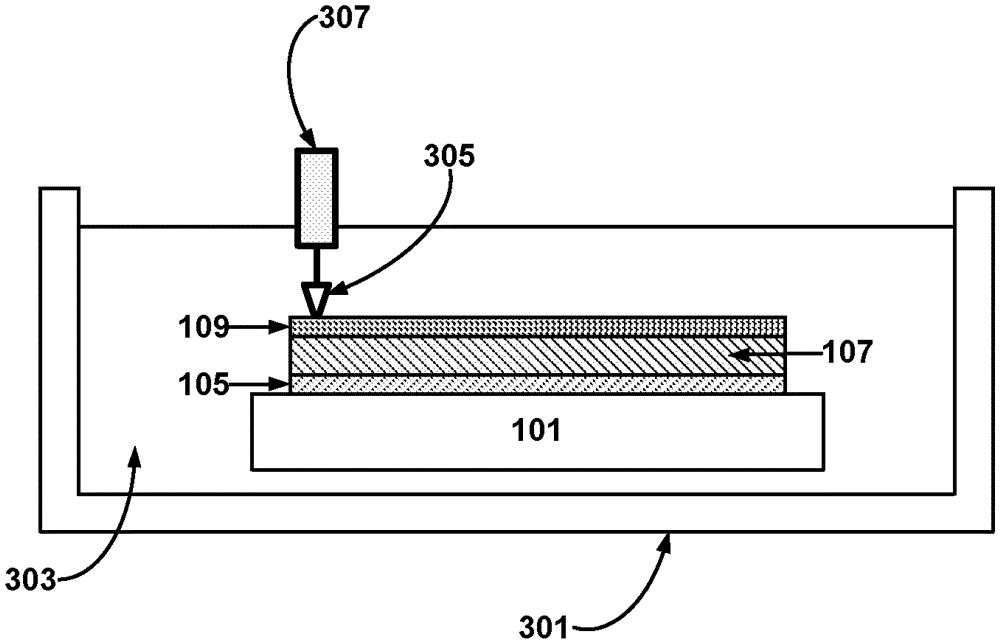

[0105] The functional substrate temporarily bonded to the carrier substrate using the fragile silica inorganic adhesive is exposed to an aggressive ultrasonic bath. Small cracks and liquid penetration into the adhesive layer were observed. This proves that exposure to ultrasound can weaken the bond between the adhesive and the functional substrate and assist in separation.

Embodiment 2

[0107] Use elastic adhesive (surface tension γS=17mJ / m 2 ) The adhesive strength of temporarily bonding the functional substrate to the carrier substrate follows figure 1 The method shown in water (surface tension γ L =72mJ / m 2 ) It is made and tested in the ultrasonic tank, and there is no malfunction. The same equipment in propanol (lower surface tension than water (γ L =23mJ / m 2 ) In the liquid), delamination was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com