Patents

Literature

40results about How to "Lower fluid temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

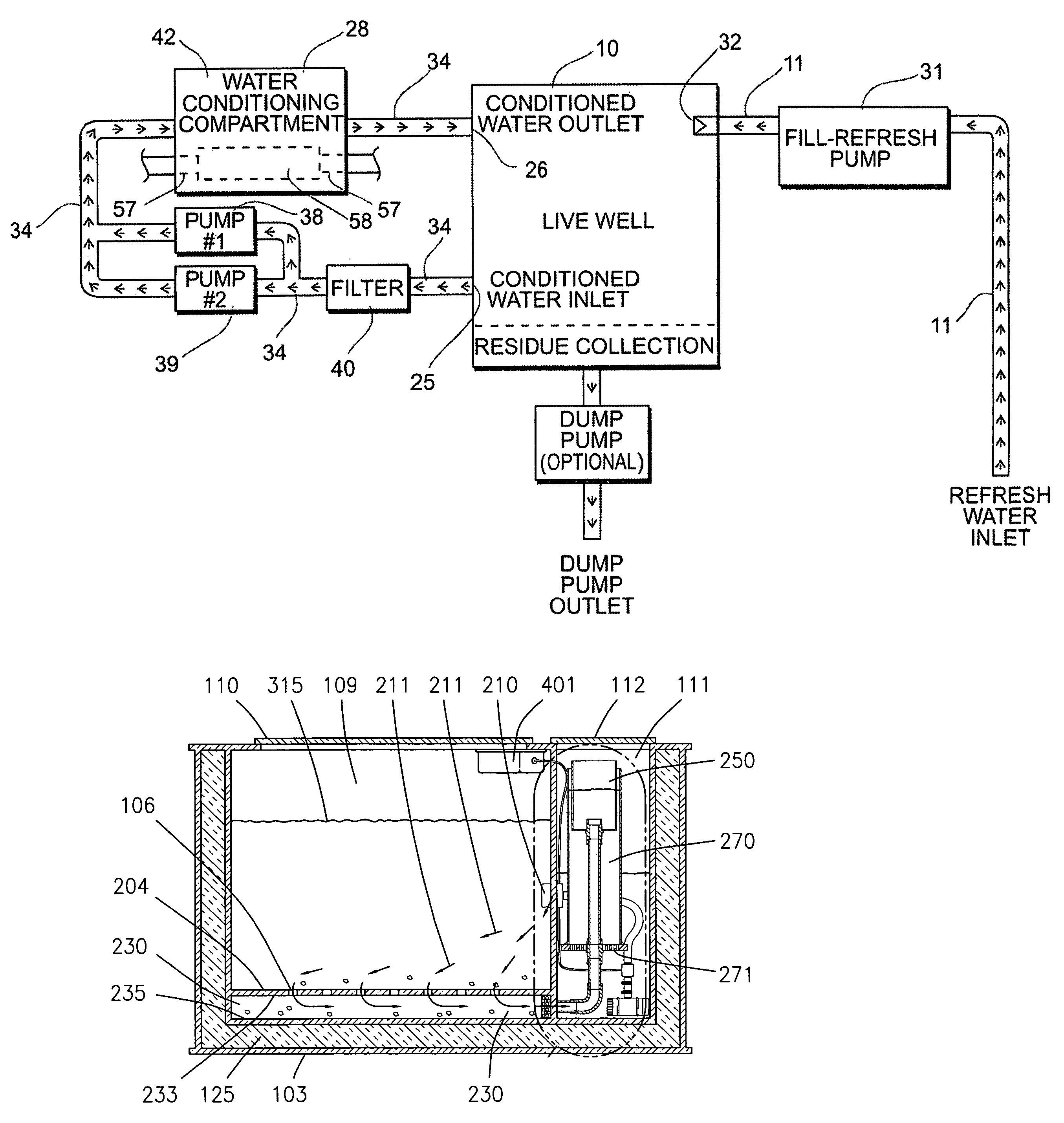

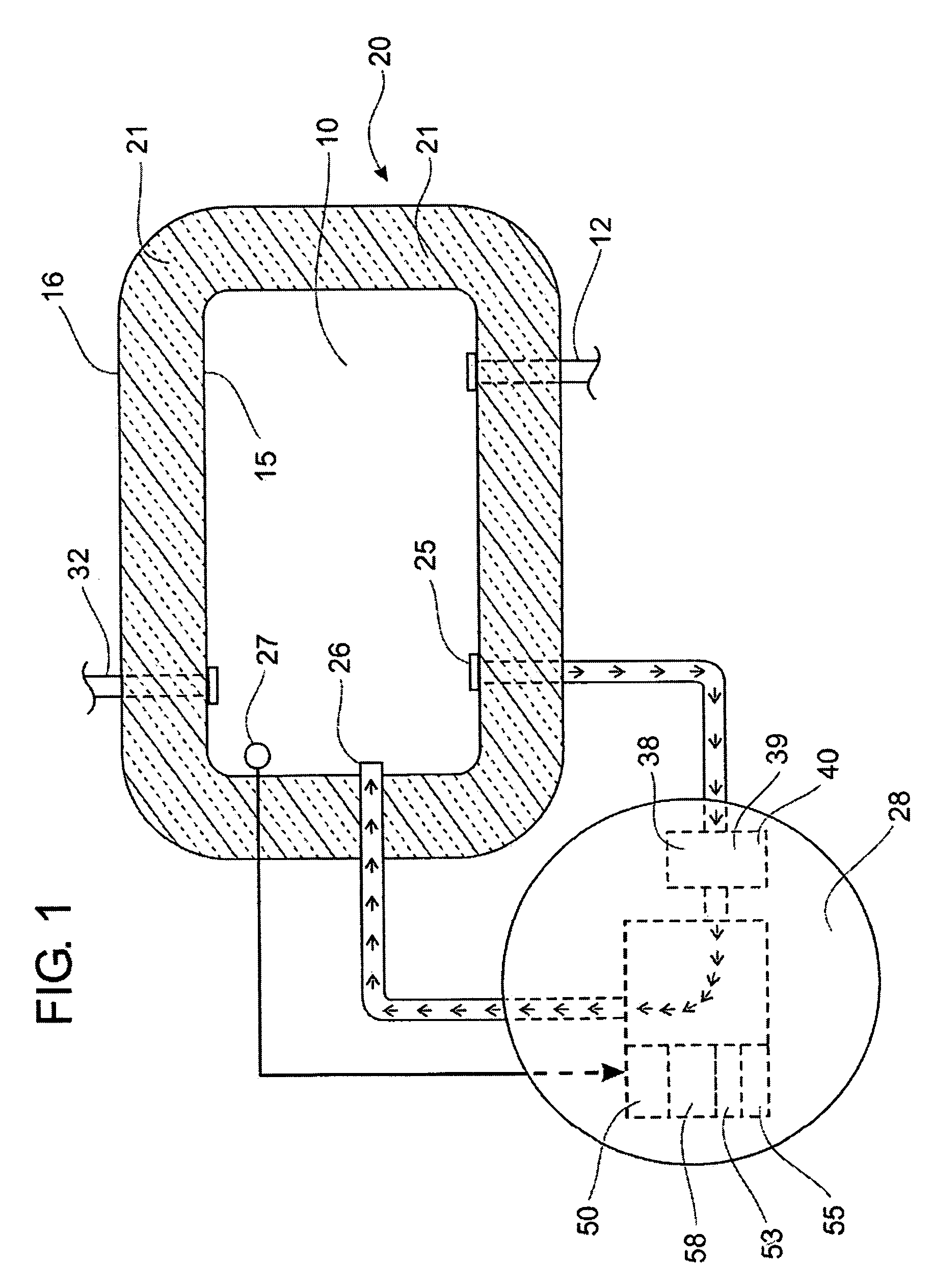

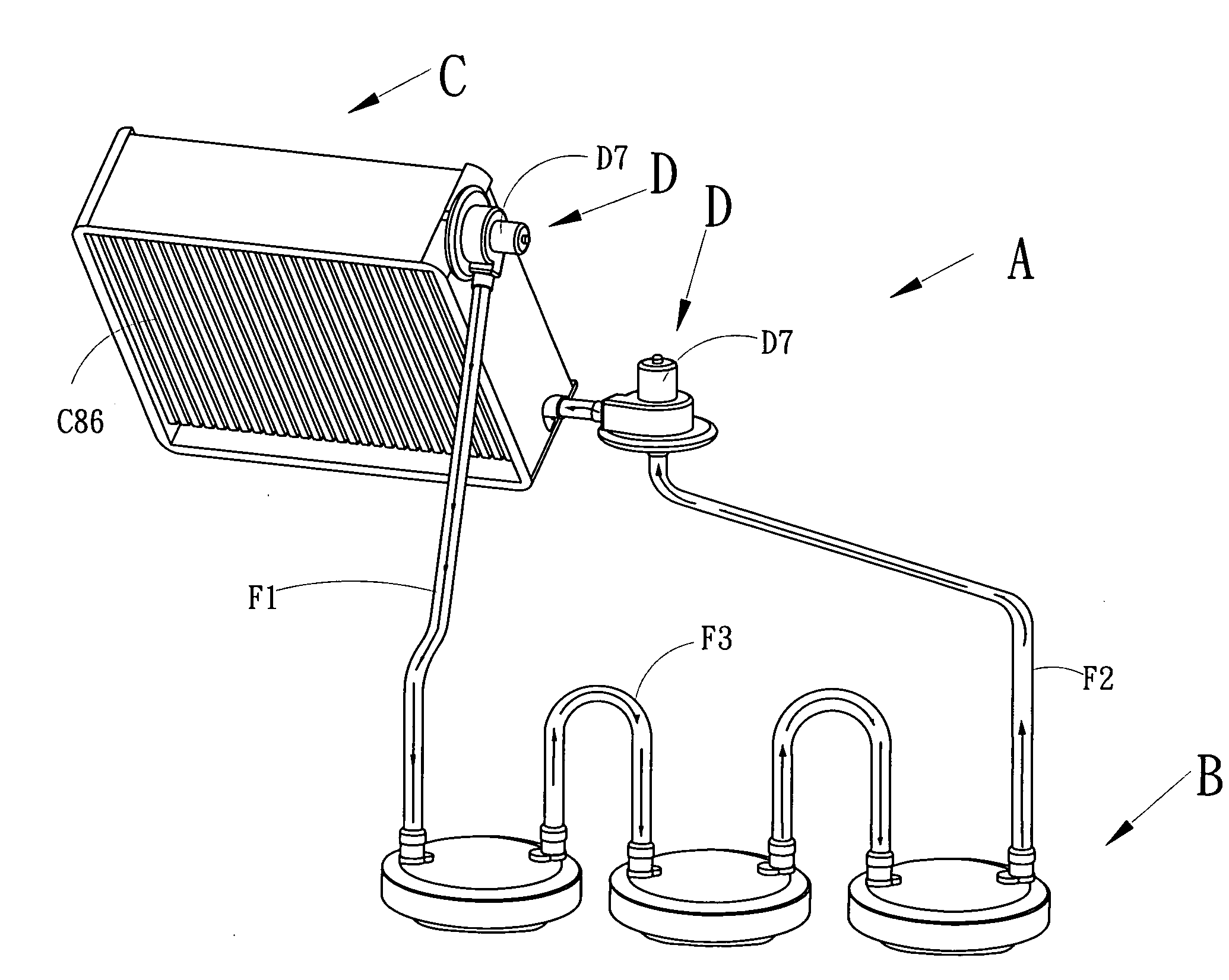

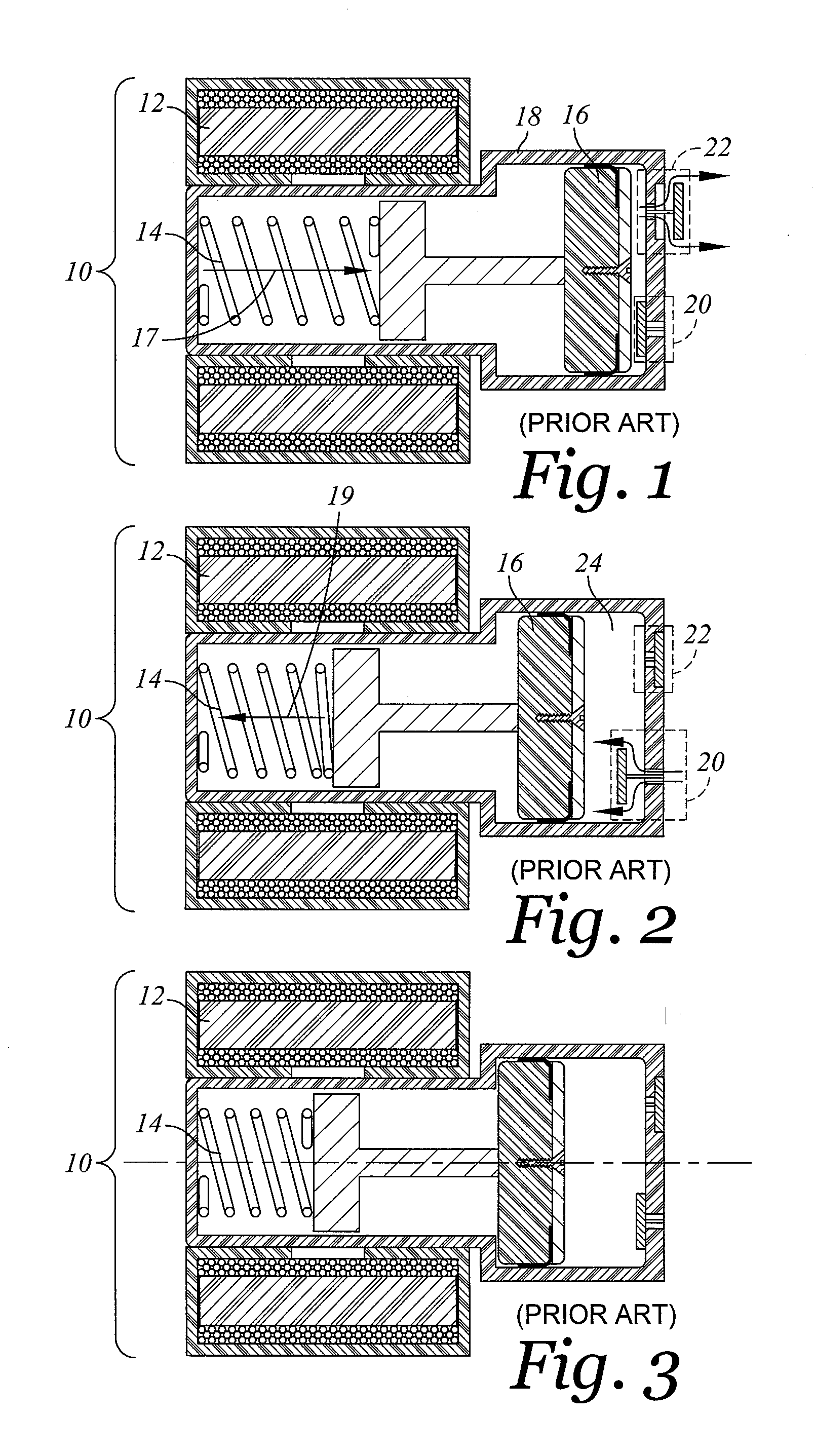

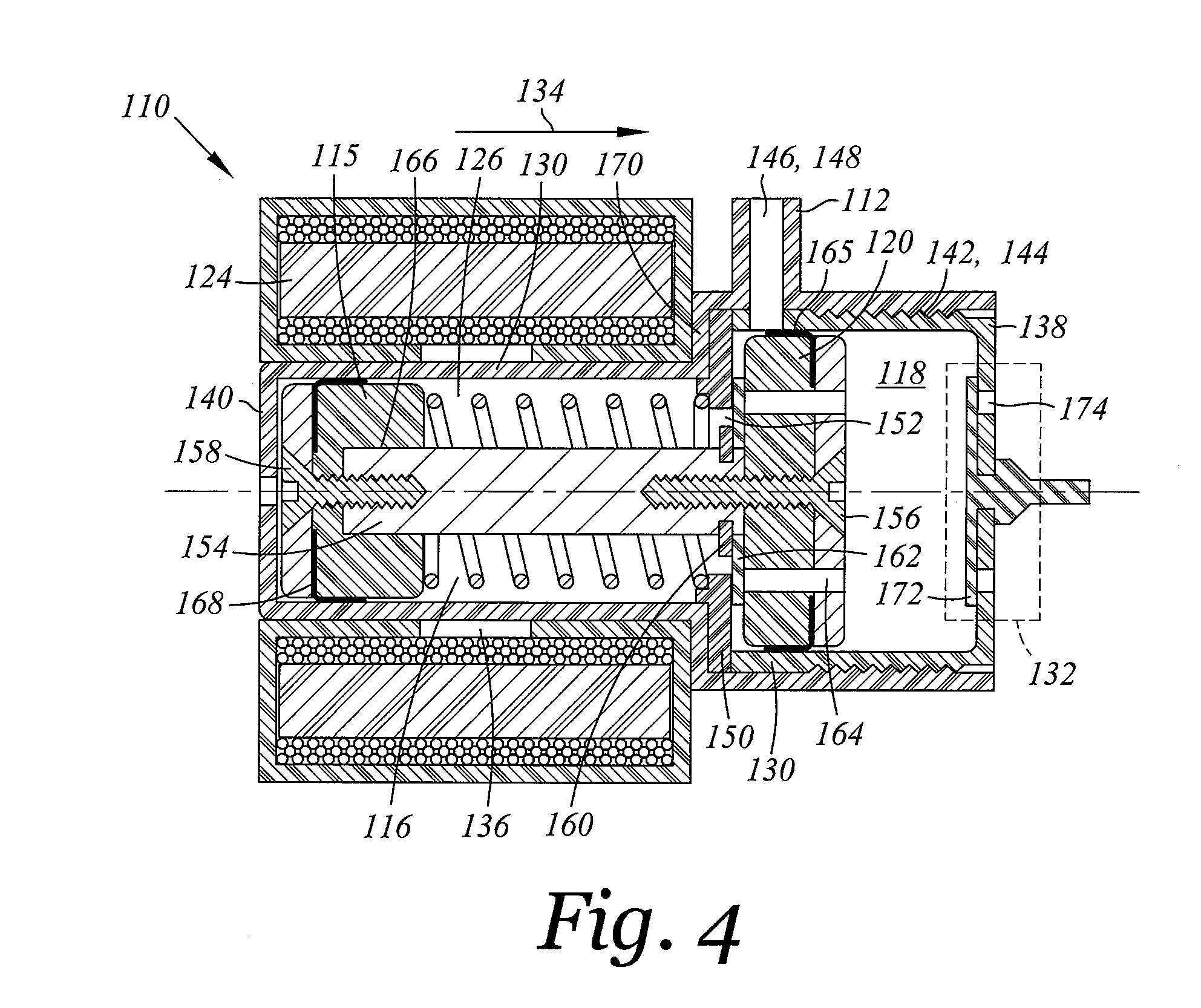

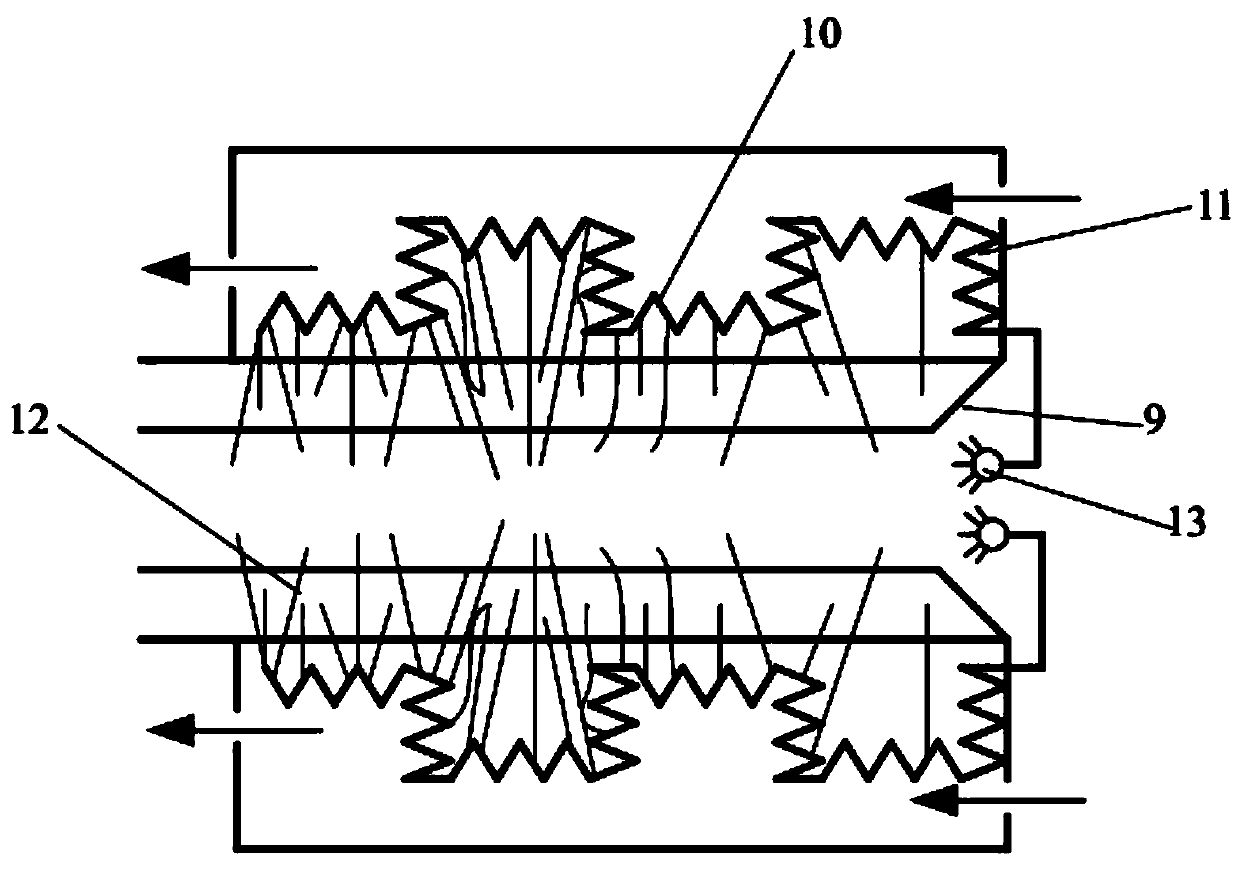

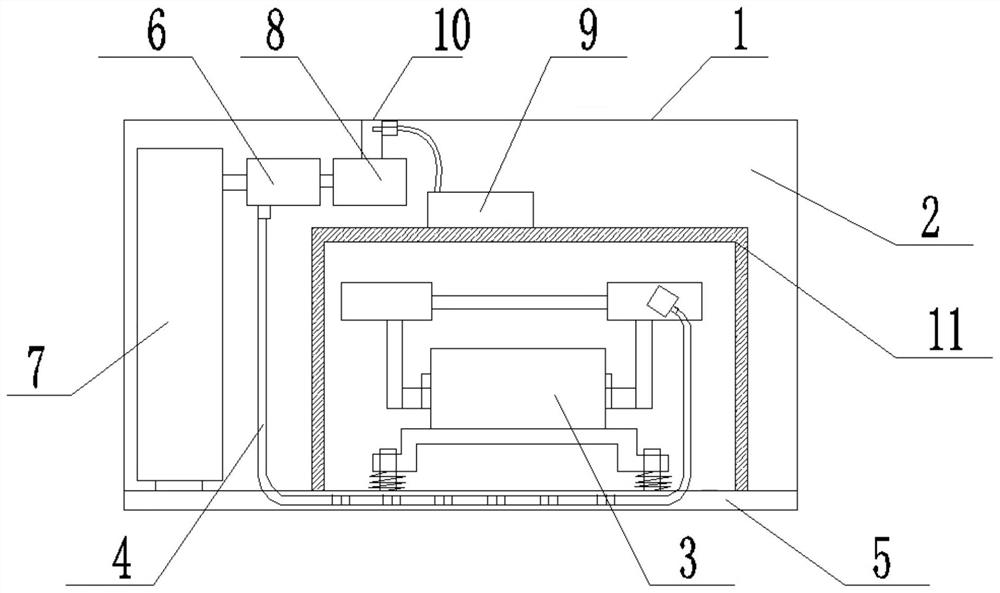

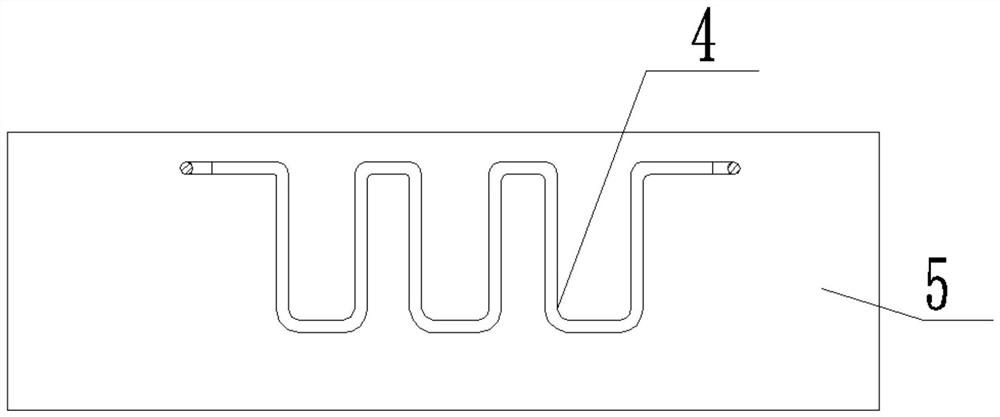

Fish or fish bait life preservation apparatus and method

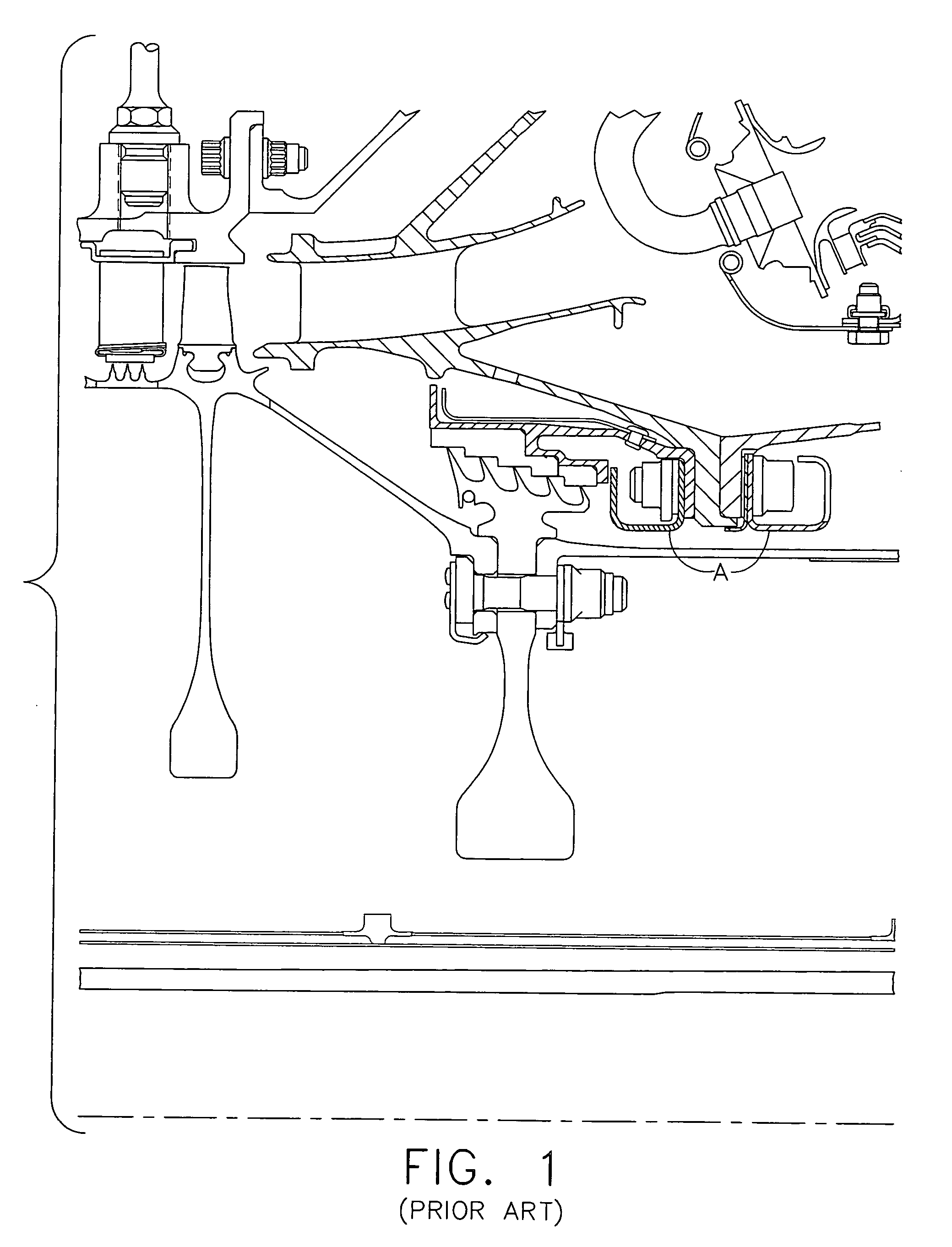

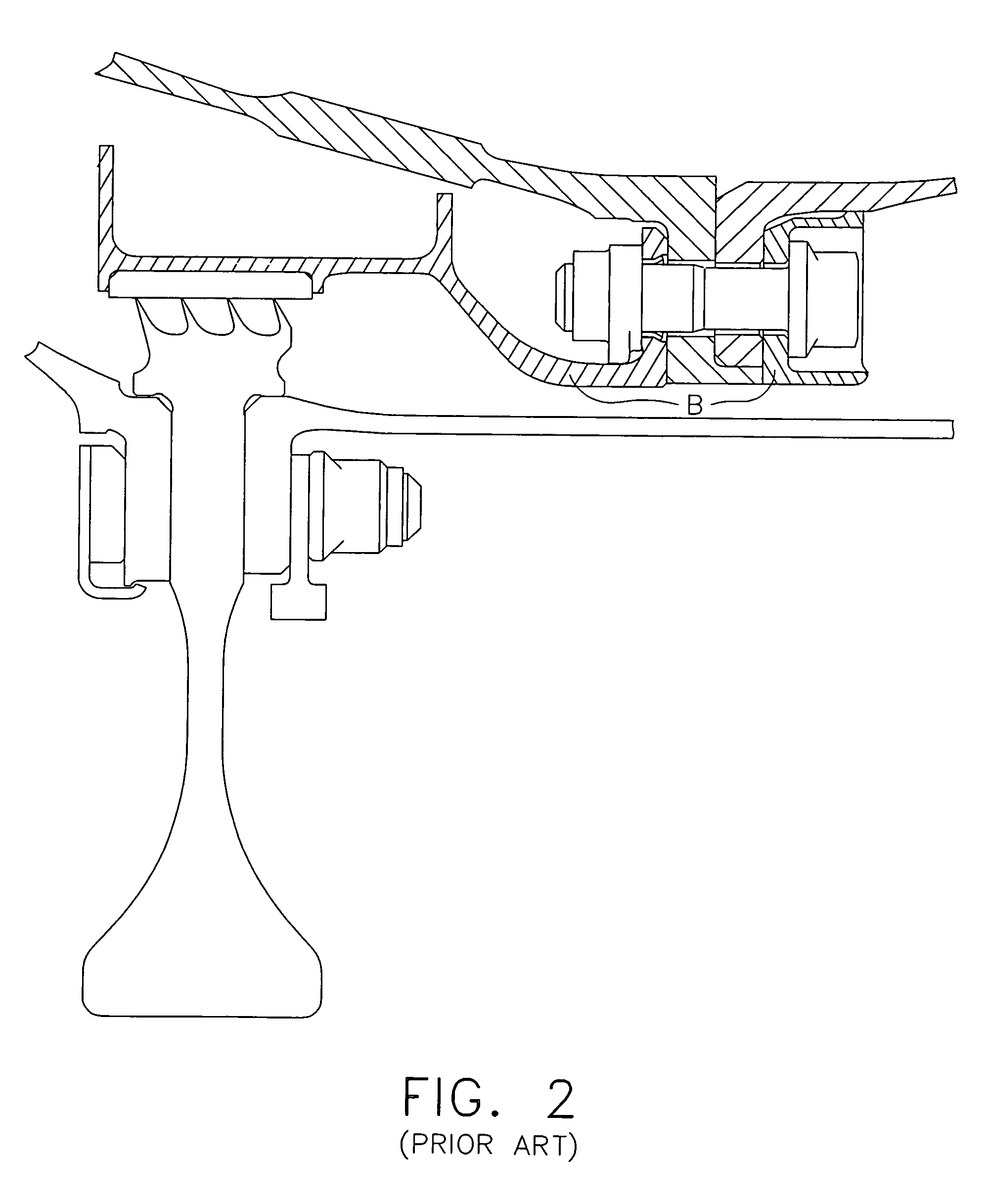

InactiveUS7024814B1Enhance captureLower fluid temperaturePisciculture and aquariaOther angling devicesRefrigerantEngineering

A novel system, apparatus and method of operation for use in watercraft, terrestrially bound motor vehicles and fixed based land applications where water from a live well or bait tank is withdrawn, filtered, climactically controlled and conveyed through a water conditioning unit containing in part a heat exchanging unit with a generally serpentined contour water passageway, the water passageway formed and structured in a manner to allow water, or another fluid within the passageway to abut and surround a generally serpentine form tubular conduit containing a pressurized refrigerant with the water routed within the passageway maintaining continuous contact with the conduit then exiting the heat exchanging unit returned to the live well tank or bait tank.

