Device for downward conveying concrete

A technology for concrete and pumping pipes, which is applied in construction, infrastructure engineering, etc., can solve the problems of concrete segregation, easy pipe blockage, and difficult pipe blockage, etc., and achieve the effect of increasing its own gravity and friction, and increasing concrete resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

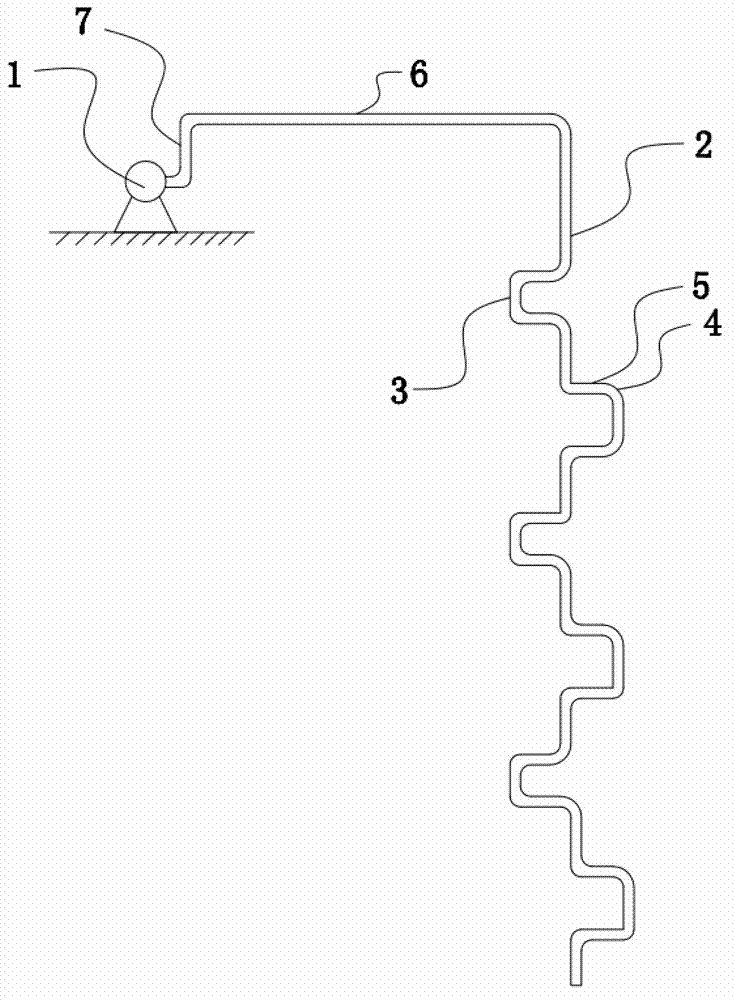

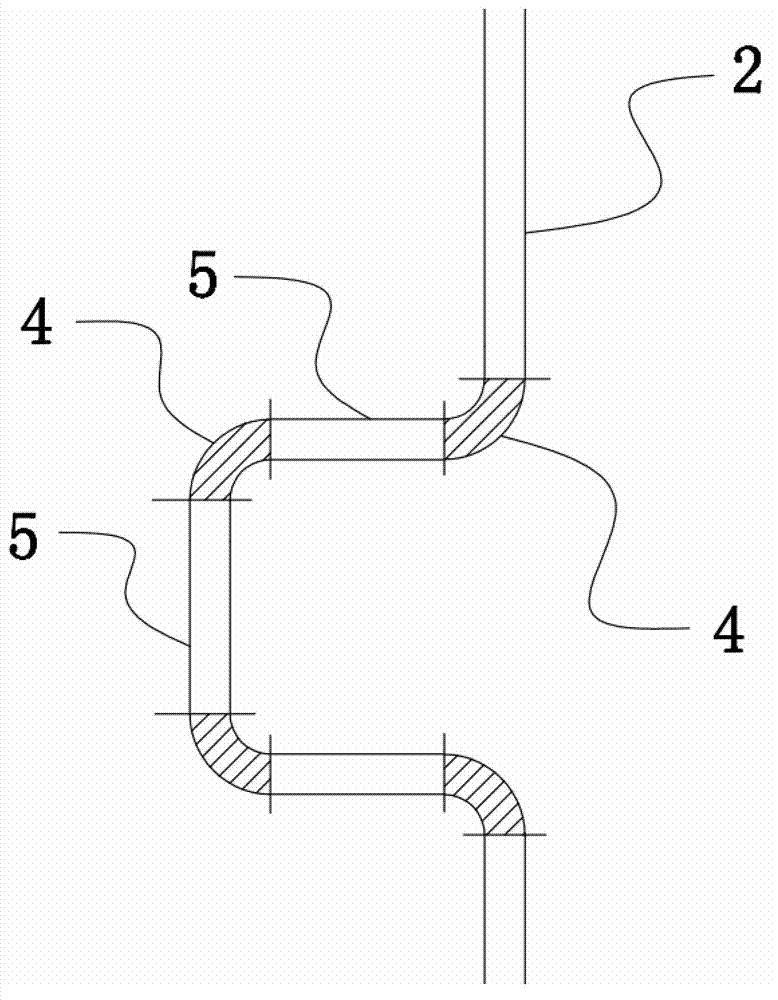

[0025] Such as figure 1 and figure 2 As shown, the present embodiment is a device for conveying concrete downwards, including a pump truck 1 arranged on a high floor, the pump port of the pump truck 1 is connected with a pumping pipe 2 extending vertically downwards, through which the pumping pipe 1 2 and the pump truck 1 realize pumping of concrete. The pumping pipe 2 is provided with a detour 3 . The inlet and outlet ends of the detour 3 are coaxially arranged on the pumping pipe 2 . Lateral extension, that is, the circuitous pipeline extends laterally. By setting the circuitous pipeline extending laterally along the pumping tube 2, the flow direction of the pumping tube 2 that originally only extends downward in the vertical direction is changed to enhance the pumping pressure and The friction between the concrete and the inner wall of the pipeline reduces the flow rate due to the gravity of the concrete itself, thus avoiding the concrete falling with its own weight with...

Embodiment 2

[0029] Such as figure 1 As shown, in this embodiment, a horizontal connecting pipe 6 is arranged between the pump port and the pumping pipe 2, the inlet end of the horizontal connecting pipe 6 is connected to the pump port, and the inlet end of the horizontal connecting pipe 6 is higher than The pump port, optimally, the inlet end of the horizontal connecting pipe 6 is 1m to 2m higher than the pump port, and the concrete is in an upward trend during pumping, which increases the self-gravity and friction of the concrete in the front section.

[0030] In order to increase the self-gravity and friction of the concrete in the front section, a vertical connecting pipe 7 is arranged between the inlet end of the horizontal connecting pipe 6 and the pump port, and a vertical connecting pipe 7 is provided at both ends of the vertical connecting pipe 7 for connecting the pump port. , The right-angled elbow 4 of the horizontal connecting pipe 6, through this connection method, the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com