Method for discontinuously acquiring underground pressure pulse of inflatable bored well

A downhole pressure and air-filled drilling technology, which is applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problem that the ground detection equipment cannot receive pulse signals, etc., to ensure safe directional drilling and improve drilling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

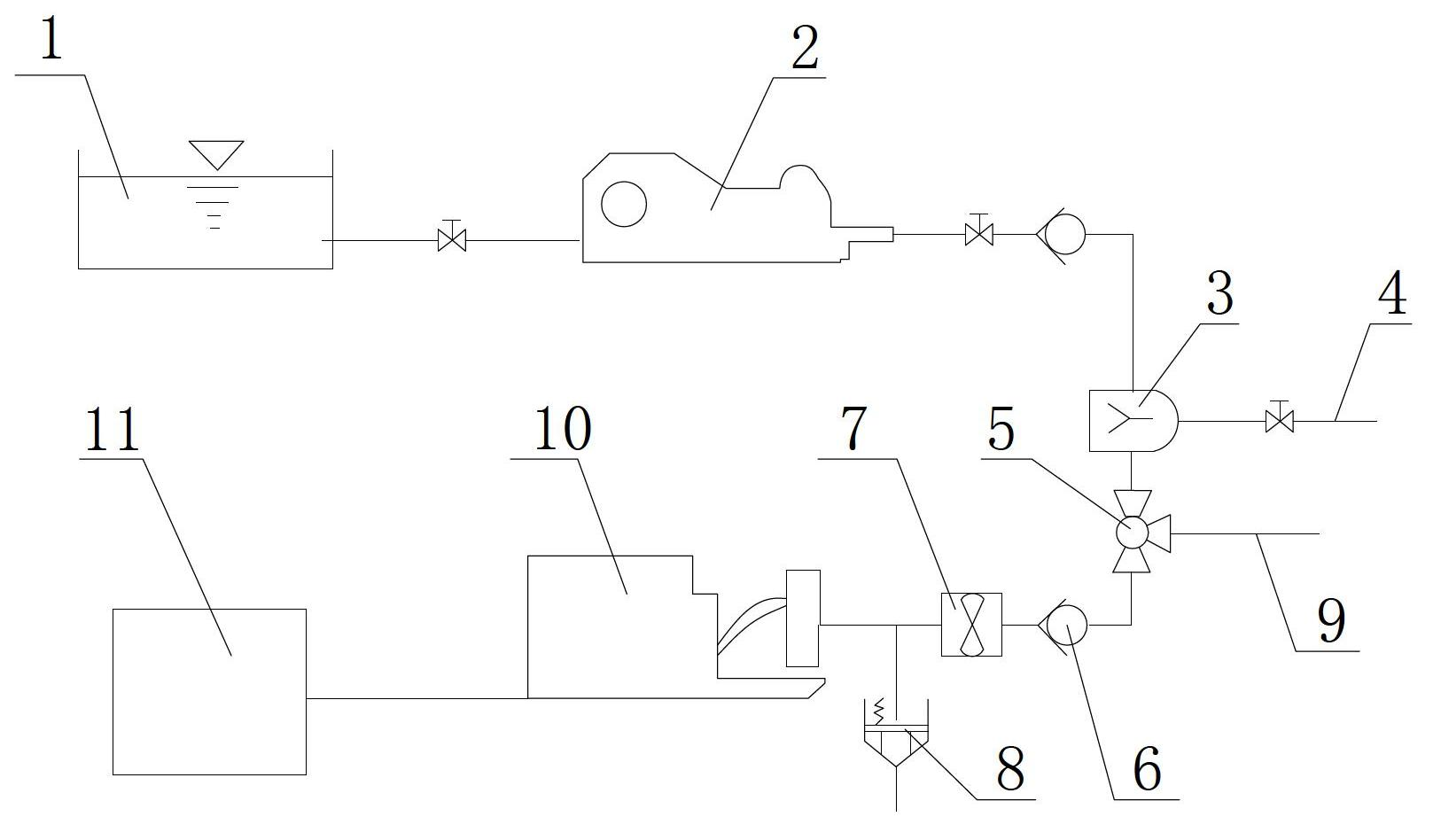

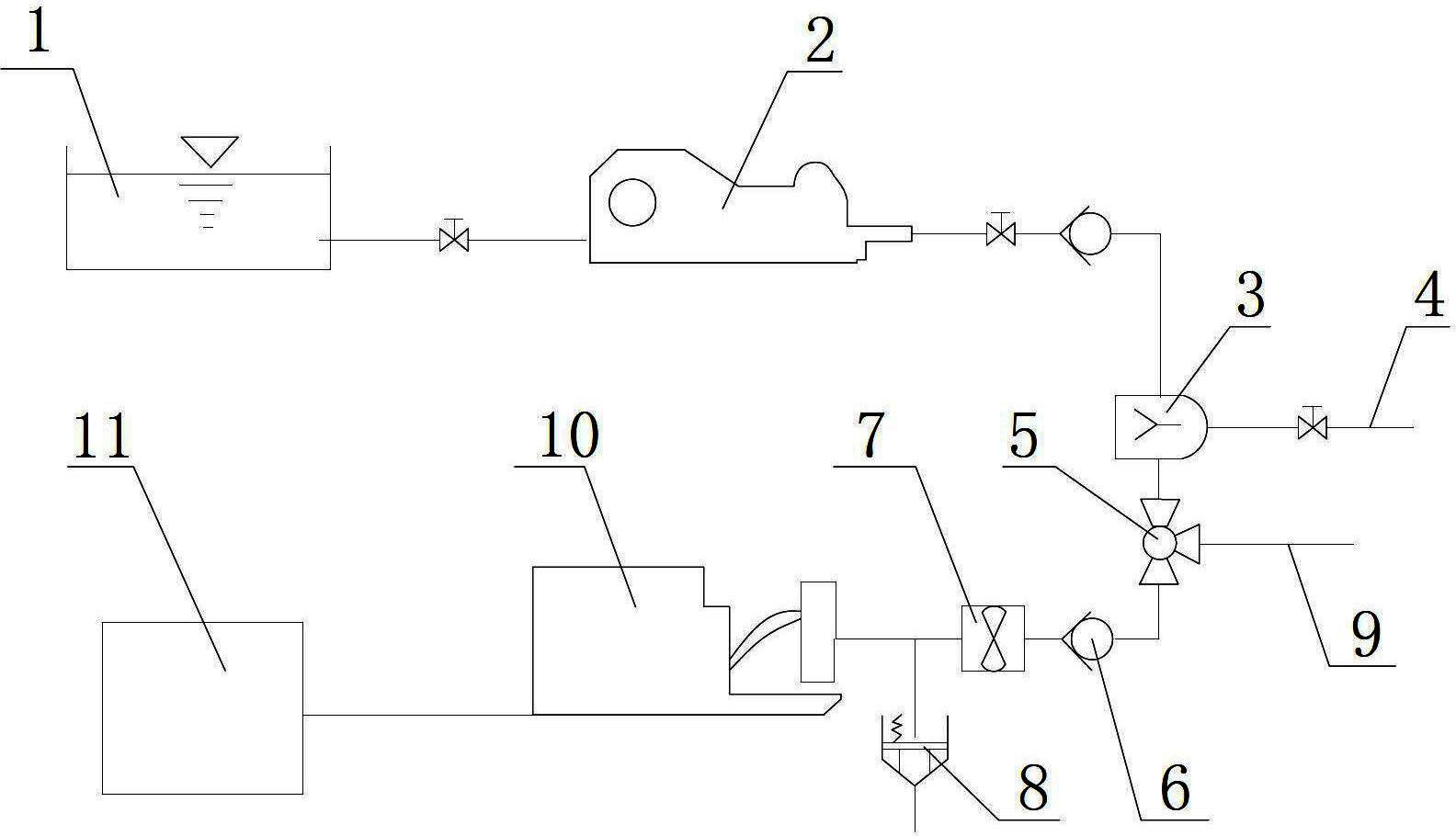

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] The present invention comprises the following steps:

