Checking and assessment robot in electric pipeline and assessment method

A power pipeline and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of small power pipelines, lack of inspection instruments, and lack of objective accuracy, so as to achieve convenient and reliable use, simple structure, and ensure the safety of cable laying and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

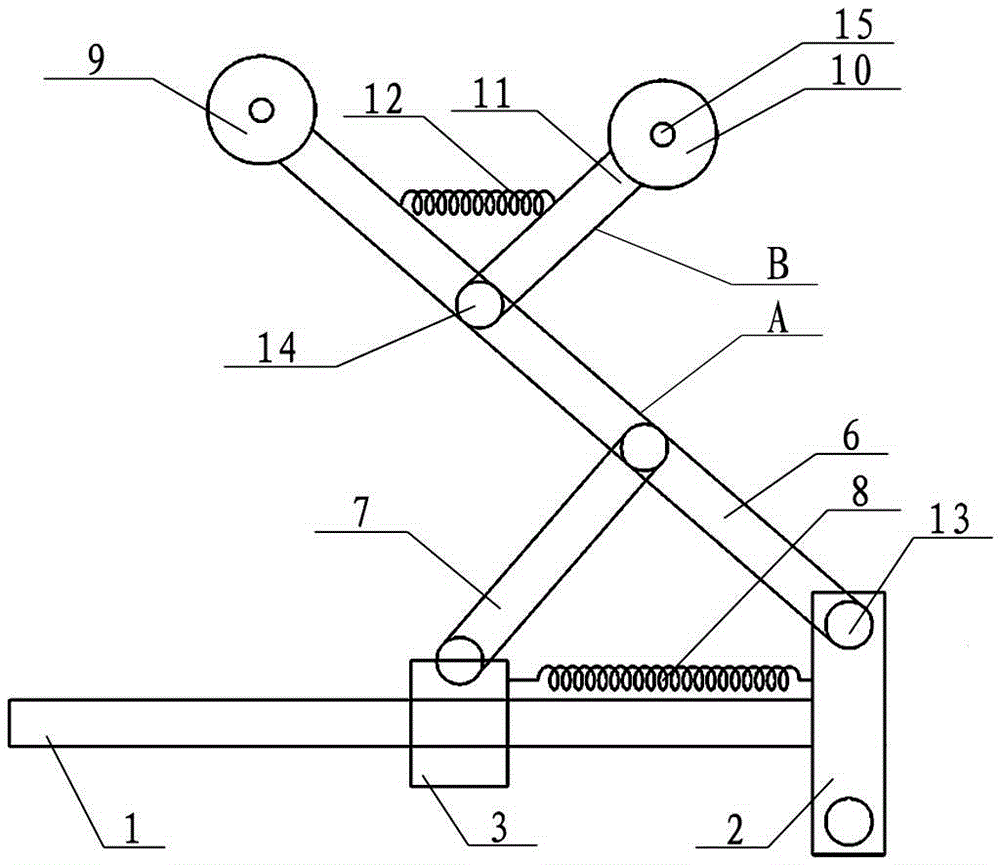

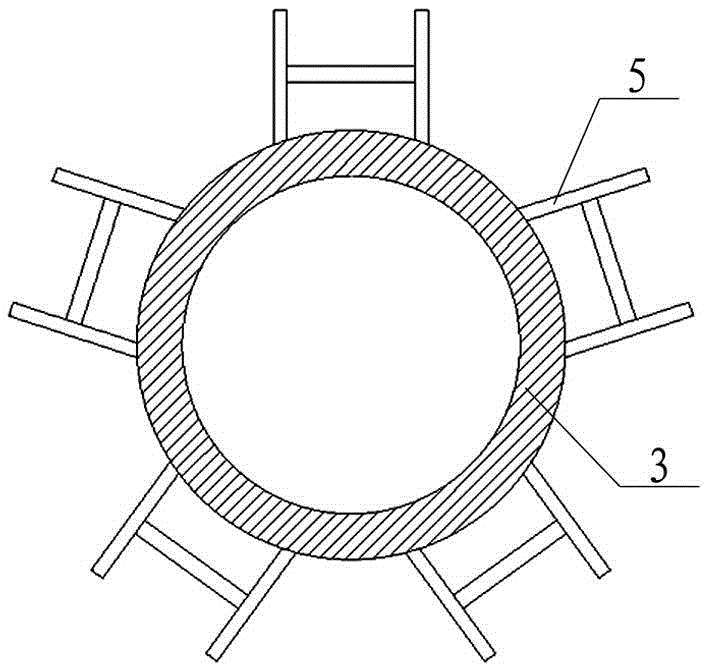

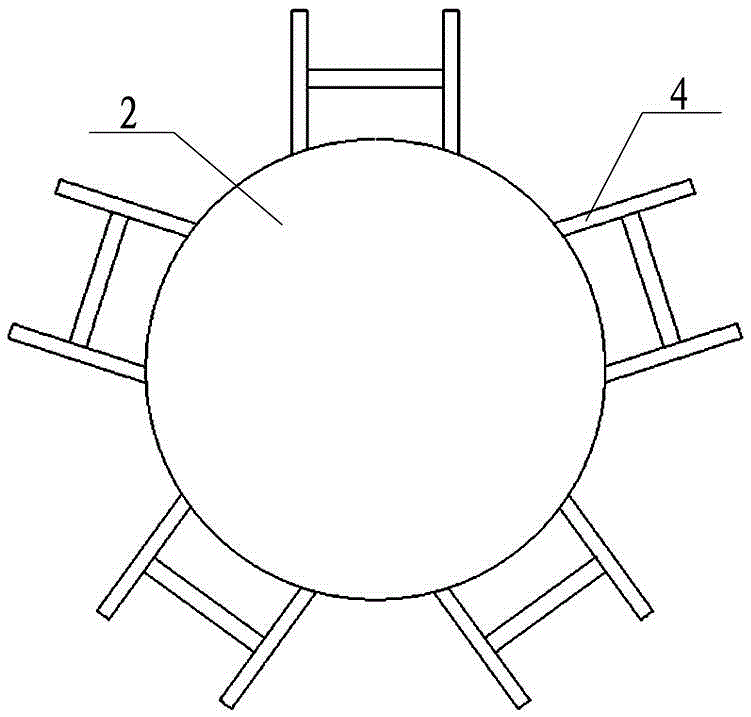

[0019] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, an inspection and evaluation robot in a power pipeline according to the present invention includes a vertical pole 1 that can move axially forward, and a circular or ring-shaped connecting member 2 is fixed at the front end of the vertical pole 1. An annular supporting sliding member 3 is sleeved on the vertical rod 1, and the outer ring edges of the connecting member 2 and the supporting sliding member 3 are respectively provided with at least three radially connected H-shaped hinges 4, 5, wherein the connecting Each of the H-shaped hinges 4 on the component 2 is hinged with an A-wheel support rod 6, and each of the H-shaped hinges 5 on the supporting sliding member 3 is also hinged with a short strut 7, and the short strut 7 The front end of the A wheel is hinged in the middle of the A-wheel support rod 6, and at least one sliding limiting spring 8 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com