Sand homogenizing device used before tile paving for building construction

A technology for building construction and paving tiles, which is applied to buildings, building structures, roads, etc., can solve problems such as inability to achieve depth, shallow pits, unified adjustment, etc., to achieve convenient operation, increase friction coefficient, increase The effect of the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

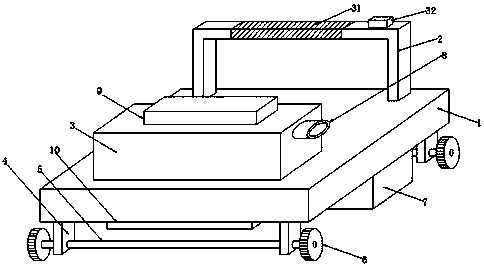

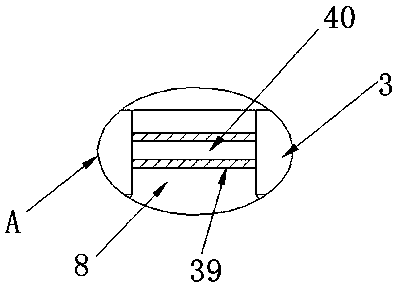

[0035] Example one, such as figure 1 As shown, according to an embodiment of the present invention, a sand leveling device for building construction before paving tiles includes a base 1, a handle 2 is provided on the upper side of the base 1, the roller 6 is a rubber wheel, and the upper end of the handle 2 is sleeved Anti-slip cover 31, one side of the anti-slip cover 31 and the upper end of the handle 2 is provided with a control switch 32, the upper end of the base 1 is provided with a box 3 on the other side, the lower end of the base 1 is surrounded by support rods 4, two sets of supports A movable shaft 5 is interspersed between the rods 4, the two ends of the movable shaft 5 are sleeved with rollers 6, the lower end of the base 1 is located between the two sets of movable shafts 5, and an adjusting device 7 is provided. The lower end of the box body 3 is located on the base The bottom of 1 is provided with a discharge port 8, the upper end of the box body 3 is provided w...

Embodiment 2

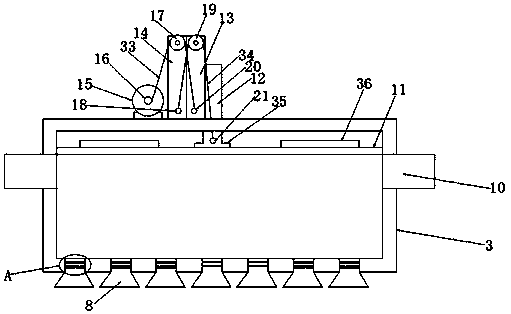

[0037] Example two, such as Figure 2-4 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the pressing device 9 includes a pressing plate 11 located at the inner upper end of the box 3, and the upper end of the pressing plate 11 is provided with a movable rod 12, the movable rod A movable rod 13 is provided on one side of the one 12, and a fixed rod 14 is provided on the side of the movable rod 13 away from the movable rod 12. The movable rod 12 and the movable rod 13 penetrate the upper end of the box 3, and the fixed rod 14 Located at the upper end of the box body 3, the fixed rod 14 is far away from the movable rod two 13 and is provided with a motor 15 at the upper end of the box body 3. The output shaft of the motor 15 is provided with a rotating wheel 16, and the fixed rod 14 is provided with a side upper end Pulley one 17, fixed pole 18 is provided at the lower end of one side of fixed rod 14, pulley two 19 is provided at...

Embodiment 3

[0039] Example three, such as Figure 2-4 As shown, on the basis of the first and second embodiments, the present invention provides a technical solution: the rotating wheel 16, the pulley one 17, and the fixed column two 20 are connected by a draw rope 33, and the fixed column 18, the pulley The two 19 and the fixed column three 21 are connected by a draw rope two 34. The upper end of the pressure plate 11 and the two sides of the movable rod 12 are provided with counterweights 35, and the pressure plate 11 and the lower end of the movable rod 12 are bolted 36 fixed.

[0040] By setting the pull rope 33, the work of the motor 15 can realize the up and down movement of the movable rod two 13. By setting the pull rope 34, the work of the motor 15 can realize the movement of the upper end of the movable rod 12, by setting the counterweight 35 , Increase the weight of the pressure plate 11, facilitate the downward movement of the pressure plate 11, complete the rapid discharge of mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com