Machine-dependent compensation in ink units and dampening units

A technology of ink and speed compensation, applied in general parts of printing machinery, printing presses, rotary printing presses, etc., can solve the problem of the influence of wetting agent measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

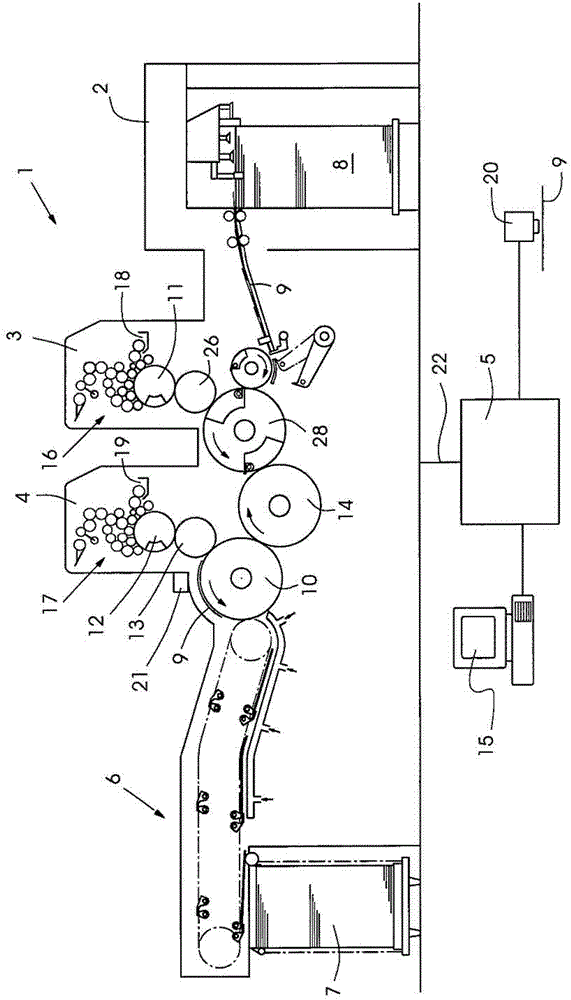

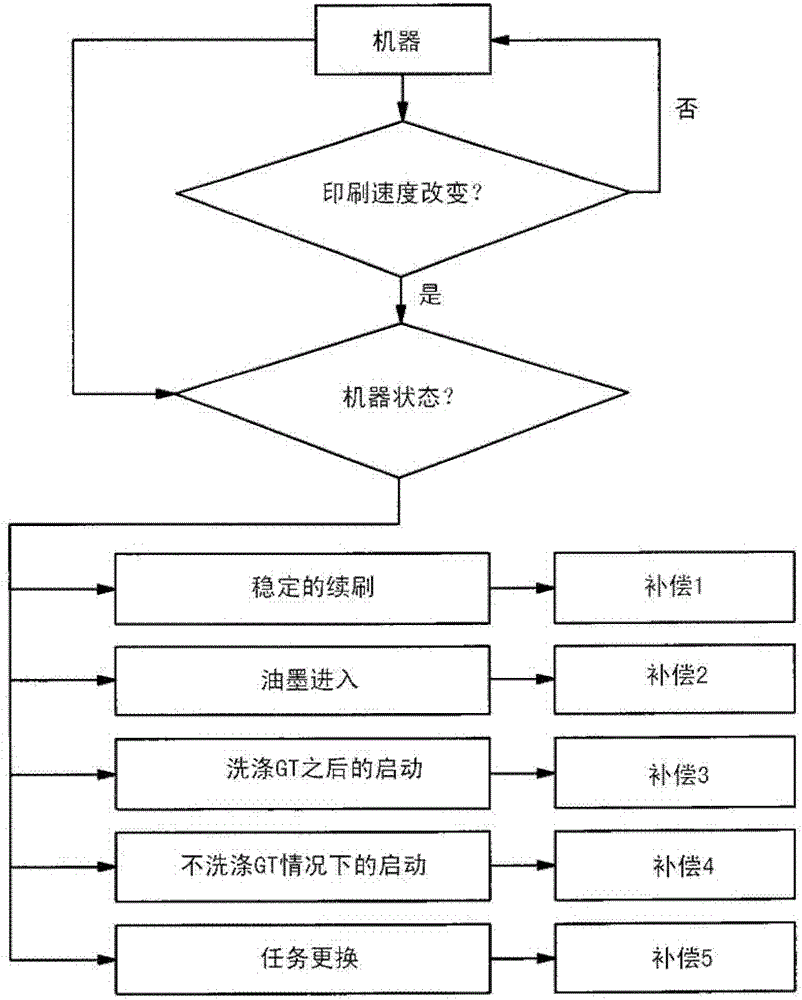

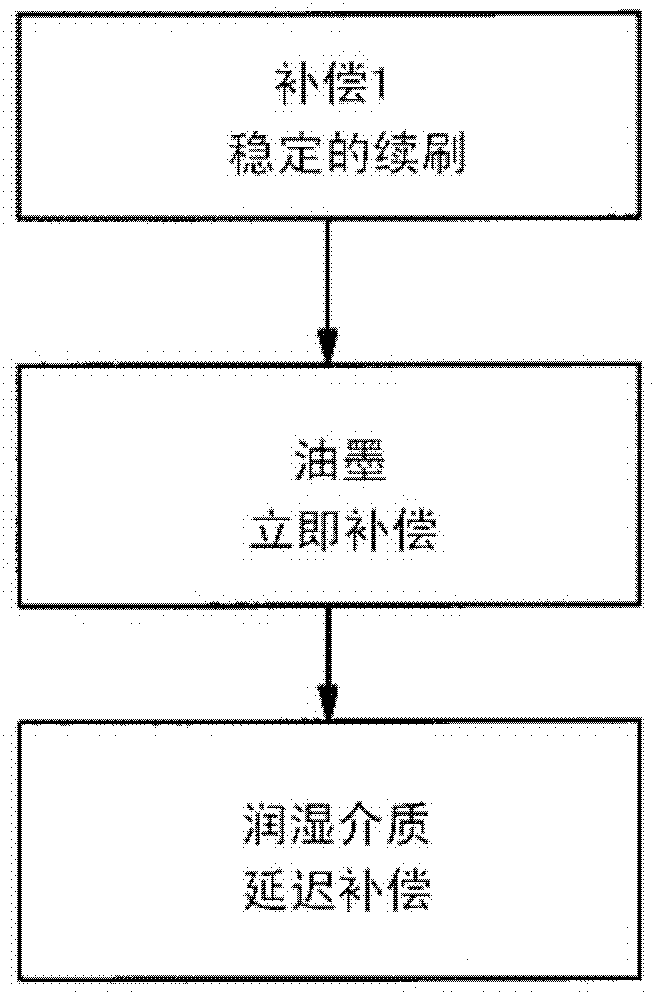

[0021] exist figure 1 The printing machine 1 is shown as having two printing units 3 , 4 which each have an inking unit 16 , 17 and a dampening unit 18 , 19 . The ink units 16 , 17 are used for ink metering and have servo motors which are connected to the control computer 5 of the printing press 1 . The ink metered into the ink units 16 , 17 can be dampened by means of the dampening units 18 , 19 . The dosing of dampening medium into the dampening devices 18 , 19 can also be controlled by the control computer 5 . In the printing units 3 , 4 the metered and dampened ink is first transferred to the plate cylinders 11 , 12 with printing plates and from there to the blanket cylinders 13 , 26 . From there, the printed image is then transferred in the printing nip between the blanket cylinders 13 , 26 and impression cylinders 10 , 28 onto the printed sheet 9 in the printing press 1 . The printing material 9 is transferred between the two printing units 3 , 4 by means of a transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com