Continuously variable transmission

一种无级变速器、初级的技术,应用在皮带/链条/齿轮、机械设备、传动装置等方向,能够解决成本上升、重量增加等问题,达到成本降低、零件数量少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, embodiments of the present invention and their advantages will be described in detail with reference to the drawings.

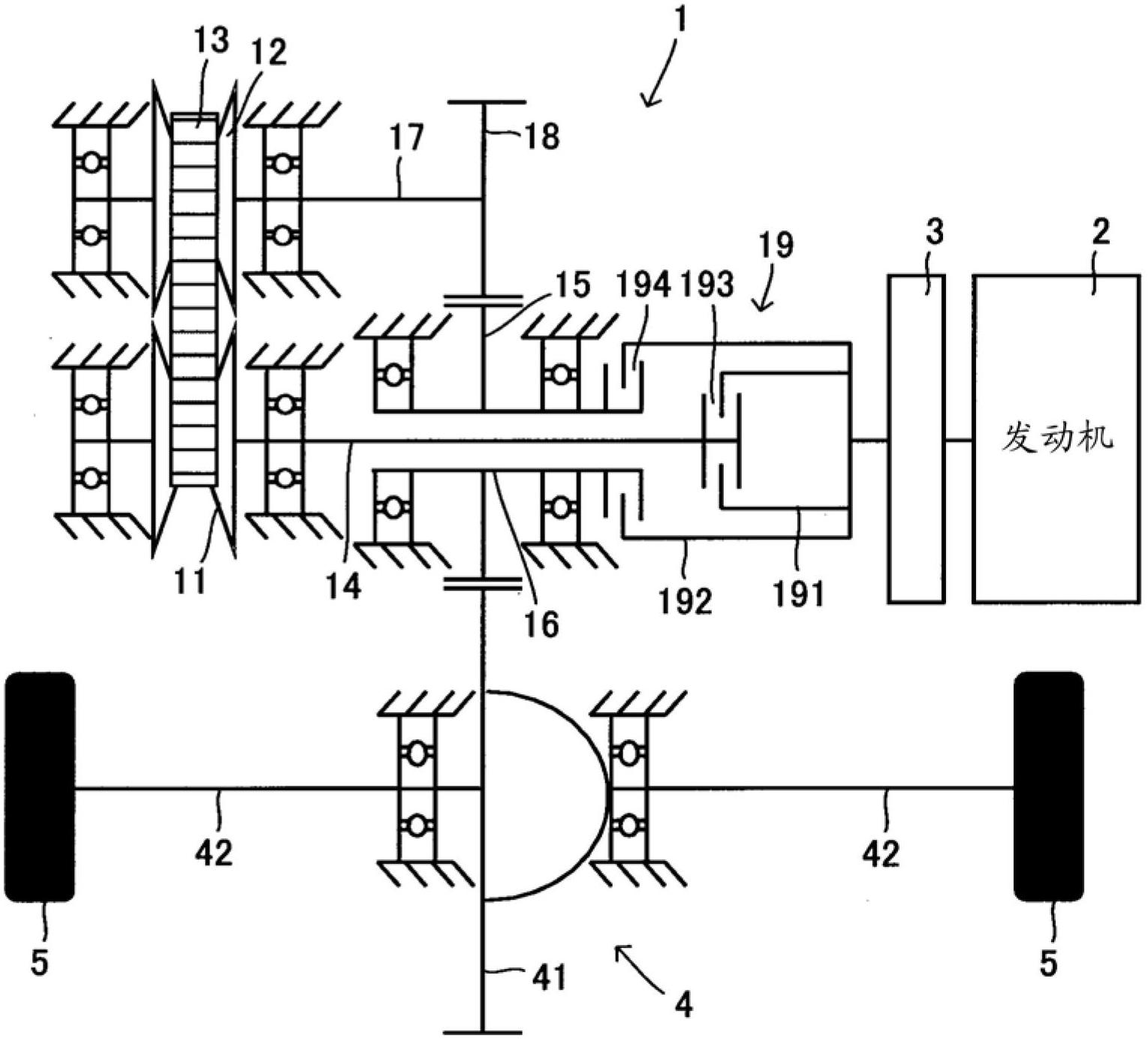

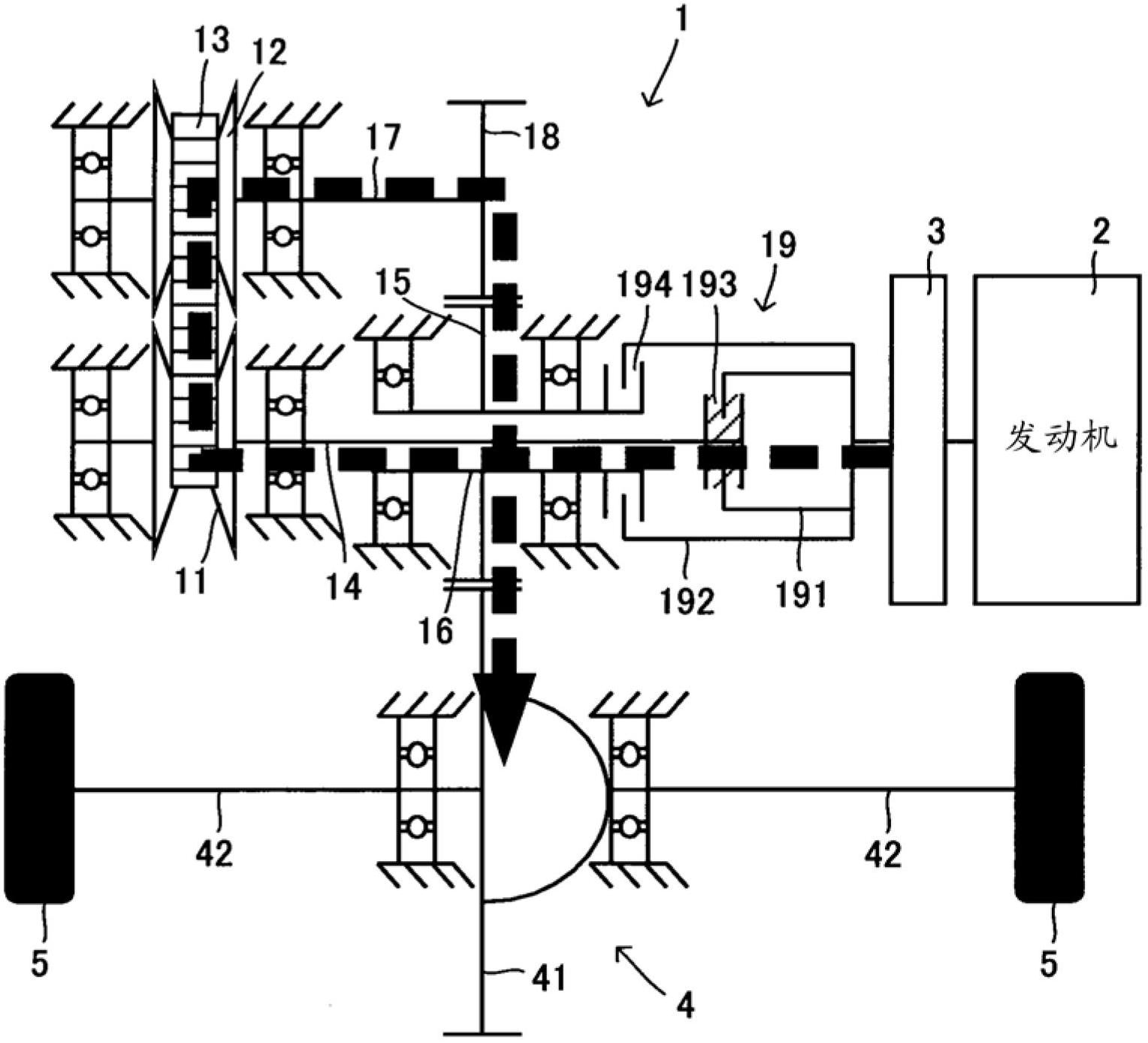

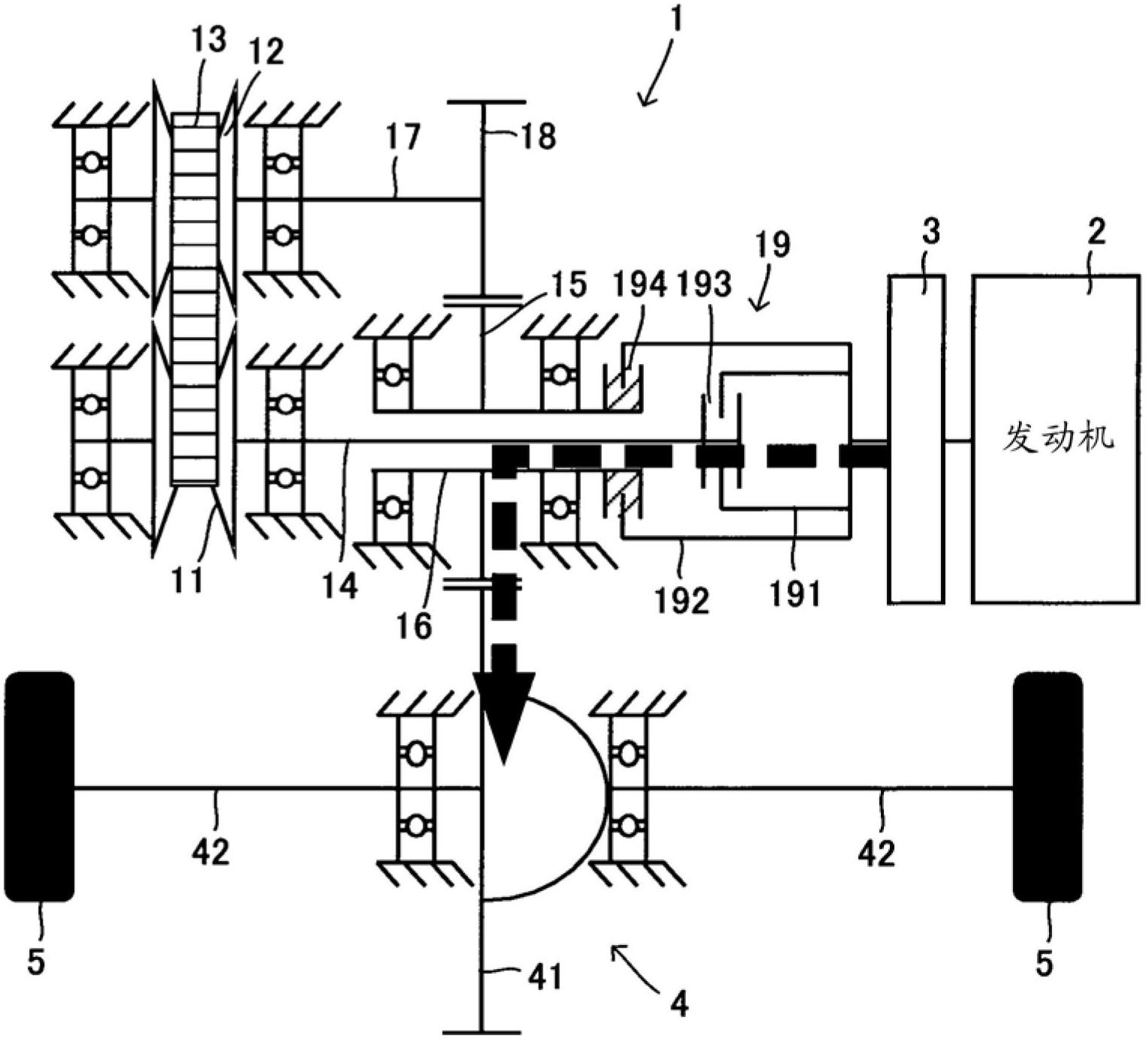

[0016] figure 1 A schematic configuration of a vehicle equipped with a continuously variable transmission (hereinafter referred to as “CVT”) 1 according to the first embodiment is shown. This vehicle has an engine 2 as a power source, and the power of the engine 2 is transmitted to drive wheels 5 via a starting mechanism (for example, a torque converter) 3 , a CVT 1 , and a differential mechanism 4 .

[0017] The CVT 1 has a primary pulley 11 , a secondary pulley 12 , and a belt 13 (an endless flexible member) wound between the pulleys 11 and 12 . The pulleys 11 and 12 are respectively composed of a fixed conical plate and a movable conical plate arranged opposite to the fixed conical plate. A hydraulic cylinder (not shown) is provided on the back surface of the movable conical plate, and the movable conical plate can be displaced in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com