Standing wave pipe coupling cavity used for wide-band low-distortion equal-amplitude equal-phase calibration

A standing wave tube and coupling cavity technology, applied in the field of acoustic measurement, can solve the problems of limited low frequency range, achieve wide frequency range, reduce waveform distortion, and low distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

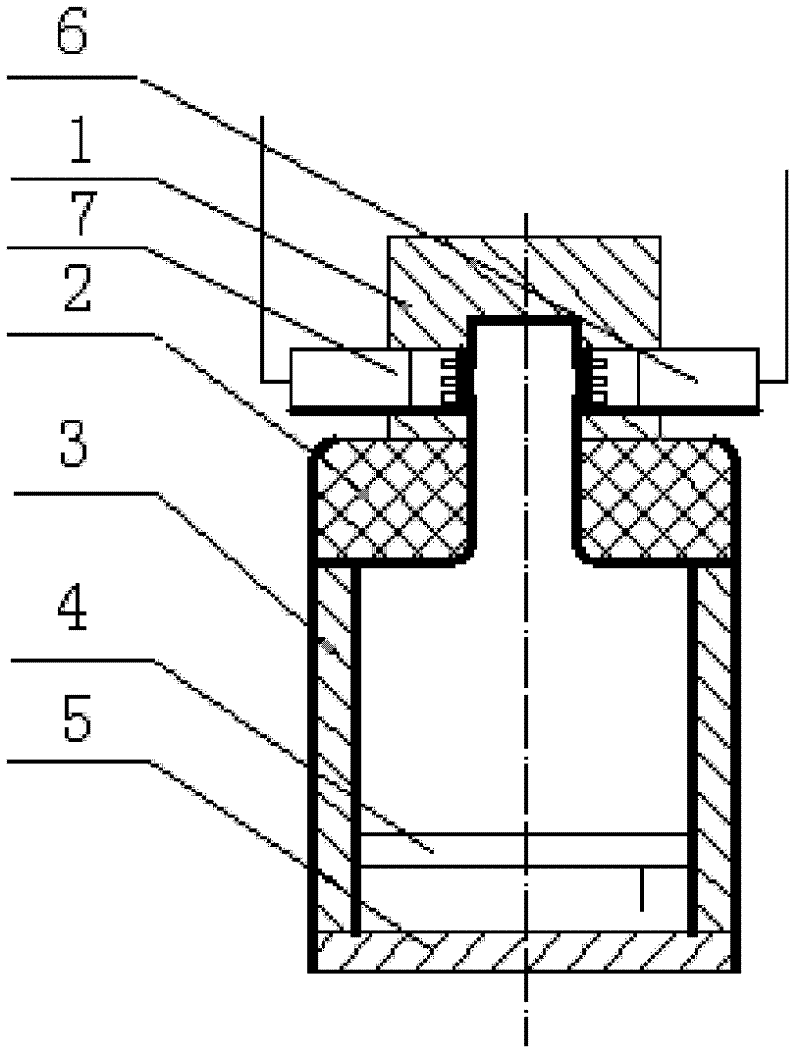

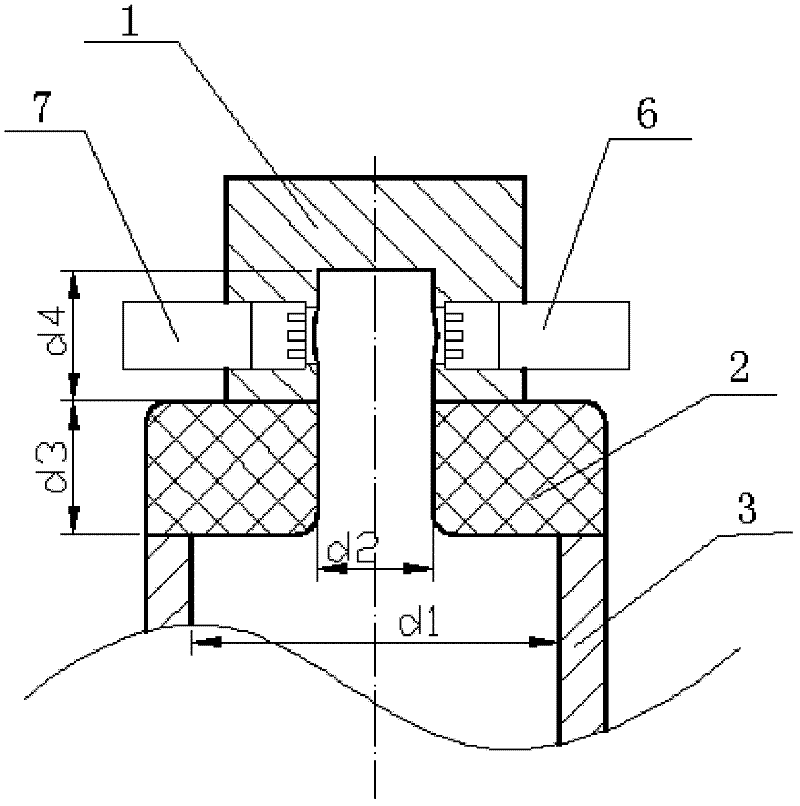

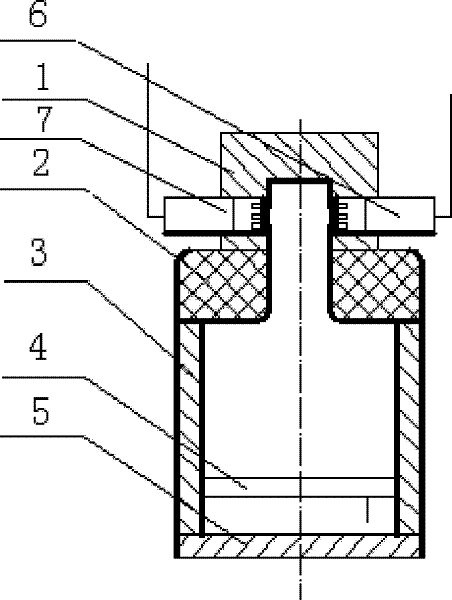

[0017] Such as figure 1 , figure 2 As shown, a standing wave tube coupling cavity for broadband low distortion, equal amplitude and equal phase calibration includes a coupling cavity 1, a variable cross-section reflector 2, a standing wave tube 3 and a rear end cover 5, wherein the hollow tube with an inner diameter d1=90mm A loudspeaker 4 is installed at the lower end of the standing wave tube 3 of the circular tube structure, and is sealed and fixed by the rear end cover 5; the variable cross-section reflective end 2 of the cylindrical cover-shaped structure with a circular through hole in the center is sealed and fixed with the upper end of the standing wave tube 3 Connection, wherein, the thickness of the variable cross-section reflective end 2 is d3=30mm, the diameter of the central circular hole of the variable cross-section reflective end 2 is d2=20mm; the coupling cavity 1 is a cylindrical structure with a cylindrical groove in the center of one end, and the central c...

Embodiment 2