[0018] A. Keep the liquid injection volume constant, and gradually increase the gas injection volume. When there is no downhole pressure pulse feedback signal, the maximum gas holdup rate under the condition of the gas injection rate is the upper limit of the critical gas holdup rate, which is the gas holdup rate threshold value of the measurement-while-drilling equipment;

[0019] B. When the ground detection equipment cannot receive the signal, open the vent valve to discharge the gas, stop the gas injection immediately, and keep injecting the drilling fluid;

[0020] C. When the ground detection equipment can receive the pulse signal, close the release valve, and inject gas with the same amount of gas injected at the last moment before the gas stop.

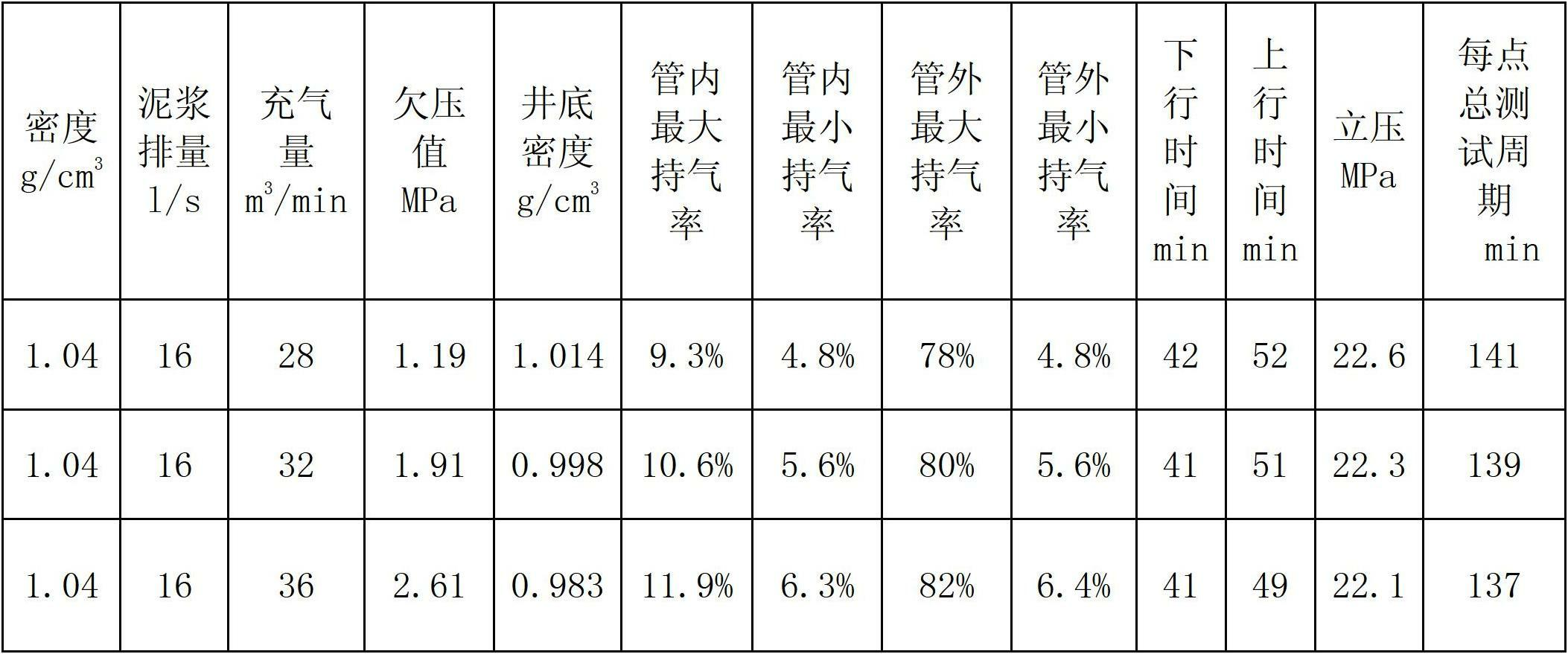

[0021] Drilling adopts the conventional pneumatic drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com