Owner:MCDOUGLE FR ONEIL

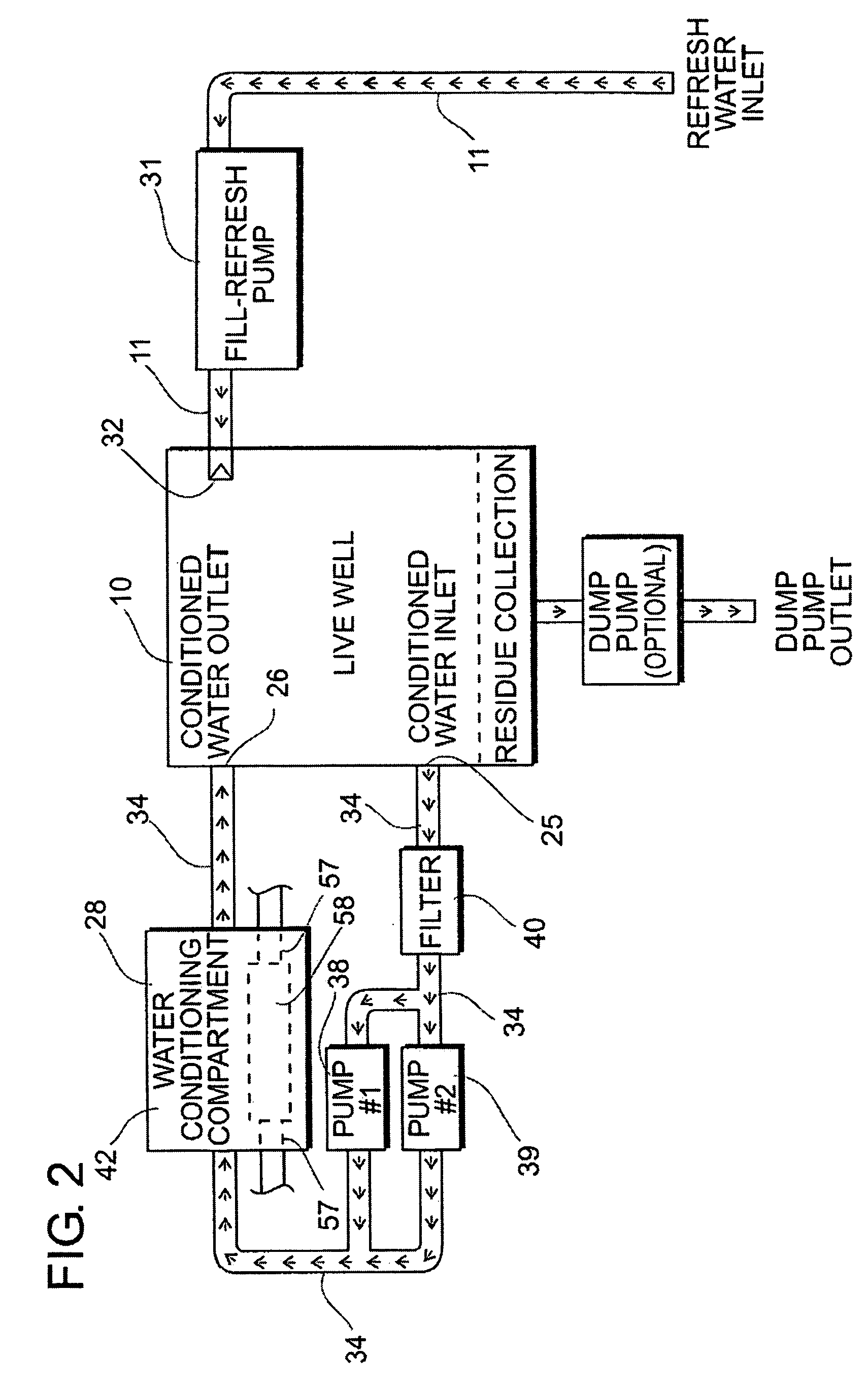

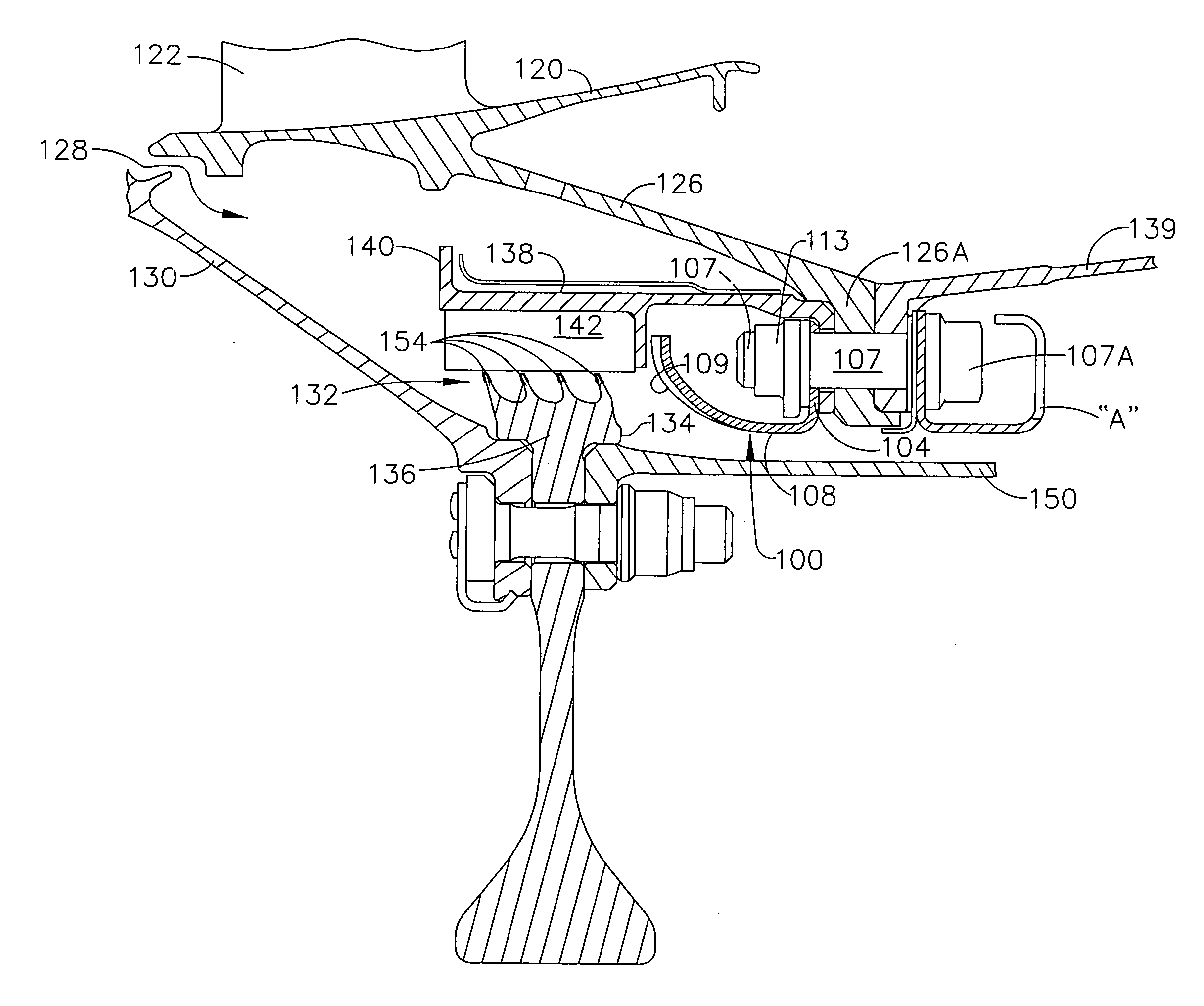

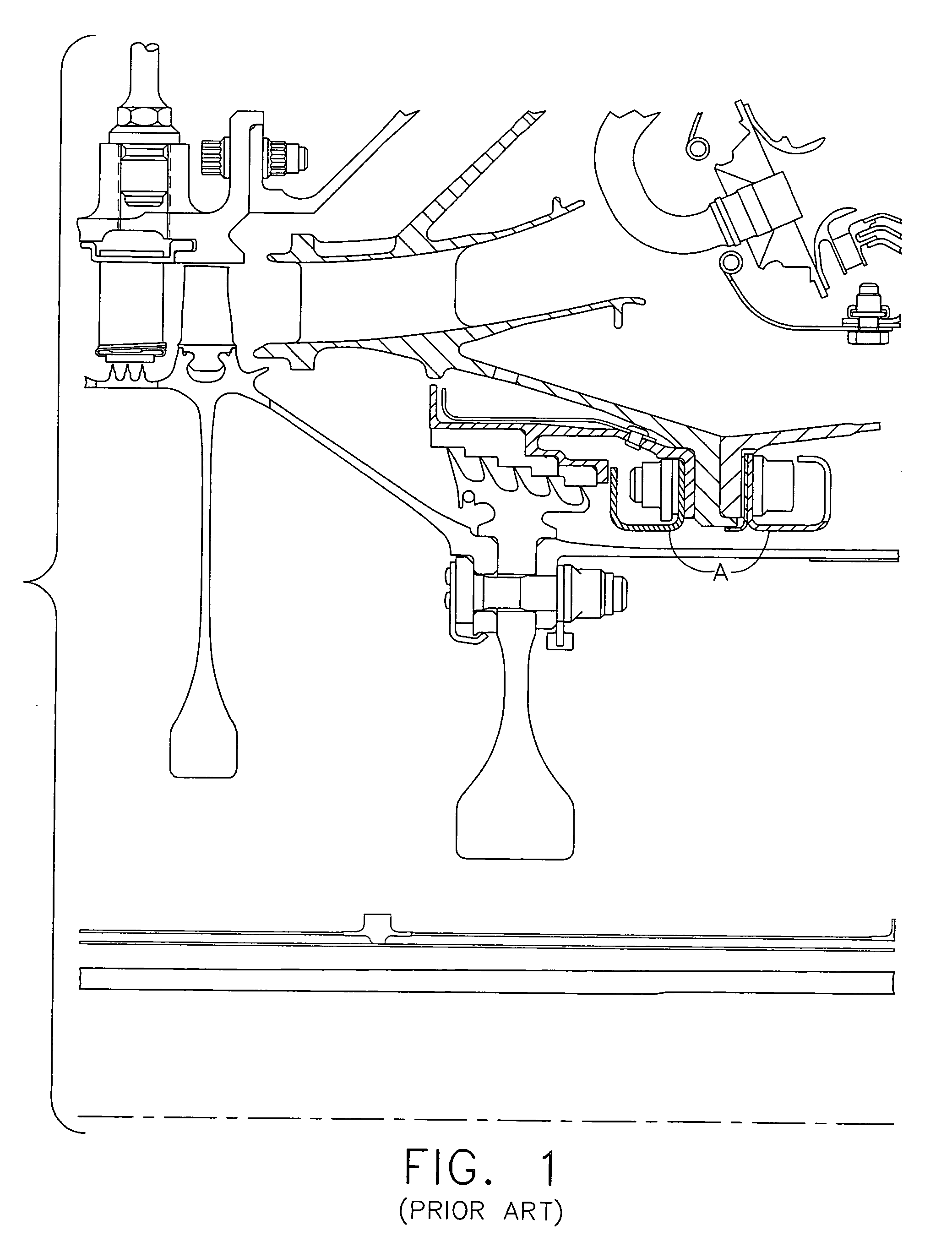

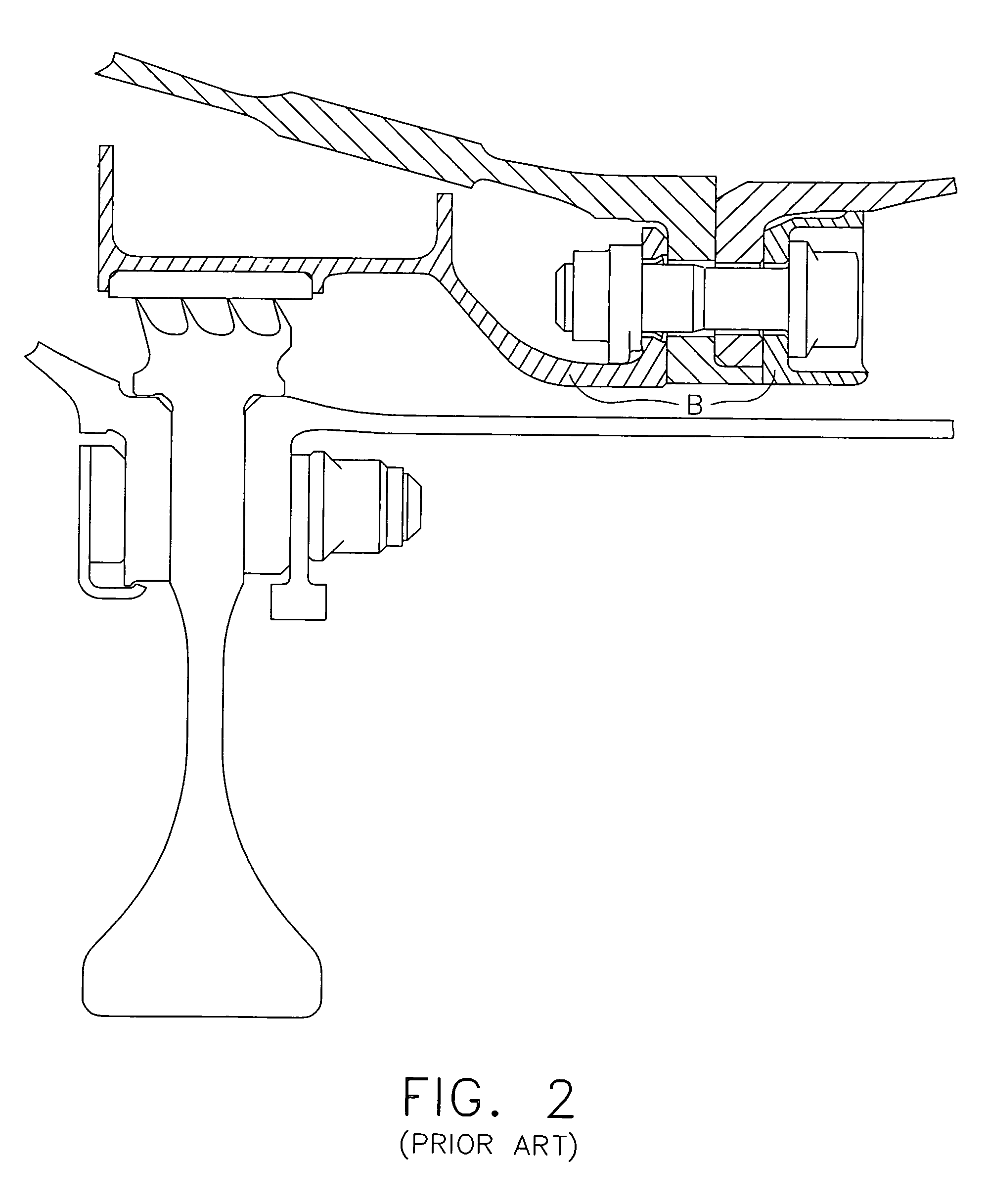

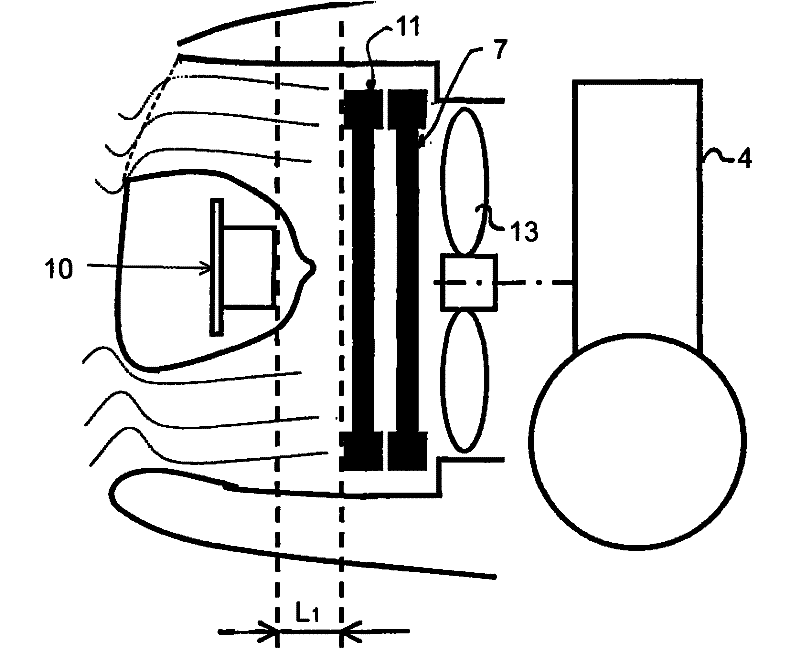

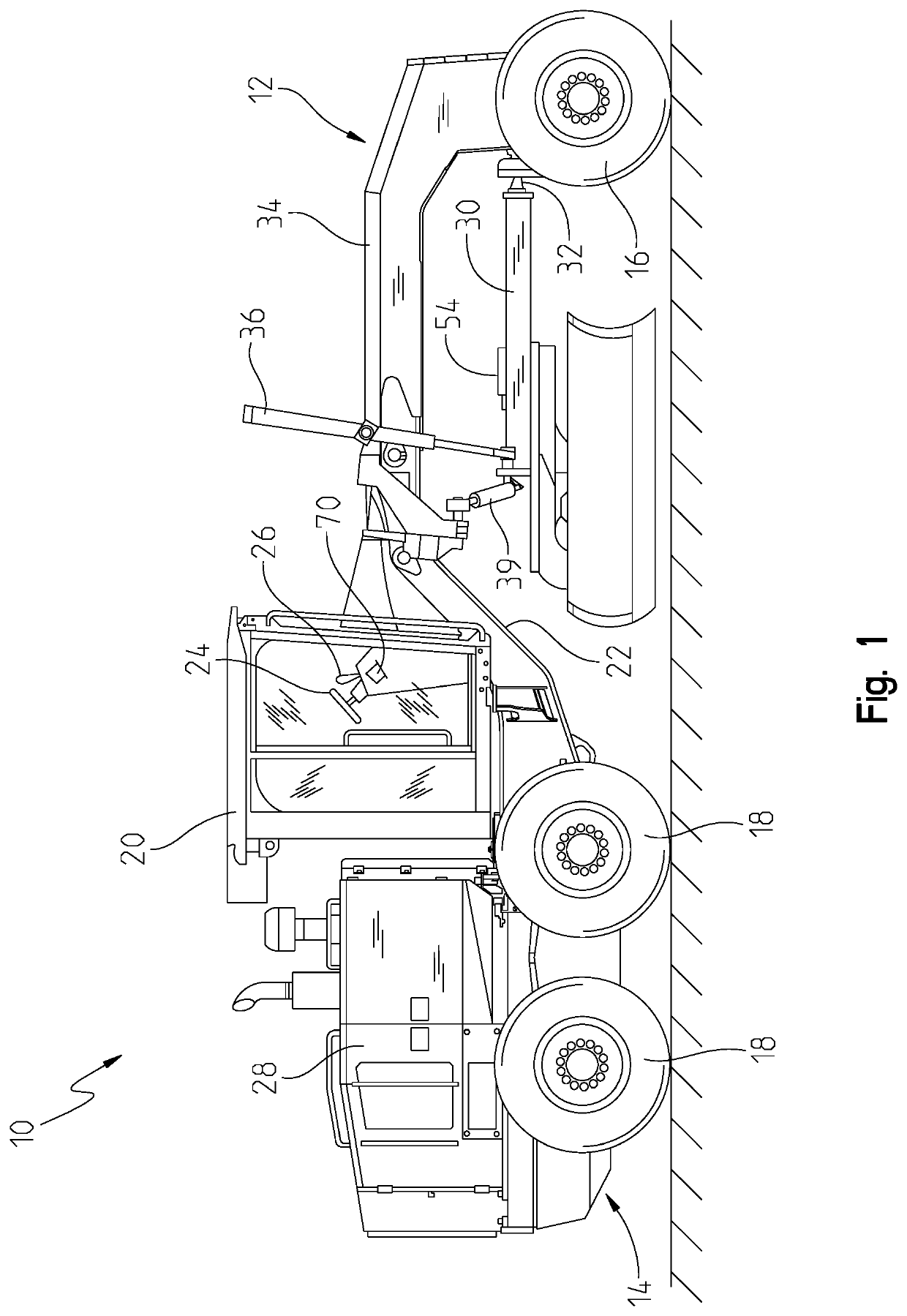

Swirl-enhanced aerodynamic fastener shield for turbomachine

ActiveUS7094020B2Minimize temperature riseInhibition of attachmentEngine sealsPump componentsTurbineEngine mount

A fastener shield for use in a fluid flow path within a gas turbine engine for reducing fluid drag and heating generated by fluid flow over a plurality of circumferentially spaced bolts. The fastener shield has a radially-extending, downstream-facing mounting flange with a plurality of circumferentially spaced bolt holes positioned to receive respective engine mounting bolts therethrough and to attach the mounting flange to elements of the turbine engine. A curved, upstream-facing fastener shield cover is positioned in spaced-apart relation to the mounting flange for at least partially covering and separating an exposed, upstream-facing portion of the bolts from the fluid flow to thereby reduce drag and consequent heating of the bolts. A plurality of closely spaced-apart, spirally-oriented channels are formed in the fastener shield cover for deflecting the fluid flow impinging on the fastener shield cover, thereby increasing the tangential velocity and lowering the relative temperature of the fluid flow.

