Preshrinking machine for knitted blanket

A pre-shrinking machine and woolen blanket technology, which is applied in textile processing machine accessories, shrinking, textiles and papermaking, etc., can solve the problems that the shrinking effect is not very good, and the production efficiency of fabrics is difficult to improve, so as to improve the pre-shrinking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

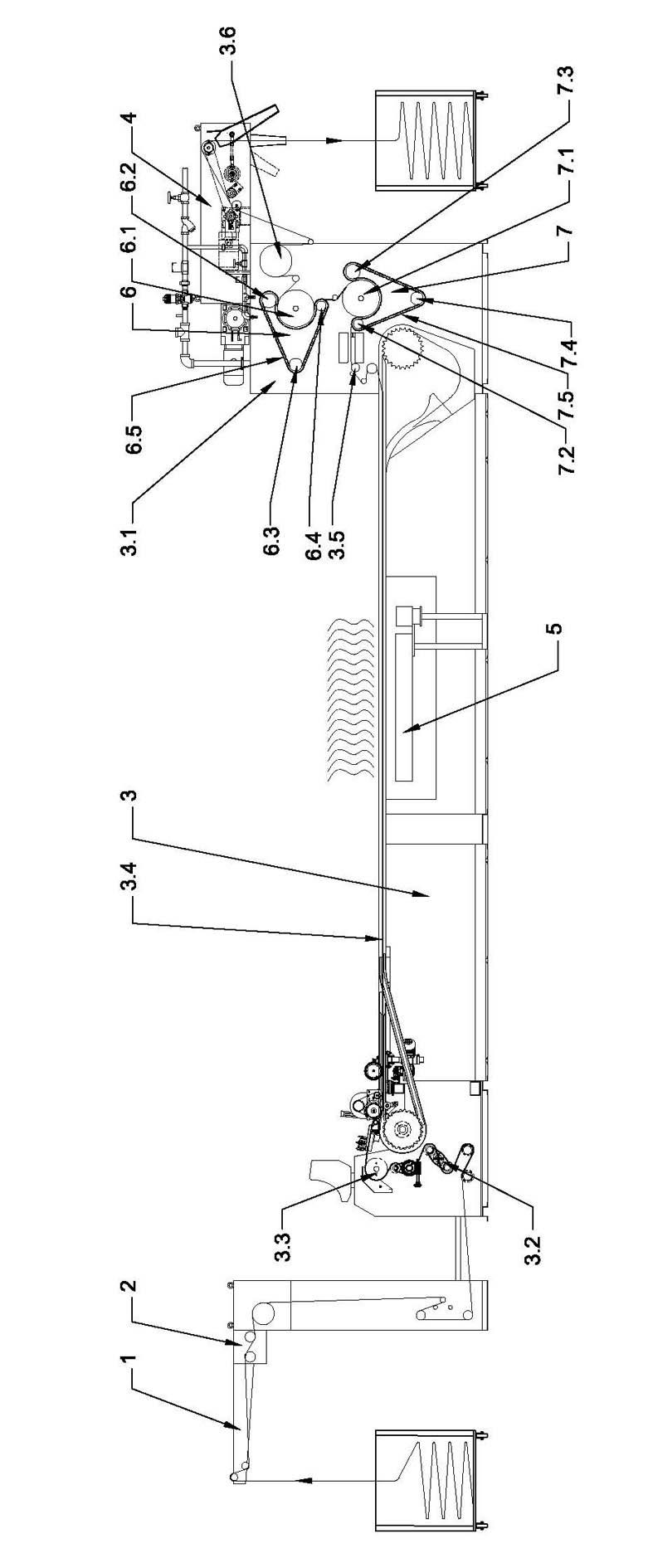

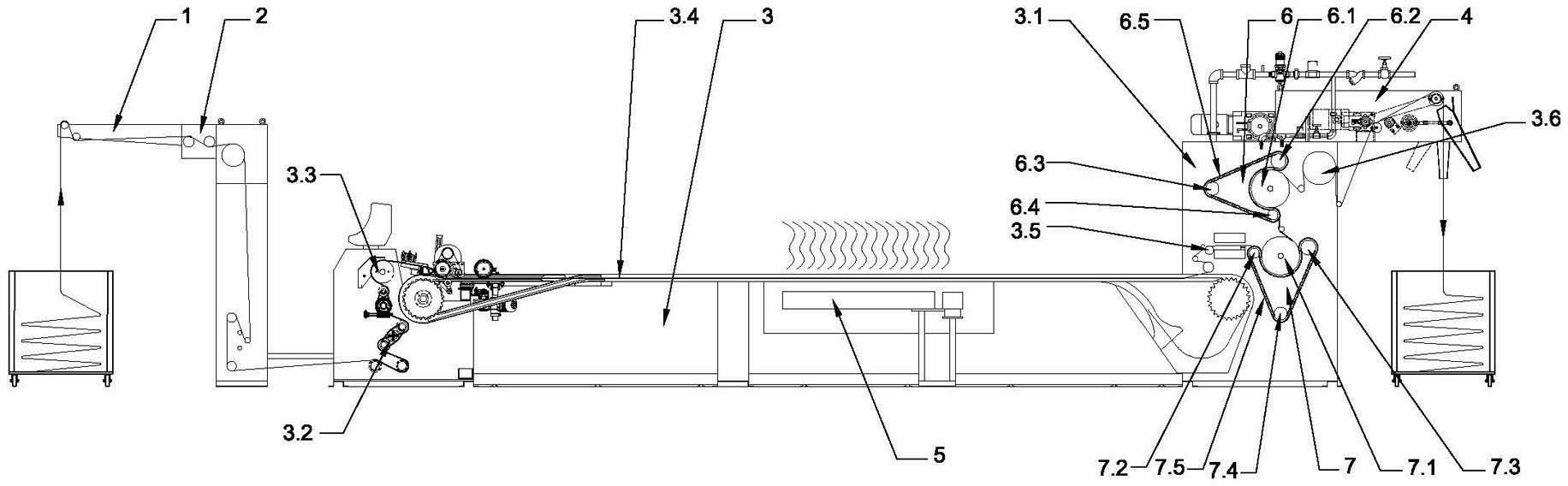

[0007] like figure 1 As shown, the knitted wool blanket pre-shrinking machine includes a cloth input frame 1, an electromechanical centering device 2, a needle rail device 3, a cloth output frame 4 and a steam tank 5, wherein the needle rail device 3 includes a frame 3.1, a cloth input roller 3.2, Feeding roller 3.3, needle rail 3.4, cloth outlet roller 3.5 and cooling roller 3.6; it is characterized in that the needle rail device 3 also includes an upper blanket finishing device 6 and a lower blanket finishing device 7; the upper blanket finishing device 6 includes an upper blanket driving roller 6.1 , upper blanket upper roller 6.2, upper blanket forward roller 6.3, upper blanket lower roller 6.4 and upper blanket 6.5, upper blanket upper roller 6.2, upper blanket forward roller 6.3 and upper blanket lower roller 6.4 respectively arranged on the upper Above, in front of and below the blanket driving roller 6.1, the upper felt 6.5 is set on the upper blanket turning roller 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com