Clamping devices and brackets with clamping devices

A technology of clamping devices and tensioning parts, applied in the field of clamping devices, can solve problems such as easy failure, complexity, and wear, and achieve the effects of good anti-slip resistance, simple structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

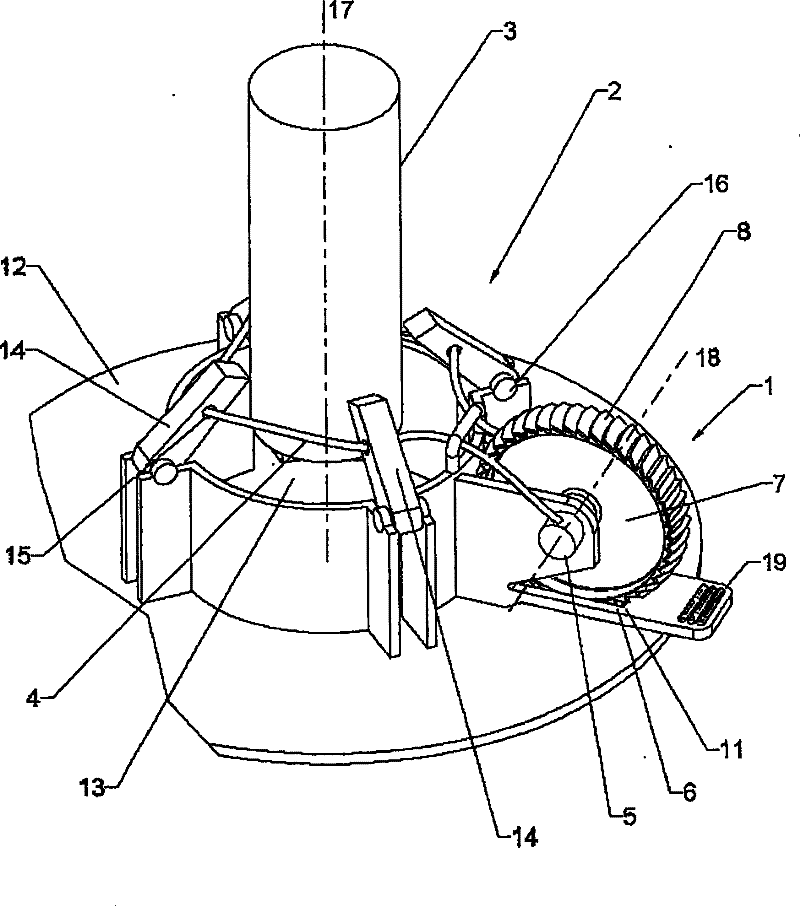

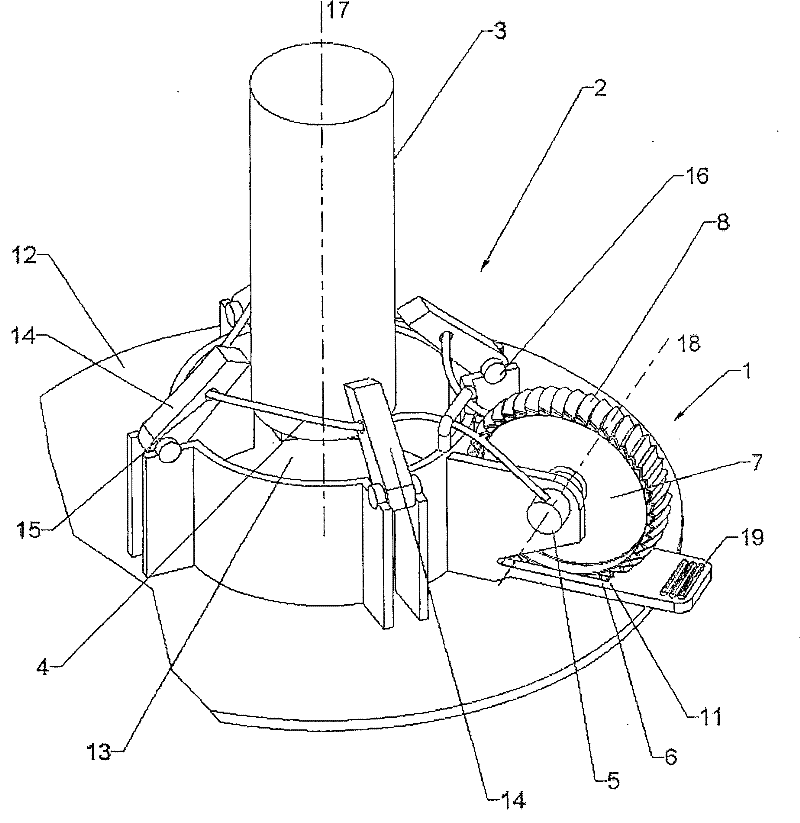

[0034] figure 1 Represents the bracket 2 for clamping a rod 3, comprising a base 12, a mounting area 13 and fixing elements 14, which can be moved around an axis of rotation 16 toward the The support axis of symmetry 17 moves. The fastening elements 14 are movable by means of the flexible force transmission element 4 , preferably a cable, which slides through all the fastening elements 14 in the guide bore 15 .