Owner:GENERAL ELECTRIC CO

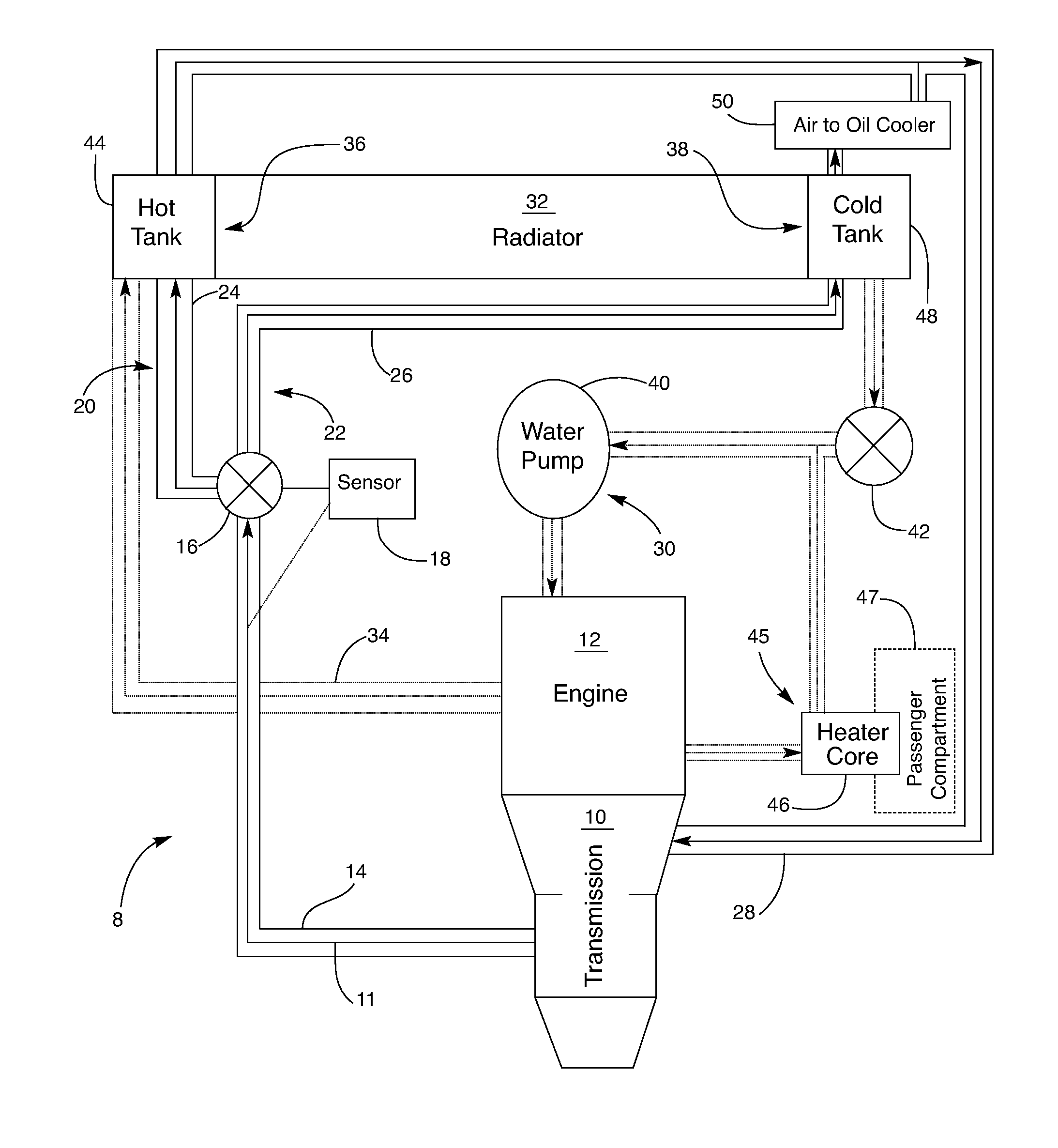

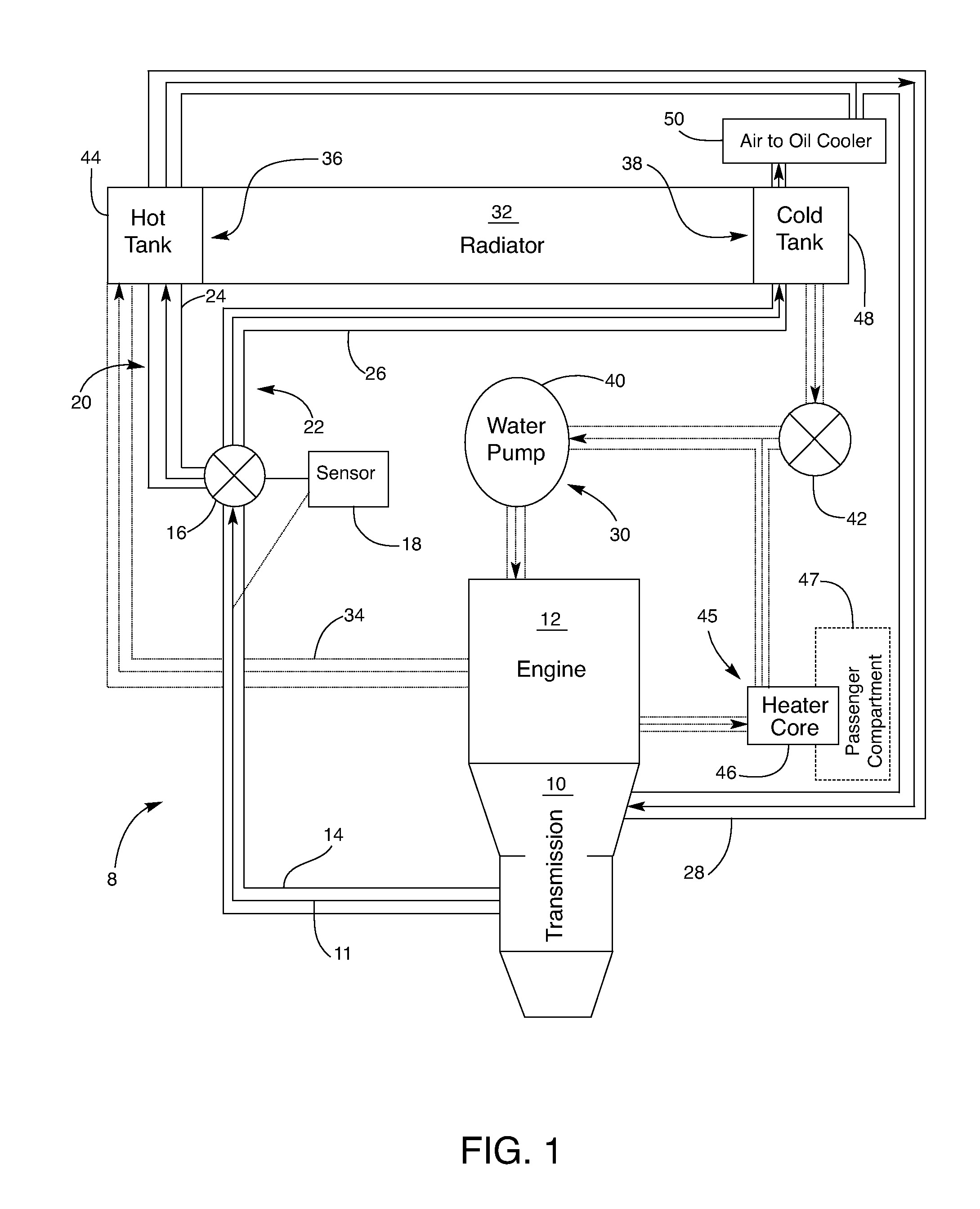

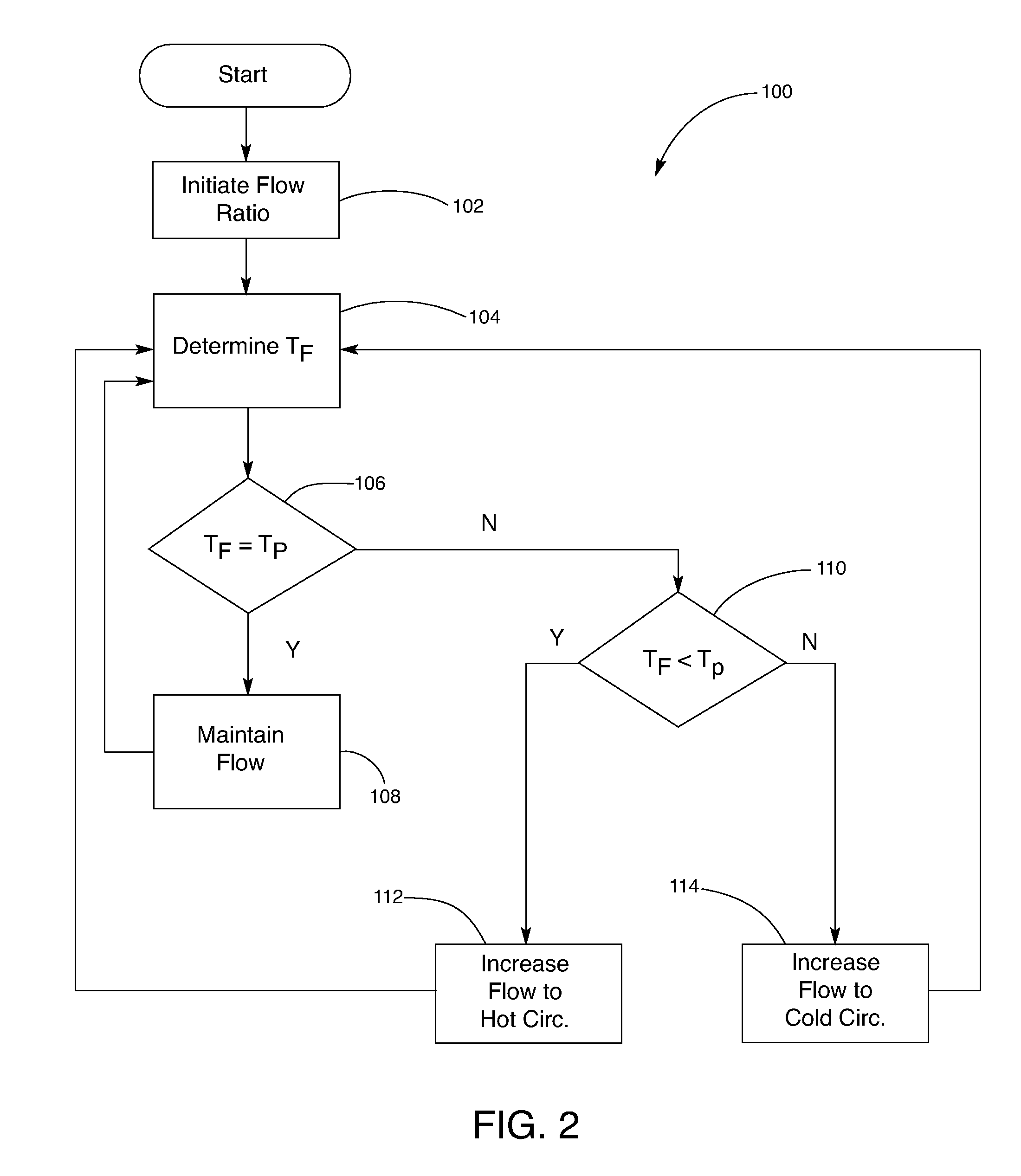

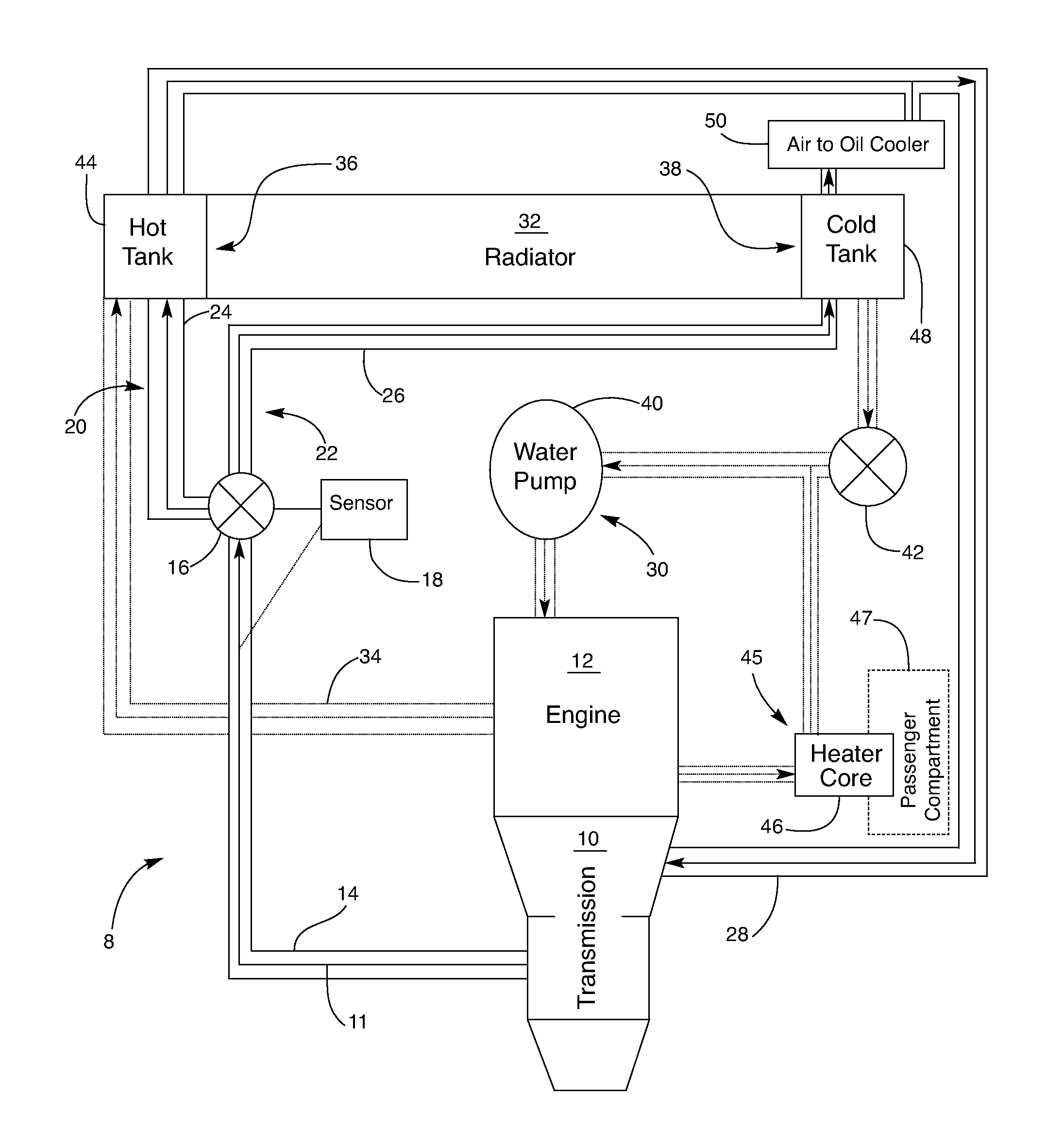

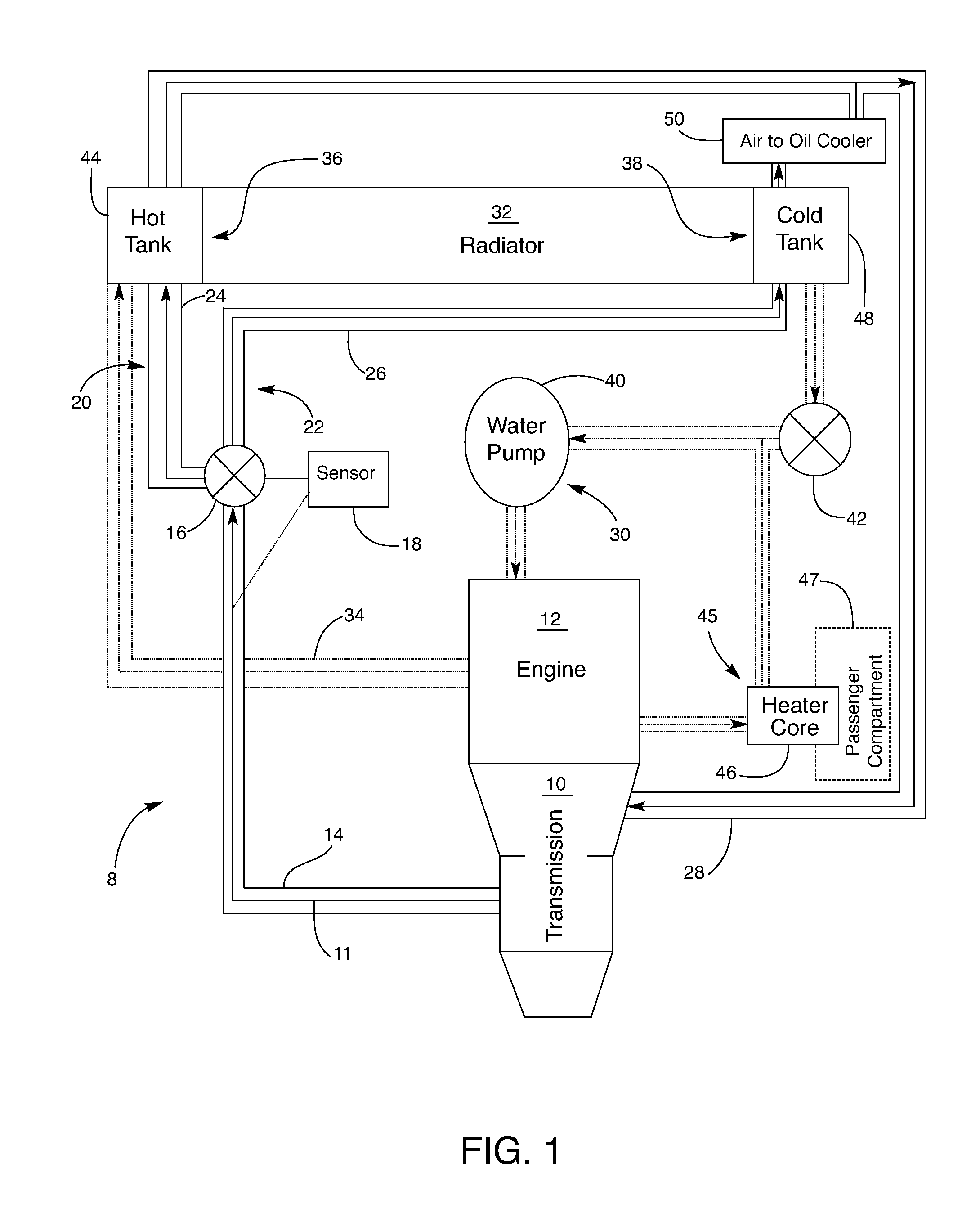

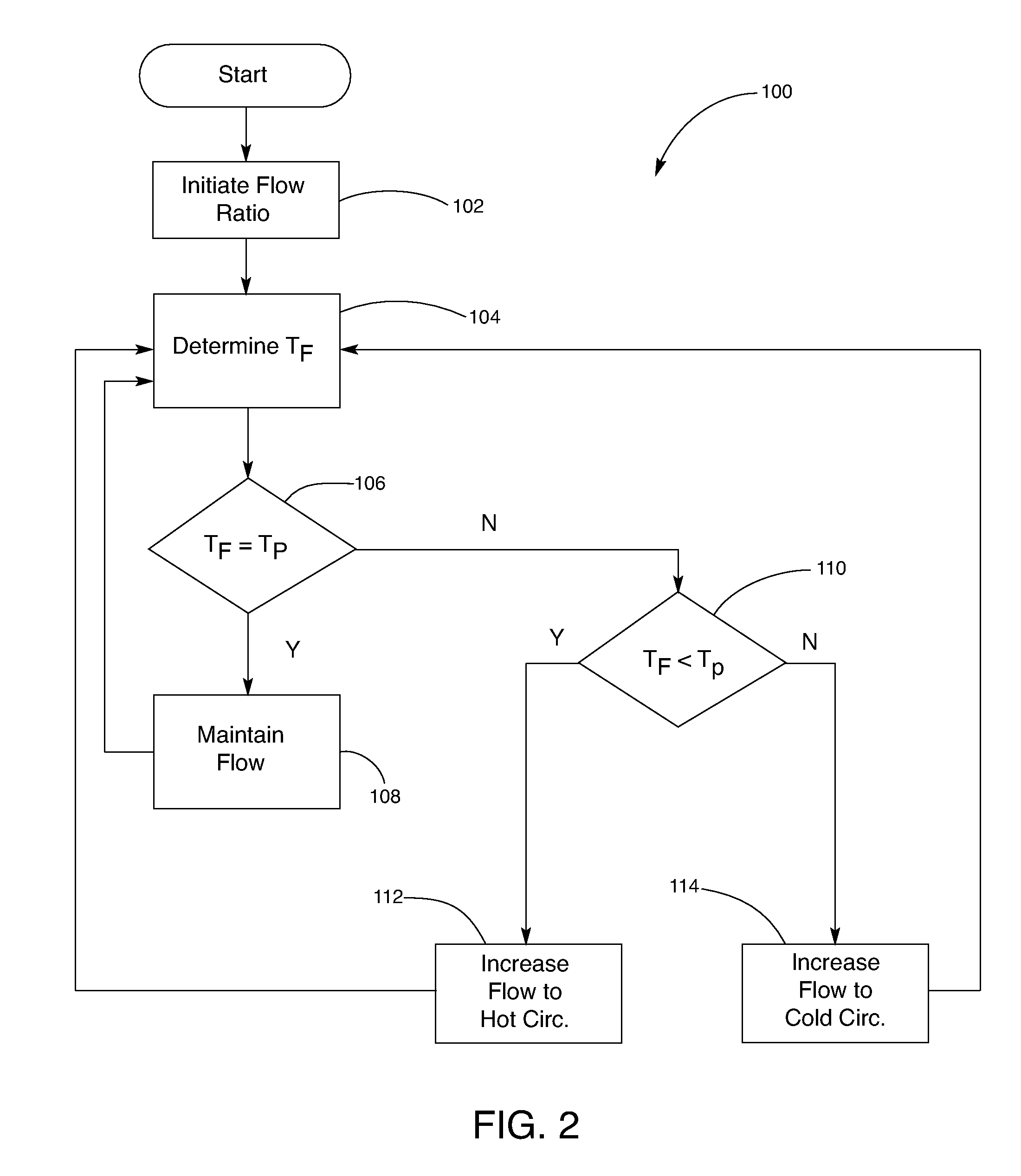

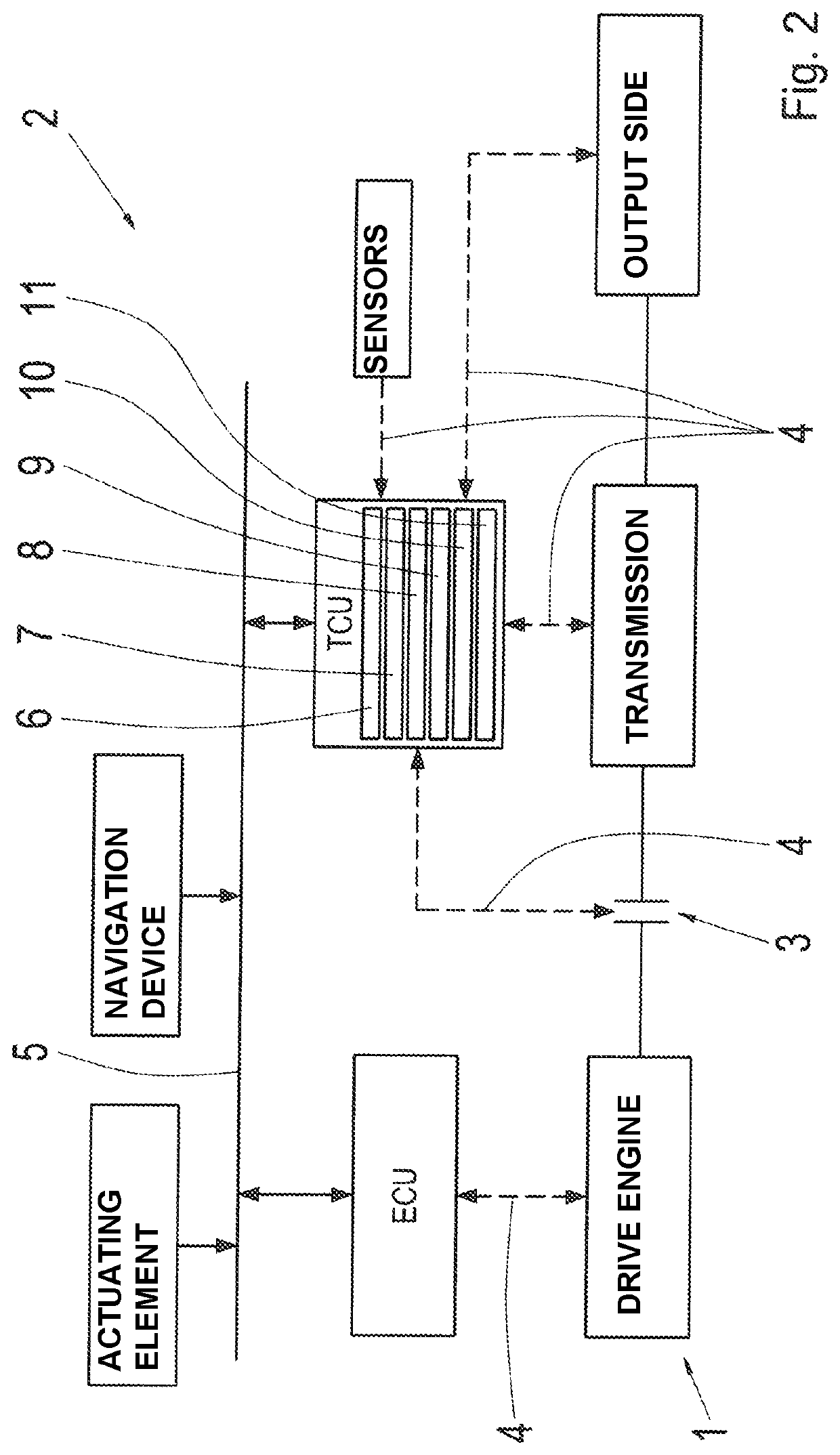

Active thermal management system and method for transmissions

ActiveUS8116953B2Lower fluid temperatureDigital data processing detailsEngine controllersThermal management systemEngineering

An active thermal management system and method for selectively warming and cooling transmission fluid in a transmission usable with a vehicular engine is provided. The active thermal management system includes a thermal sensor which measures transmission fluid temperature and signals a valve to selectively communicate transmission fluid flow into one or more discrete fluid circuits.

Owner:GM GLOBAL TECH OPERATIONS LLC

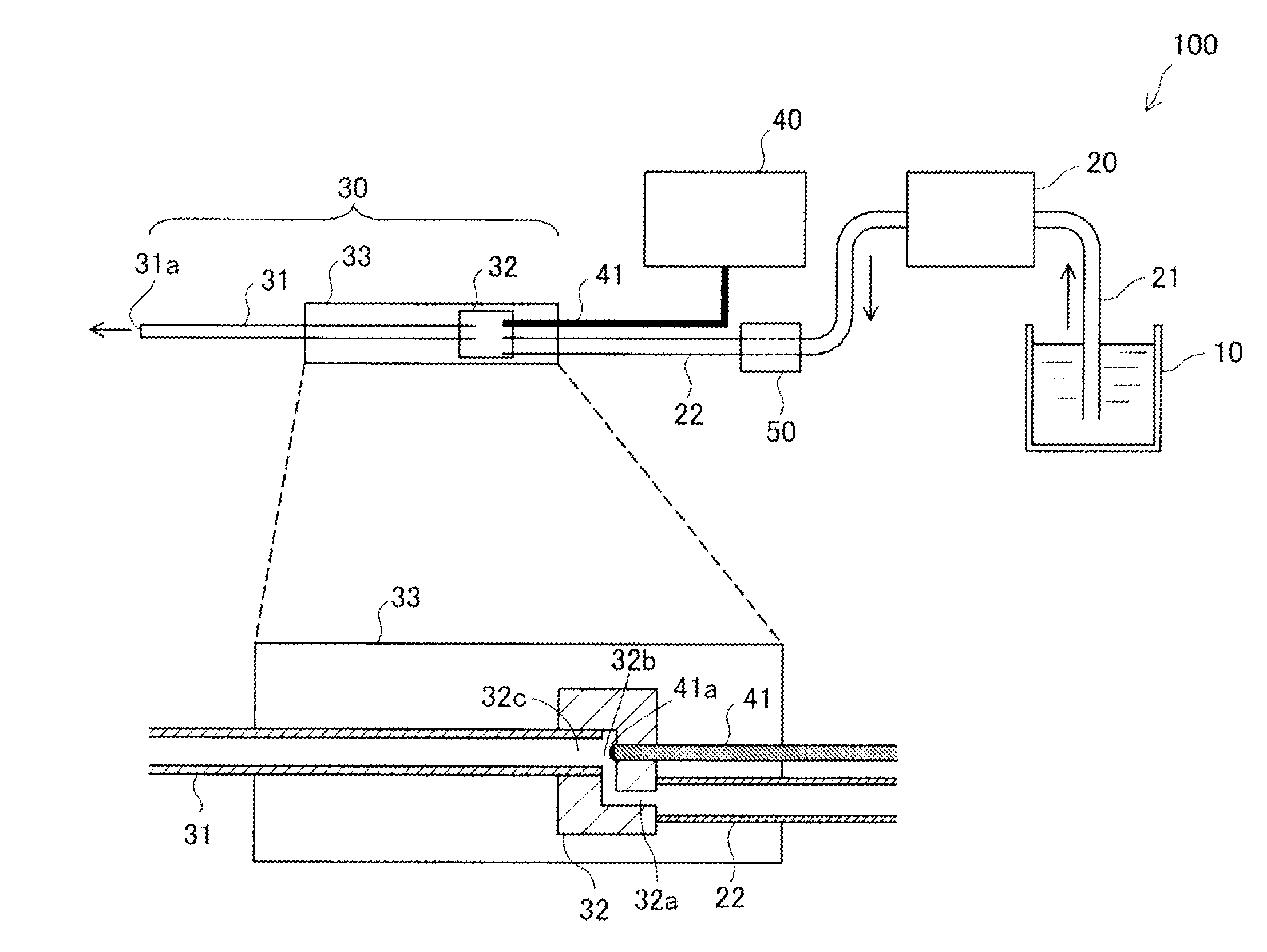

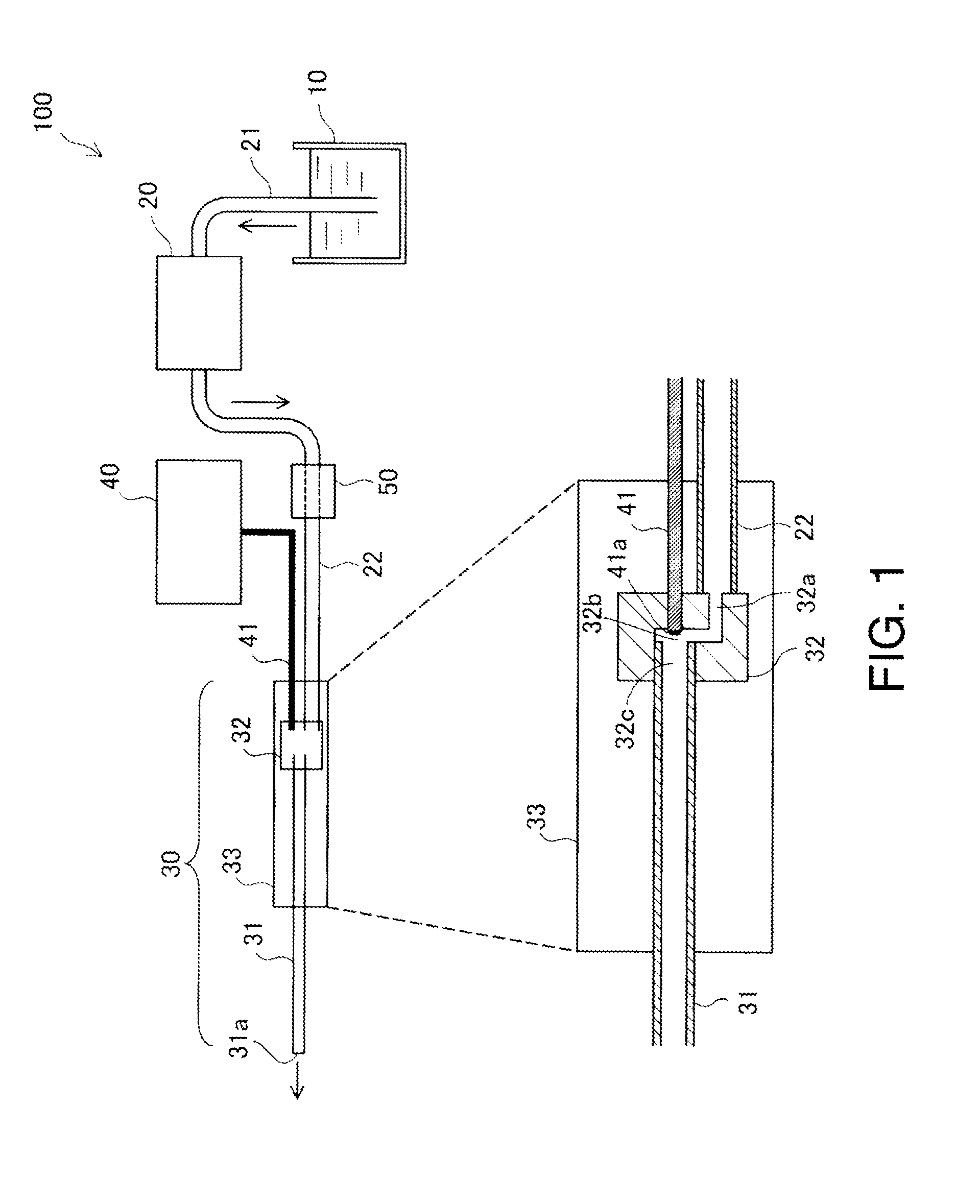

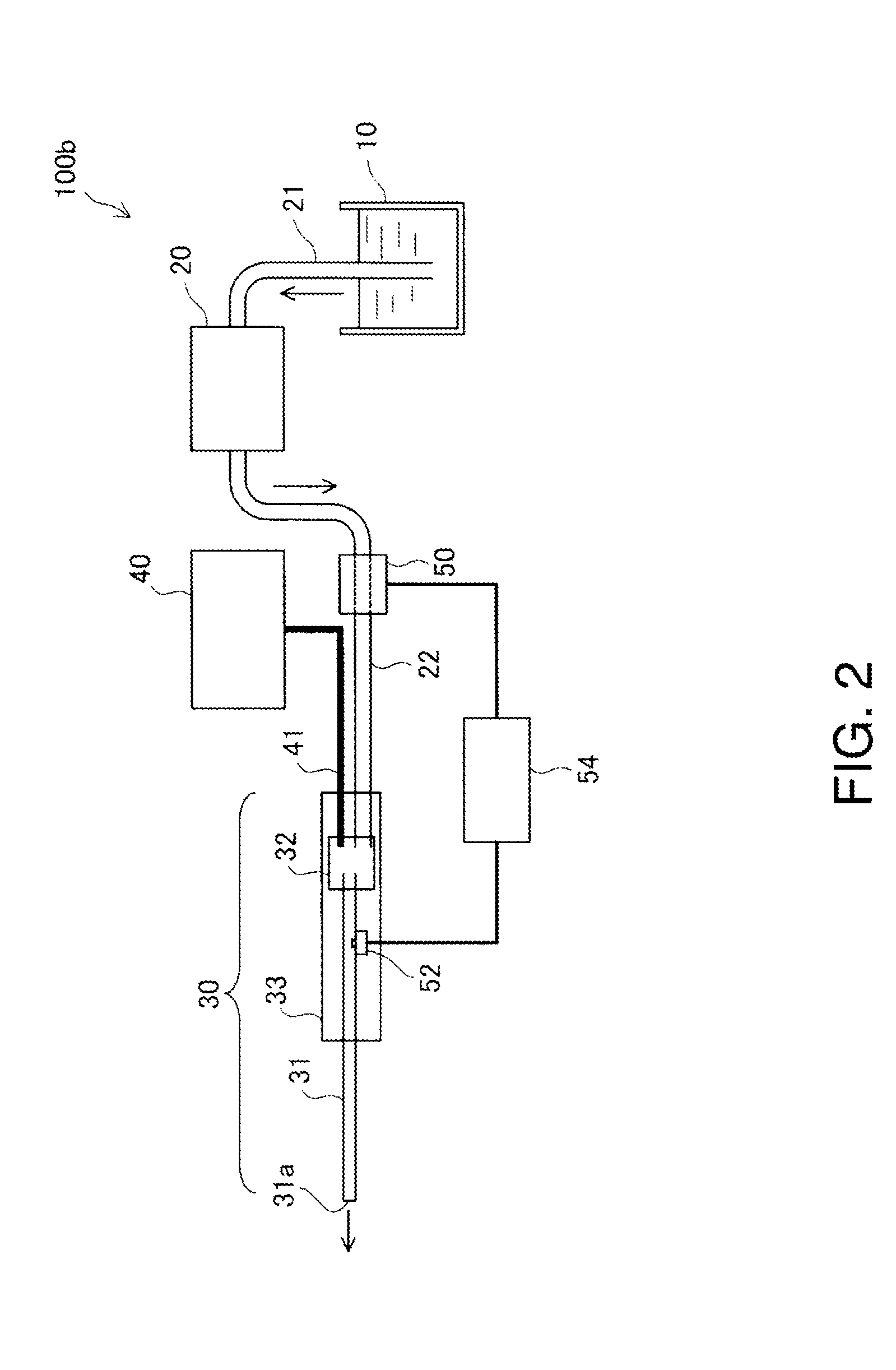

Fluid ejection device

InactiveUS20140277023A1Lower fluid temperatureReduce the temperatureLiquid surface applicatorsSpray nozzlesEngineeringBiomedical engineering

Owner:SEIKO EPSON CORP

Active thermal management system and method for transmissions

ActiveUS20090182473A1Reduce temperatureLower fluid temperatureDigital data processing detailsEngine controllersThermal management systemEngineering

An active thermal management system and method for selectively warming and cooling transmission fluid in a transmission usable with a vehicular engine is provided. The active thermal management system includes a thermal sensor which measures transmission fluid temperature and signals a valve to selectively communicate transmission fluid flow into one or more discrete fluid circuits.

