Self-tapping plug and connector assembly using same

A self-tapping, plug-in technology, applied to the parts of the connection device, the device for connecting, engaging/disconnecting the connected parts, etc., can solve the problems of low locking and unlocking efficiency, and achieve low locking and unlocking efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

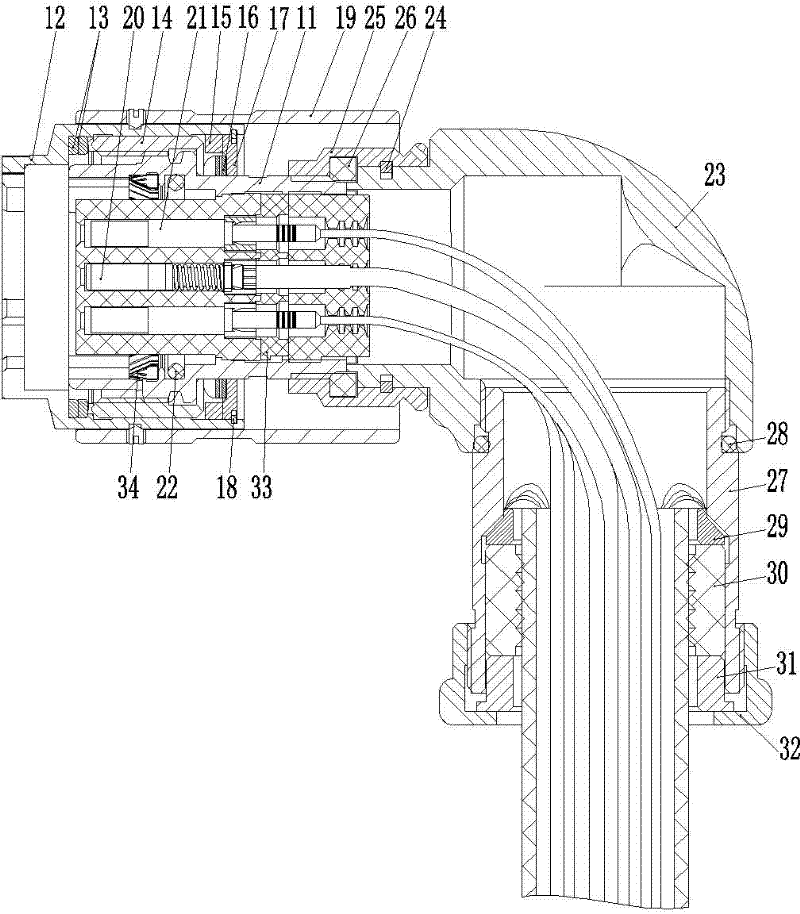

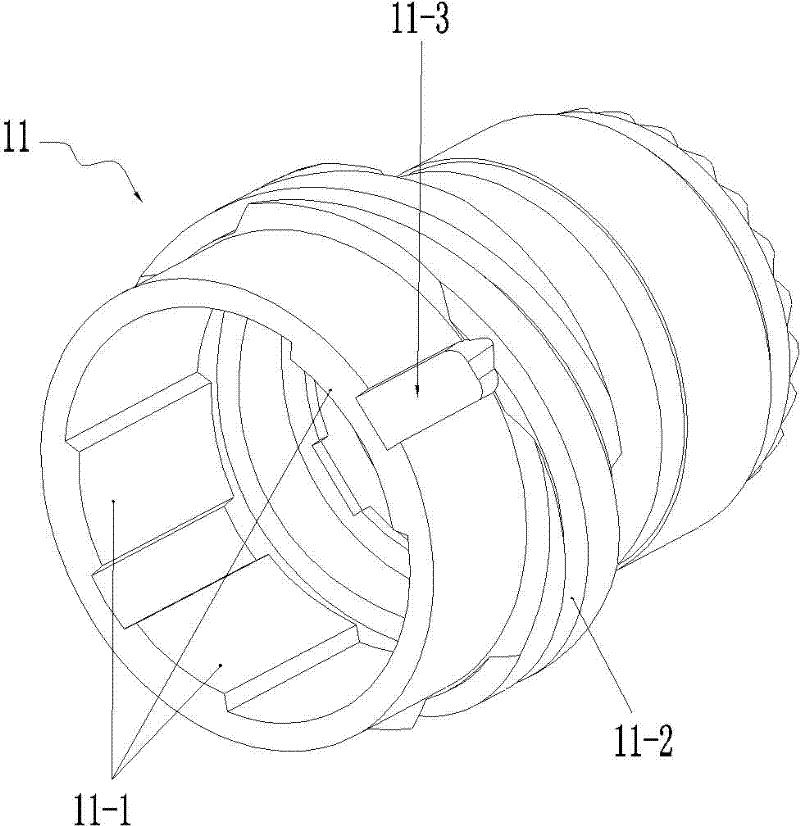

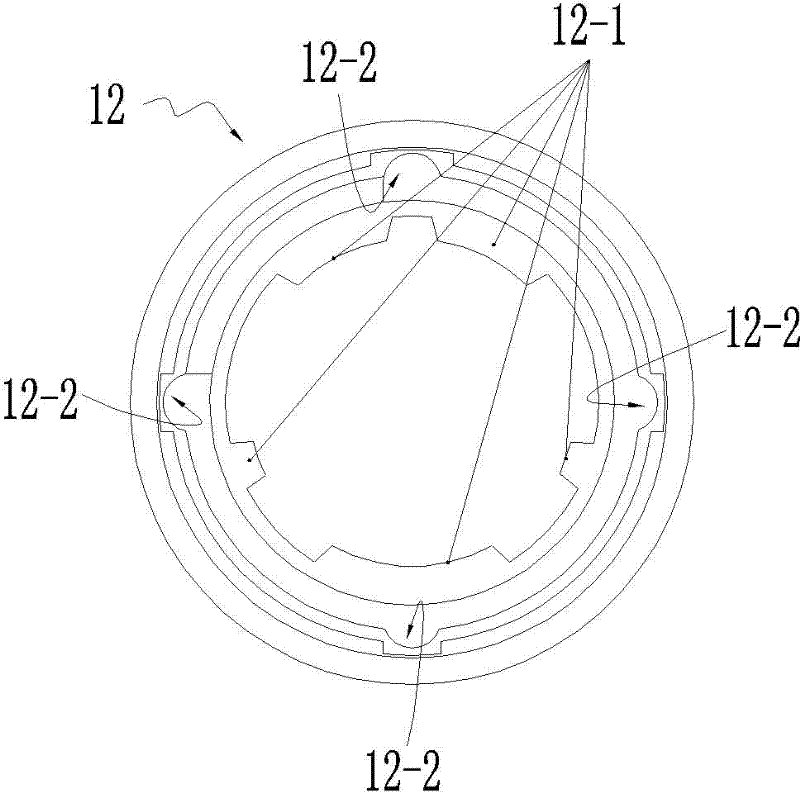

[0036] Embodiment 1 of the self-tapping plug of the present invention, such as Figure 1-8 As shown, it includes a plug housing 11. The plug housing 11 adopts a spline housing, which is cylindrical as a whole and has a plug-in section at the front end. A guide positioning key 11-1 is provided on the inner wall of the plug-in section. When mated with the adapter socket, the guide positioning key 11-1 plays the role of guiding, positioning and anti-rotation. In addition, an external thread section 11-2 is provided behind the plug-in section of the plug housing 11 and passes through the external thread section. 11-2 is equipped with a connecting cap 12. The connecting cap 12 is in the shape of a stepped sleeve and includes a small diameter section at the front end and a large diameter section at the rear end. The front end of the small diameter section is provided with a convex key 12-1 on the inner wall surface. The convex key 12-1 is used for snapping into the ring groove on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com