Rotary drum and workpiece processing device

A technology for drums and components, applied in the field of drums and workpiece processing devices, which can solve the problems of reducing the inner cavity, reducing the processing capacity of workpieces in the drum, and affecting the working efficiency of the drum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

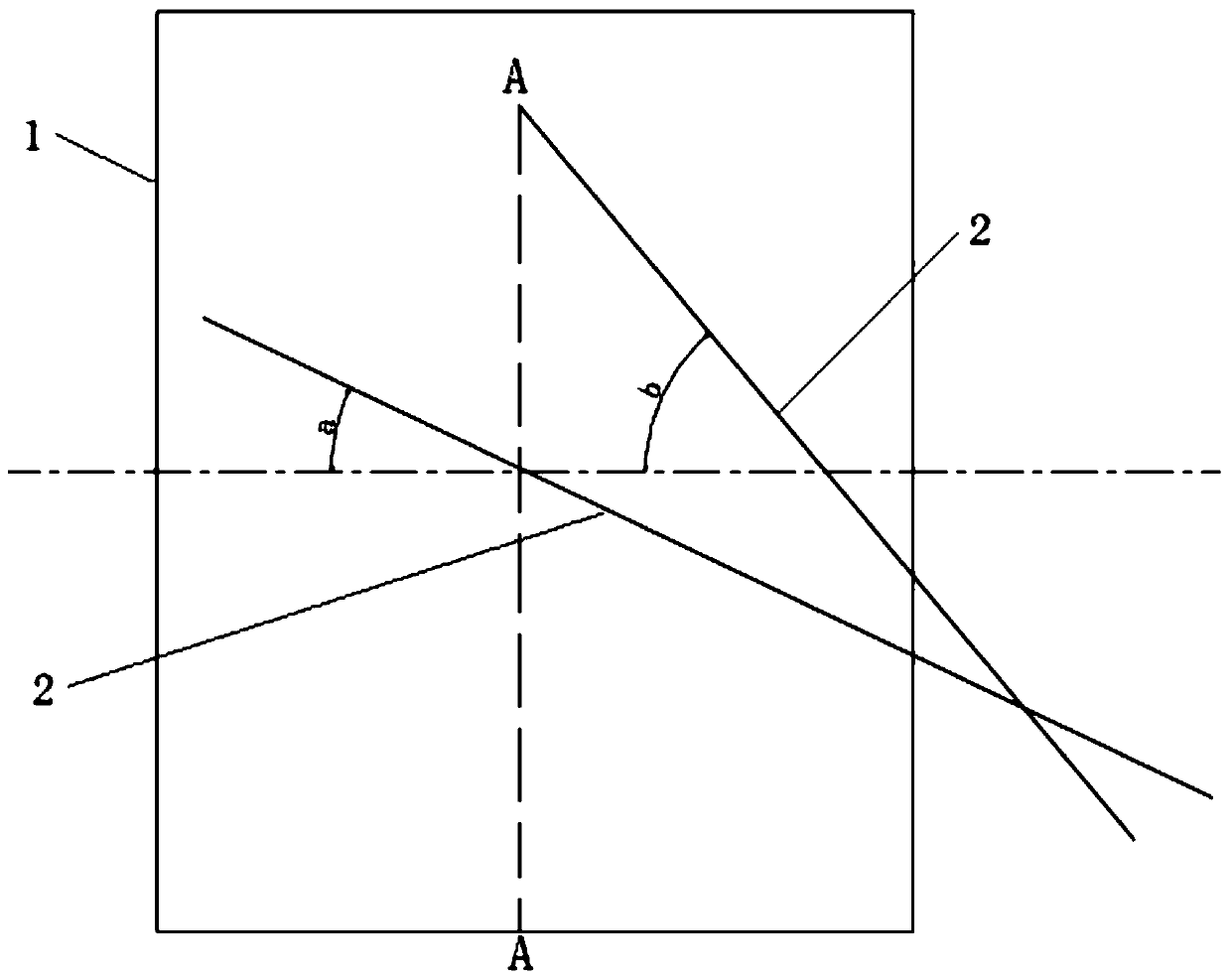

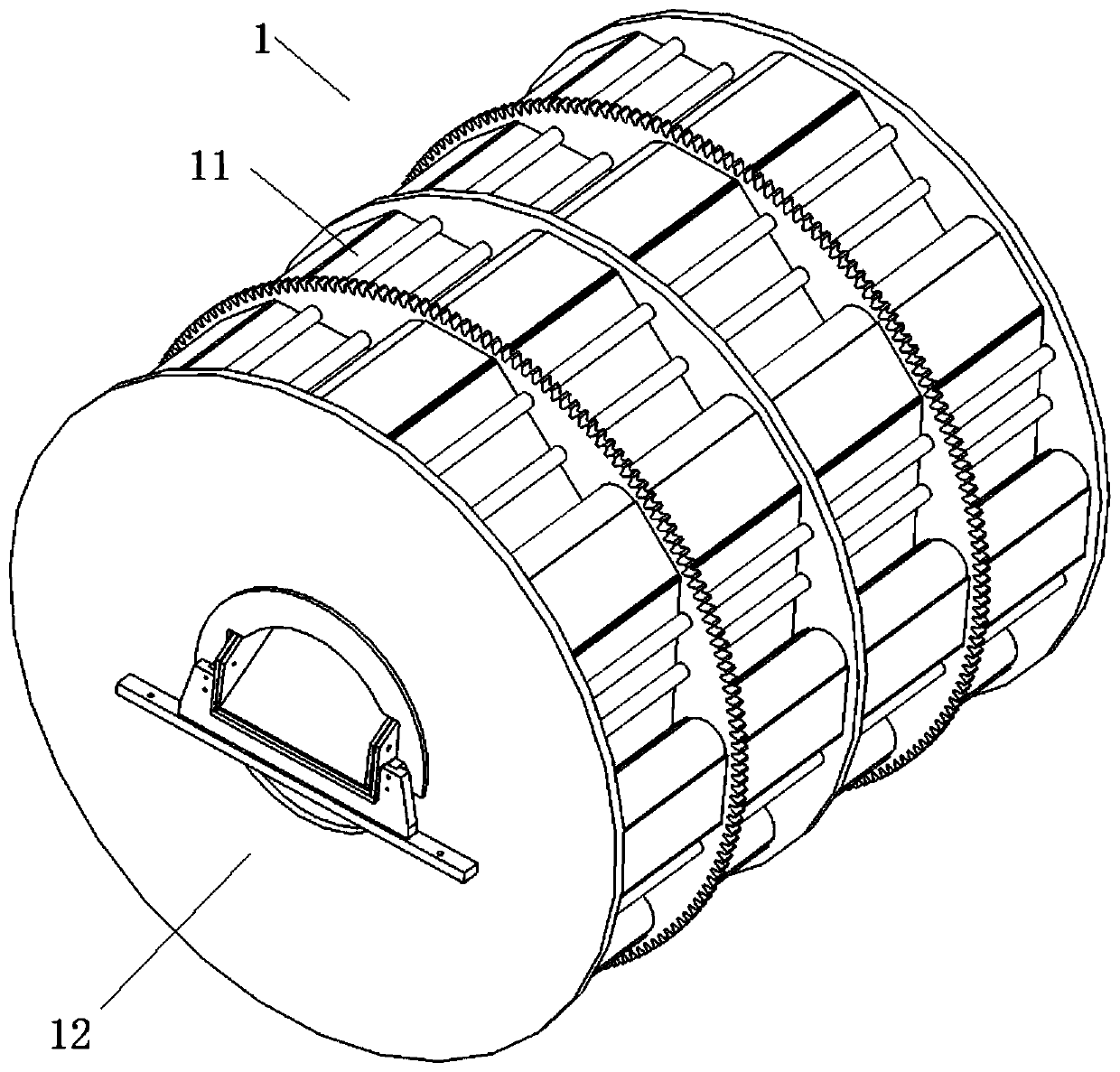

[0065] This embodiment provides a drum, such as Figure 2 to Figure 9 As shown, it includes a bucket body 1 and a conveying mechanism 2 , wherein the bucket body 1 is rotatably arranged on a frame 7 in such a way that the discharge steering and the working steering can be changed.