Owner:GM GLOBAL TECH OPERATIONS LLC

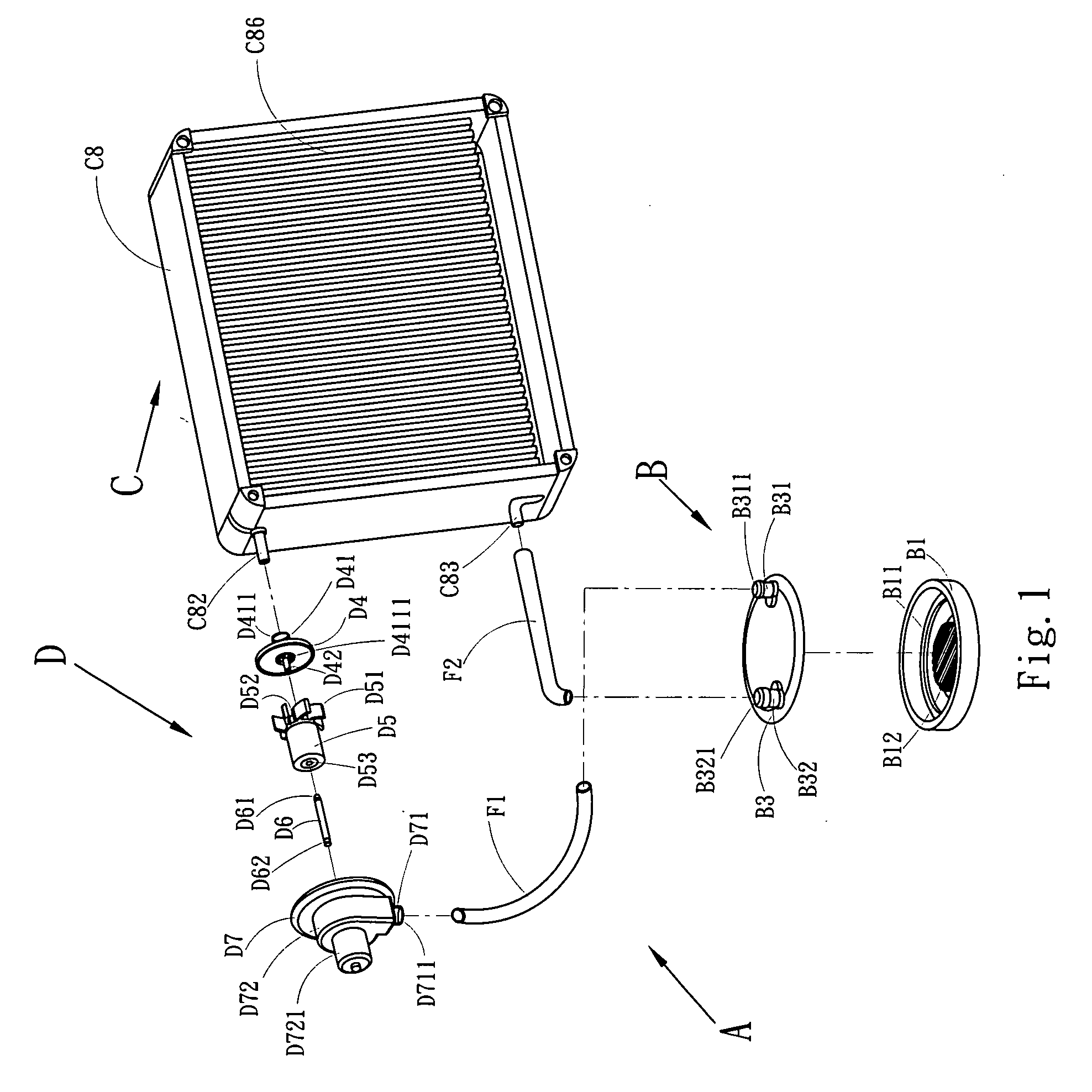

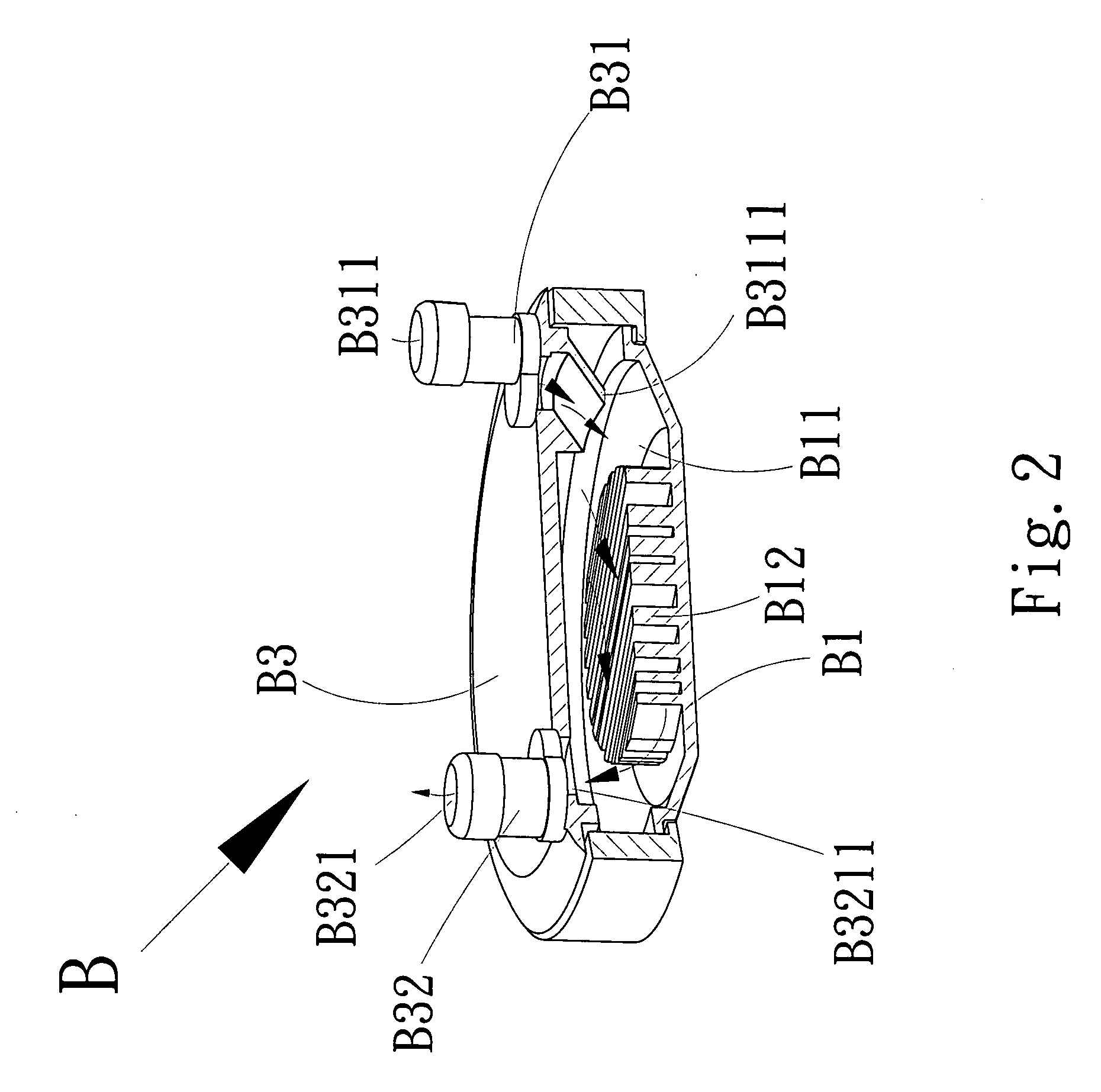

Water-cooling heat-dissipating module of electronic apparatus

InactiveUS20090090489A1Lower fluid temperatureReduce the temperatureDomestic cooling apparatusSemiconductor/solid-state device detailsHeat conductingElectron

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

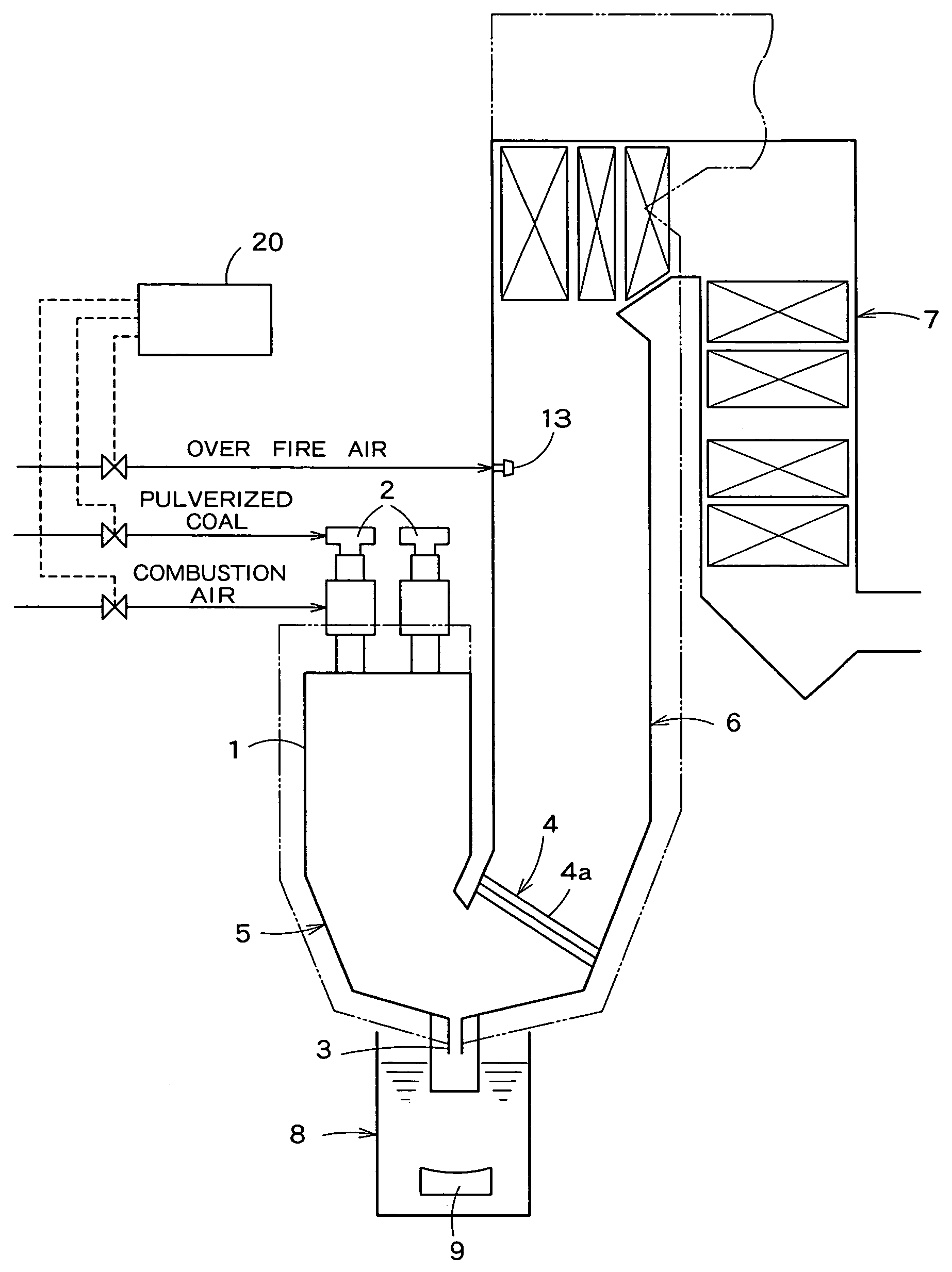

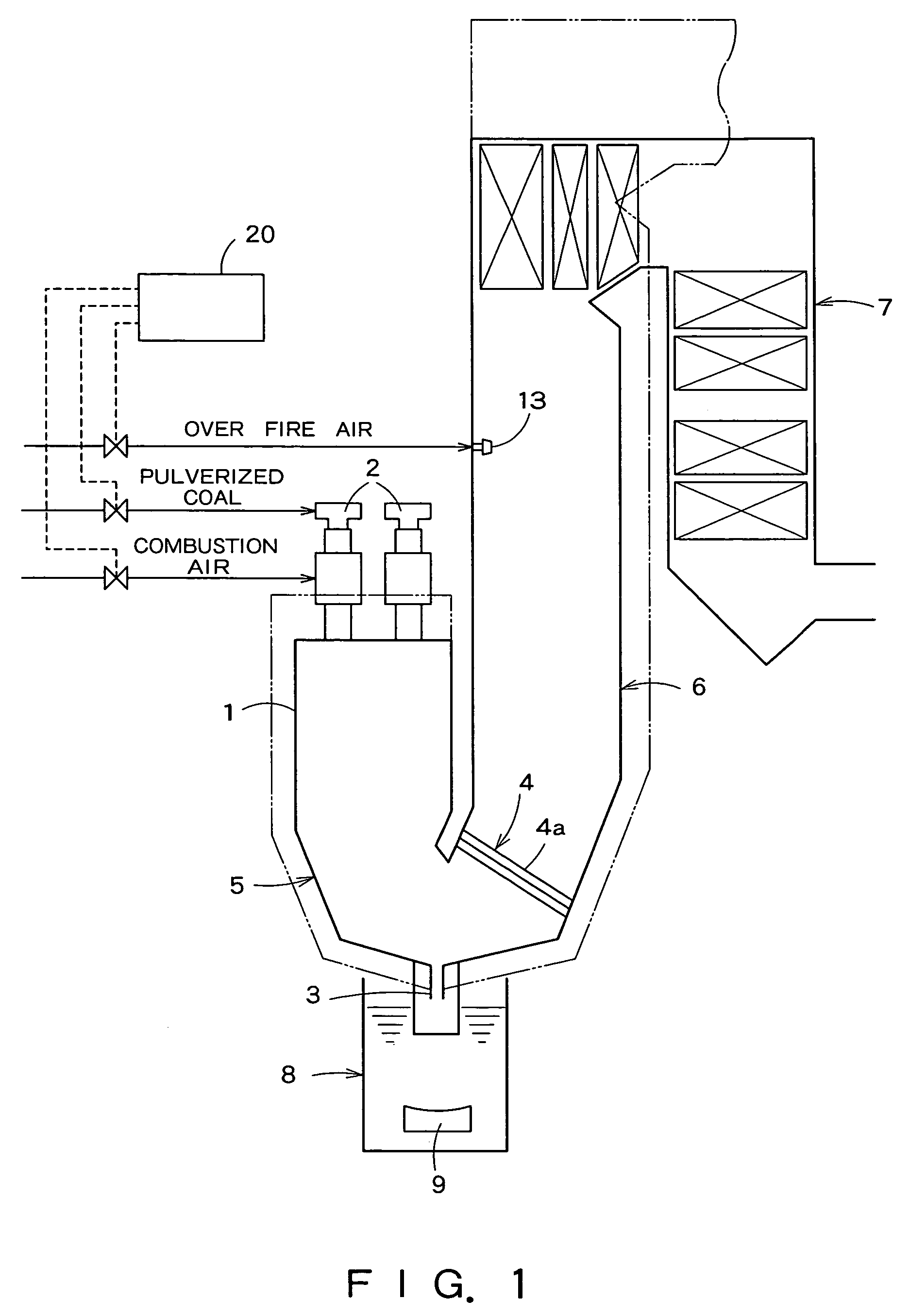

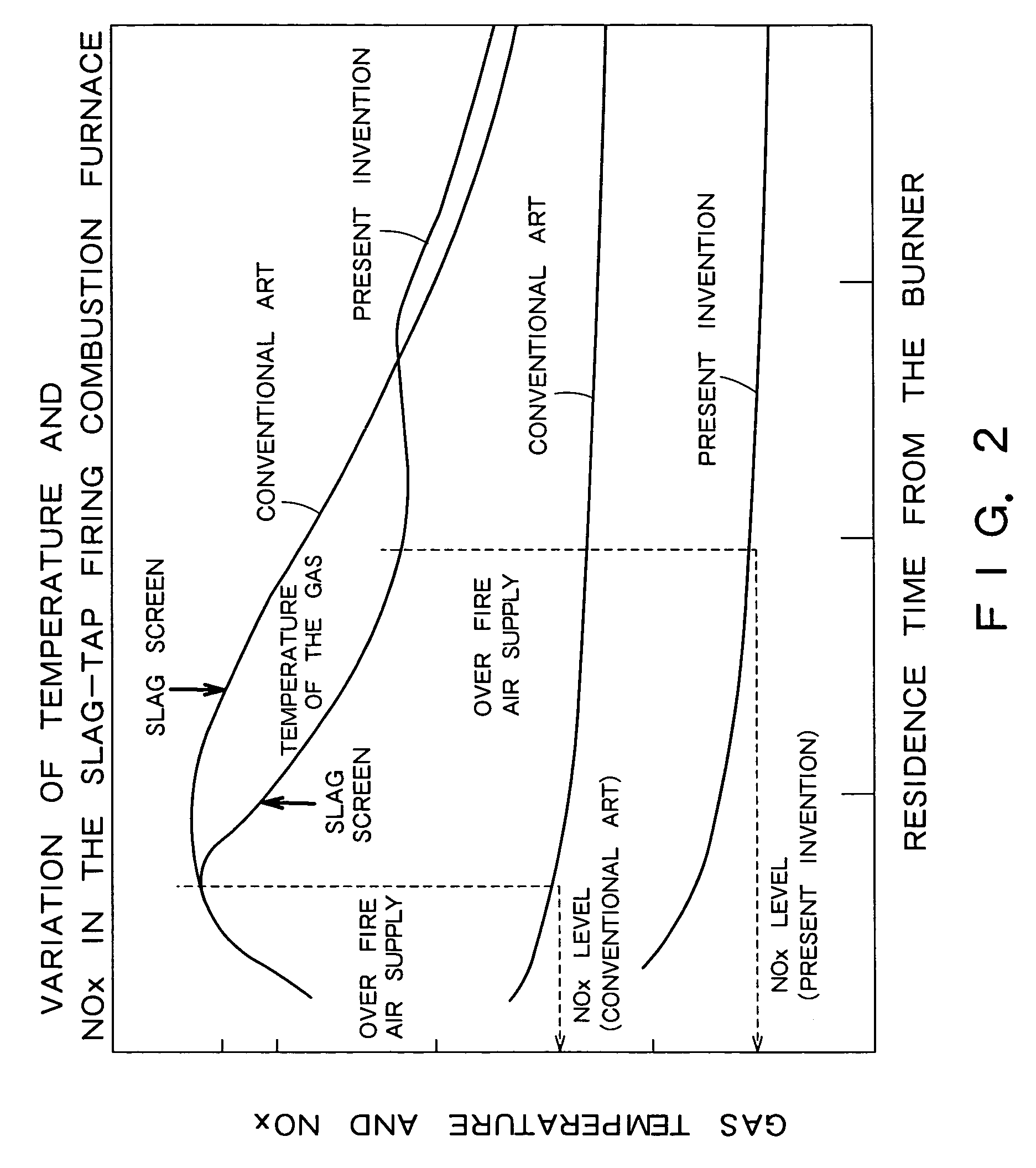

U-type slag-tap firing boiler and method of operating the boiler

InactiveUS7077069B2Reduce the production of nitrogen oxidesGuaranteed functionPulverulent fuel combustion burnersNon-combustible gases/liquids supplyCombustionSlag

A boiler includes a coal pulverizer that pulverizes coal; a coal combustion unit that combusts gasified pulverized coal that has been pulverized by the coal pulverizer; a furnace that combusts gasified fuel generated by the coal combustion unit; a slag formation unit provided in an ash outlet of the coal combustion unit; means for supplying primary air, for supply of the pulverized coal; to the coal pulverizer; means for supplying secondary air, for gasified combustion, to the coal combustion unit; and means for supplying tertiary air, for gasified fuel combustion, to the furnace.

Owner:KAWASAKI HEAVY IND LTD

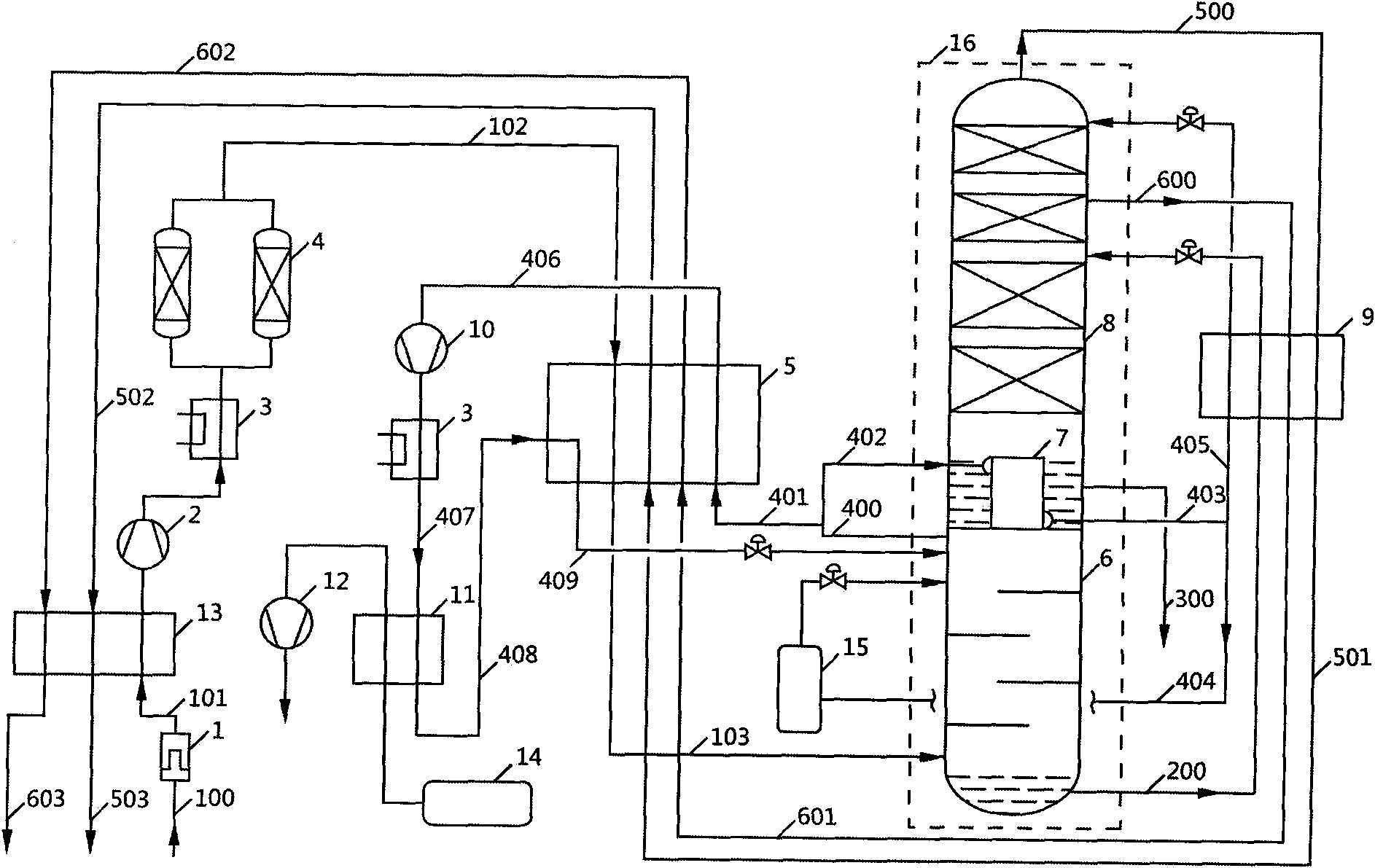

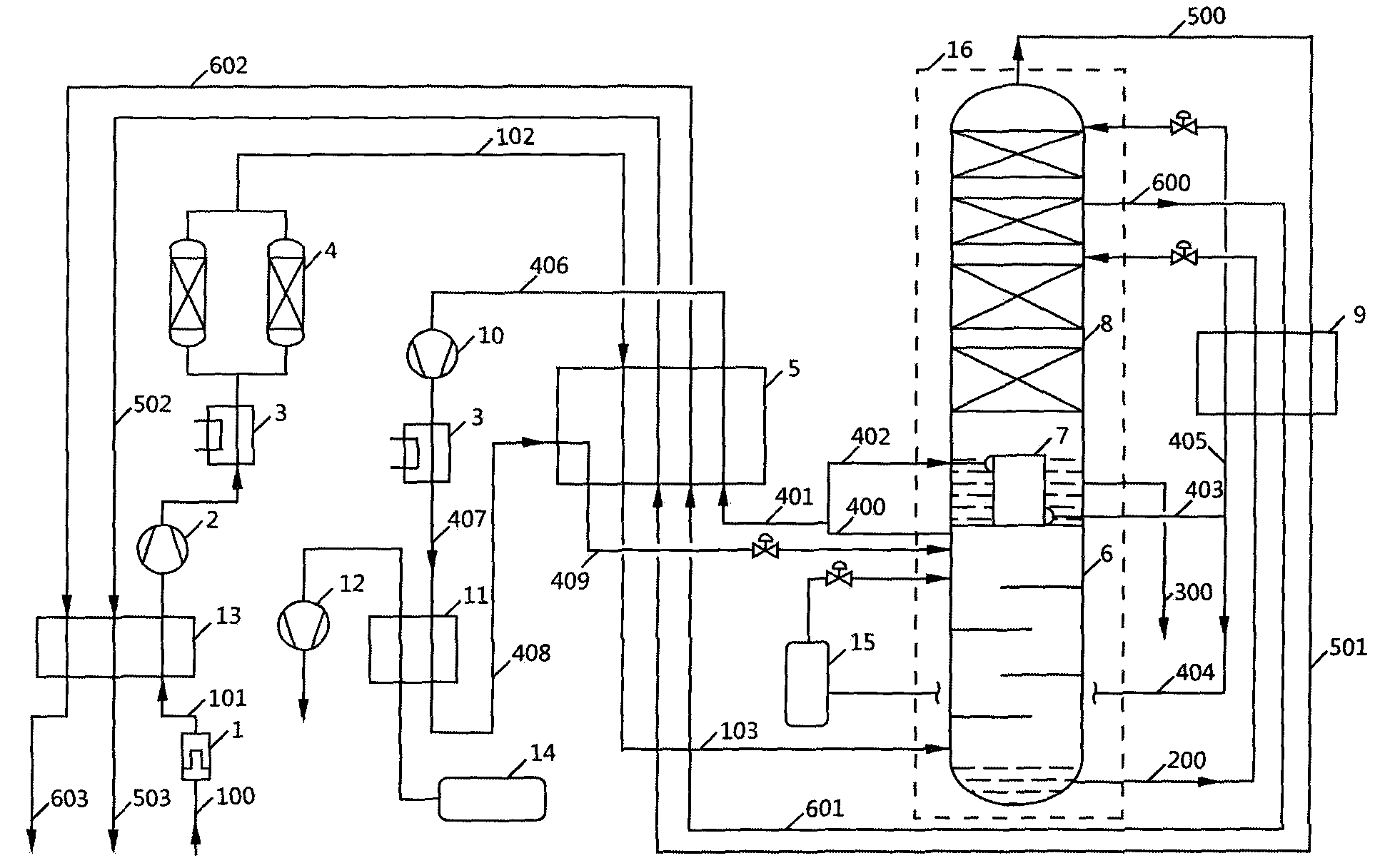

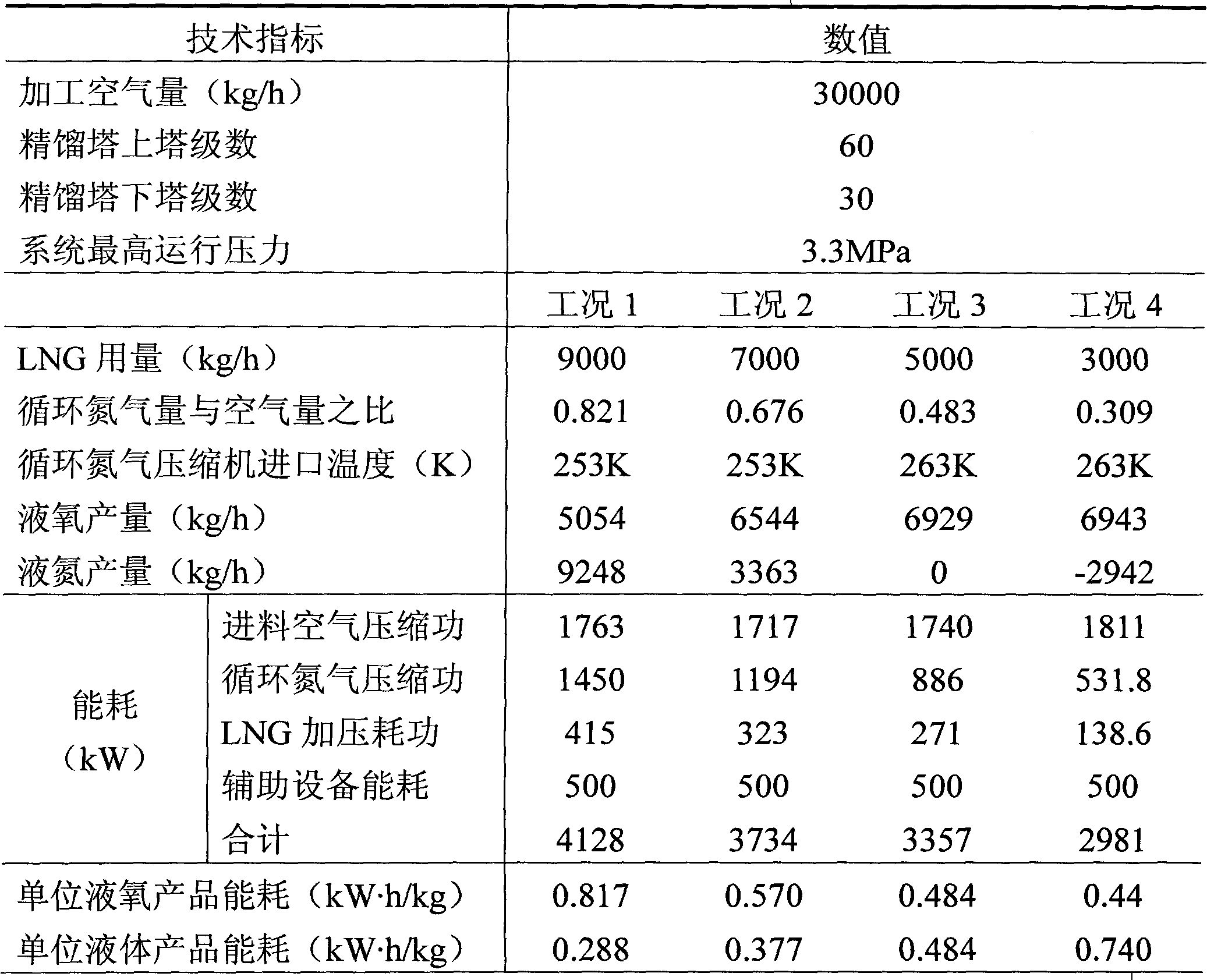

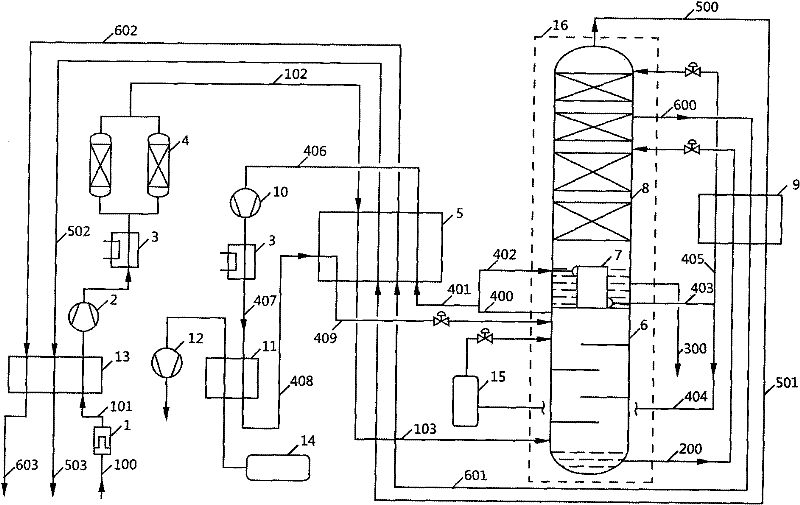

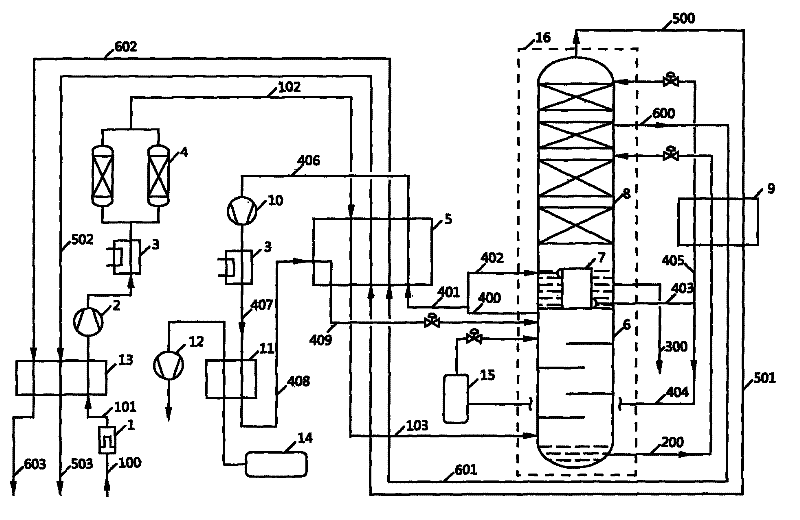

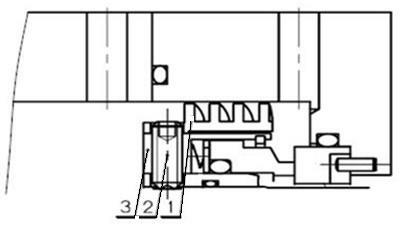

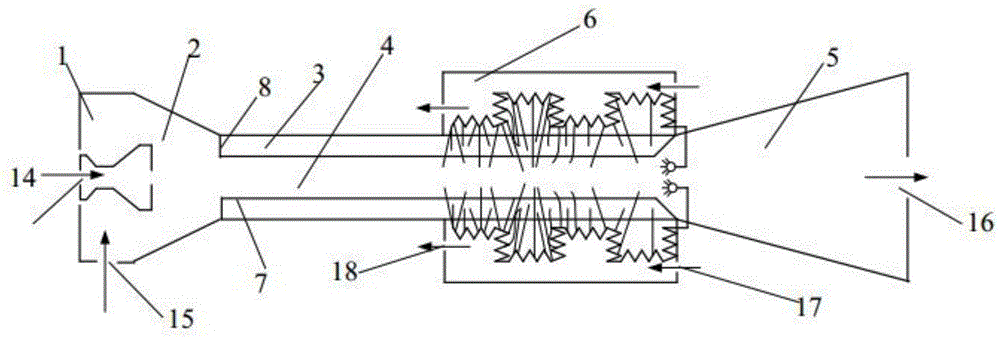

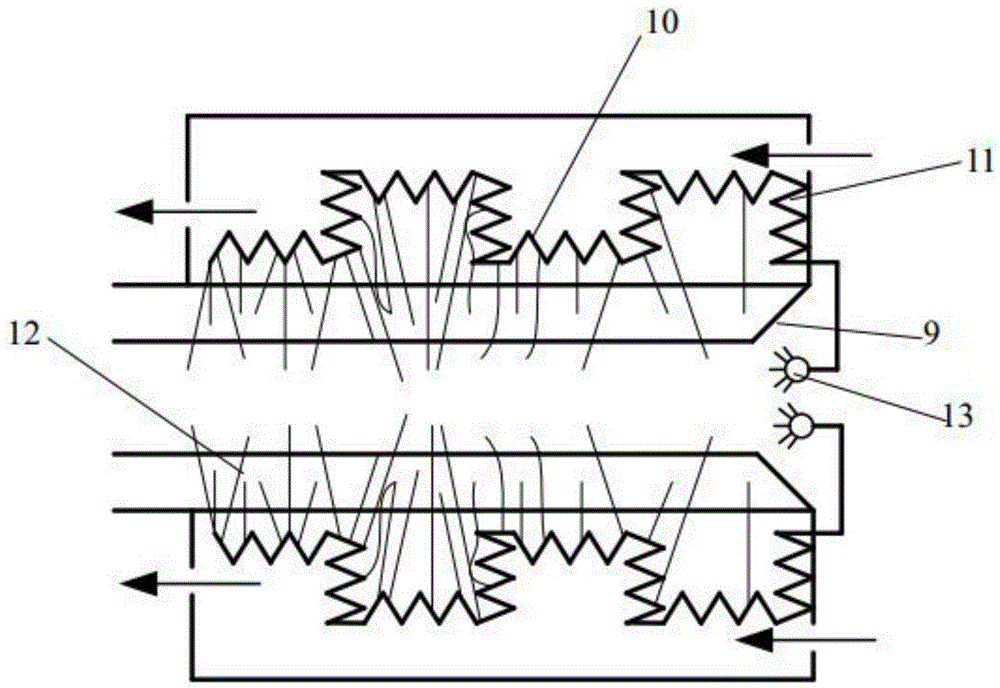

Backward flow type air separation system and method based on cold energy utilization of LNG (Liquefied Natural Gas) satellite station

InactiveCN101839612AAvoid low temperature compression problemsReduce the temperatureSolidificationLiquefactionTO-263Engineering

The invention discloses backward flow type air separation system and method based on the cold energy utilization of an LNG (Liquefied Natural Gas) satellite station. The invention adapts to the fluctuation of LNG dosage by adjusting the amount of cycled nitrogen, and complements the refrigerating output requirements required by the system simultaneously during the deficiency of the refrigerating output of the LNG by utilizing the method of flowing liquid nitrogen backwards. A nitrogen external circulation system is eliminated after the LNG cold energy is introduced in the air separation process, and the equipment of a nitrogen turbo-expander and a Freon refrigeration unit is omitted so that the process is simplified. The temperature of the circulation nitrogen at the outlet of a main heat exchanger is increased to 253 to 263 K from traditional 100 k around, and the problem of low temperature compression of the circulation nitrogen in the traditional system is avoided. The temperature of other flows of fluid of the main heat exchanger for cooling feeding air is reduced due to the increased temperature of the outlet of the circulation nitrogen, and the rest cold energy exchanges heat with the feeding air in front of a compressor and is exhausted after the temperature recovers to the room temperature, therefore, the temperature of the feeding air is further reduced to 273 to 280 K, and the energy consumption of the air compressor is saved.

Owner:ZHEJIANG UNIV

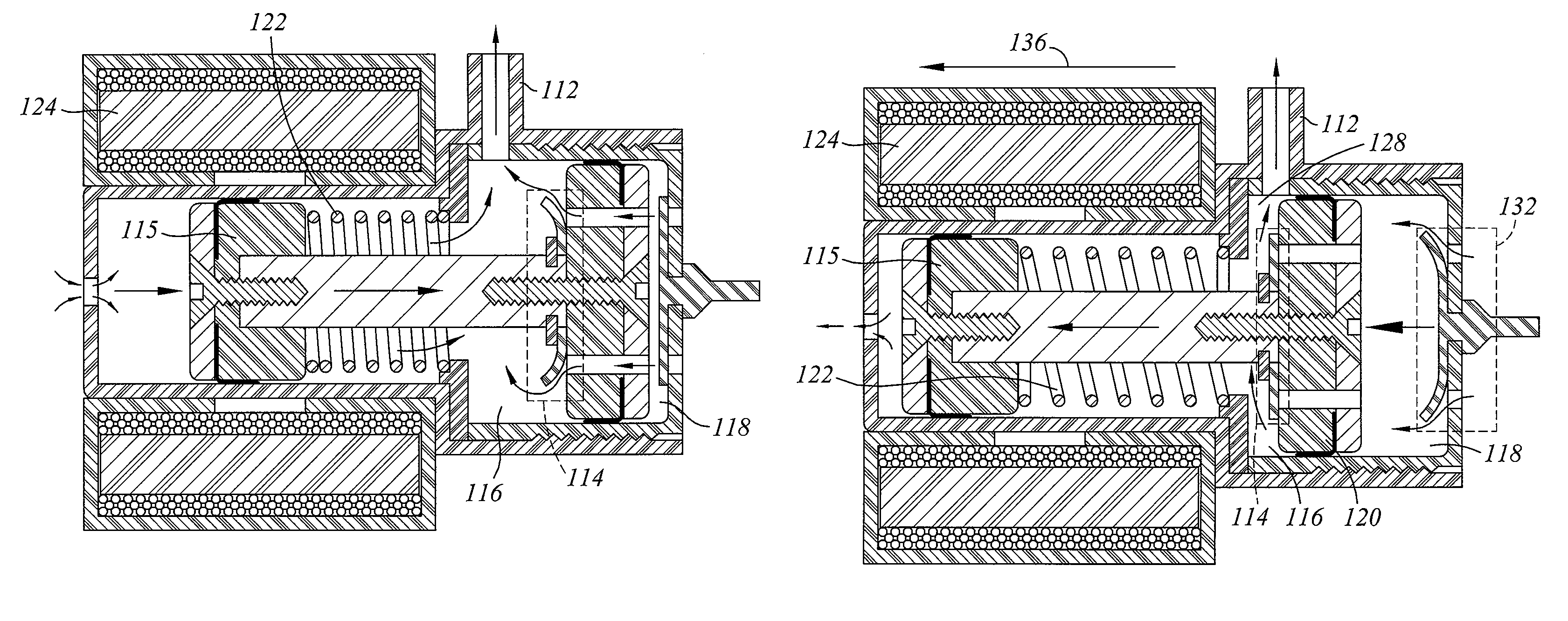

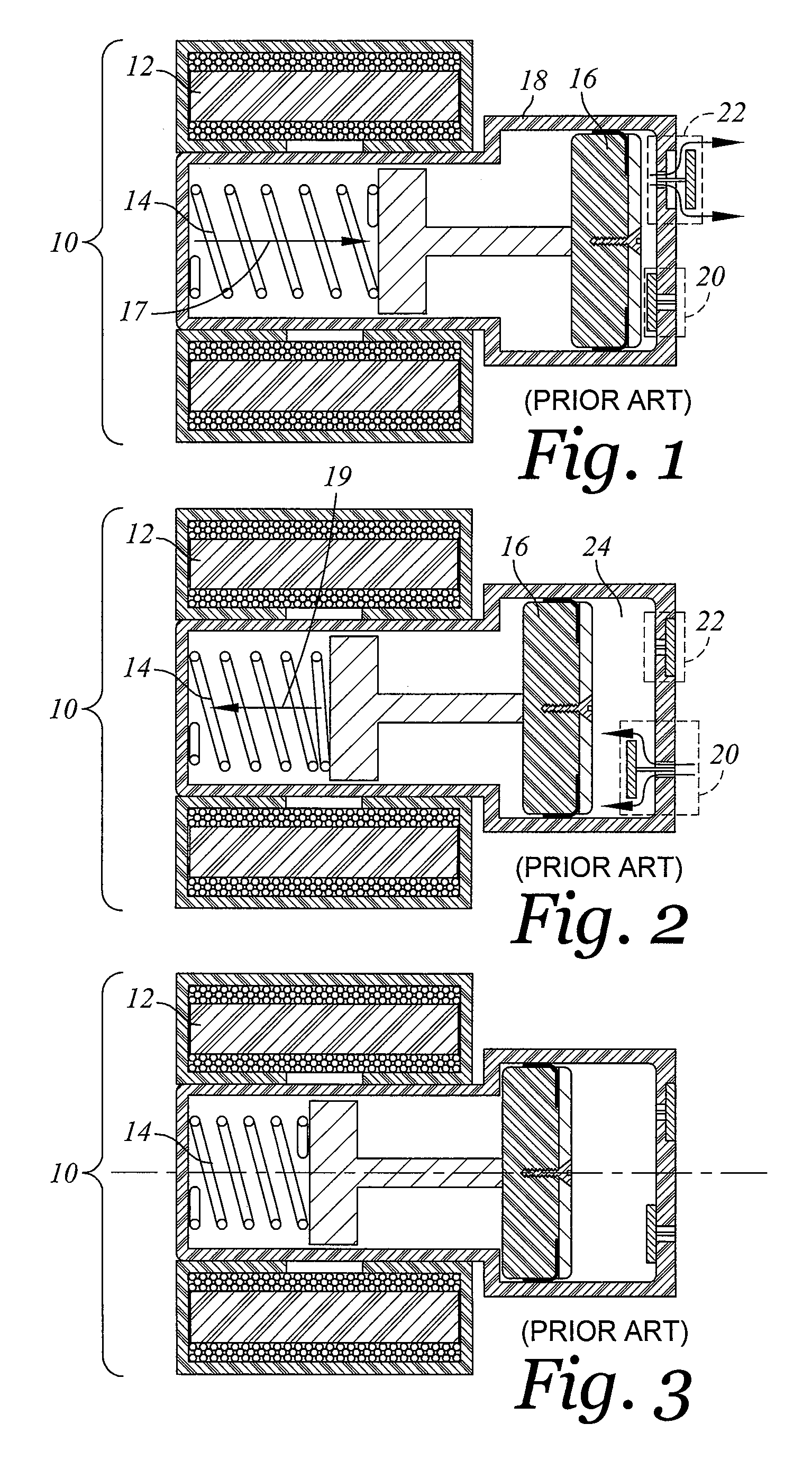

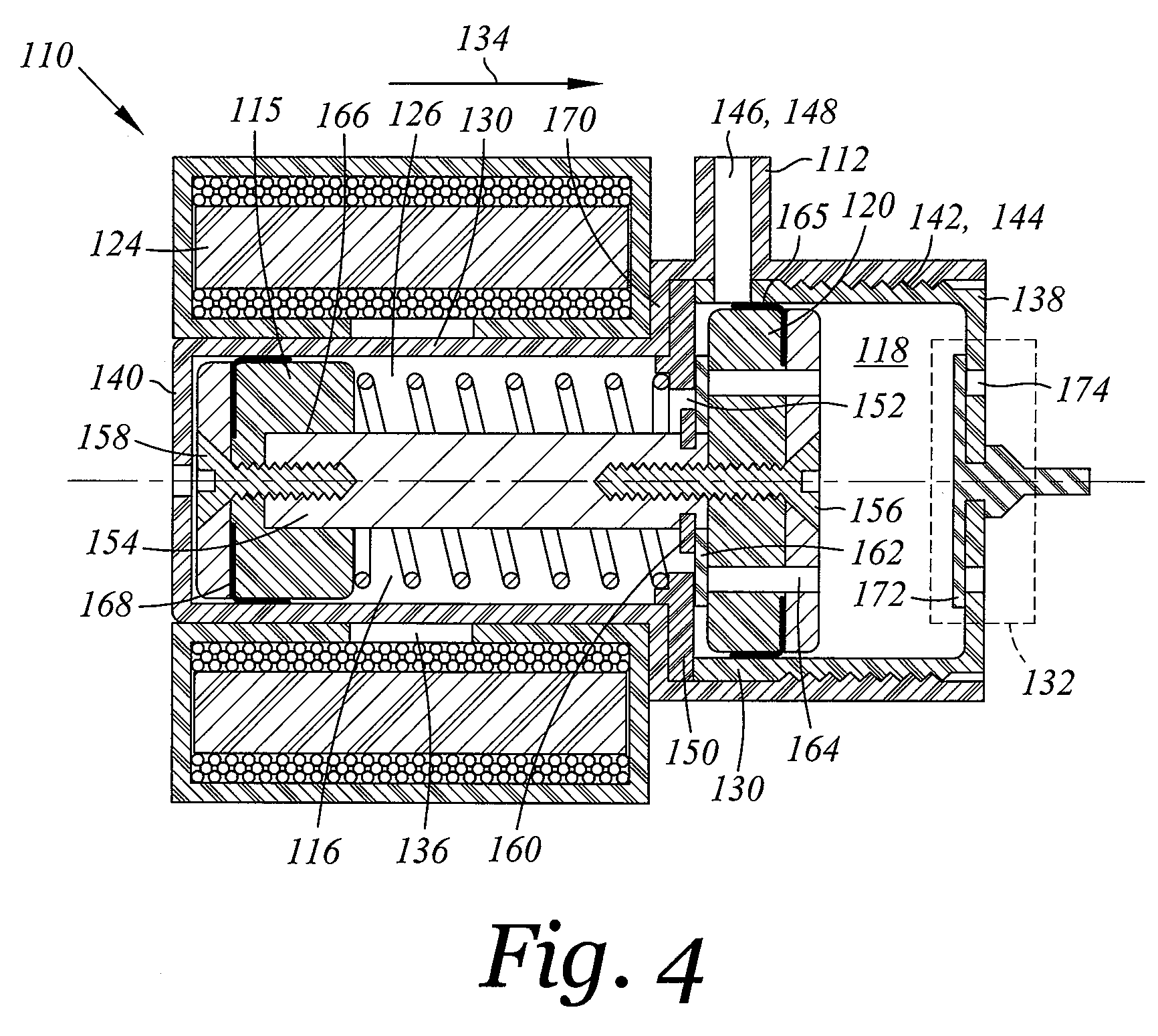

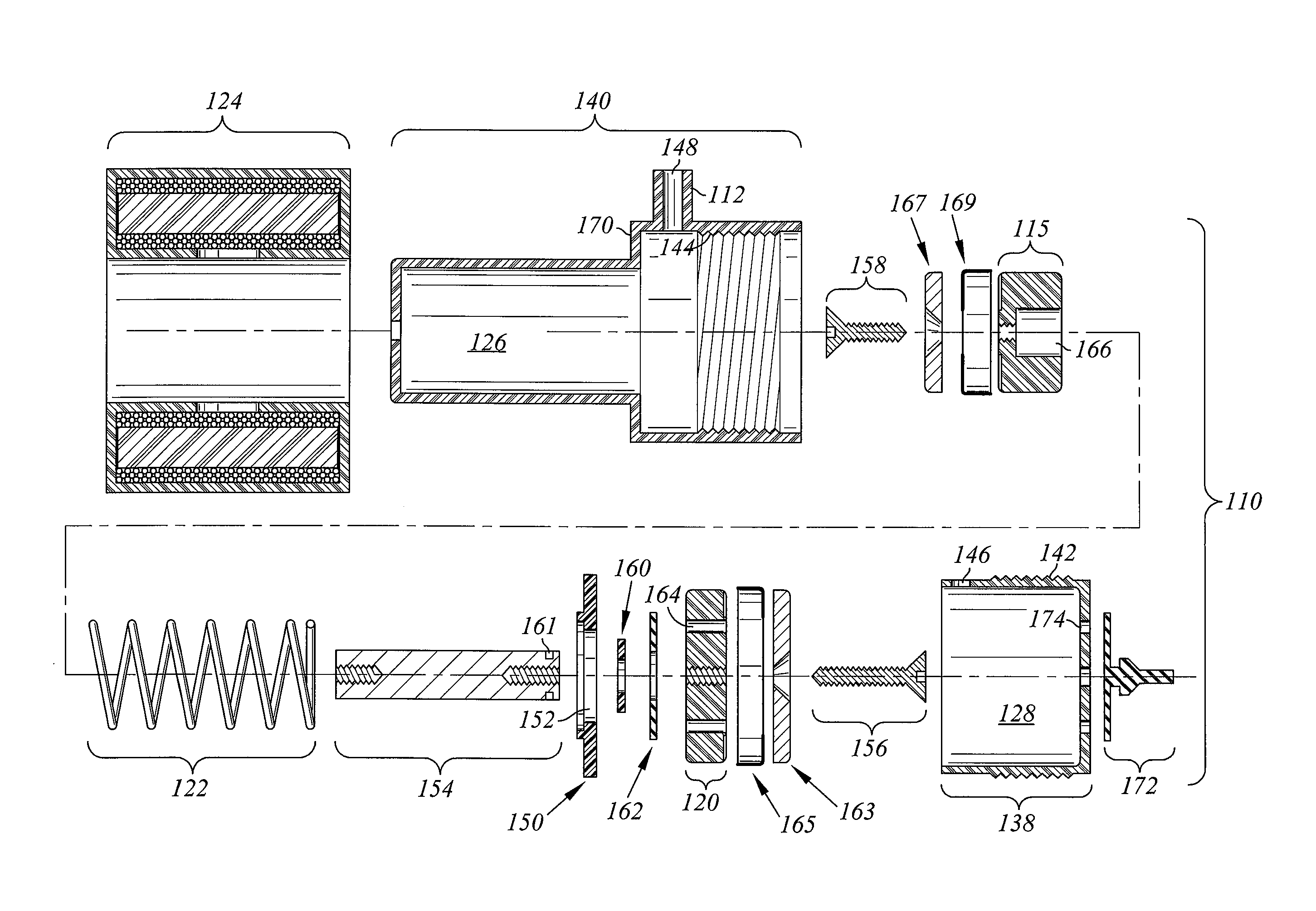

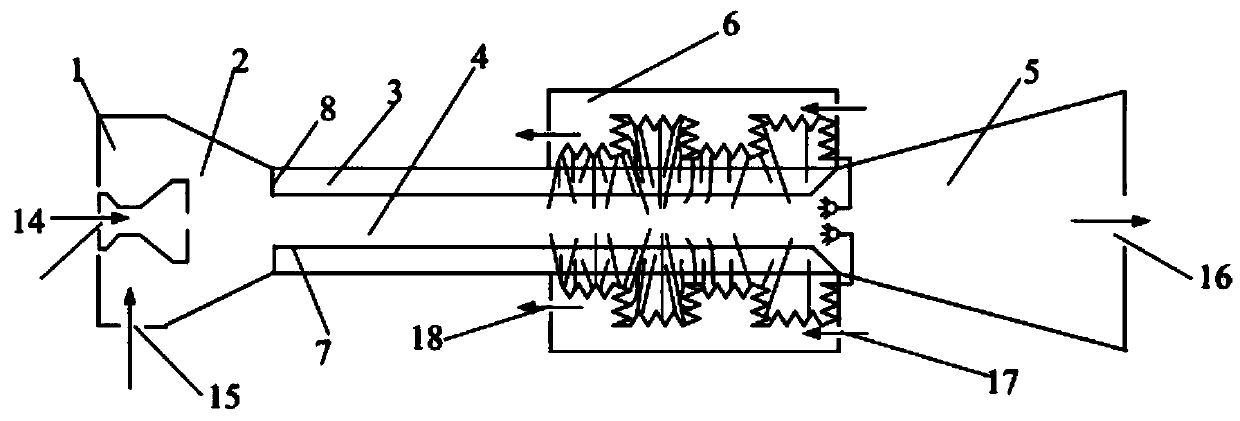

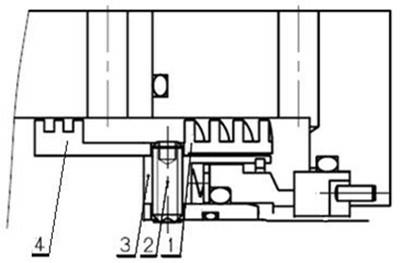

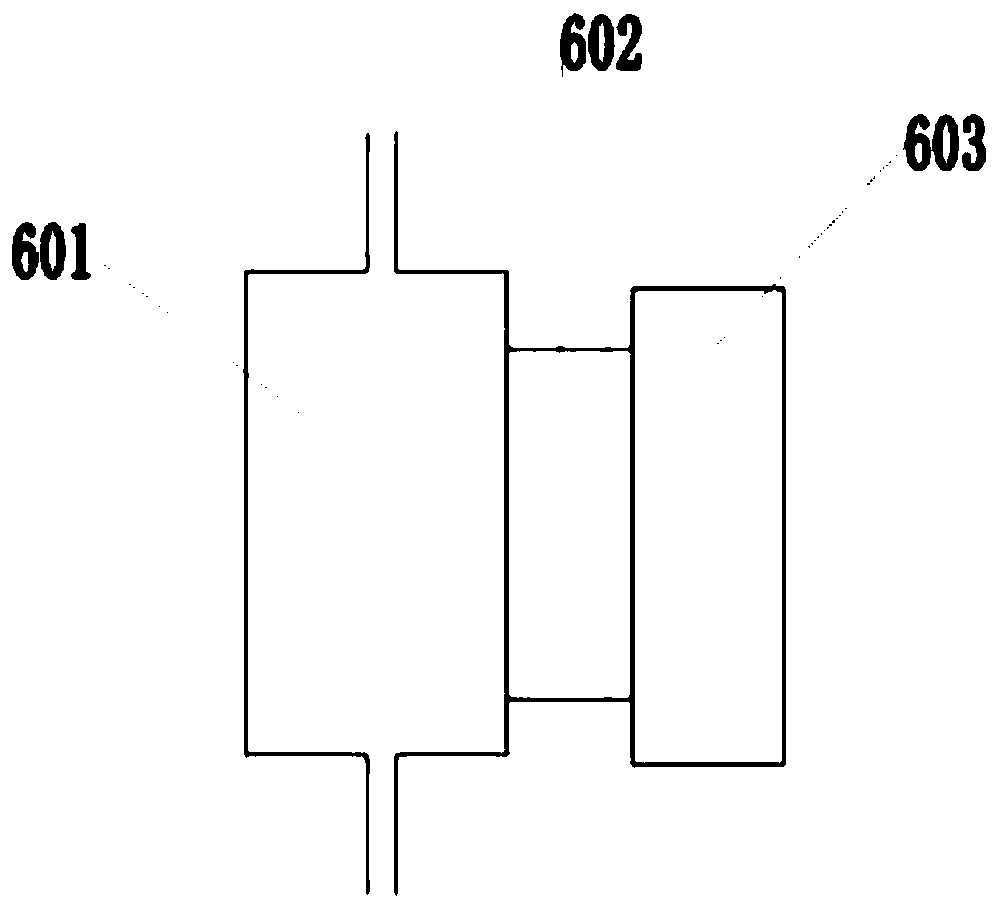

Double acting fluid pump

ActiveUS8550794B2Small volumeIncrease volumePositive displacement pump componentsServomotor componentsMechanical engineeringDouble acting

A double acting dual stroke fluid pump with pressure assists is disclosed. First and second pistons are mounted to a common shaft which reciprocates within first and second cavities during compression and suction strokes. The second piston may have a one way valve which opens and closes during the compression and suction strokes to enable the fluid pump to force fluid out of the outlet during both the compression and suction strokes.

Owner:PROVIDENCE ENTERPRISE LTD

Double Acting Fluid Pump

ActiveUS20120034119A1Small volumeIncrease volumePositive displacement pump componentsServomotor componentsReciprocating motionEngineering

A double acting dual stroke fluid pump with pressure assists is disclosed. First and second pistons are mounted to a common shaft which reciprocates during compression and suction strokes. During each of the strokes, fluid is pumped out at an outlet. This is accomplished by way of a one-way valve on the second piston. The one-way valve is opened or closed depending on whether the first and second pistons are in the compression or suction strokes. Additionally, pressure from the outlet assists in traversing the first and second pistons in the compression stroke. During the suction stroke, the fluid pressure applies a force on the first piston to counteract the fluid pressure on the second piston so that a smaller spring may be used. The size requirements of the solenoid and spring are reduced. Additionally, the fluid pump provides lower pressure spikes compared to prior art fluid pumps since fluid is pumped out during both the compression and suction strokes and also provides a more even flow of fluid out of the fluid pump.

