Anti-skidding tyre

A tire, anti-skid technology, applied in anti-skid devices, vehicle parts, tire parts and other directions, can solve the problems of poor anti-skid, unsuitable for walking in winter, etc., to achieve the effect of good anti-skid and improved friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

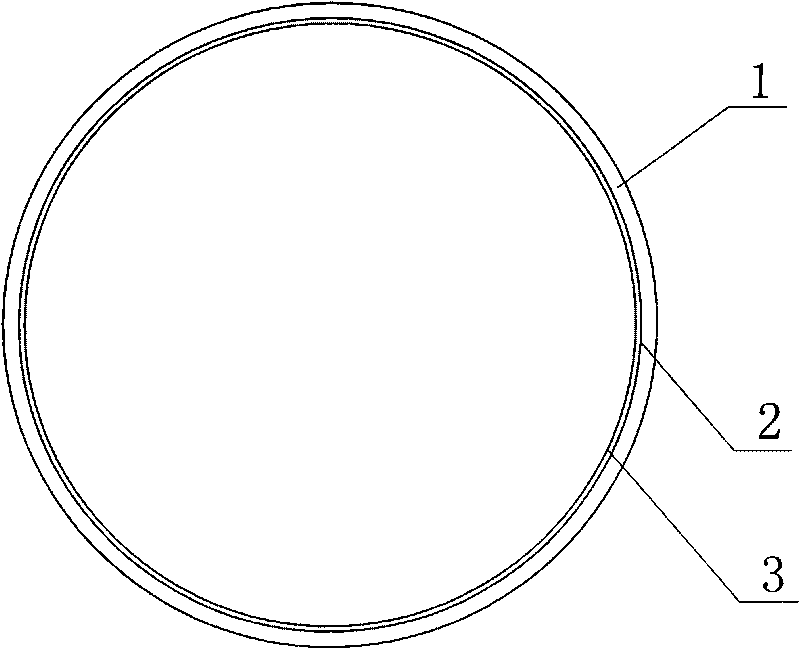

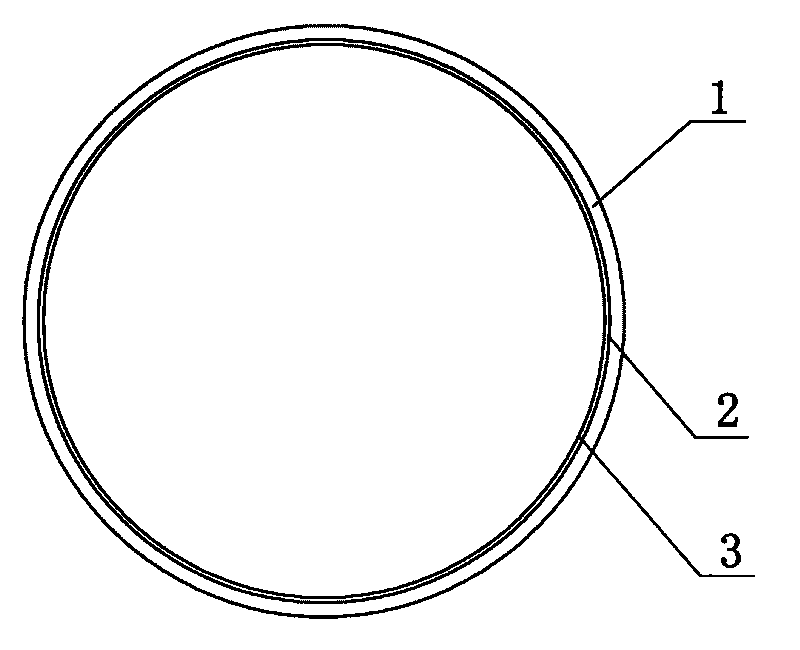

[0010] figure 1 Among them, the lower surface of the outer tire layer 1 of the anti-skid tire is made of a material with a larger friction coefficient, the inner surface of the outer tire layer 1 is coated with a self-adhesive coating 2, and the self-adhesive coating 2 is pasted with a composite film 3.

[0011] The material with a higher coefficient of friction is a combination of elastic material and solid particles. Elastic materials such as: latex, rubber, PVC, etc., solid particles such as: sand, metal powder, etc.

[0012] During use, as long as the compound film on the self-adhesive coating is torn off, and the outer tire layer is stuck on the outer surface of the tire, the frictional force of the tire to the ice surface can be improved. When not in use, the anti-skid tire can be torn off from the outer surface of the tire.

[0013] The invention can be used for anti-skid of vehicles in winter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com