Efficient compression plate device

A press plate, high-efficiency technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large volume, increased production costs, insufficient force of the press plate and cylinder, etc., to achieve the effect of large gravity and enhanced thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

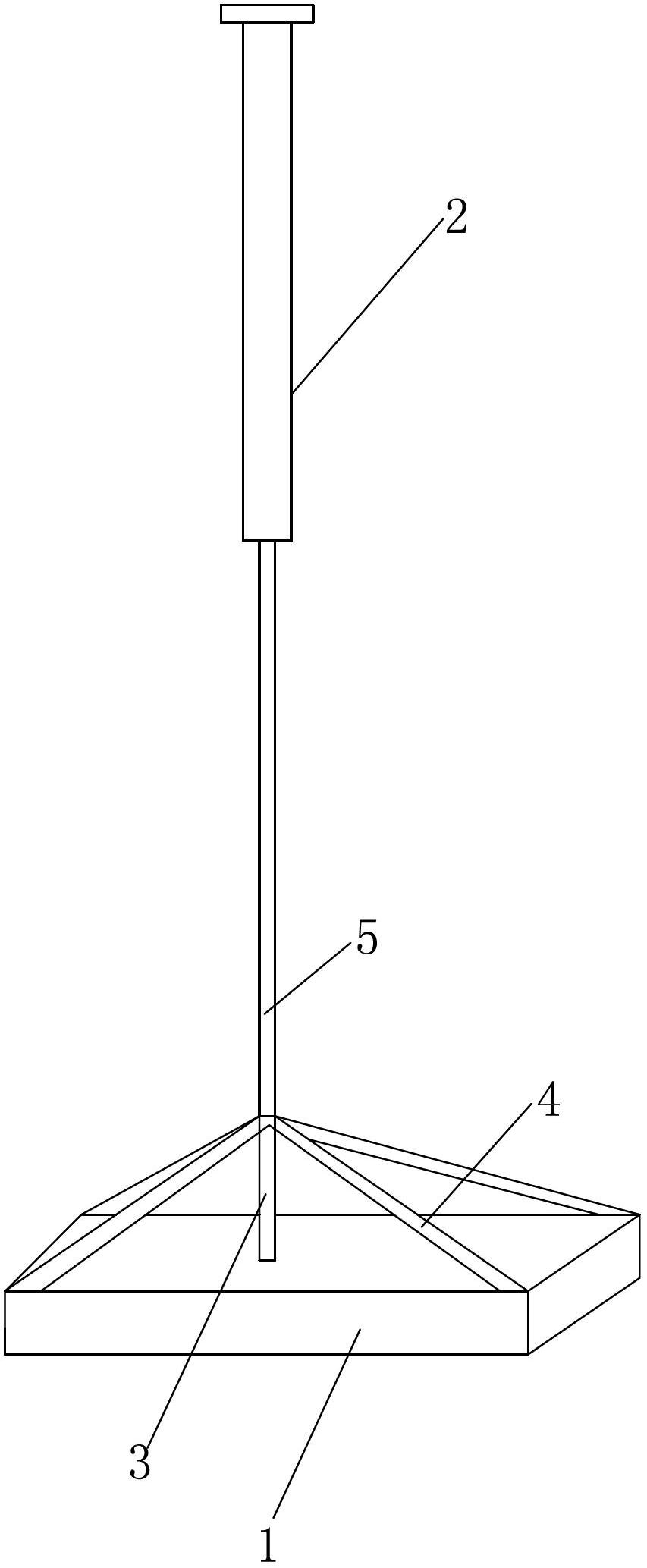

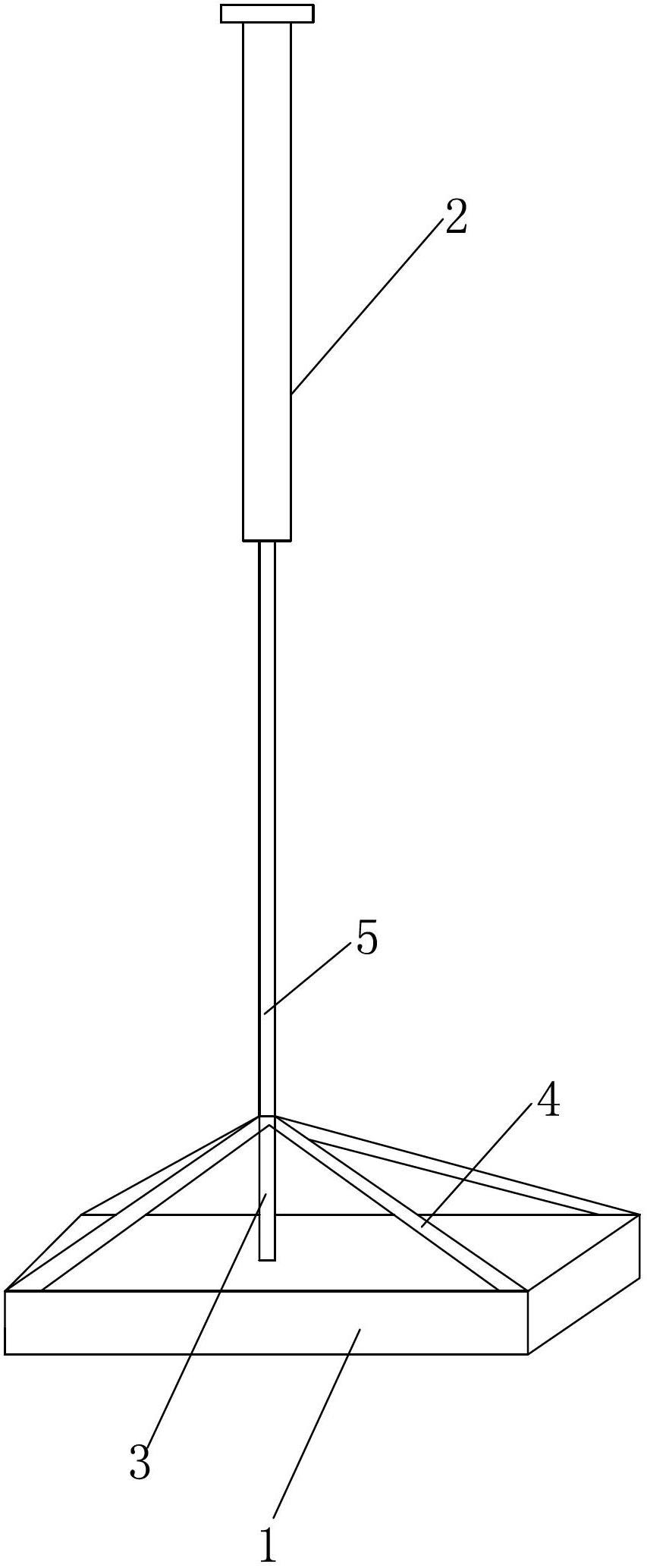

[0013] Embodiment: a kind of high-efficiency platen device, such as figure 1 As shown, the pressing device includes a pressing plate 1, a connecting seat and an oil cylinder 2, the pressing plate 1 is a steel plate, the thickness of the pressing plate 1 is 3 cm, and the pressing plate 1 is connected to the oil cylinder 2 through the connecting seat.

[0014] Specifically, the connecting seat includes a central rod 3, the central rod 3 is vertically arranged, the bottom of the central rod 3 is welded and fixed to the pressure plate 1, and the top of the central rod 3 radiates to the surroundings with at least four inclined rods 4 , the lower end of the oblique rod 4 is welded and fixed with the pressure plate 1, and the top of the center rod 3 is connected with the piston rod 5 of the oil cylinder 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com