Coherent combination of high-power fiber laser full optical fiber structure and high brightness beam controlling method

A fiber laser, coherent synthesis technology, applied in the structure/shape of the active medium, lasers, laser components, etc., to enhance stability, solve poor beam quality, and solve low duty cycle and spatial instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings.

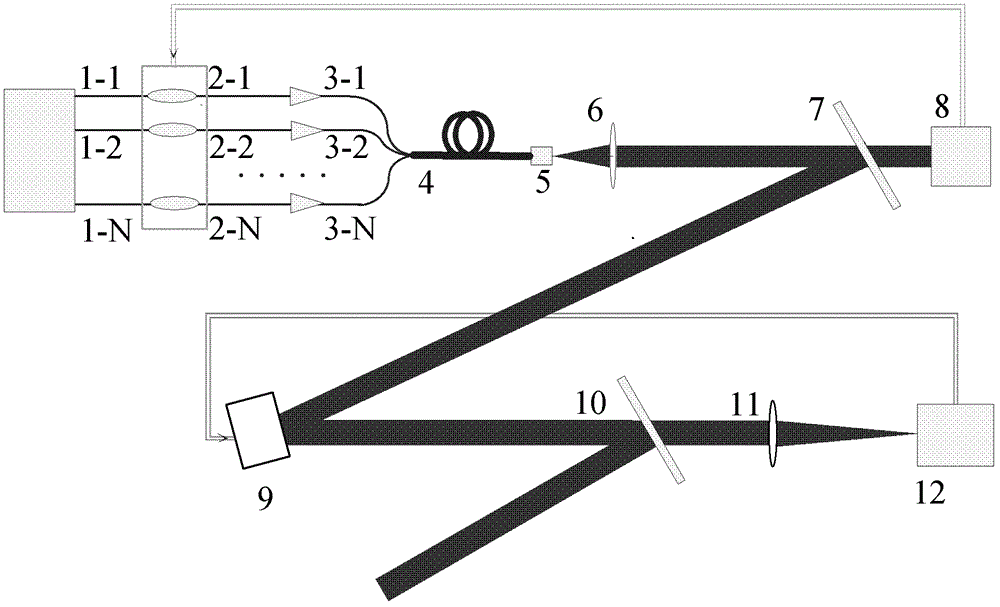

[0023] figure 1 It is a structural schematic diagram of a method for realizing high-power fiber laser all-fiber structure coherent combination and high-brightness beam control proposed by the present invention. 1-1, 1-2, ... 1-N are N channels of seed light respectively, 2-1, 2-2, ... 2-N are N channels of phase modulators respectively, 3-1, 3-2, ... 3- N are N-way amplification systems, respectively. According to actual needs, the amplification system can be one-stage or multi-stage cascaded. The output laser light of the N-way amplification system is combined into a multimode optical fiber through the beam combiner 4. Since the core radius of the multimode optical fiber is larger, it can withstand high-power laser light. 5 is a laser collimator, which collimates the combined high-energy laser beams and outputs them to free space. The beam splitter 7 splits the laser light int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com