Steel dam bottom shaft side water stop structure

A bottom shaft and water stop technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of water leakage at both ends of the soft rubber belt, unreliable contact of the soft rubber belt, and gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

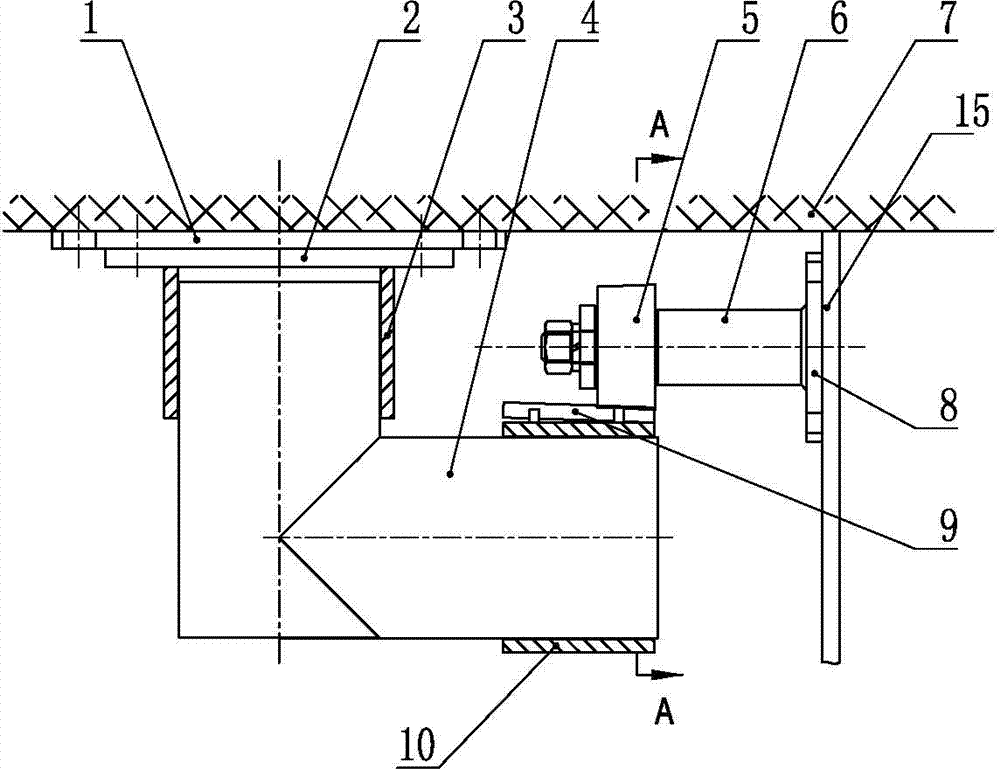

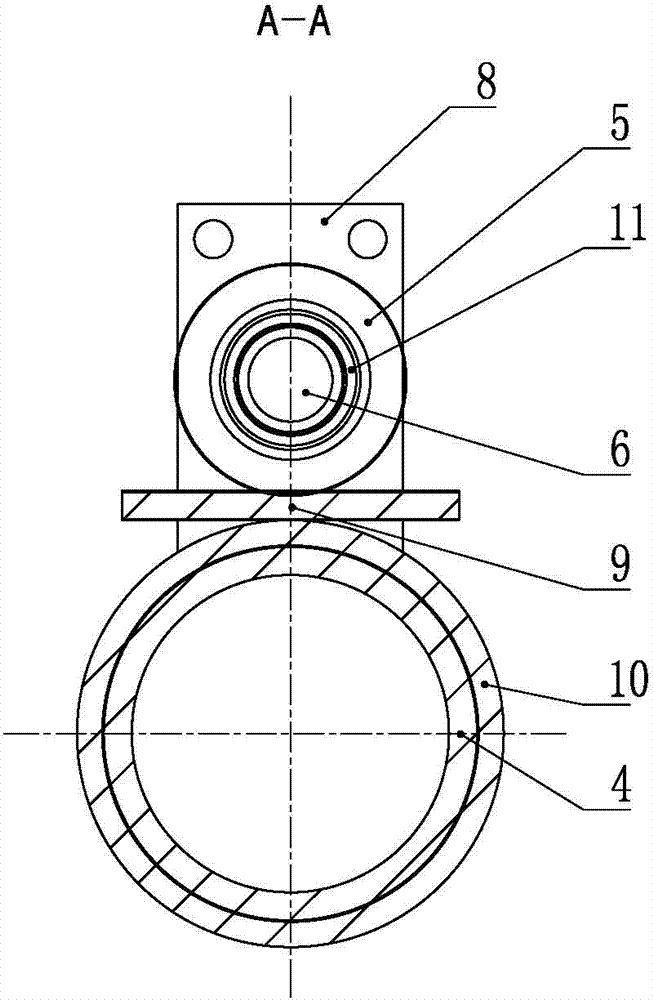

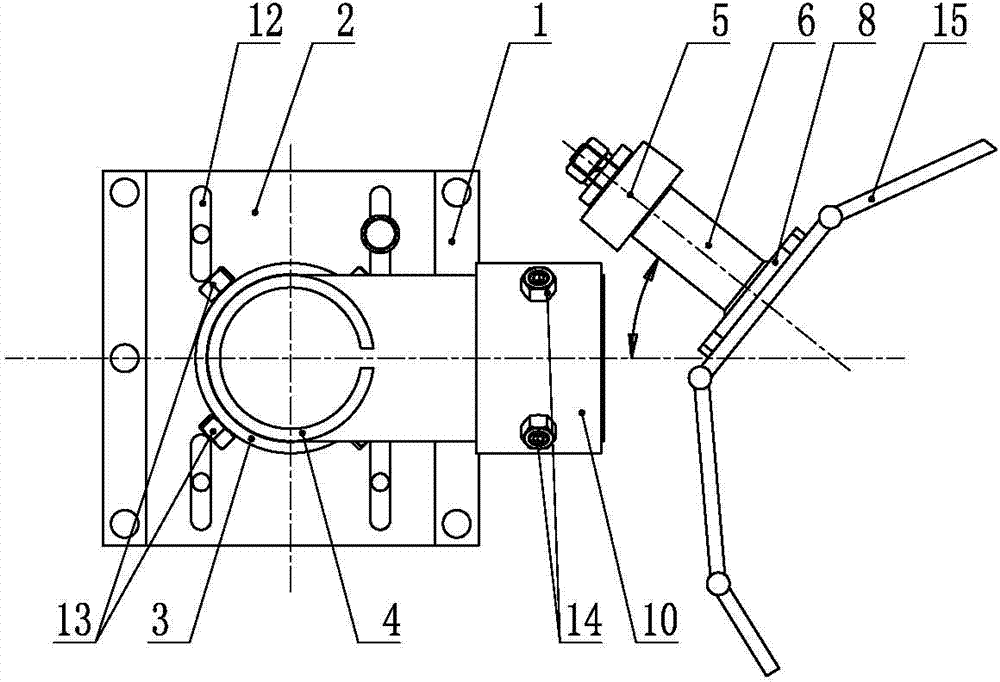

[0019] Such as figure 1 As shown in -5, it is the water-stop structure at the bottom shaft side of the steel dam, and its structure includes connecting plate 1 for fixing on the gate wall 7 and connecting plate 2 8 for fixing on the chain plate assembly 15; connecting plate 1 1 is fixed with a positioning plate 2, and the positioning plate 2 is provided with a strip groove 12, and the bolts passing through the strip groove 12 are connected between the connecting plate-1 and the positioning plate 2; Part 3, the first fixing part 3 is a pipe fitting, the first fixing part 3 is sleeved on one end of the right-angle elbow 4, the right-angle elbow 4 is welded and connected by two metal pipes perpendicular to each other, and the other end of the right-angle elbow 4 is outside The second fixing part 10 is sleeved, and the second fixing part 10 is also a pipe fitting. The side of the second fixing part 10 is provided with a guide plate 9; A bearing 11 is installed between the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com