Anti-skid stud

An anti-skid pin and plug-in technology, applied in the direction of tire tread/tread pattern, wheels, tire parts, etc., can solve the problems of not providing road surface skid resistance, unreasonable cost, etc., to improve side stability and better road surface. The effect of anti-skid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

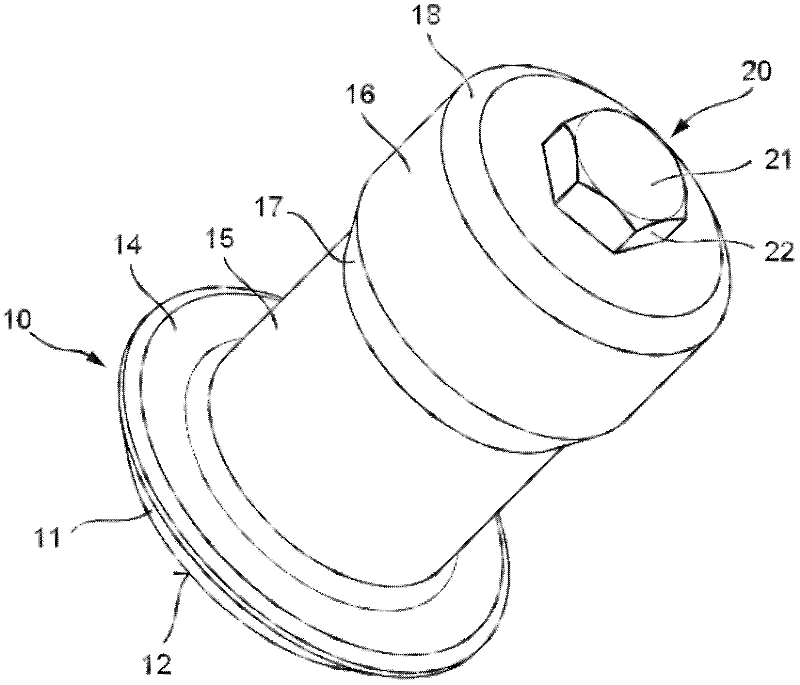

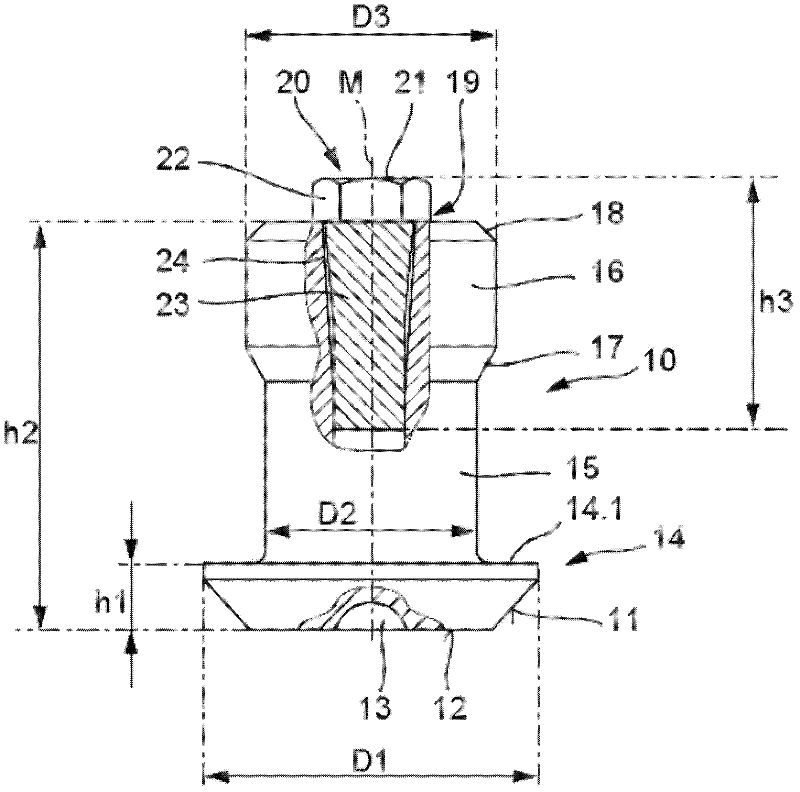

[0024] figure 1 A cleat is shown with a bearing part 10 manufactured as a metal casting, in particular an aluminum casting.

[0025] Such as figure 2 As can be clearly seen, the bearing part 10 has a flange part 14 designed as a fastening foot, which forms a lower, flat bearing surface 12 in which, for reasons of weight reduction, recesses 13 are deep-cut.

[0026] An annular circumferential bevel 11 adjoins at an angle to the bearing surface 12 . This bevel 11 transitions via a circular cross-section into a shoulder 14.1, which is oriented perpendicularly to the central longitudinal axis M of the anti-skid pin.

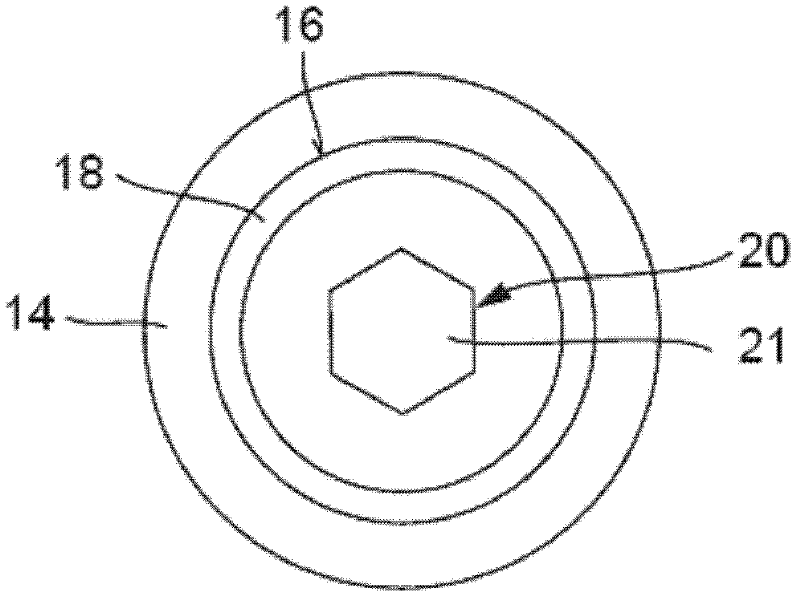

[0027] Such as image 3 It is shown that the shoulder 14 . 1 runs annularly around the central longitudinal axis M . The flange part 14 itself is configured as a frusto-conical shape and has a first largest diameter D1 (eg ≧7.5 mm, currently 8.2 mm). In the region of the shoulder 14 . 1 the holder 15 is molded onto the flange part 14 . The holding portion 15 h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap