Magnetic particle inspection method for small-size pipe socket fillet weld of boiler header

A boiler header, magnetic particle detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of a large number of tube bases, dense tube bases, special fillet weld structure, etc., to achieve broad application prospects, low solution efficiency, and high detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

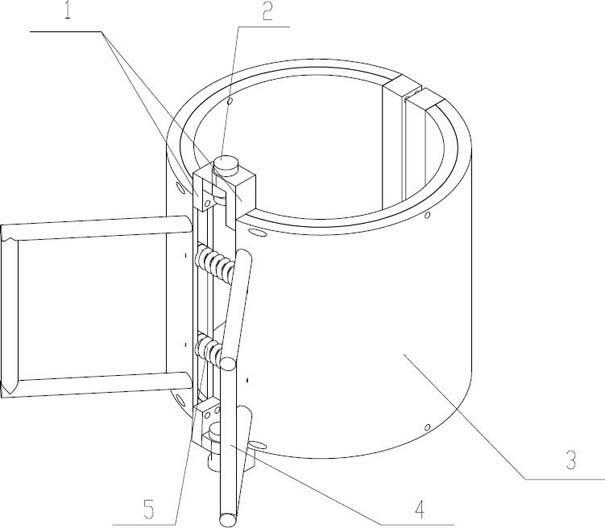

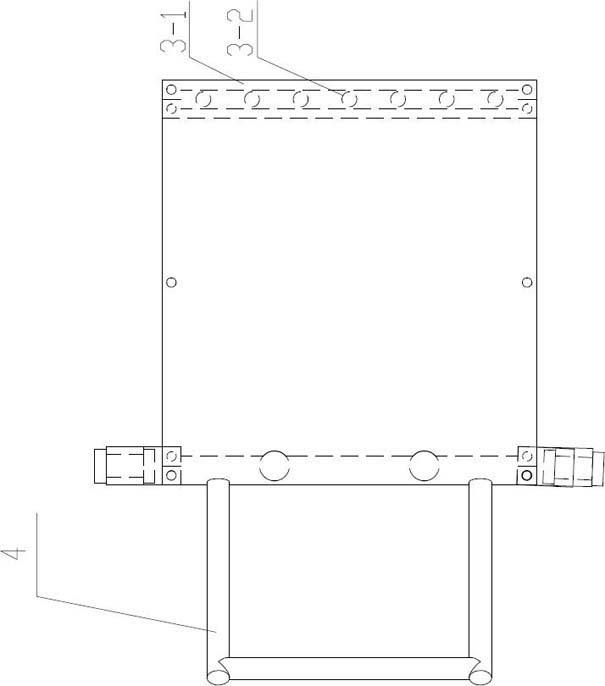

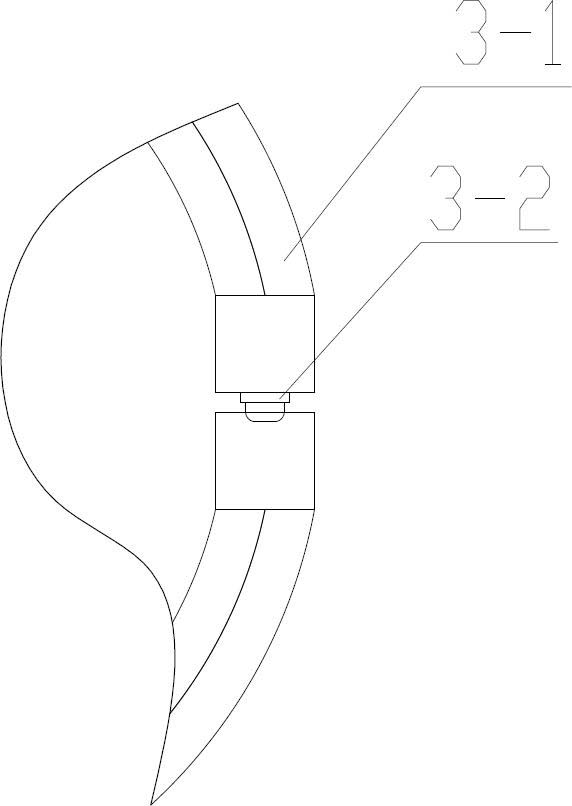

[0036] See attached Figure 1-4 , which is the open coil used in the present invention. Its structure is: it is hinged by two split semi-circular cables 3. The cable includes a cable skeleton 3-1 and is embedded in the cable skeleton 3. The wires 3-2 in -1; one end of the two cables hinged are provided with two support frames 1 up and down, the two support frames 1 are equipped with a pin shaft 2, between the two cables 3 at the end There is a spring 5 and an operating handle 4 that can control the opening and closing of the two cables; the other end of the two cables 3 is a wire contact end, which forms a closed coil through the opening and closing of the cables 3 . The arrangement principle of wire 3-2 is as follows: Figure 7 As shown, when the cable 3 is closed, the lines with the same number at both ends of the conductor are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com