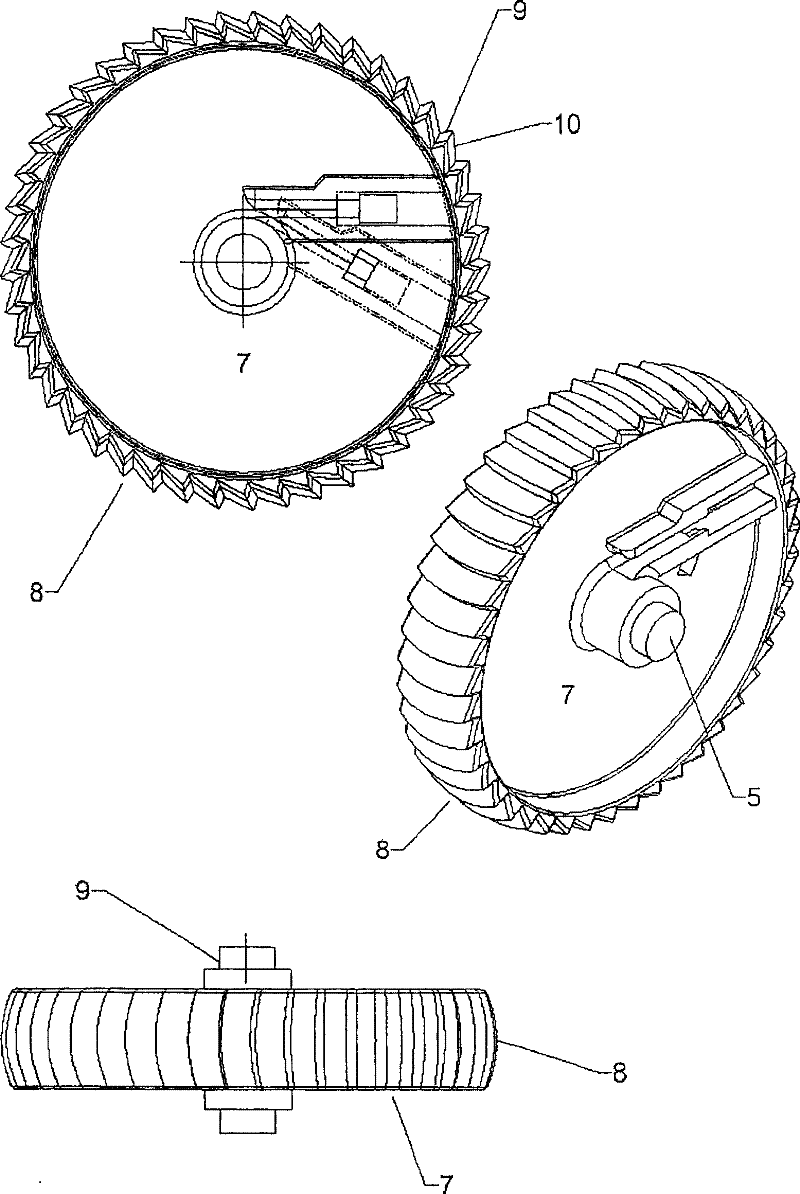

[0035] To clamp the rod-shaped part 3 , the flexible force-transmitting element 4 is tensioned in the clamping device 1 attached to the support 2 . The clamping device 1 consists of a rotatable clamping part 5 on which the flexible force transmission part 4 is wound for clamping the fastening element 14 . For actuating the tensioning element, a drive wheel 7 is provided, which is connected in a rotationally fixed manner to the tensioning element 5 with the same axis of rotation 18, and can also be integrally formed on the tensioning element if necessary. The drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com