Plate differential temperature hydroforming device capable of realizing radial pressurizing and hydraulic blank pressing

A liquid-filled forming and pressurized device technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult temperature control, no consideration of forming ability, low heating efficiency, etc., to improve the forming limit of sheet metal, Promotes the expansion of applications and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

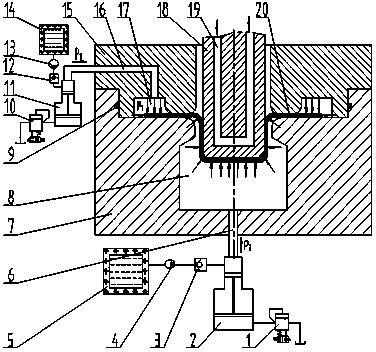

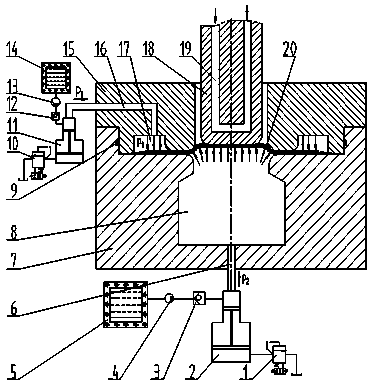

[0020] see figure 1 , a plate material differential temperature liquid-filled forming device that can realize radial pressure and hydraulic blanking provided by an embodiment of the present invention includes: a punch 18, a blank holder 15, a die 7, a first pressurizing device 2, The second booster device 11 , the first electromagnetic proportional overflow valve 1 , the second electromagnetic proportional overflow 10 , the first fluid heating device 5 and the second fluid heating device 14 .

[0021] The sheet material 20 is located between the die 7 and the blank holder 15; the die cavity 8 is provided inside the die 7, and the bottom of the die 7 is provided with a liquid injection hole 6, which communicates with the die cavity 8, The outer port of the liquid injection hole 6 is connected to the high-pressure end of the first booster device 2, and the high-pressure end of the first booster device 2 is connected to the first fluid heating device 5 through the check valve 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com