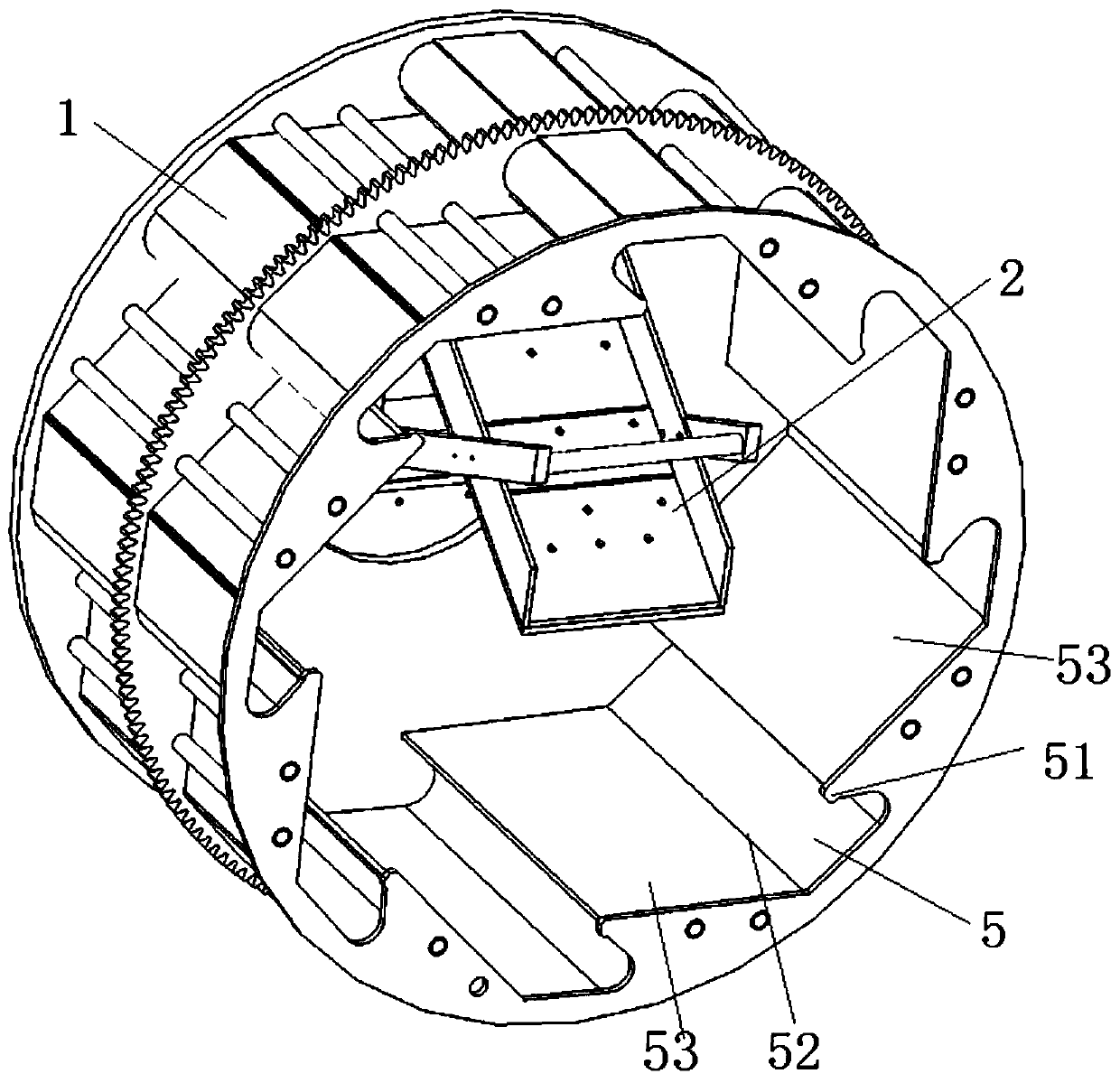

[0066] Such as Figure 4 As shown, the bucket body 1 includes a cylinder body 11, two side baffles 12 and a scoop member 5, wherein the two side baffles 12 are mounted on the frame 7, and the axial ends of the cylinder 11 are open, and the bucket The axial ends of the main body 1 are respectively rotatably arranged on the corresponding side baffles 12 and form a working inner cavity with the two side baffles 12, so that the barrel body 1 is rotatably arranged on the frame 7 On; the two side baffles 12 are respectively provided with a feed port 121 and a discharge port 122 .

[0067] As for the scooping material 5 , the scooping material 5 can be provided as the inner wall of the cylinder 11 , or ...

Embodiment 2

[0089] This embodiment provides a drum. Compared with the drum provided in Embodiment 1, the difference is that the number of sliding material parts 21 provided by the conveying mechanism is different, and other structures are the same as in Embodiment 1. Please refer to Embodiment 1.

[0090] Specifically, in this embodiment, the conveying mechanism has three, four, five, six, seven and so on a plurality of sliding material members 21 . That is, at least one sliding material part 21 is also arranged between the first sliding material part and the second sliding material part in embodiment 1, and among all the sliding material parts 21, the first sliding material part is at the starting position, and the second sliding material part is at the initial position. The second sliding material part is located at the end position, except for the second sliding material part, all other sliding material parts 21 are arranged in the inner cavity of the barrel body.

[0091] Among the p...

Embodiment 3

[0100] This embodiment provides a workpiece processing device, for example, the workpiece processing device is an electroplating device, or a cleaning device, and its workpiece processing device includes the drum provided in Embodiment 1 or Embodiment 2, such as Figure 10 As shown, the drum is rotatably arranged in the tank body 4. For example, a drive motor is arranged on the frame 7, a drive gear is fixed on the output shaft of the drive motor, and a ring gear is arranged on the circumferential outer wall of the drum. The driving gear meshes with the ring gear, so that when the driving motor rotates in the forward direction, the barrel body 1 is driven to be in the working direction, and when the driving motor is rotated in the reverse direction, the barrel body 1 is driven in the discharging direction.

[0101] In the workpiece processing device of this embodiment, since the drum of embodiment 1 or embodiment 2 is used, the workpiece processing device can ensure the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com