Method for adjusting position of silk-screen character on IMD (in-mould-decoration) sheet

A technology of character position and adjustment method, which is applied to printing devices, printing, etc., and can solve the problems of complex adjustment methods, repeated tests, low efficiency, and poor accuracy of character setting positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

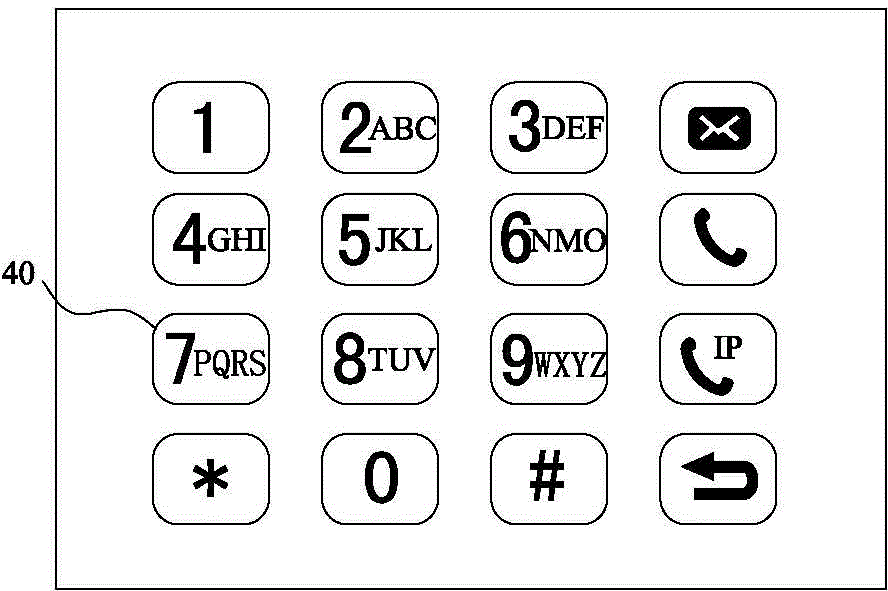

[0027] The specific implementation method of the preferred embodiment of the present invention can be carried out according to the following steps:

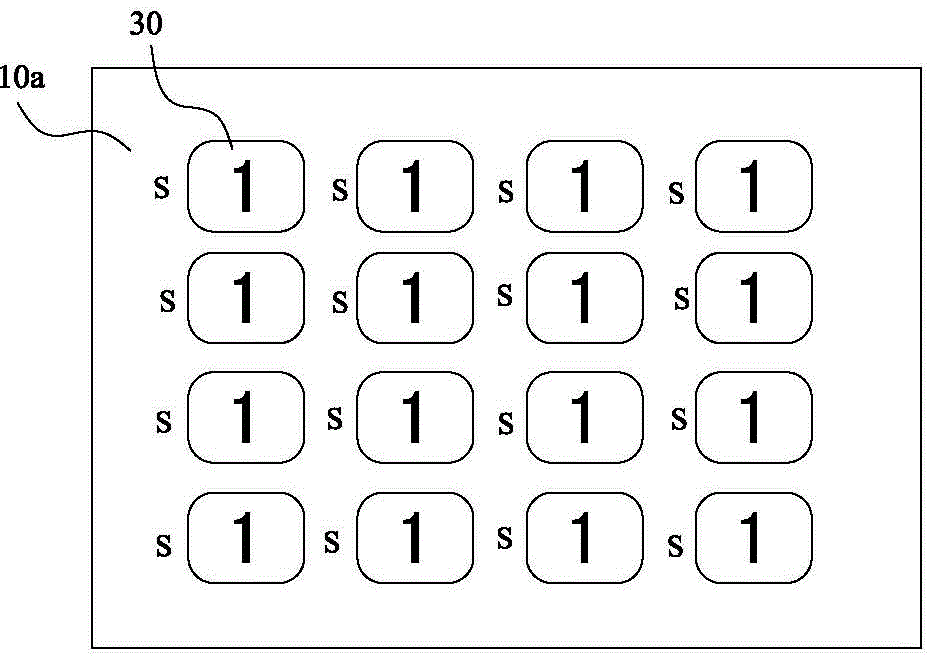

[0028] The first step: take a set character on a film, and record the position S of the character;

[0029] The second step: use the film of the first step to make the first screen version with characters;

[0030] The third step: select a template printed with the predetermined correct character position as the IMD sheet, and use the screen made in the second step to perform silk screen printing on the IMD sheet;

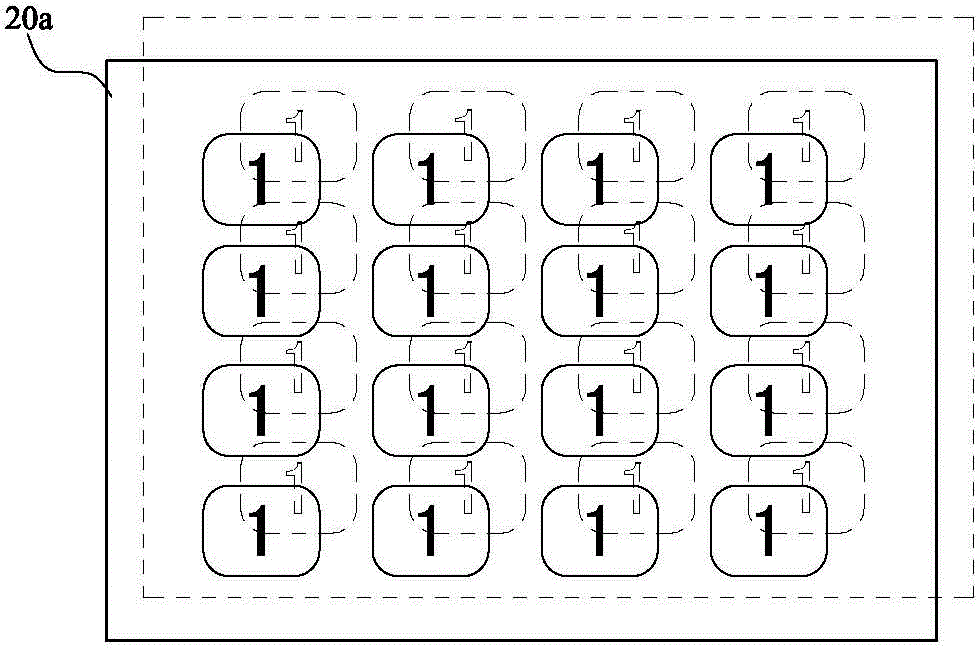

[0031] Step 4: Compare the character position after silk screen printing in the third step with the predetermined reference character position in the IMD sheet, and measure the deviation value △ of the character position between the two;

[0032] Step 5: Set different correction values A according to the deviation value △;

[0033] Step 6: Take the second film to make the second screen: determine the initial posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com