Cutting insert for a cutting tool

A technology for cutting blades, cutting tools, applied in the direction of cutting blades, knives for lathes, manufacturing tools, etc., capable of solving problems such as poor chip formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

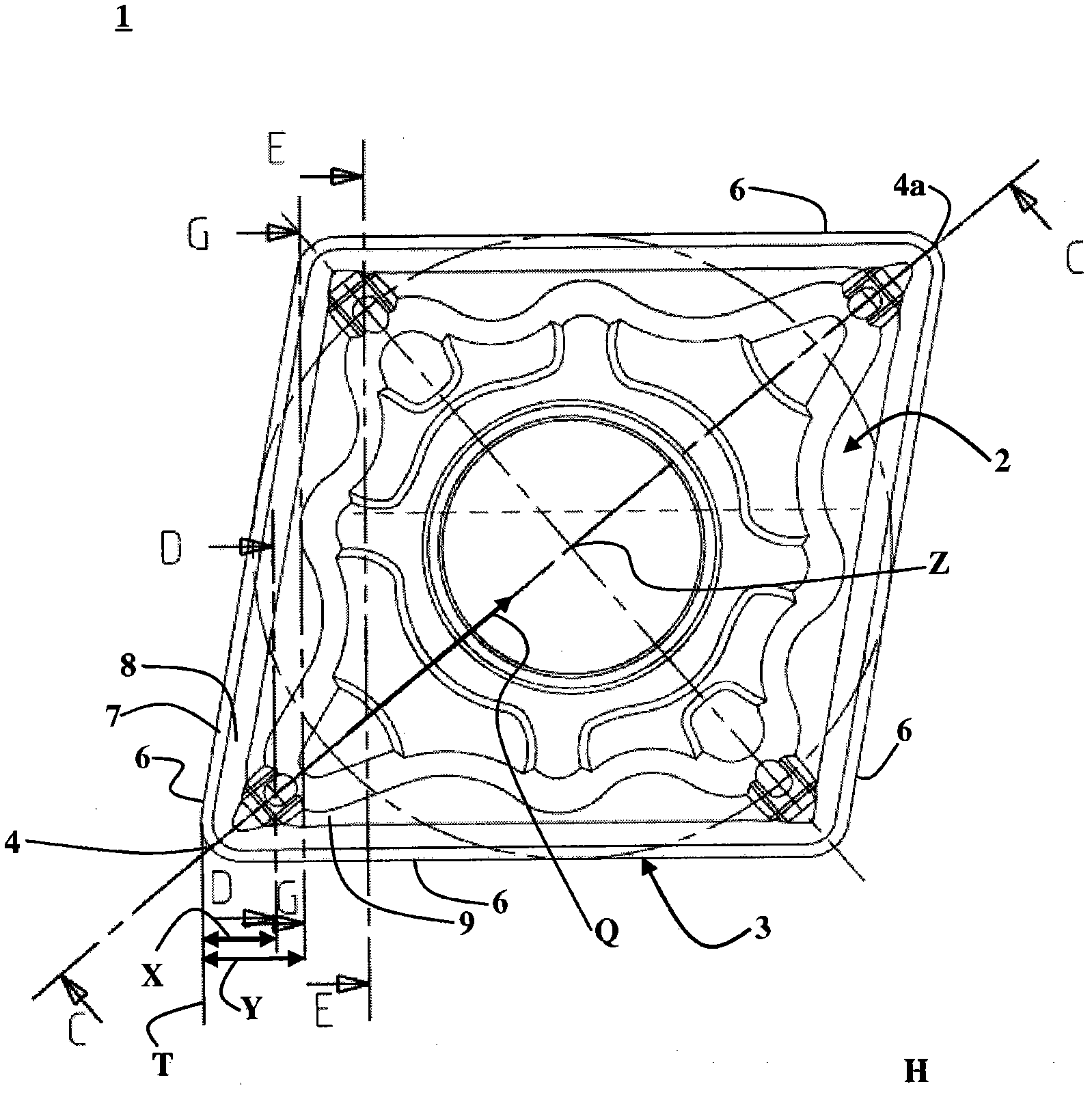

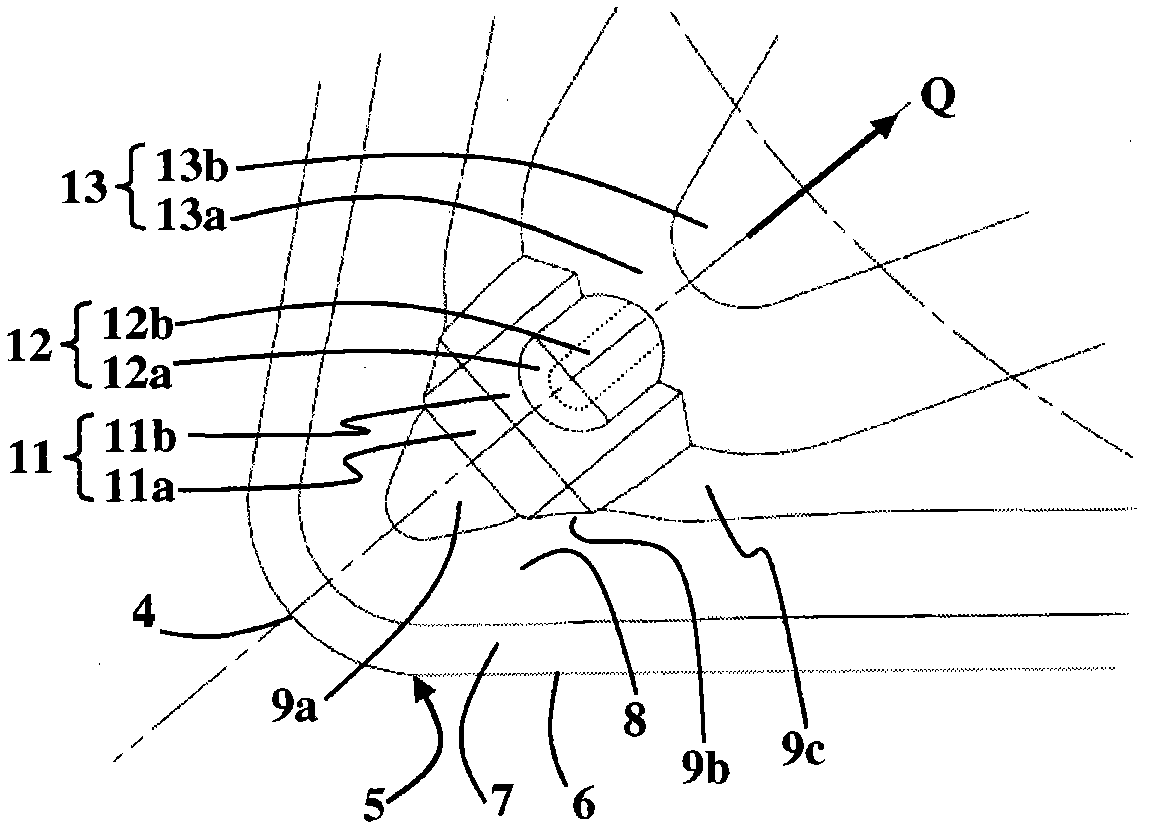

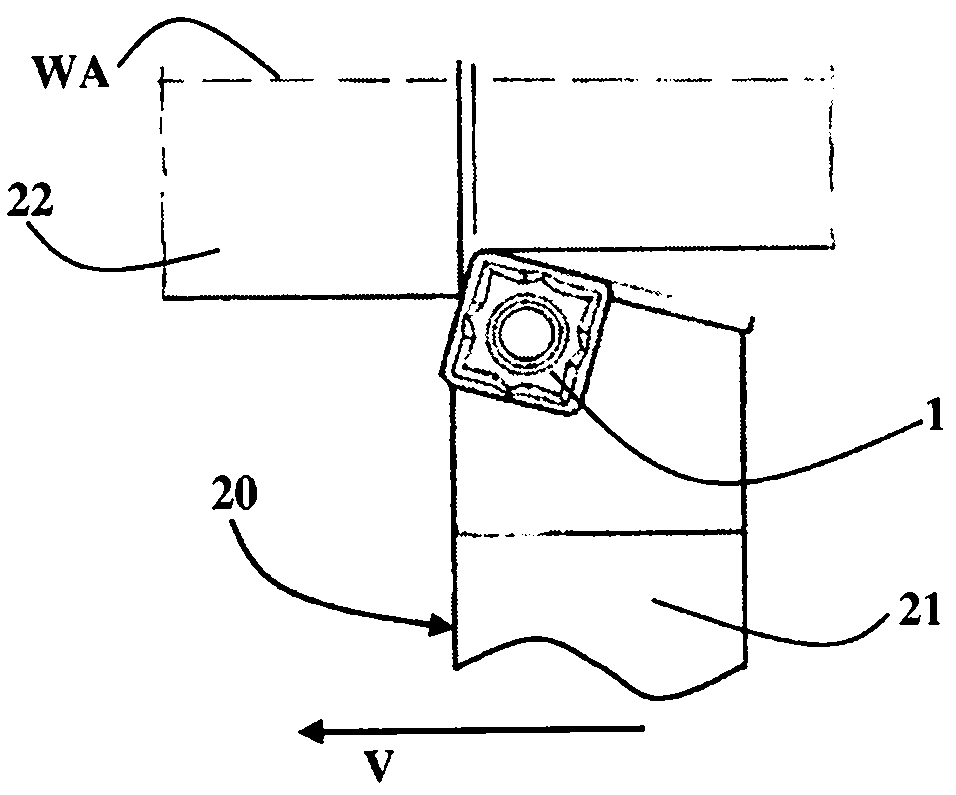

[0031] An exemplary embodiment is described below with reference to the accompanying drawings. figure 1 Shown is a plan view of a cutting blade -1- according to an embodiment. The cutting blade - 1 - according to the exemplary embodiment is designed as an indexable blade. Cutting blade-1-has a top surface-2-( figure 1 shown) and the bottom surface arranged on the rear side (not shown) of the cutting blade -1-. It should be noted that the use of the references "bottom" and "top" faces assumes a certain orientation of the cutting blade, which orientation has been chosen to enable a better understanding of the following description and does not represent a limitation. In this case, the "bottom" face can of course also be arranged to the side or above the "top" face, depending on the orientation of the cutting blade.

[0032] In an exemplary embodiment, the bottom surface is designed in the same way as the top surface -2- and is arranged generally (except for the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com