Novel flat plate-shearing mechanism

A shearing and flat plate technology, applied in the field of new flat plate shearing mechanism and shearing mechanism, can solve the problems of high labor intensity, low production efficiency, waste of shearing materials in the shearing mechanism, etc., so as to overcome the high labor intensity and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

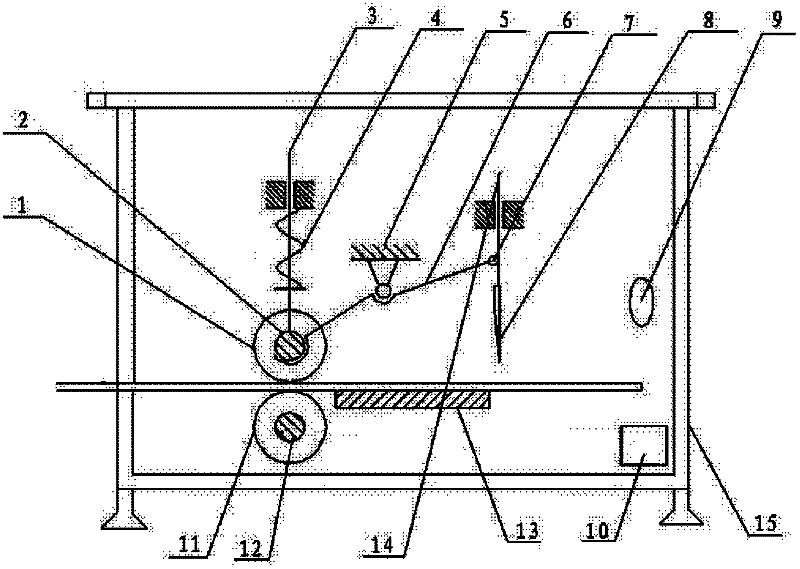

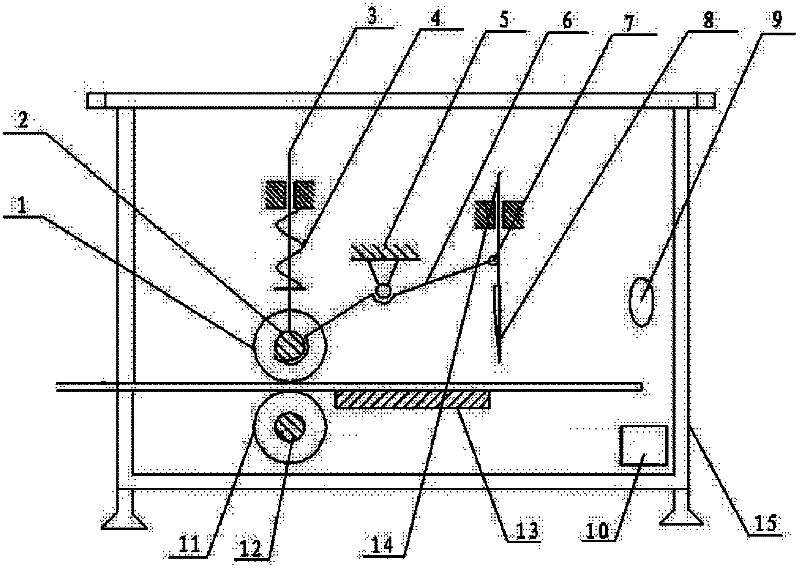

[0010] The shearing mechanism has a roller (1), and the roller (1) is installed on the deployment pressure rod (3) through the roller shaft (2), and the multi-position spring (4) is installed on the deployment pressure rod (3). The joint connecting rod (6) is installed on the supercharging support (5), and one end of the double joint connecting rod (6) is connected with the roller shaft (2), and the other end is connected to the scissors through the double joint connecting rod pin (7). The plate knife seat (14) is connected, and the single-sided cutter (8) is installed on the top of the shear plate knife seat (14), and the contact infrared ray emitting device (9) and the contact infrared ray receiving device (10) are installed on the two-way Above the guide rail (13), the bidirectional guide rail (13) is installed on the top of the shearing plate mechanism body (15), and at the lower end of the shearing plate mechanism body, positioning roller shafts (12) and positioning roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com