Safety shoe and method for manufacturing same

A manufacturing method and technology of safety shoes, applied to footwear, soles, insoles, etc., can solve the problems of water leakage, short service life of safety shoes, environmental pollution of safety shoes, etc., achieve good air permeability and reduce the possibility of water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

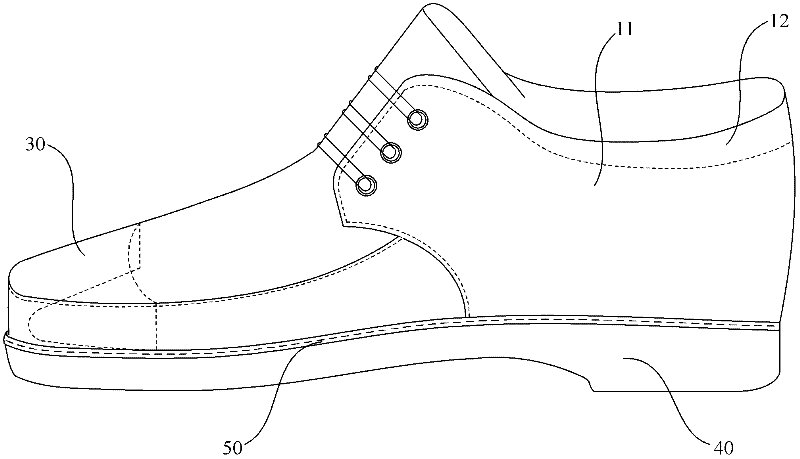

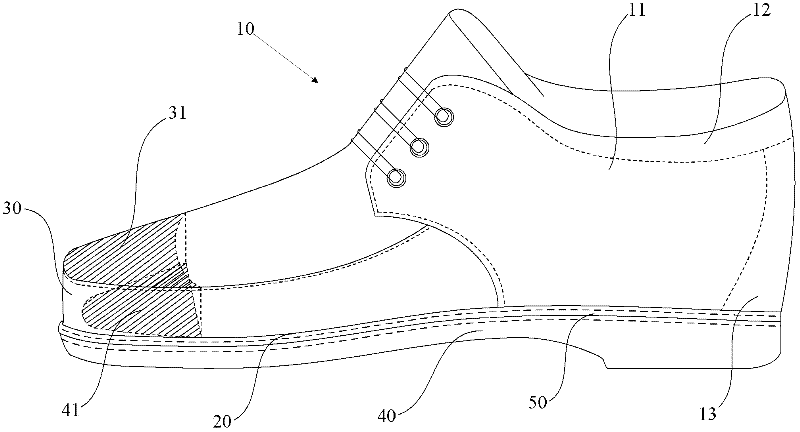

[0032] Please focus on reference figure 2 , figure 2 Schematic diagram of the structure of the safety shoes provided by the embodiment of the present invention. Such as figure 2 As shown, the embodiment of the invention provides a kind of safety shoes, and the safety shoes include:

[0033] The upper part 10 includes a shoe inner 11 and a shoe upper 12, the shoe upper 12 is wrapped outside the shoe inner 11, the shoe upper 12 and the shoe inner 11 except the part near the toe and the part near the sole The part of 40 is not bonded, and the other parts are bonded together;

[0034]A midsole plate 20, which is connected to the part of the shoe inner lining 11 close to the sole 40;

[0035] Toecap 30, which is placed outside the part of the shoe inner 11 near the toe and bonded together with the part of the shoe inner 11 near the toe, except for the part of the shoe upper 12 near the toe that is near the sole 40 All other parts are bonded to the outside of the toe cap 30 ...

Embodiment 2

[0048] The part of the inner lining 11 of the safety shoes provided in this embodiment is close to the sole 40 and the edge of the midsole plate 20 is stitched together by seaming process, and the structure of the rest of the safety shoes provided in this embodiment is the same as that of the safety shoes in the first embodiment above. The structure is the same, and will not be repeated here.

