Pump ring used for mechanical seal

A technology of mechanical seals and pump effect rings, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as poor fluid circulation, high heat on the sealing end surface, and short service life of mechanical seals, so as to reduce fluid temperature and improve pump performance. Sending capacity, increase the effect of fluid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

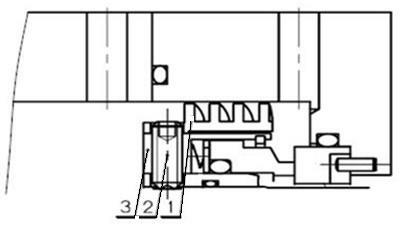

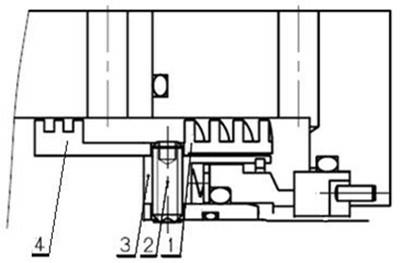

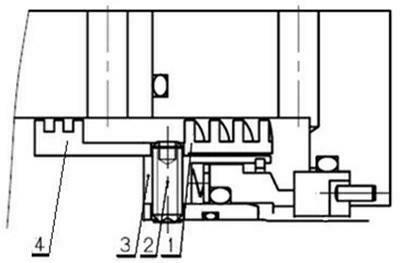

[0011] Such as figure 2 As shown, a pump effect ring for a mechanical seal includes a spiral pump effect 1, and a labyrinth seal 4 is connected to one side of the spiral pump effect 1; the spiral pump effect 1 and the labyrinth seal 4 are an integral structure; The tooth width, tooth height and the gap with the pump cover of the labyrinth seal 4 have different design dimensions according to different working condition parameters.

[0012] The present invention is installed on the drive sleeve 3 through the top wire 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com