Owner:PROVIDENCE ENTERPRISE LTD

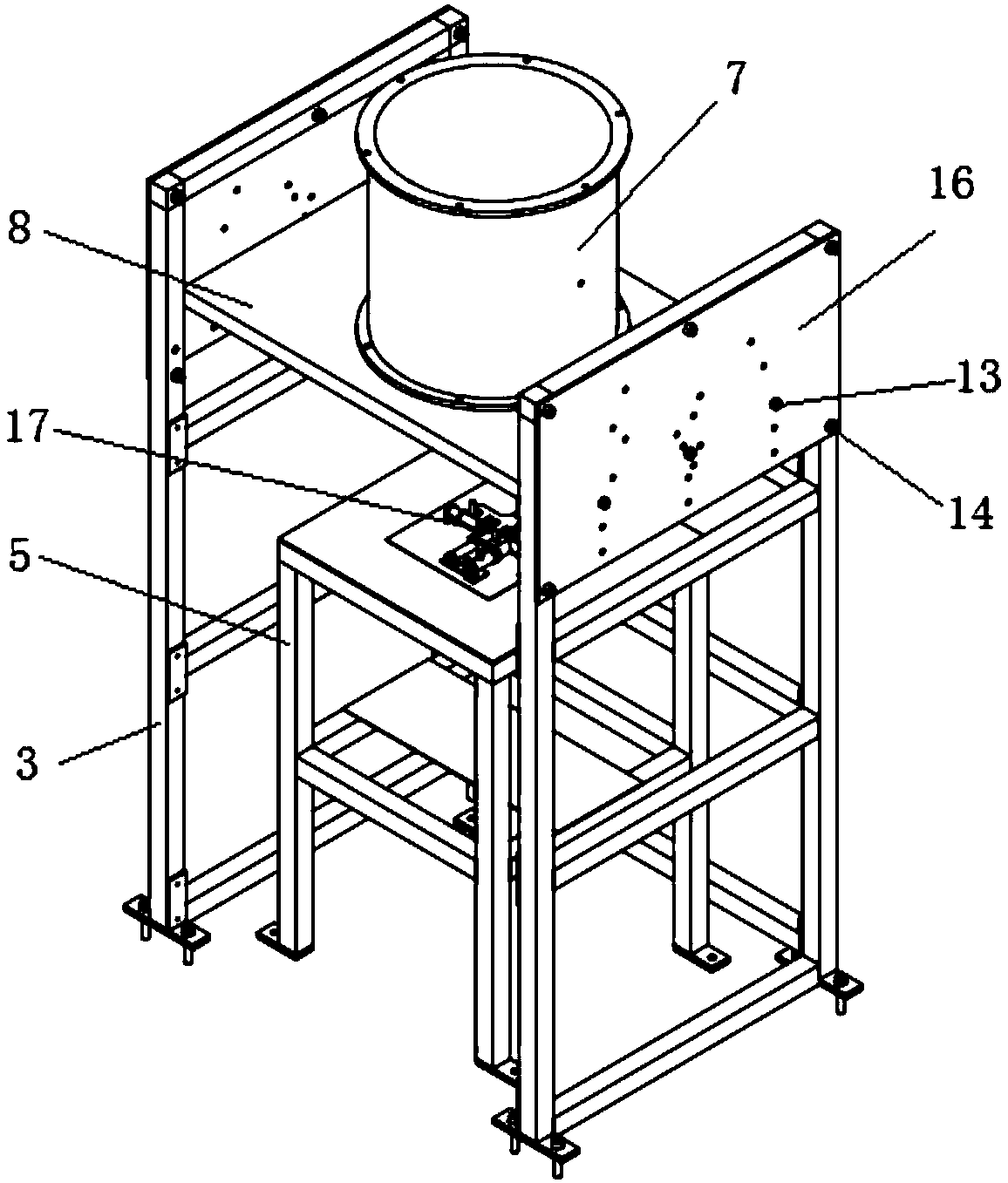

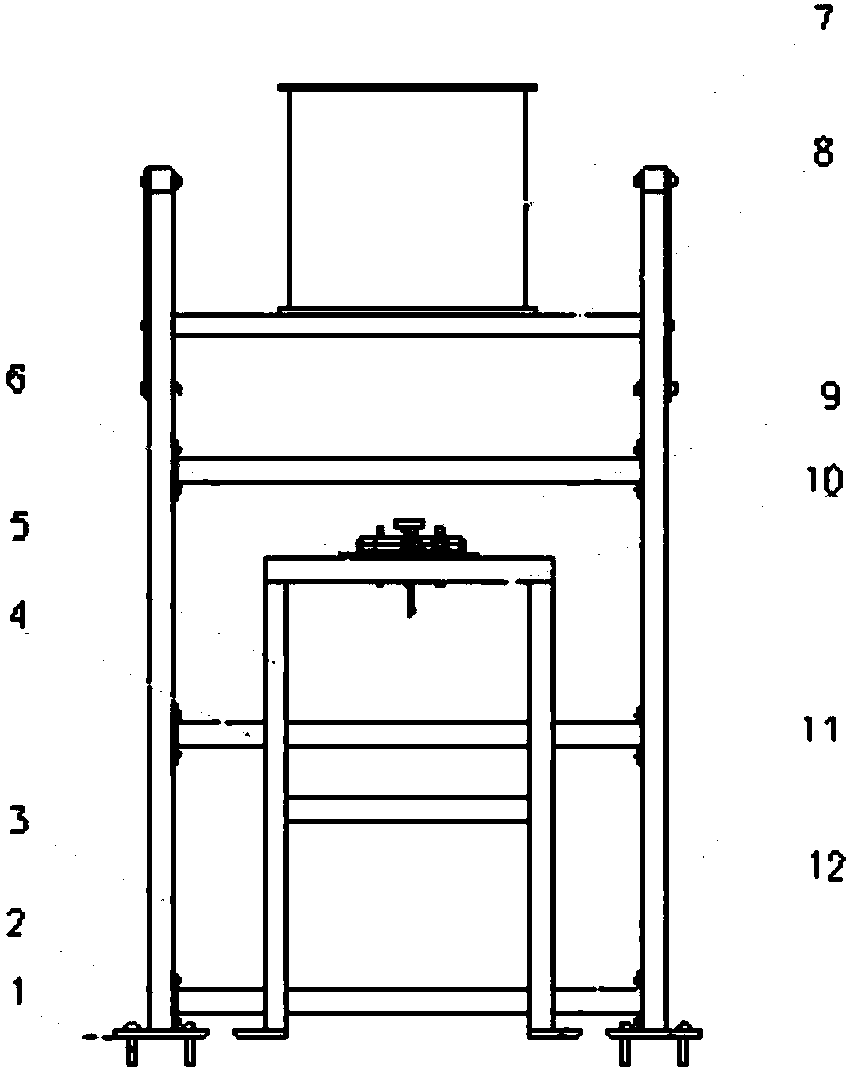

Aluminum alloy pressure casting workpiece multi-medium air cooling device

The invention relates to an aluminum alloy pressure casting workpiece multi-medium air cooling device. An axial flow fan is fixed to a fan supporting plate. The two sides of the fan supporting plate are connected to a multi-station adjustable working panel through a bolt. The multi-station adjustable working panel is fixed to the fan supporting frame through a bolt. The fan supporting plate adjusts the height and the angle of the axial flow fan by changing the connecting position of the bolt and the multi-station adjustable working panel. The upper portion of the axial flow fan communicates with an air pipe of an air cooler, or a nozzle atomizing device is additionally arranged between the axial flow fan and a pressure casting workpiece, and switching of multiple media is achieved. A workpiece table is arranged in the fan supporting frame and located under the axial flow fan. The pressure casting workpiece is fixed to the workpiece table through a locating clamp. The workpiece table isconnected with temperature measuring devices through thermocouple fixing devices. The multiple temperature measuring devices are arranged on the portion, difficult to cool, of the bottom of the pressure casting workpiece, the temperature measuring devices are connected with a thermodetector, the thermodetector transmits measured data to the computer end, and the temperature change situation of the workpiece can be monitored in real time.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Swirl-enhanced aerodynamic fastener shield for turbomachine

ActiveUS20060056957A1Minimize temperature riseAerodynamic effectEngine sealsPump componentsTurbineEngine mount

A fastener shield for use in a fluid flow path within a gas turbine engine for reducing fluid drag and heating generated by fluid flow over a plurality of circumferentially spaced bolts. The fastener shield has a radially-extending, downstream-facing mounting flange with a plurality of circumferentially spaced bolt holes positioned to receive respective engine mounting bolts therethrough and to attach the mounting flange to elements of the turbine engine. A curved, upstream-facing fastener shield cover is positioned in spaced-apart relation to the mounting flange for at least partially covering and separating an exposed, upstream-facing portion of the bolts from the fluid flow to thereby reduce drag and consequent heating of the bolts. A plurality of closely spaced-apart, spirally-oriented channels are formed in the fastener shield cover for deflecting the fluid flow impinging on the fastener shield cover, thereby increasing the tangential velocity and lowering the relative temperature of the fluid flow.

Owner:GENERAL ELECTRIC CO

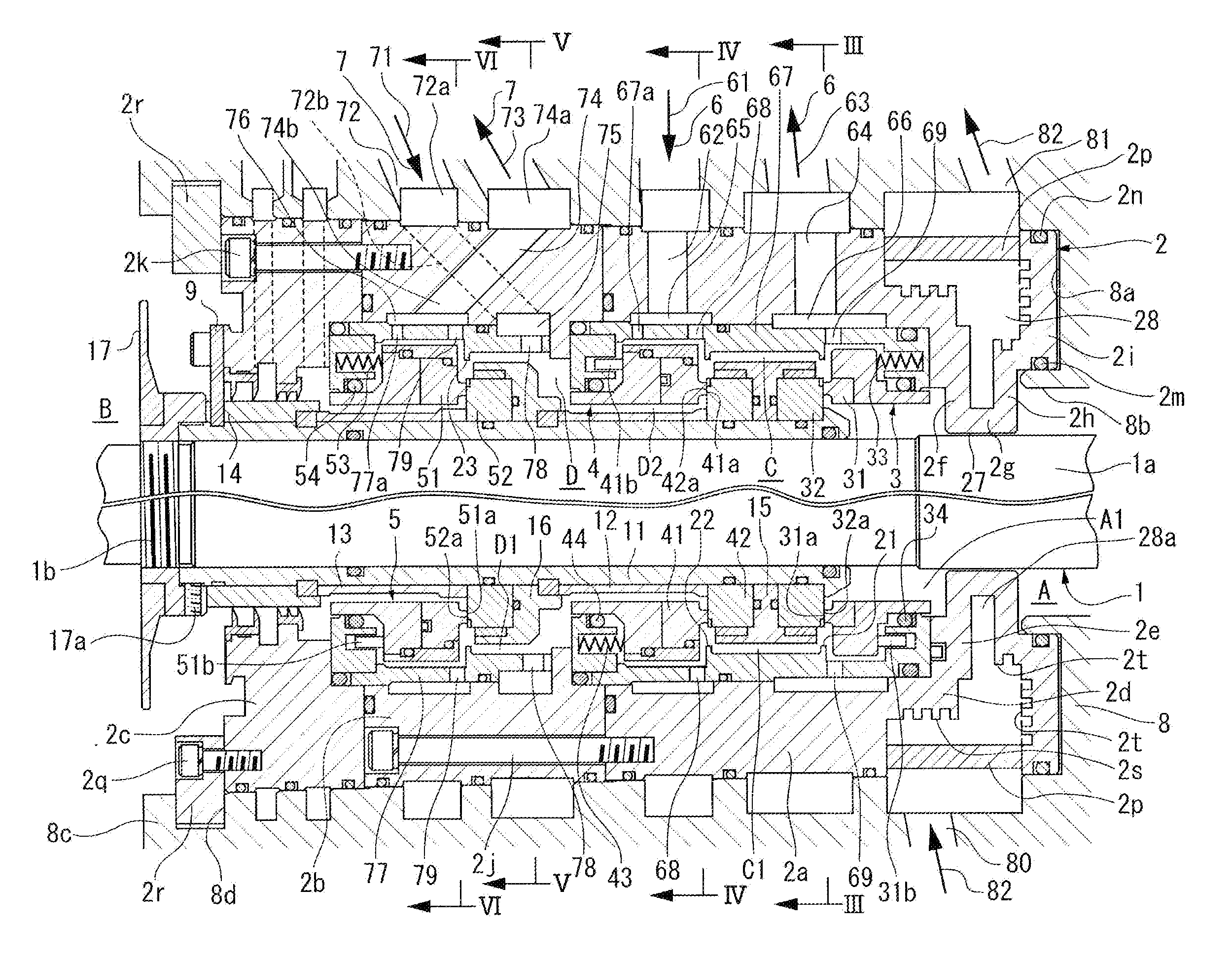

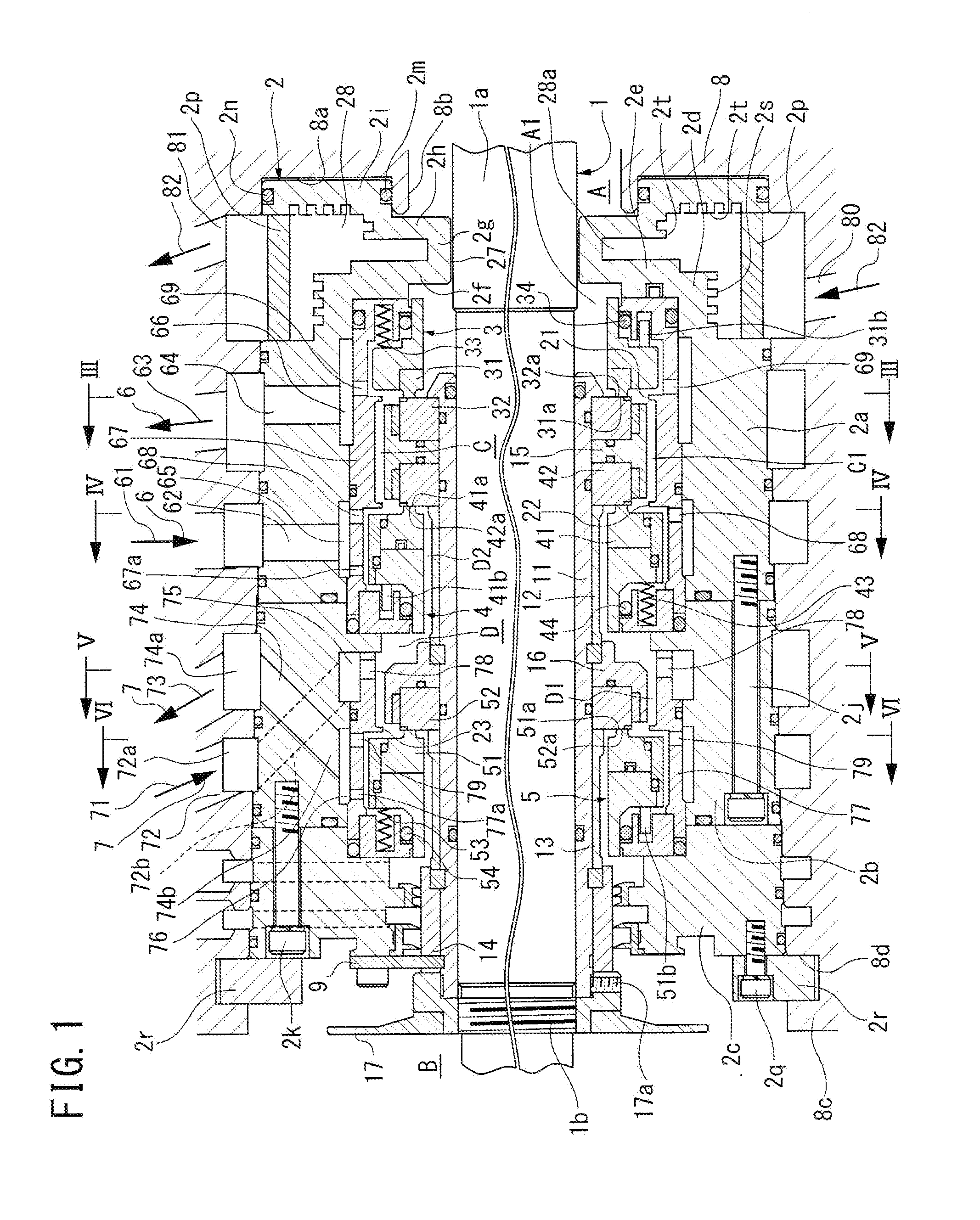

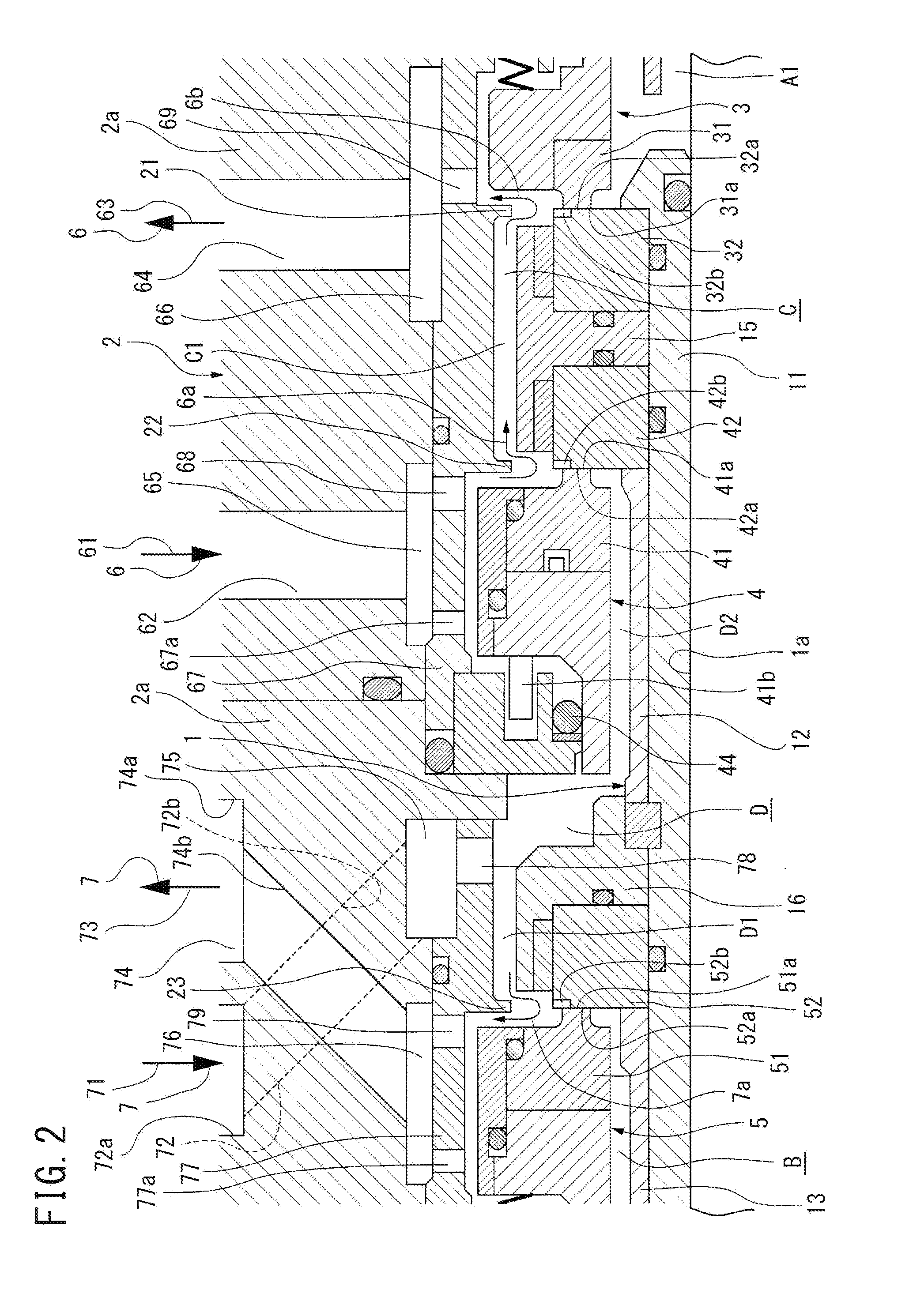

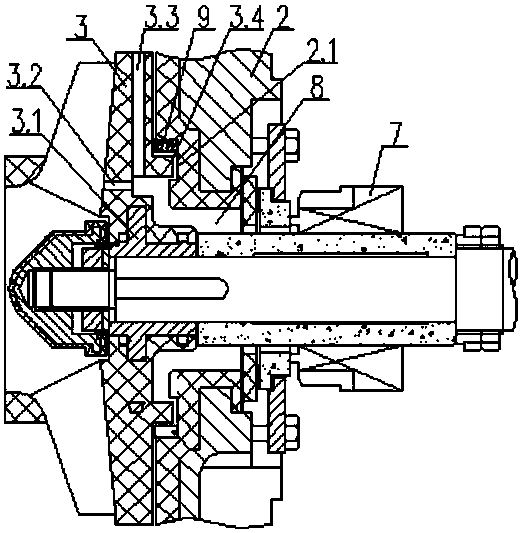

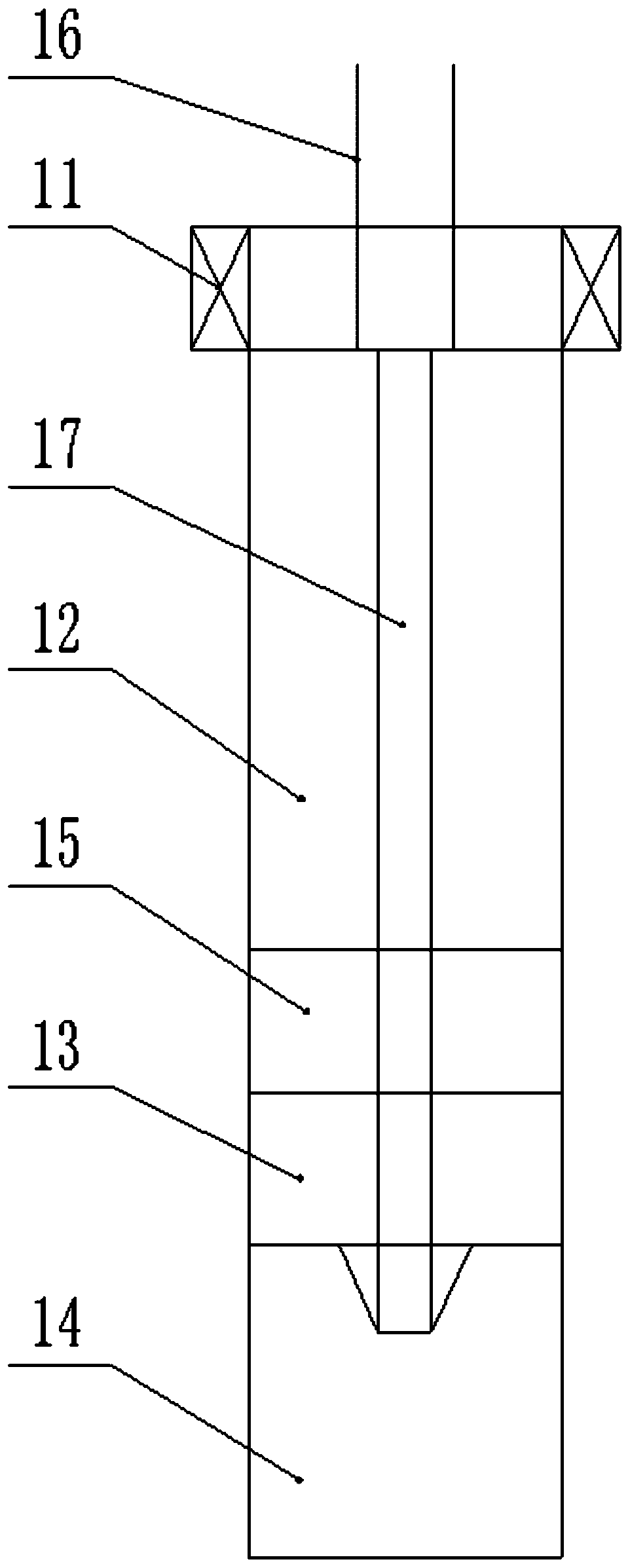

Shaft-seal device for high-temperature fluid

InactiveUS8770589B2Improve sealing functionImprove cooling effectEngine sealsCooling chamberEngineering

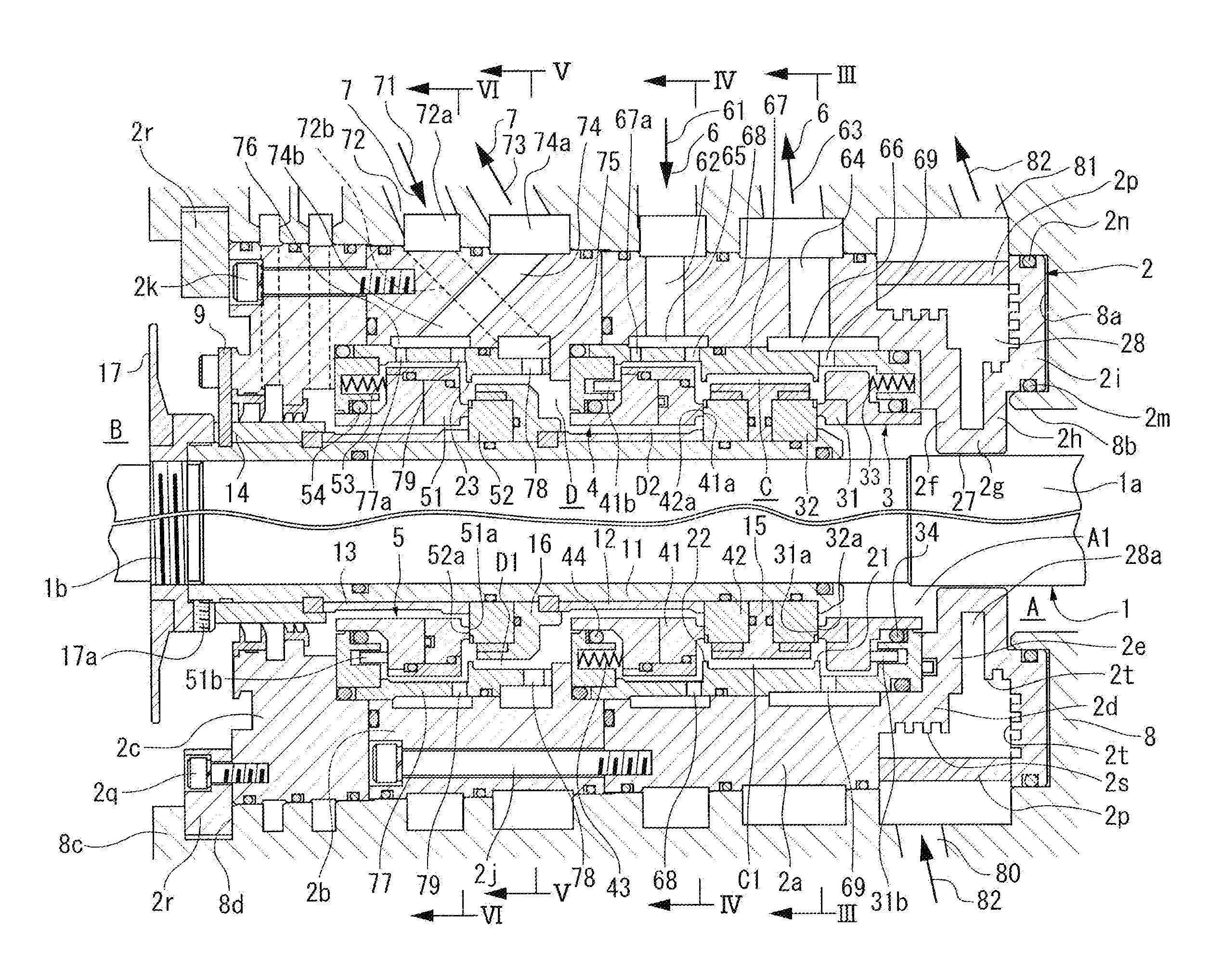

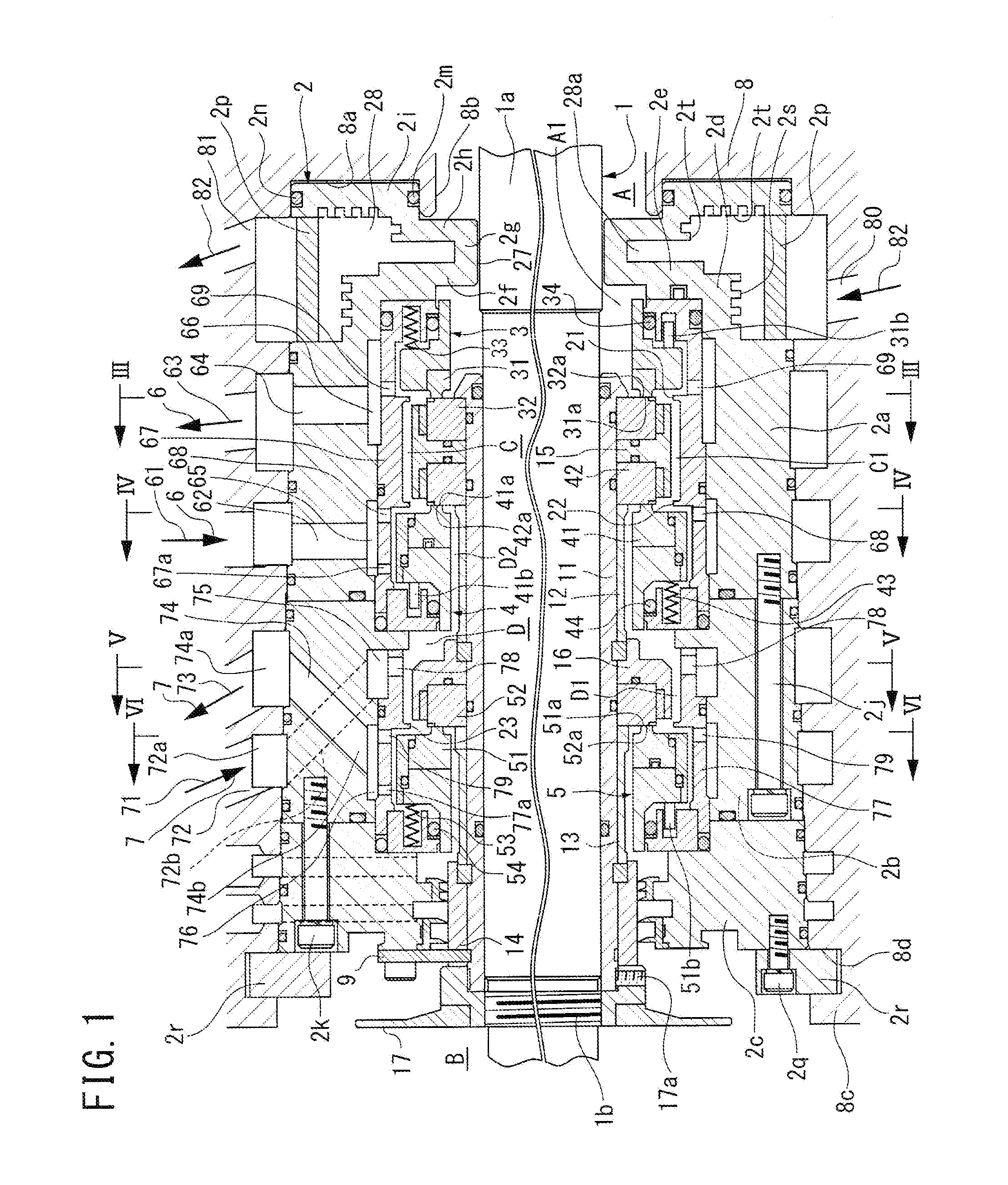

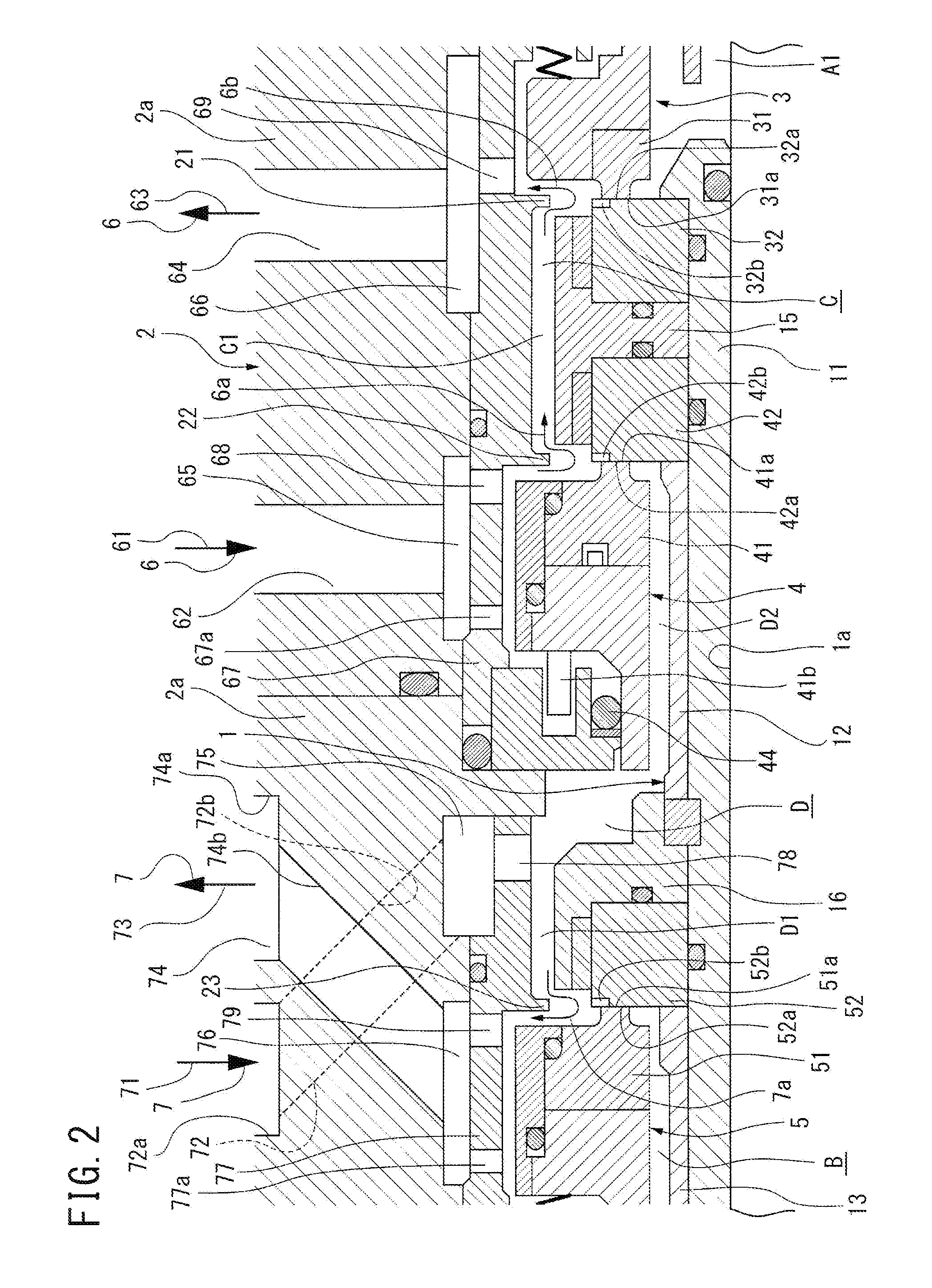

A shaft-seal device for high-temperature fluid including a seal case (2) formed as a metallic cylindrical structure of a single unit and comprised of a main body portion (2a, 2b, 2c), first and second holding portions (2d, 2e), first and second partition portions (2f, 2h), a channel formation portion (2g) forming a minute annular channel (27) with the outer circumference surface of a rotary shaft (1), and an o-ring holding portion (2i). The seal case is installed in an apparatus housing (8) with first and second o-rings (2m, 2n) in between. The intra-seal case region (A1), in which sealing rings (31, 32, 41, 42, 51, 52) of mechanical seals (3, 4, 5) are provided, and the high-temperature fluid region, which is an intra-apparatus housing region (A), are partitioned by a cooling chamber (28) into and from which coolant (82) is supplied and discharged via feed / discharge coolant paths (80, 81).

