Conductive wire for motor, and coil for motor

一种马达、导线的技术,应用在绝缘载体上的导电层、预防/减少绕组头中的涡流损耗等方向,能够解决周长差、细线散乱、无法维持细线集合状态等问题,达到提高耐久性、抑制接合部分离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

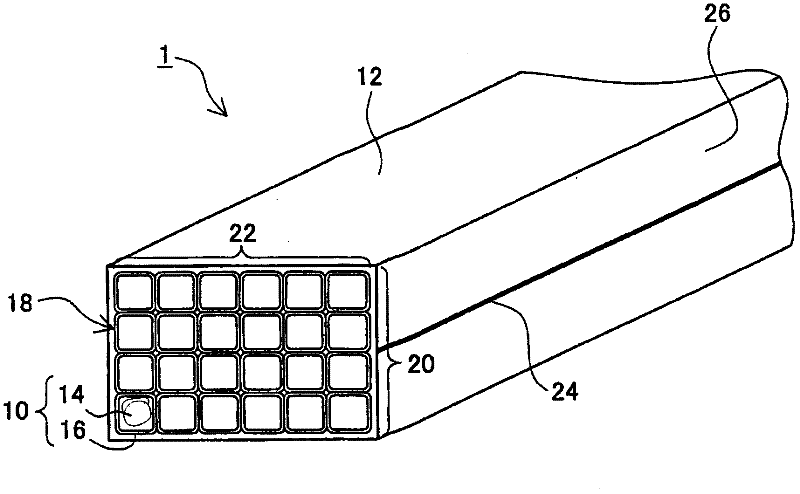

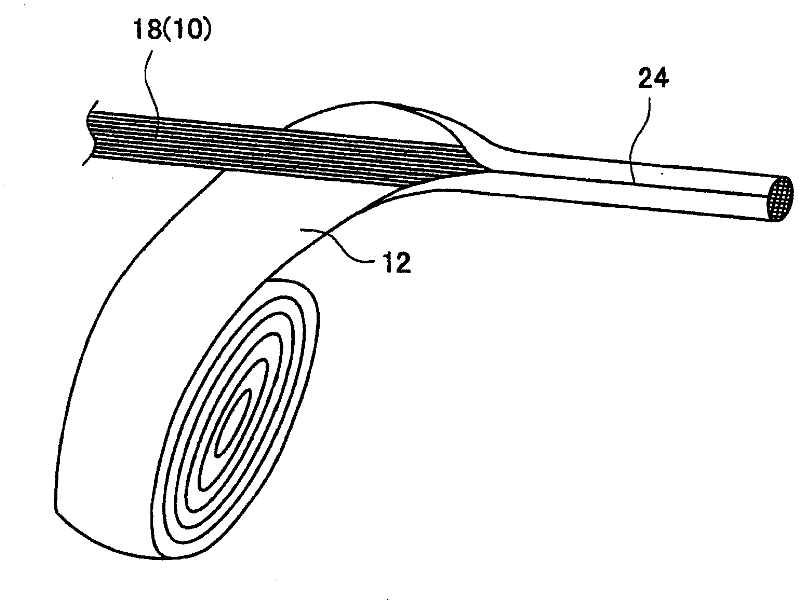

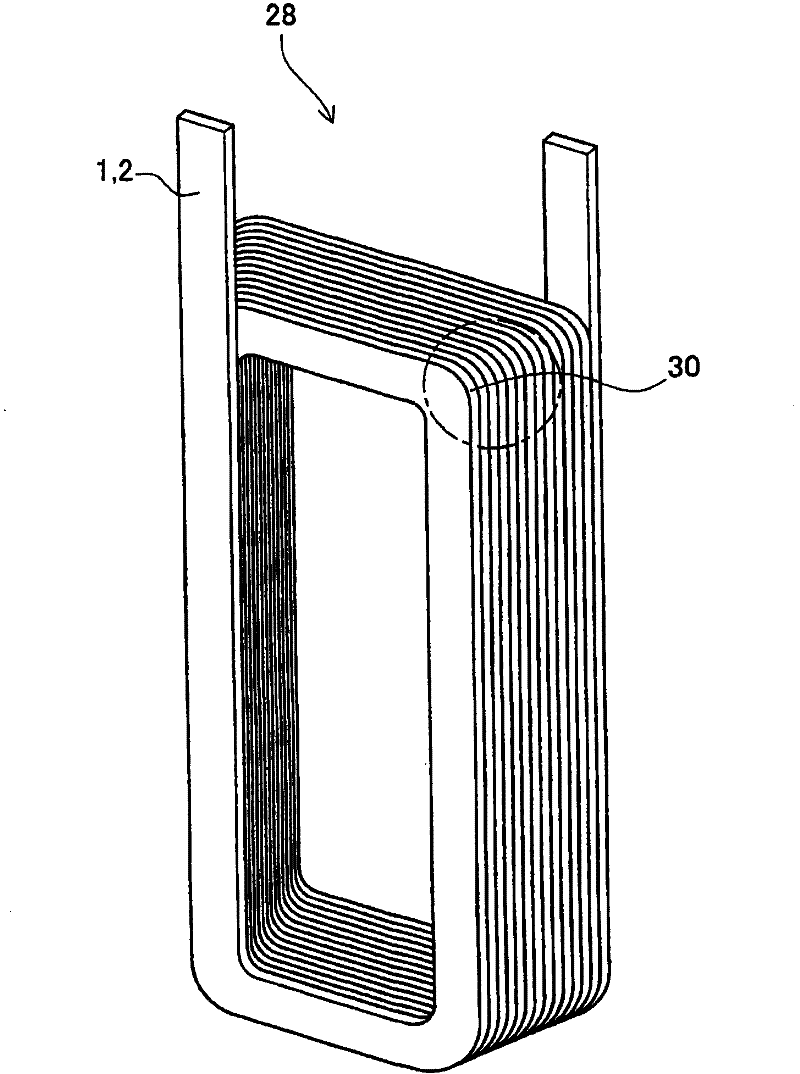

[0043] The flat wire 1 of embodiment 1 is as figure 1 Shown are a plurality of fine wires 10 as well as foil 12 or the like. In addition, the foil material 12 is an example of the "foil member" of this invention. Also, for the sake of illustration, figure 1 The illustrated flat wire 1 omits an insulating layer provided by coating an enamel resin or the like on the outer peripheral surface to ensure insulation.

[0044] The thin wire 10 is a member in which an insulating portion 16 is provided on an outer peripheral surface of a core wire 14 . The core wire 14 is an electrical conductor, and is formed in a linear shape from a conductive metal such as copper, aluminum, silver, gold, or an alloy thereof, for example. The insulating portion 16 is formed of enamel resin, metal oxide, or the like.

[0045] Such as figure 1 As shown, the flat lead wire 1 is formed by covering the outer peripheral surface of an aggregate thin wire 18 in which a plurality of thin wires 10 are bund...

Embodiment 2

[0064] The flat wire 2 of embodiment 2 is as Figure 5 Shown are a plurality of filaments 10 and bands 32 and the like. The thin wire 10 is the same as that of Example 1. Such as Figure 5 As shown, the flat wire 2 is formed by winding a tape 32 in a helical shape on the outer peripheral surface of an aggregated thin wire 18 in which a plurality of thin wires 10 are bundled together. In addition, the belt 32 is an example of the "belt-shaped member" of this invention. In the following description, the same reference numerals are assigned to the same constituent elements as those in Embodiment 1, and description thereof will be omitted.

[0065] In addition, the material of the tape 32 is the same metal as the core wire 14 of the thin wire 10 (that is, a metal having the same resistance value) or a metal having a resistance value higher than that of the core wire 14 of the thin wire 10 . For example, when the core wire 14 of the thin wire 10 is made of copper, the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com