[0019] Such as figure 1 , figure 2 As shown, a standing wave tube coupling cavity for broadband low distortion, equal amplitude and equal phase calibration includes a coupling cavity 1, a variable cross-section reflection end 2, a standing wave tube 3 and a rear end cover 5, wherein the hollow tube with an inner diameter d1=100mm A loudspeaker 4 is installed at the lower end of the standing wave tube 3 of the circular tube structure, and is sealed and fixed by the rear end cover 5; the variable cross-section reflective end 2 of the cylindrical cover-shaped structure with a circular through hole in the center is sealed and fixed with the upper end of the standing wave tube 3 Connection, wherein, the thickness of the variable cross-section reflective end 2 is d3=35mm, the diameter of the central circular hole of the variable cross-section reflective end 2 is d2=25mm; the coupling cavity 1 is a cylindrical structure with a cylindrical groove in the center of one end, and the cen...

Embodiment 3

[0021] Such as figure 1 , figure 2 As shown, a standing wave tube coupling cavity for broadband low distortion, equal amplitude and equal phase calibration includes a coupling cavity 1, a variable cross-section reflection end 2, a standing wave tube 3 and a rear end cover 5, wherein the hollow tube with an inner diameter of d1 = 120mm A loudspeaker 4 is installed at the lower end of the standing wave tube 3 of the circular tube structure, and is sealed and fixed by the rear end cover 5; the variable cross-section reflective end 2 of the cylindrical cover-shaped structure with a circular through hole in the center is sealed and fixed with the upper end of the standing wave tube 3 Connection, wherein, the thickness of the variable cross-section reflective end 2 is d3=40mm, and the diameter of the central circular hole of the variable cross-section reflective end 2 is d2=30mm; the coupling cavity 1 is a cylindrical structure with a cylindrical groove in the center of one end, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com