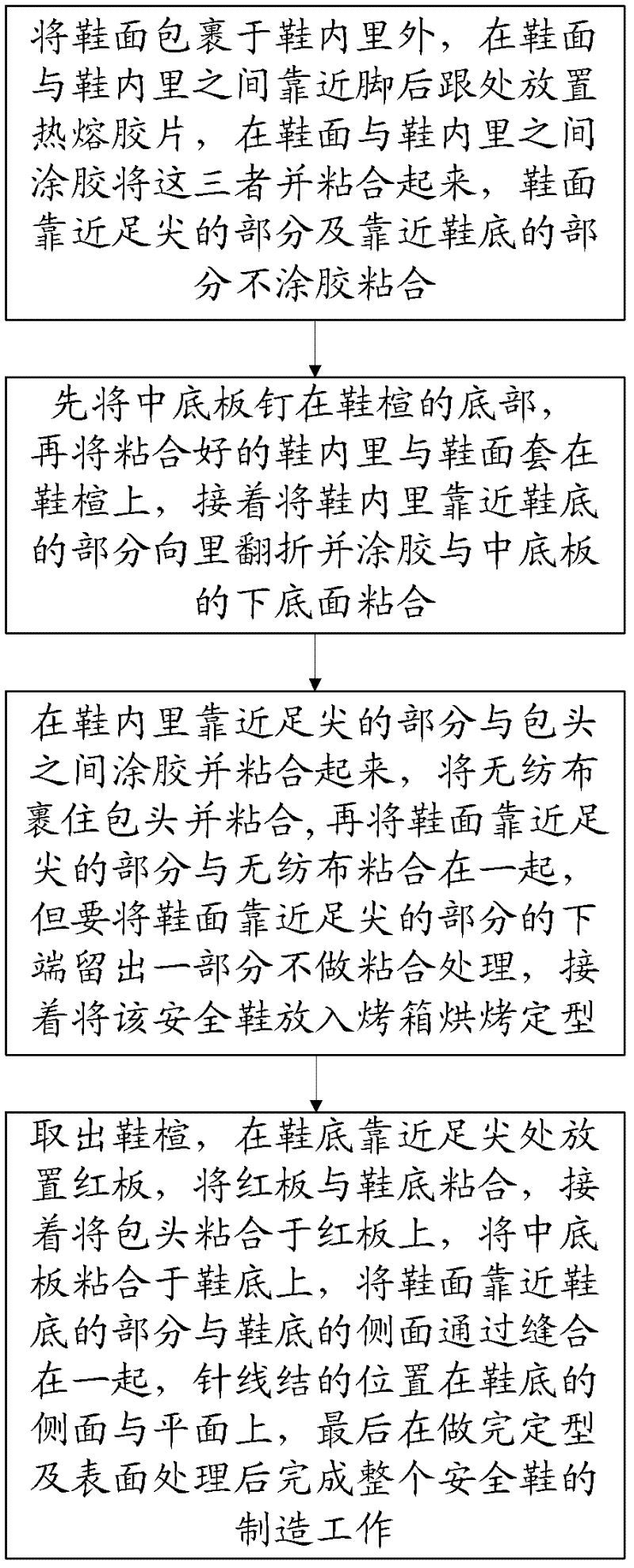

[0049] Please focus on reference Figure 4 , Figure 4 The flow chart of the manufacturing method of the safety shoes provided by Embodiment 1 of the present invention, such as Figure 4 As shown, the method for manufacturing the safety shoes provided in the embodiment of the invention comprises:

[0050] Step 1: Wrap the formed shoe upper 12 outside the shaped shoe inner 11, place a hot-melt adhesive sheet 13 between the shoe upper 12 and the shoe inner 11 near the heel, between the shoe upper 12 and the shoe inner 11 These three are bonded together by applying glue between them, an...

Embodiment 3

[0056] The shoe inner 11 and the midsole plate 20 of the safety shoes provided by this embodiment are integrally formed to form a sock cover, and the structure of the rest of the safety shoes provided by this embodiment is consistent with the structure of the safety shoes in the above two embodiments, and will not be discussed here. Let me repeat.

[0057] Please focus on reference Figure 5 , Figure 5 The flow chart of the manufacturing method of the safety shoes provided by Embodiment 1 of the present invention, such as Figure 5 As shown, the method for manufacturing the safety shoes provided in the embodiment of the invention comprises:

[0058] Step 1: Wrap the molded vamp 12 outside the molded sock, place a hot-melt adhesive sheet 13 between the vamp 12 and the sock near the heel, apply glue between the vamp 12 and the sock to seal the three or bonded together, the part of the upper 12 near the sole 40 is longer than the bottom surface of the sock cover, and this par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com