Owner:NIPPON PILLAR PACKING CO LTD +1

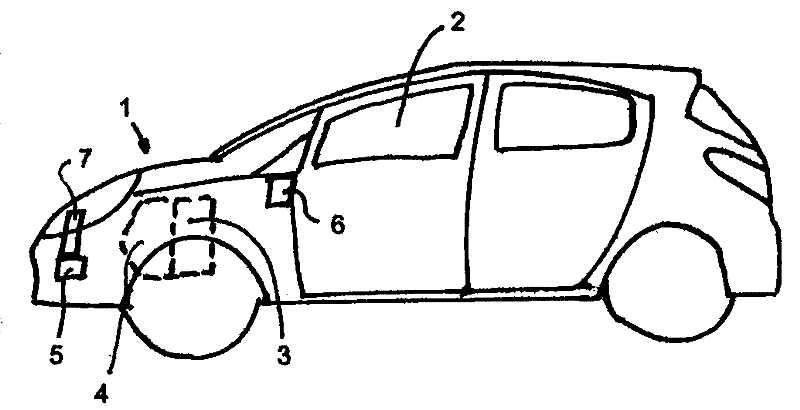

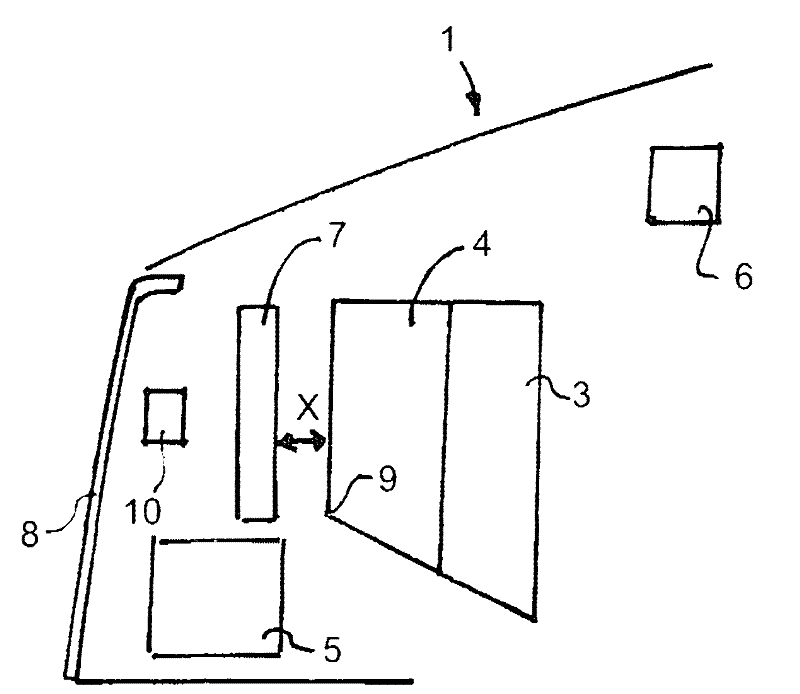

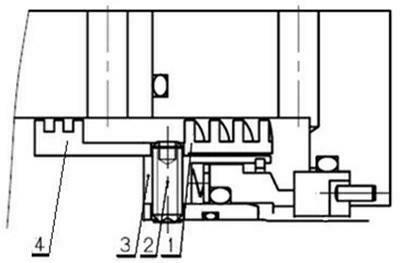

Front-end structure for a motor vehicle

InactiveCN102205790ACompact structureEfficient use ofAir-treating devicesVehicle heating/cooling devicesExternal combustion engineEngineering

A front structure 1 for a motor vehicle includes a radiator 5 of an internal combustion engine 4 and a condenser 7 of an air conditioning system 6 arranged vertically on top of each other. The radiator 5 is substantially square shaped and is located below an edge 9 of the internal-combustion engine 4, pointing in driving direction. The front end structure 1 has a low weight and a low centre of gravity. A mutual influence between the radiator 5 and the condenser 7 is avoided.

Owner:GM GLOBAL TECH OPERATIONS LLC

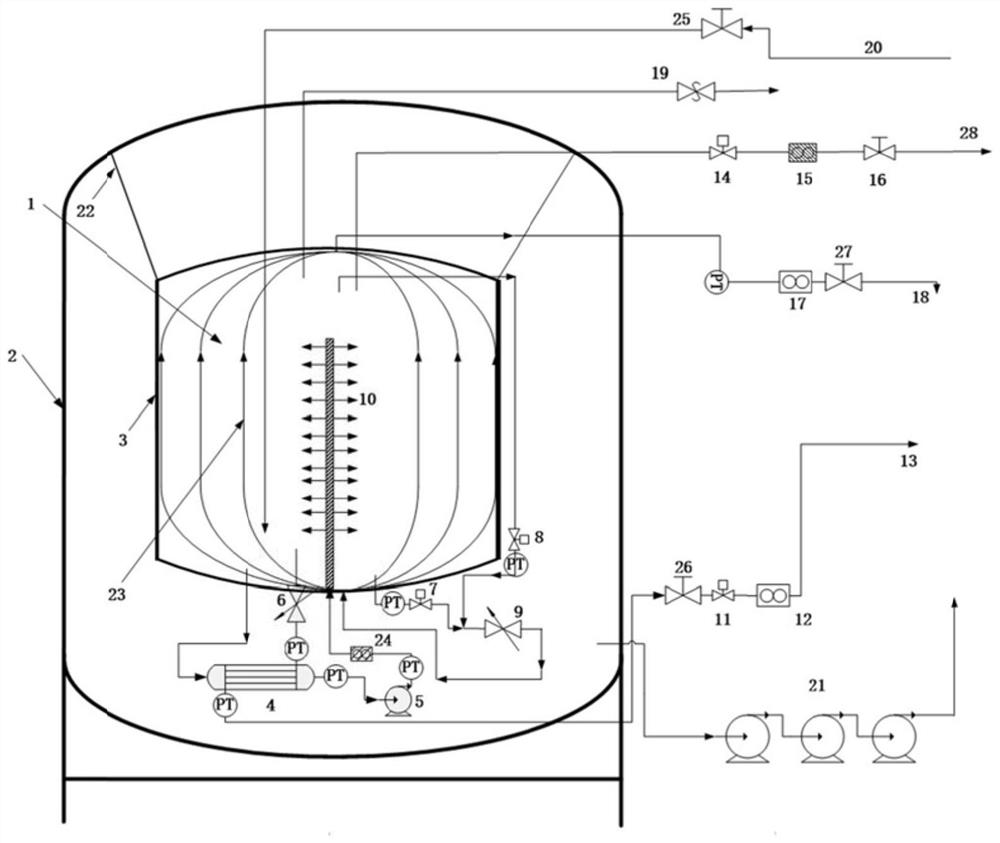

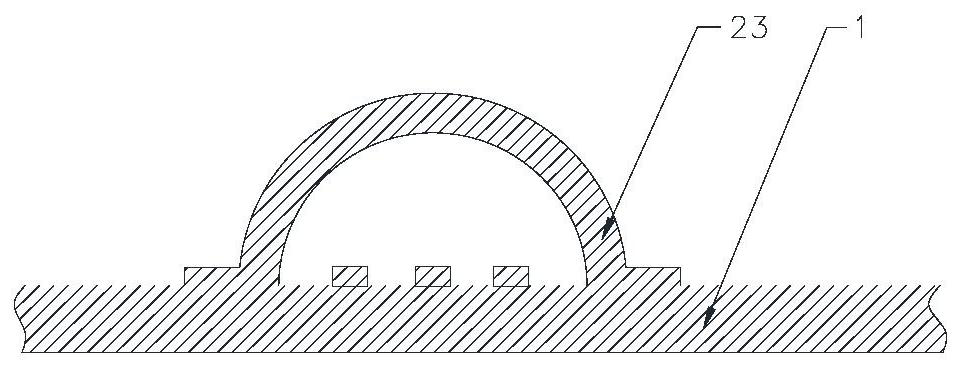

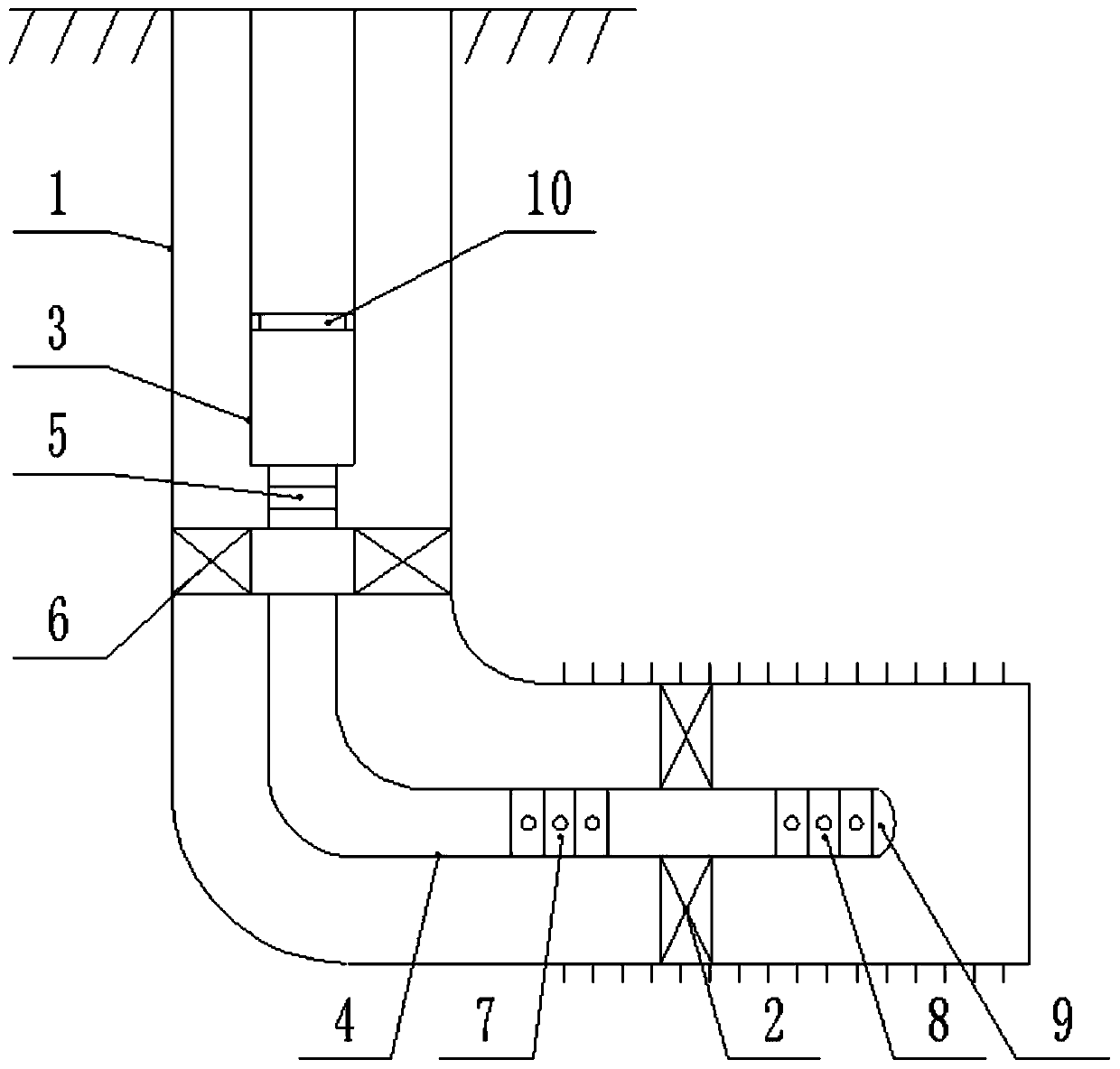

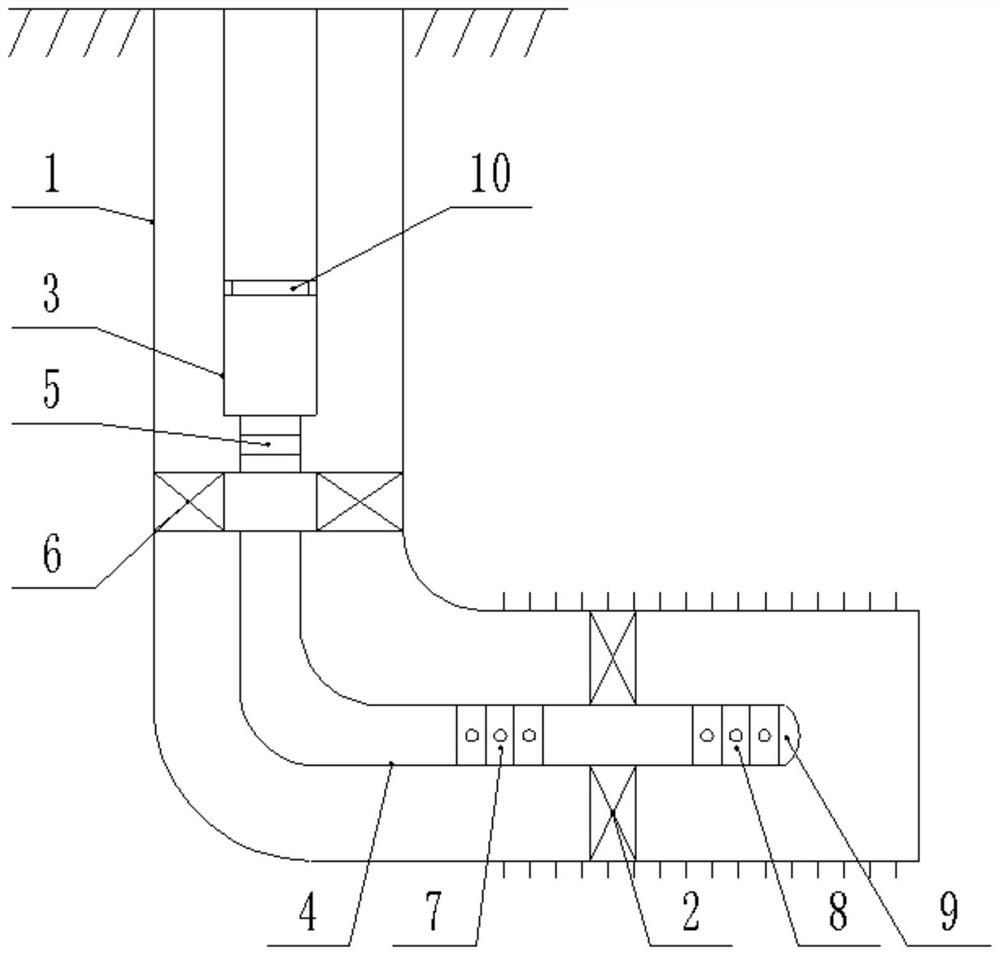

Ground integration test device and method for cryogenic propellant thermodynamic exhaust system

ActiveCN112550779AImprove stabilitySimple structureCosmonautic condition simulationsEngineeringPumping vacuum

The invention provides a cryogenic propellant thermodynamic exhaust system ground integration test device and method, the cryogenic propellant thermodynamic exhaust system ground integration test device comprises a storage tank (1), a vacuum container (2), an active thermodynamic exhaust system and a passive thermodynamic exhaust system, the storage tank (1) is located in the vacuum container (2)and is fixedly connected with the inner wall of the vacuum container (2); an interlayer between the storage tank (1) and the vacuum container (2) is vacuumized through a vacuum unit (21) to simulate the outer space environment. According to the ground integration test device and method, various exhaust schemes and combinations thereof can be tested, most test structural parts in each scheme are arranged outside the storage tank, maintenance is convenient, and the design reliability is improved; structural parts such as a jet mixing device arranged in the storage tank are simple in structure and high in stability.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Shaft-Seal Device for High-Temperature Fluid

InactiveUS20120326394A1Improve mechanical seal performanceImprove sealing functionEngine sealsCooling chamberEngineering

A shaft-seal device for high-temperature fluid including a seal case (2) formed as a metallic cylindrical structure of a single unit and comprised of a main body portion (2a, 2b, 2c), first and second holding portions (2d, 2e), first and second partition portions (2f, 2h), a channel formation portion (2g) forming a minute annular channel (27) with the outer circumference surface of a rotary shaft (1), and an o-ring holding portion (2i). The seal case is installed in an apparatus housing (8) with first and second o-rings (2m, 2n) in between. The intra-seal case region (A1), in which sealing rings (31, 32, 41, 42, 51, 52) of mechanical seals (3, 4, 5) are provided, and the high-temperature fluid region, which is an intra-apparatus housing region (A), are partitioned by a cooling chamber (28) into and from which coolant (82) is supplied and discharged via feed / discharge coolant paths (80, 81).

Owner:NIPPON PILLAR PACKING CO LTD +1

Condensation ejector

ActiveCN104190572ARelieve pressureReduce the temperatureLiquid spraying apparatusEngineeringMixing chamber

The invention discloses a condensation ejector which comprises an accepting chamber, a throat chamber, a mixing chamber, a dispersion chamber, a condensing chamber and an atomizing mechanism, wherein the accepting chamber is provided with a first inlet and a second inlet; one end of the throat chamber is communicated with the accepting chamber, and the throat chamber is located on the down stream of the second inlet; one end of the mixing chamber is communicated with the other end of the throat chamber, one end of the dispersion chamber is communicated with the other end of the mixing chamber, and a first outlet is formed in the other end of the dispersion chamber; the condensing chamber is arranged close to the outer side of the down stream of the mixing chamber in a surrounding mode and comprises a third inlet formed in the down stream end of the condensing chamber, a second outlet formed in the upstream of the condensing chamber, a plurality of main condensing pipes and a plurality of branch condensing pipes, one end of each of the condensing pipes extends into the mixing chamber, the extending directions of the branch condensing pipes are different, the other end of each of the branch condensing pipes is communicated with a main condensing pipe, one end of the main condensing pipe is sealed, and the other end of the main condensing pipe is communicated with the dispersion chamber through a fourth inlet in the dispersion chamber; the atomizing mechanism is provided with a plurality of nozzles formed in the position of the fourth inlet, and the atomizing mechanism is used for atomizing fluid in the main condensing pipe and spraying the fluid in the dispersion chamber.

Owner:广西海岛生态投资有限公司

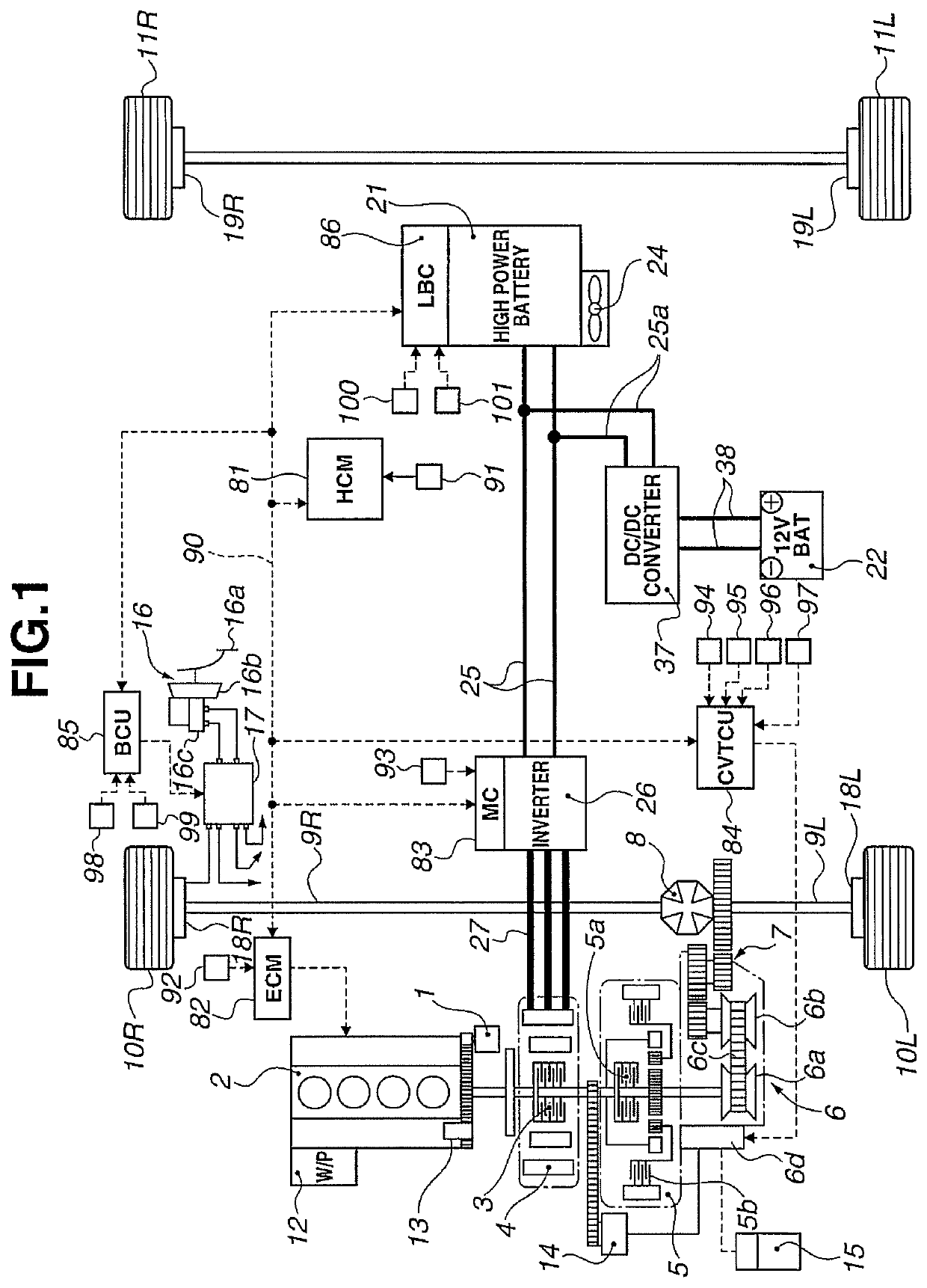

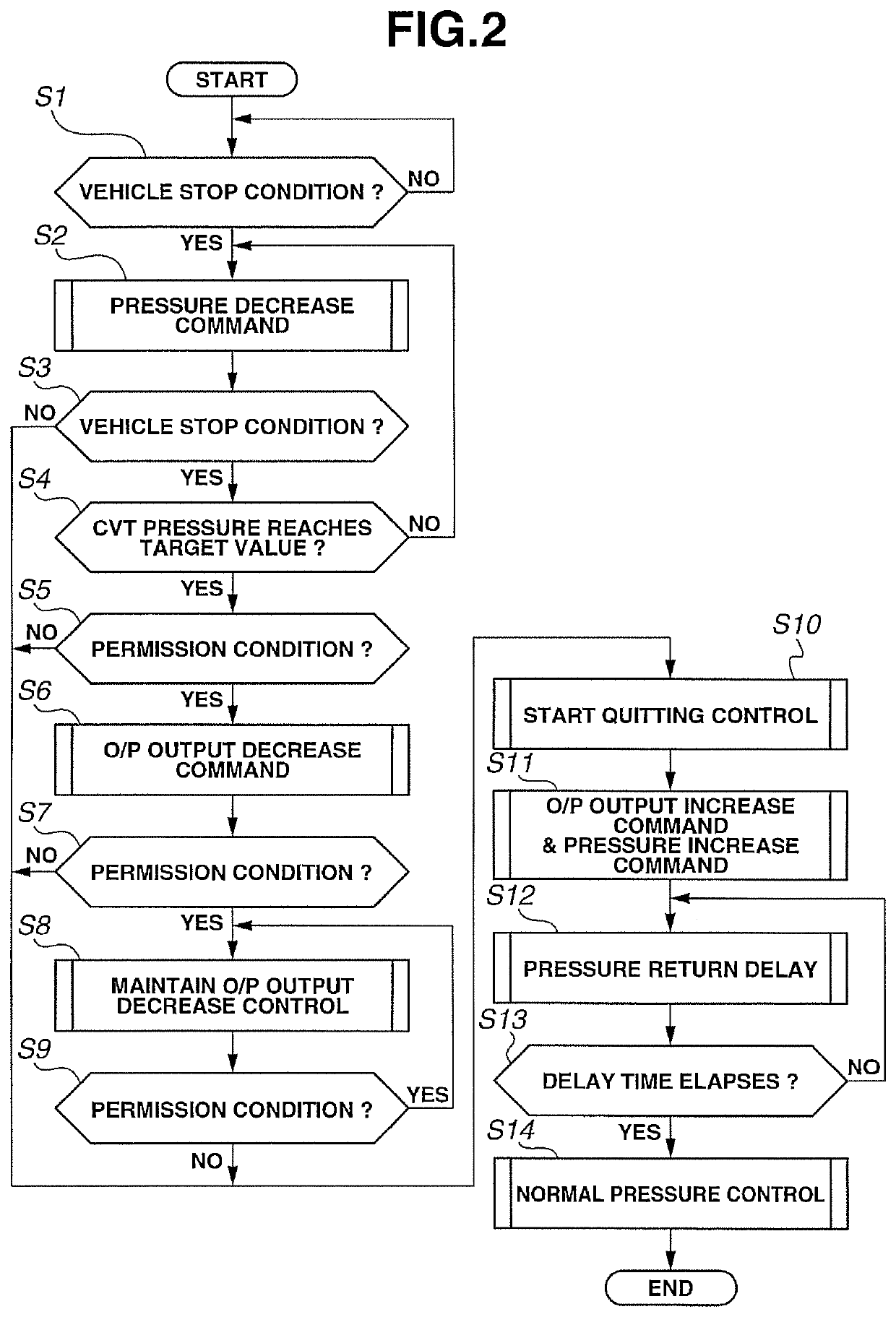

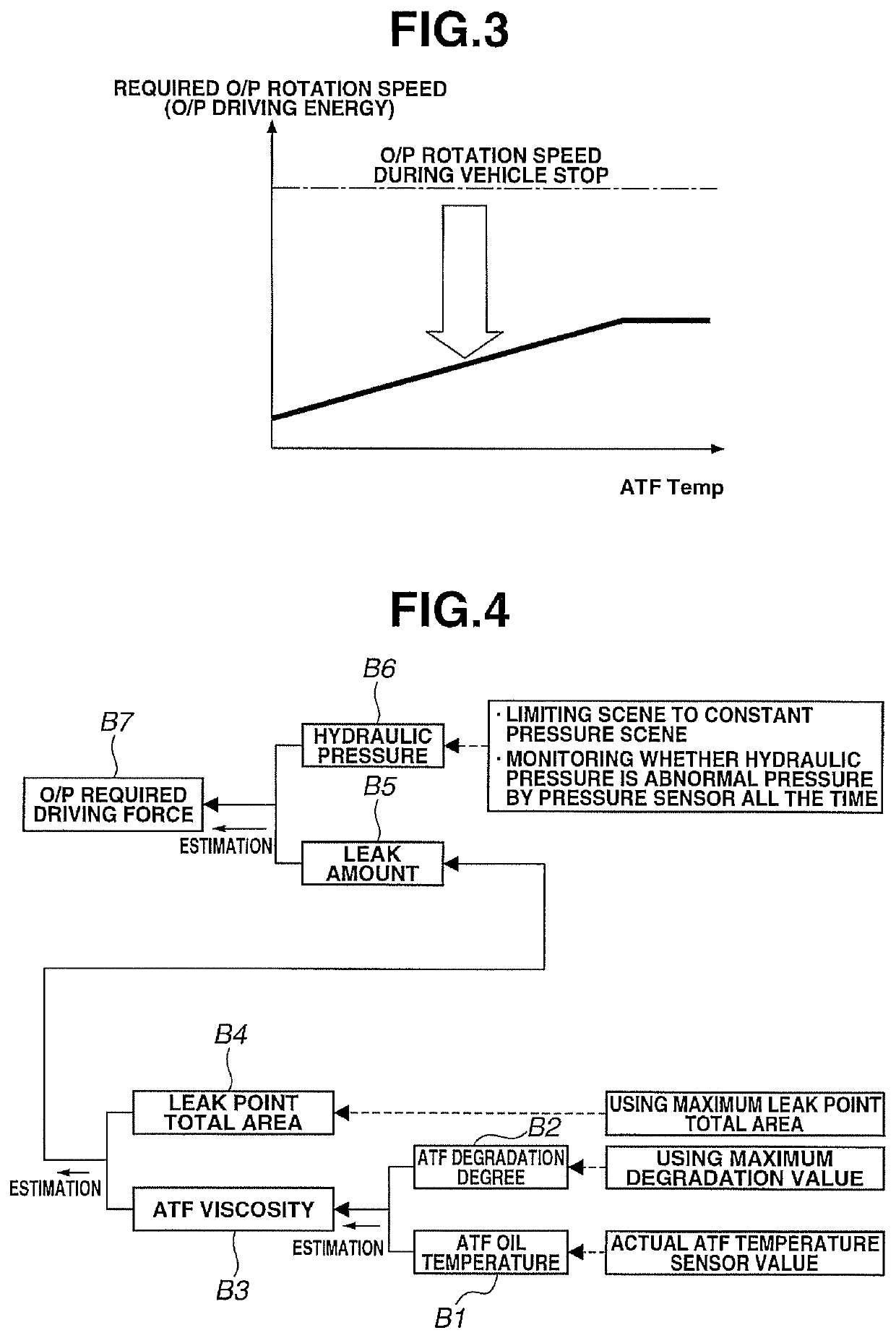

Vehicle oil pump driving control device

ActiveUS10502314B2Reduce consumptionWeaken energyGear lubrication/coolingGearing controlHybrid vehicleOil temperature

An oil pump driving control device of a vehicle having a main oil pump (14) that is driven by a motor / generator (4) and produces a pump discharge oil to a first clutch (3), a second clutch (5) and a belt-type continuously variable transmission (6) provided on a driving force transmission line. A hybrid control module (81) is provided in this FF hybrid vehicle. The hybrid control module (81) is configured to perform a control so that during vehicle stop, the lower an ATF oil temperature is, the more the pump driving energy to drive the main oil pump (14) is decreased. With this control, consumption energy during the vehicle stop can be reduced.

