Double-sided indexable turning inserts

A turning and insert technology, applied in the field of double-sided indexable turning inserts, which can solve problems such as blunt cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

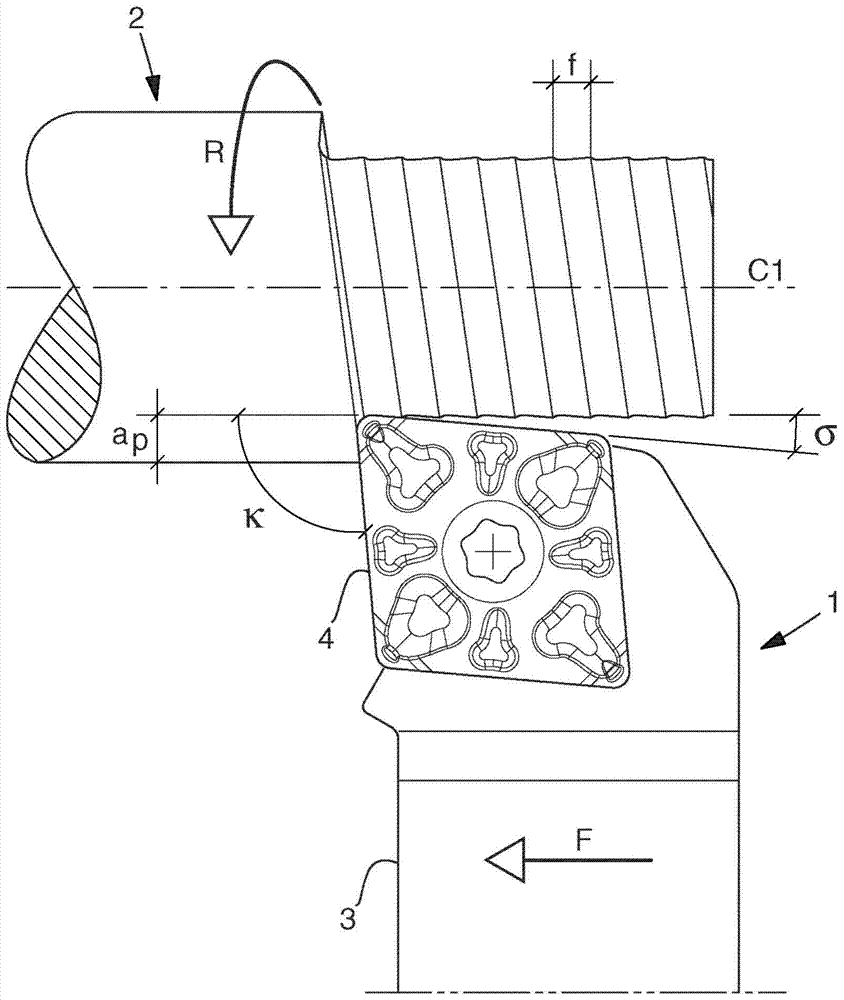

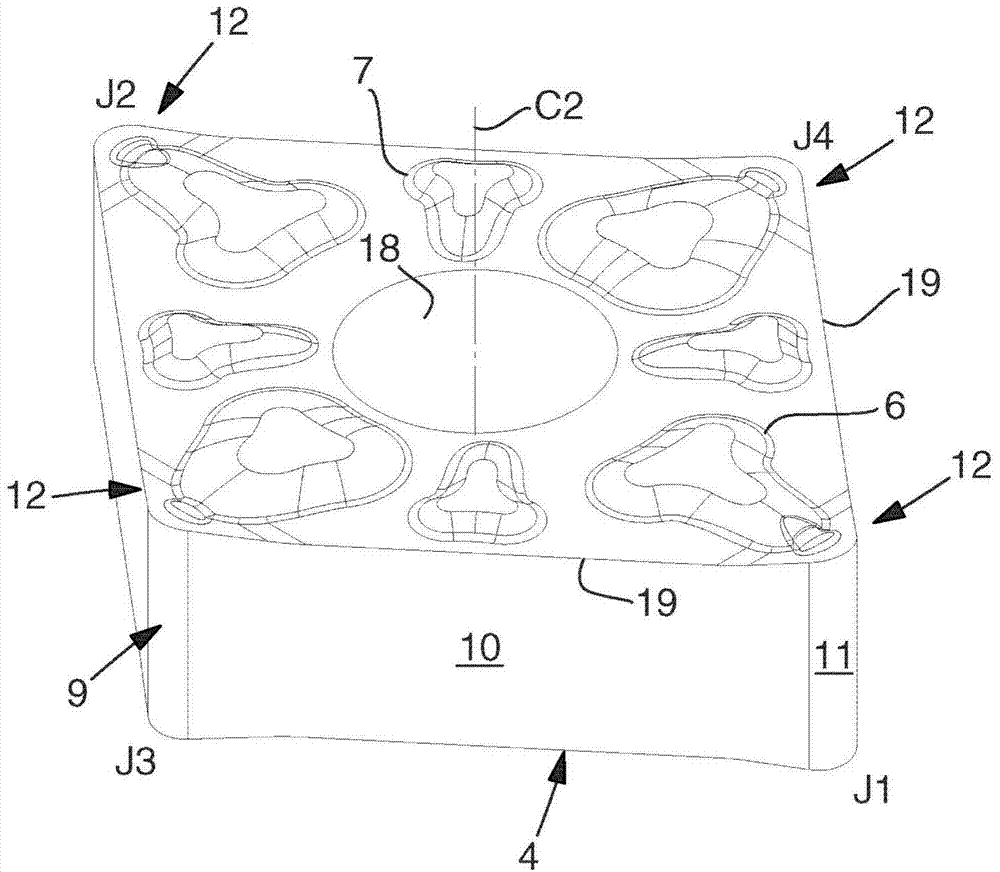

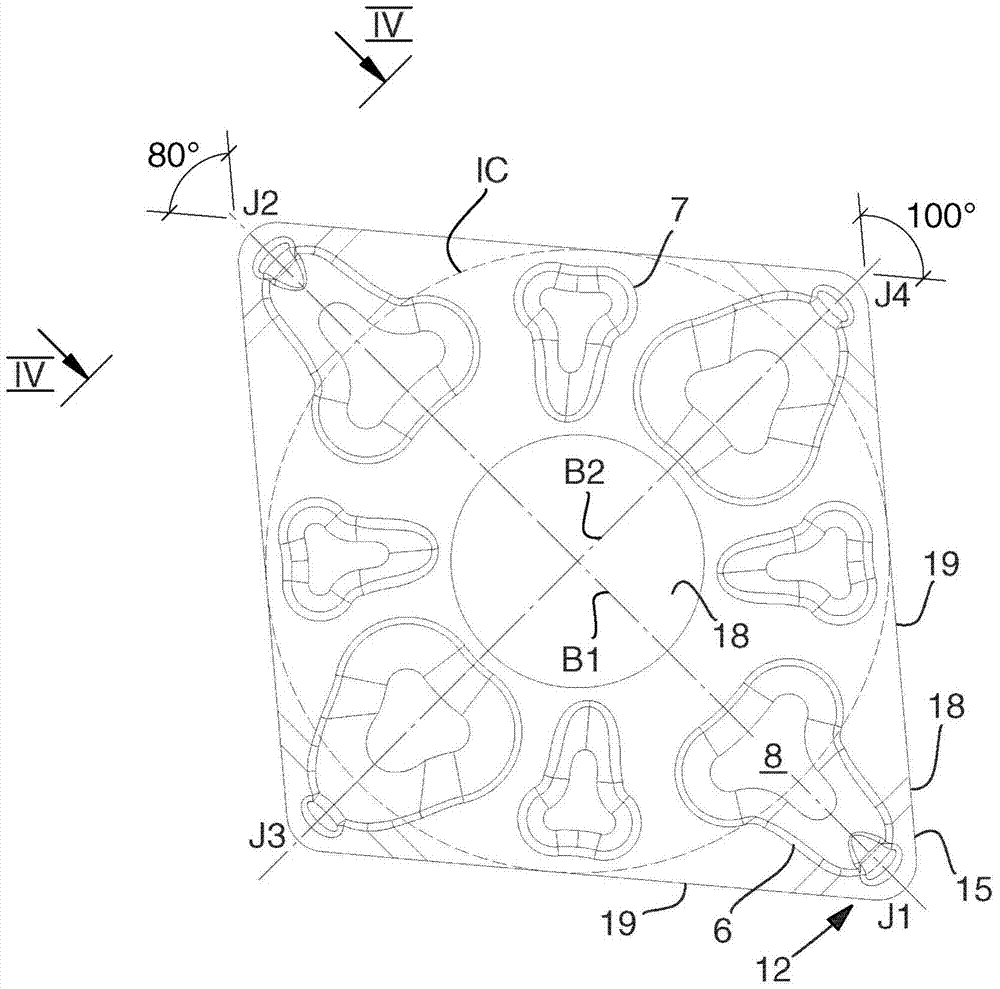

[0047] Detailed description of a preferred embodiment of the turning insert according to the invention

[0048] exist Figure 2 to Figure 4 , it can be seen that the turning insert 4 has a polygonal basic shape and comprises a pair of opposing upper and lower sides generally indicated by 5a and 5b, respectively. The turning insert is double-sided, so that the upper and lower sides are identical. For this reason, only the upper side 5a will be described in detail below.

[0049] In this case, in the upper side 5a, a plurality of mutually spaced platforms 6, 7 are comprised, said platforms individually comprising a flat surface 8, when the turning insert is turned upside down and applied into a seat in the tool holder 3 , the flat platform 8 serves as a support surface. Out of a total of eight lands, four lands, land 6 are located in the region of the corners of the turning insert, while land 7 is placed approximately in the middle between two corner lands 6 . All bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com