Owner:JATCO LTD

Backward flow type air separation system and method based on cold energy utilization of LNG (Liquefied Natural Gas) satellite station

InactiveCN101839612BAvoid low temperature compression problemsReduce the temperatureSolidificationLiquefactionEngineeringTO-263

Owner:ZHEJIANG UNIV

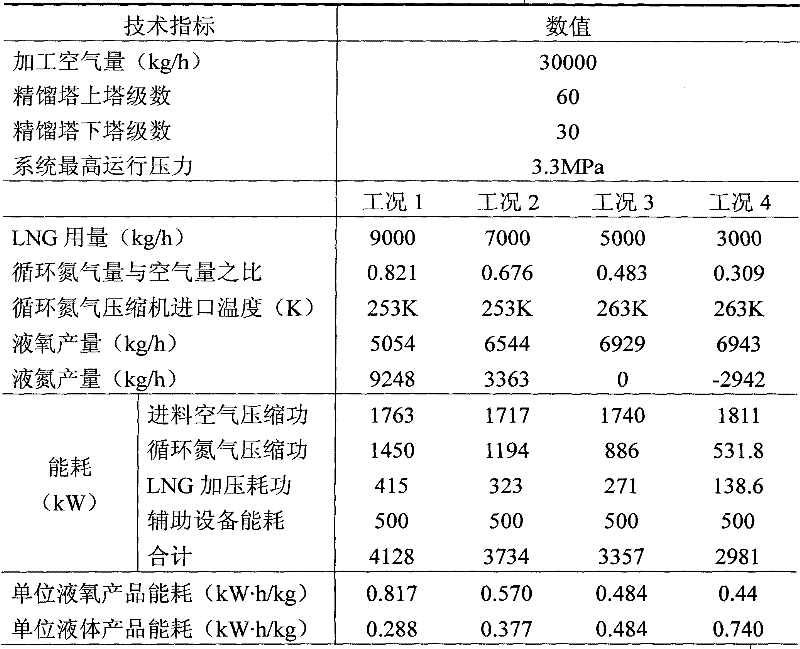

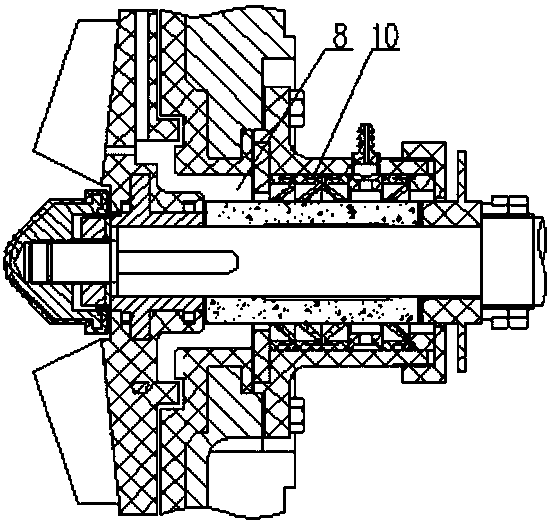

Pump ring used for mechanical seal

InactiveCN102678935AImprove pumping capacityIncrease fluid circulationEngine sealsEngineeringMechanical engineering

The invention discloses a pump ring used for a mechanical seal, which comprises a screw-type pump; and a labyrinth seal is connected to one side of the screw-type pump. The pump ring has the advantages that the pumping capacity of the pump ring is improved, and the circulation of fluid on a seal end surface is accelerated, so that the effect of heat exchange and cooling of the seal end surface can be achieved, the temperature of fluid at the seal end surface is reduced, and the service life of the mechanical seal is prolonged.

Owner:DALIAN HUAYANG SEALS

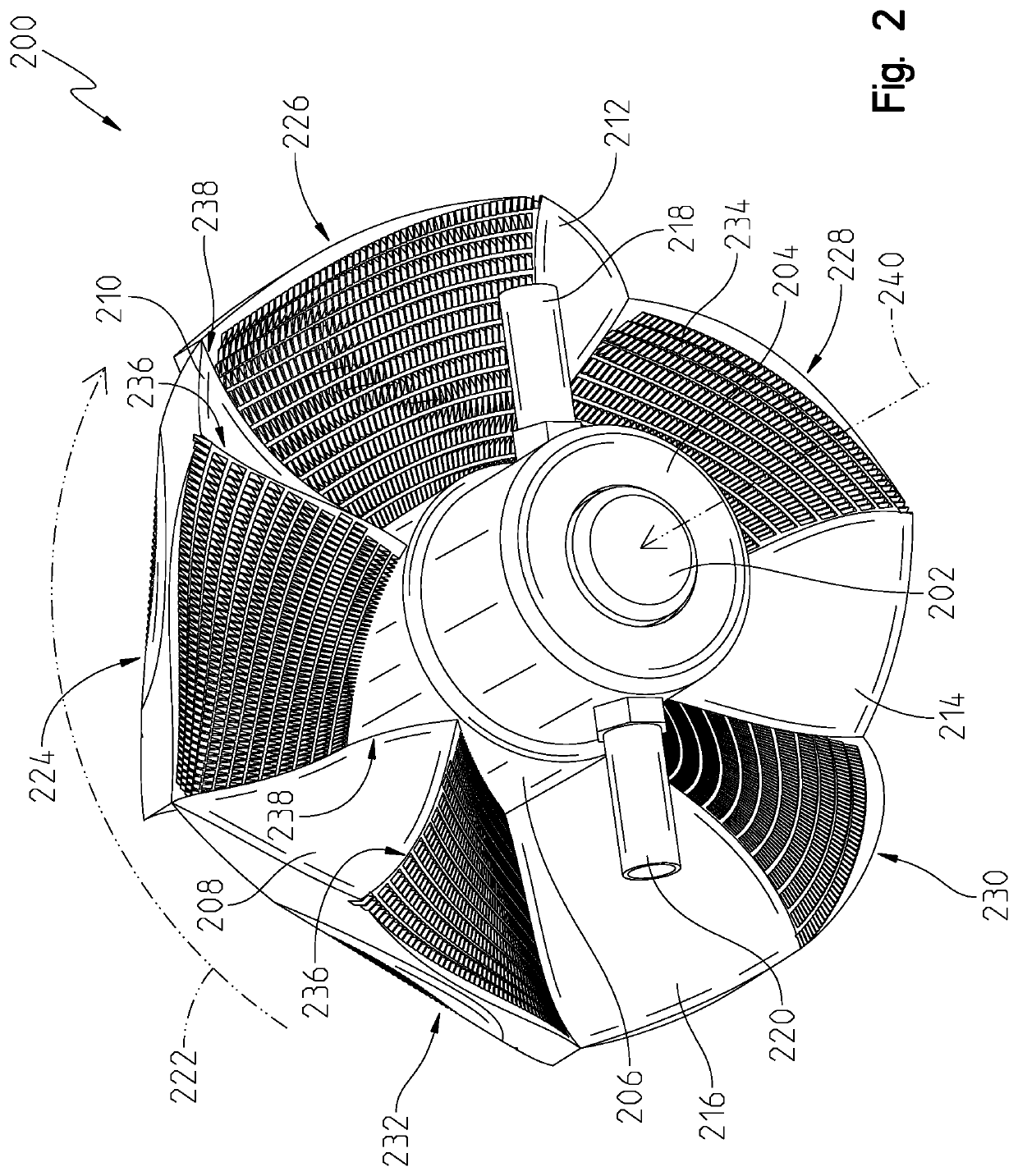

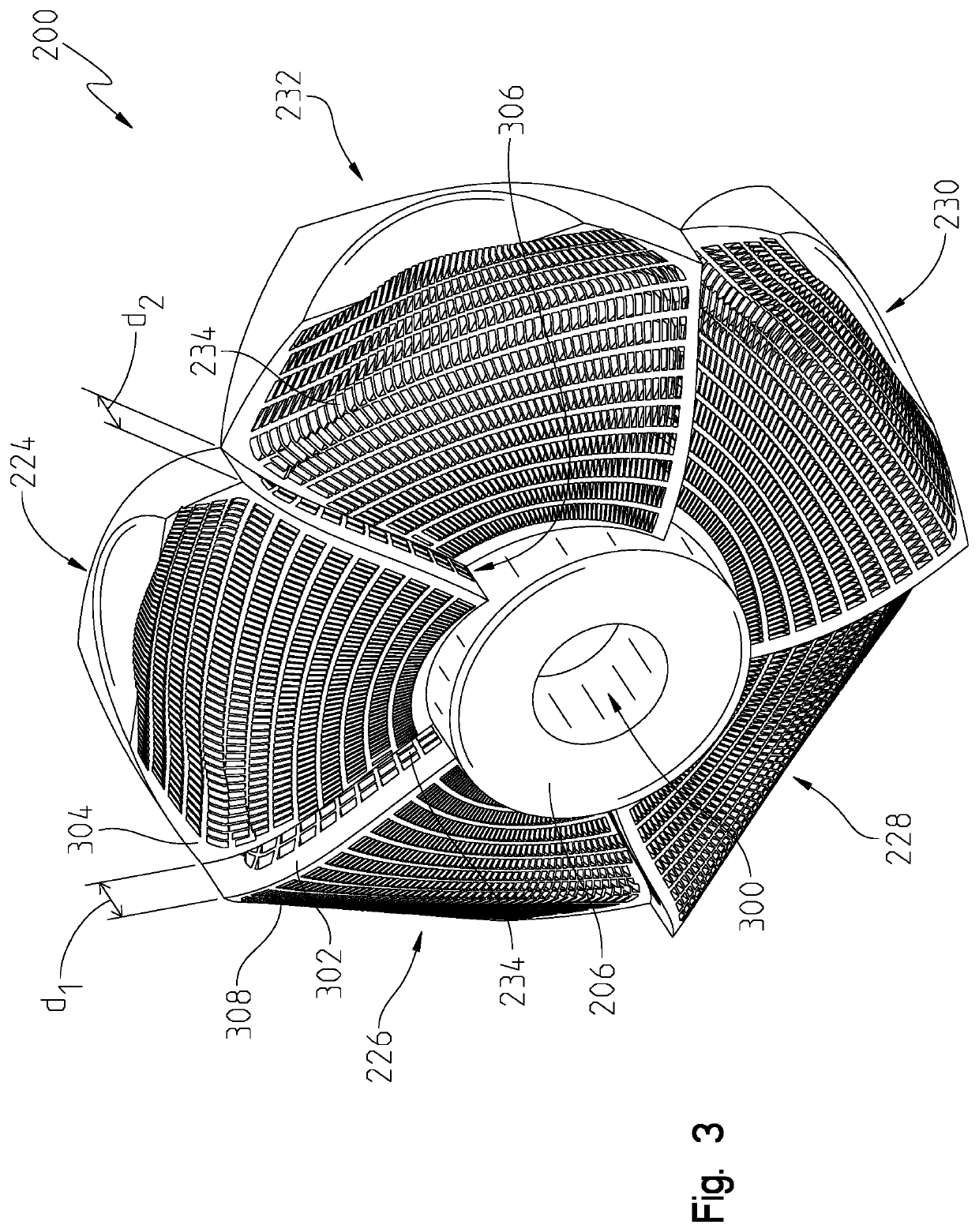

Rotary heat exchanger and system thereof

ActiveUS20200200186A1Lower fluid temperatureLiquid coolingAdditive manufacturing apparatusEngineeringFan blade

A rotary heat exchanger includes a hub configured to be rotatably driven by a shaft, a fan including a plurality of fan blades integrally coupled to the hub and extending radially outwardly therefrom, and a heat exchanger including a plurality of heat exchanger sections. The heat exchanger includes a plurality of cooling fins for receiving air from the fan. Each of the plurality of heat exchanger sections is located between two of the plurality of fan blades. The hub, the fan, and the heat exchanger are integrally formed as a single body by a three-dimensional printing process.

Owner:DEERE & CO

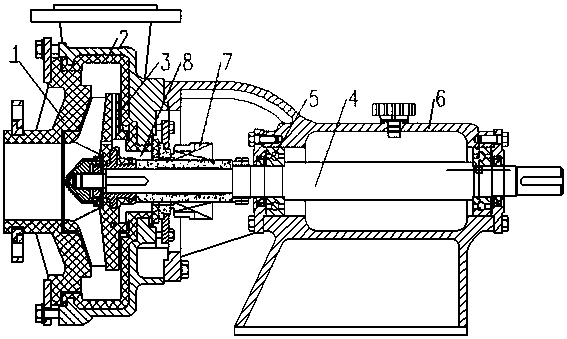

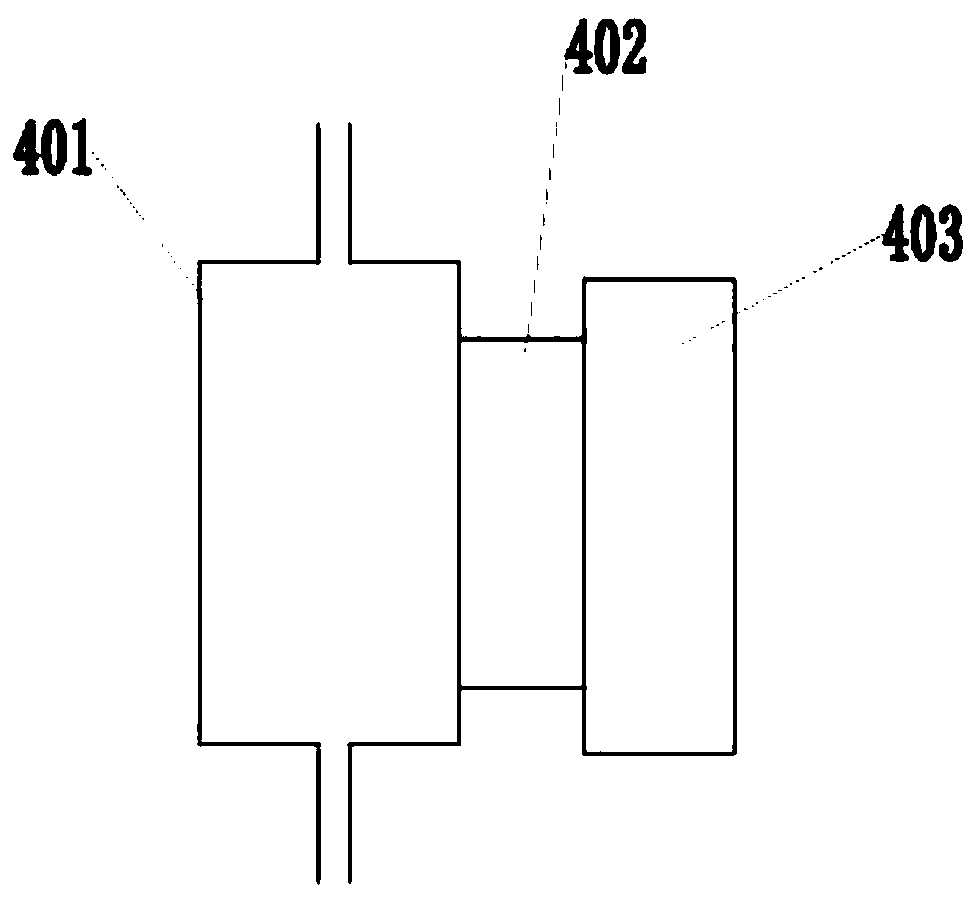

Centrifugal pulp pump

PendingCN111120397ALower fluid temperatureRelieve pressureSpecific fluid pumpsPump componentsImpellerEngineering

The invention discloses a centrifugal pulp pump which comprises a pump shell, a pump cover, a main shaft, an impeller and a shaft seal. The main shaft, the impeller and the shaft seal are arranged inthe pump shell. The impeller comprises an impeller center plate and an impeller blade arranged on the front face of the impeller center plate. Multiple pressure reducing runners are arranged in the curved surface wall thickness of the impeller center plate from the outer side wall to the inner side in the radial direction. The back face of the impeller center plate is matched with the inner surface of the pump shell in a convex-concave manner, a liquid storage cavity is defined by the back face of the impeller center plate, the inner wall of the pump shell, the front end face of the shaft sealand the outer circumferential face of the main shaft, and the pressure reducing runners communicate with the liquid storage cavity and an inner cavity of the pump shell. The pump is high in work efficiency and capable of saving energy by 5%-8%, the phenomenon that fluid of a sealing part is heated can be avoided, and the service life of the mechanical seal is long.

Owner:宜兴市宙斯泵业有限公司

Oxygen generator

InactiveCN112850652ACompression suitable forIncrease pressureOxygen preparationAir compressionHeat conducting

The invention provides an oxygen generator, and the oxygen generator comprises a compressor suitable for compressing air; a separation device; a heat dissipation pipe which is communicated with the compressor and the separation device; and a heat conducting plate which is made of a metal material, wherein at least part of the radiating pipe is in contact with the heat conducting plate. By arranging the compressor, external air can be compressed, the pressure intensity of the air can be improved, the separation device can conveniently and effectively separate oxygen, nitrogen and other gases in the air, meanwhile, the heat dissipation pipe communicating the compressor with the separation device is attached to the metal heat conduction plate, on one hand, the metal heat conduction plate is arranged on the bottom side of the oxygen generator, and the overall heat dissipation capability of the heat condition plate is improved; on the other hand, the radiating area of the radiating pipe is further increased and the temperature of fluid in the radiating pipe is effectively reduced through the fit arrangement of the radiating pipe and the heat conducting plate, so that the radiating capacity of the oxygen generator is effectively ensured and the cost and the power consumption burden of the oxygen generator are reduced without adding external drive.

Owner:GREE ELECTRIC APPLIANCES INC

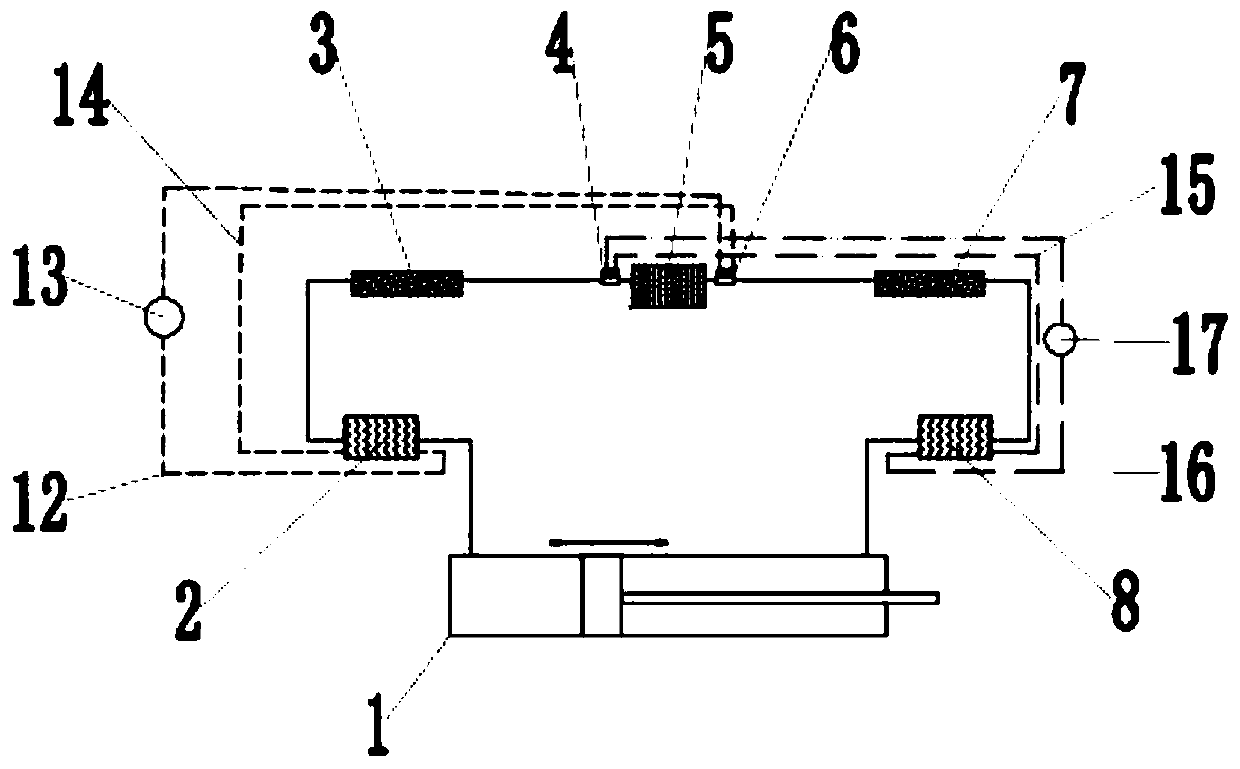

Magnetic refrigeration and semiconductor refrigeration combined refrigeration system and air conditioner

PendingCN110762893AAvoid wastingTake advantage ofMachines using electric/magnetic effectsSustainable buildingsHydraulic cylinderThermodynamics

The invention discloses a magnetic refrigeration and semiconductor refrigeration combined refrigeration system. The magnetic refrigeration and semiconductor refrigeration combined refrigeration systemcomprises a hydraulic cylinder, hot-end heat exchangers, cold accumulators and a cold-end heat exchanger; the hot-end heat exchangers comprise the first hot-end heat exchanger and the second hot-endheat exchanger; the cold accumulators comprise the first cold accumulator and the second cold accumulator; one end of the hydraulic cylinder is connected with the first hot-end heat exchanger; the other end of the hydraulic cylinder is connected with the second hot-end heat exchanger; the first hot-end heat exchanger is connected with the first cold accumulator; the second hot-end heat exchanger is connected with the second cold accumulator; the first cold accumulator and the second cold accumulator are both connected with the cold-end heat exchanger; a first semiconductor refrigeration deviceis arranged between the first cold accumulator and the cold-end heat exchanger; a second semiconductor refrigeration device is arranged between the second cold accumulator and the cold-end heat exchanger; and heat exchange loops are arranged between the second semiconductor refrigeration device and the first hot-end heat exchanger, and between the first semiconductor refrigeration device and thesecond hot-end heat exchange.

Owner:GREE ELECTRIC APPLIANCES INC

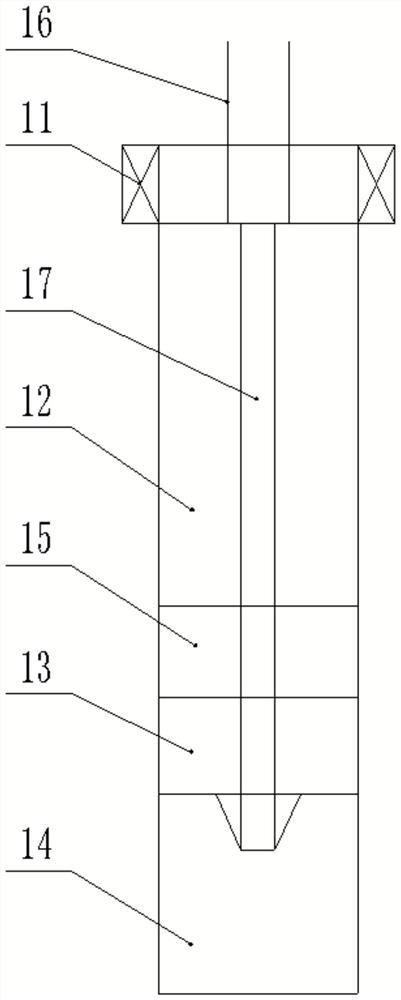

Heavy oil recovery method integrating heat injection oil production and mechanical oil production

ActiveCN109854217AReduce the temperatureSolve temperature resistanceFluid removalRecovery methodEngineering

The invention provides a heavy oil recovery method integrating heat injection oil production and mechanical oil production. The method includes the following concrete steps: S1. performing preparationwork; S2. placing a combined heat injection pipe column in a wellbore; S3. after placing the combined heat injection pipe column, installing an oil production tree, and implementing a heat injectionprocess after installing the oil production tree; S4. performing self-spraying production, measuring the temperature of produced fluid, and providing a basis for subsequent selection of a temperatureresistance level of a mechanical plucking machine tool; S5. placing the mechanical plucking machine tool; and S6. performing mechanical plucking. According to the method, the wellbore and a heat injection pipe column with large diameter are first placed, and then heat injection is performed; after the heat injection and the self-spraying production are completed, the heat injection pipe column isnot required to be moved, the oil production tree is not required to be removed, the mechanical plucking machine tool only needs to be connected by a continuous oil pipe, the mechanical plucking machine tool is sent to a predetermined position seat seal in the heat injection pipe column, then the mechanical plucking can be achieved, and so, the contradiction between temperature resistance of the mechanical plucking machine tool and high temperature of the heat injection oil production is solved well under existing technical conditions, and an important technical means is provided for development of heavy oil.

Owner:天津克睿特维科技发展有限公司

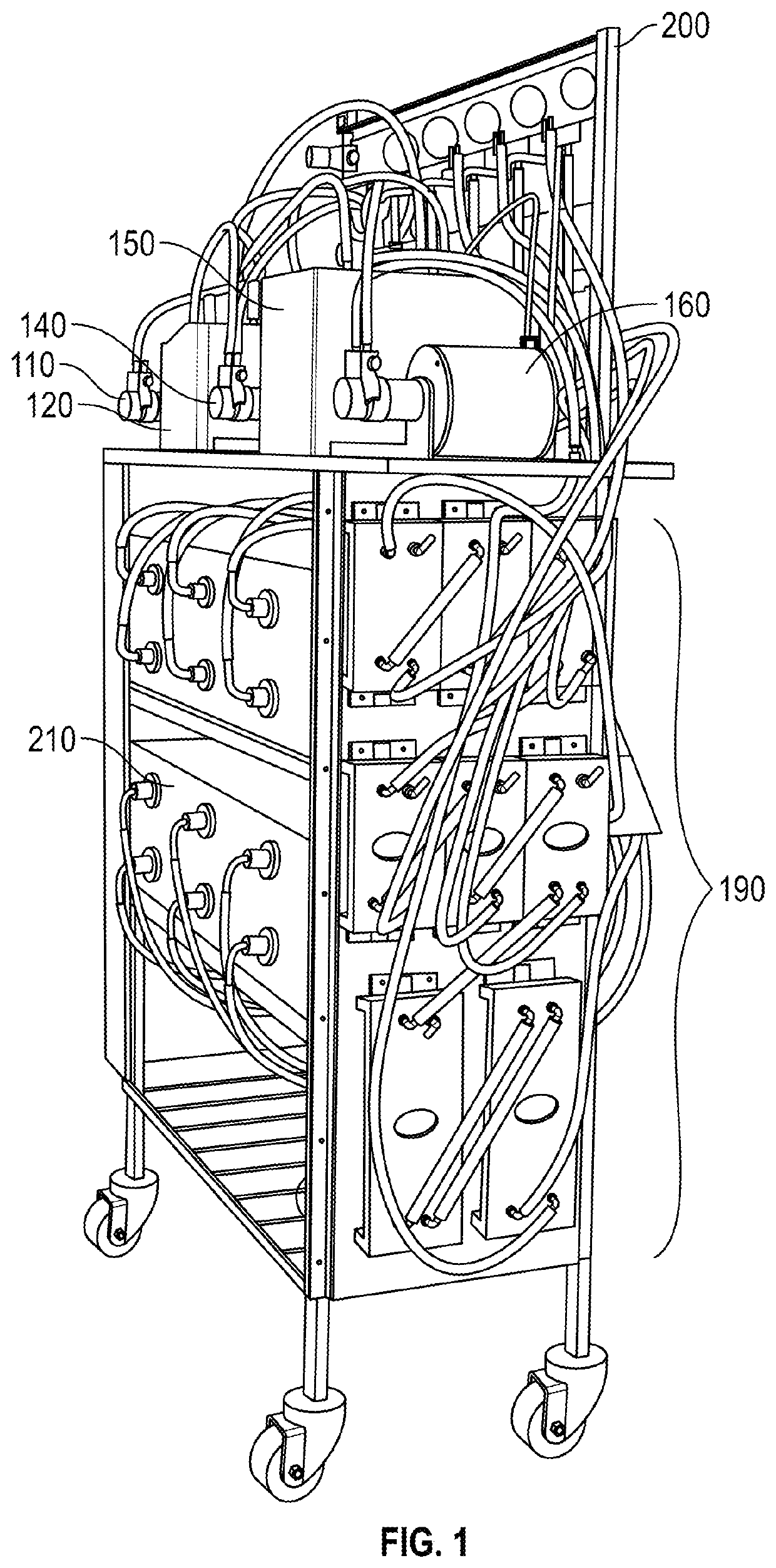

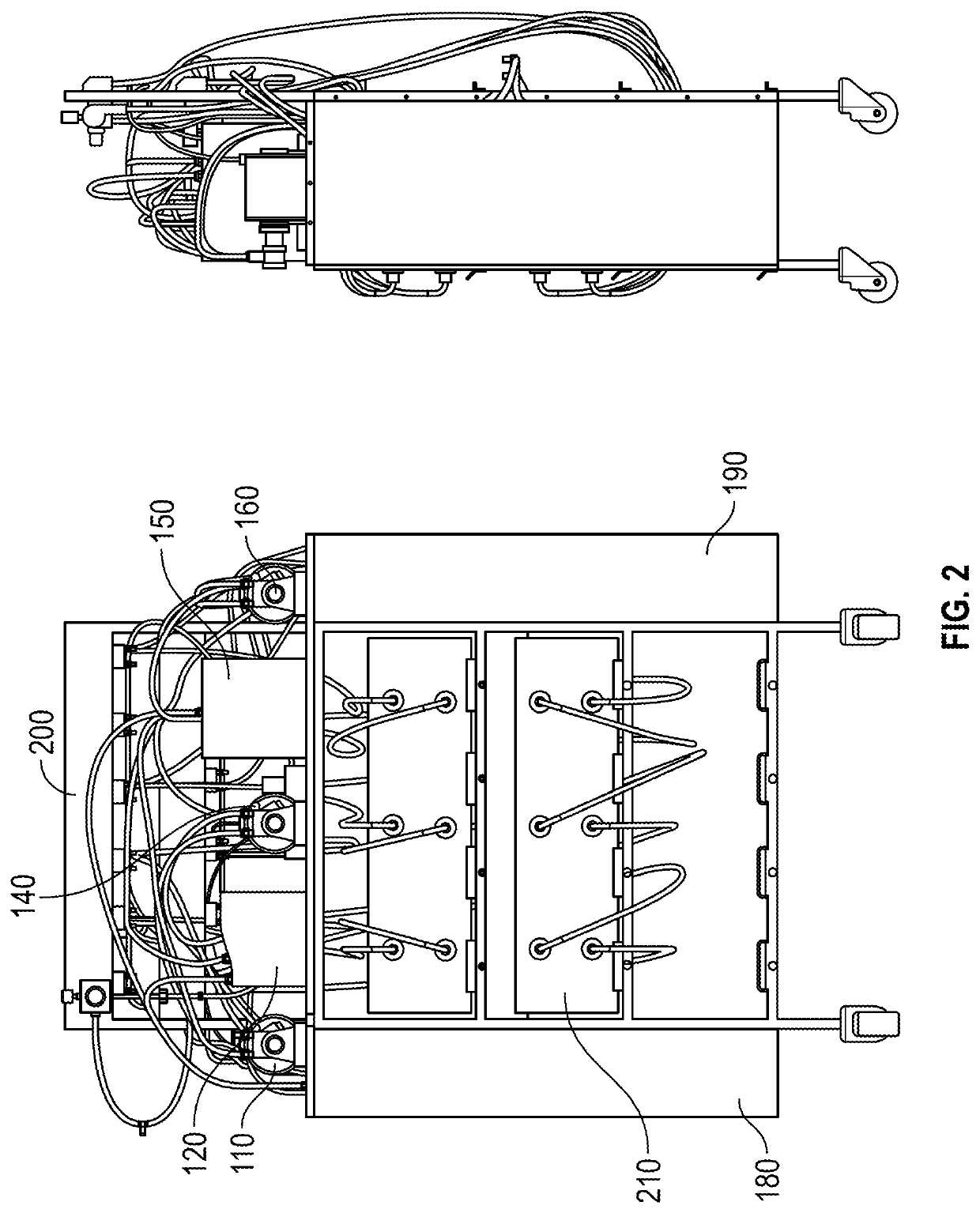

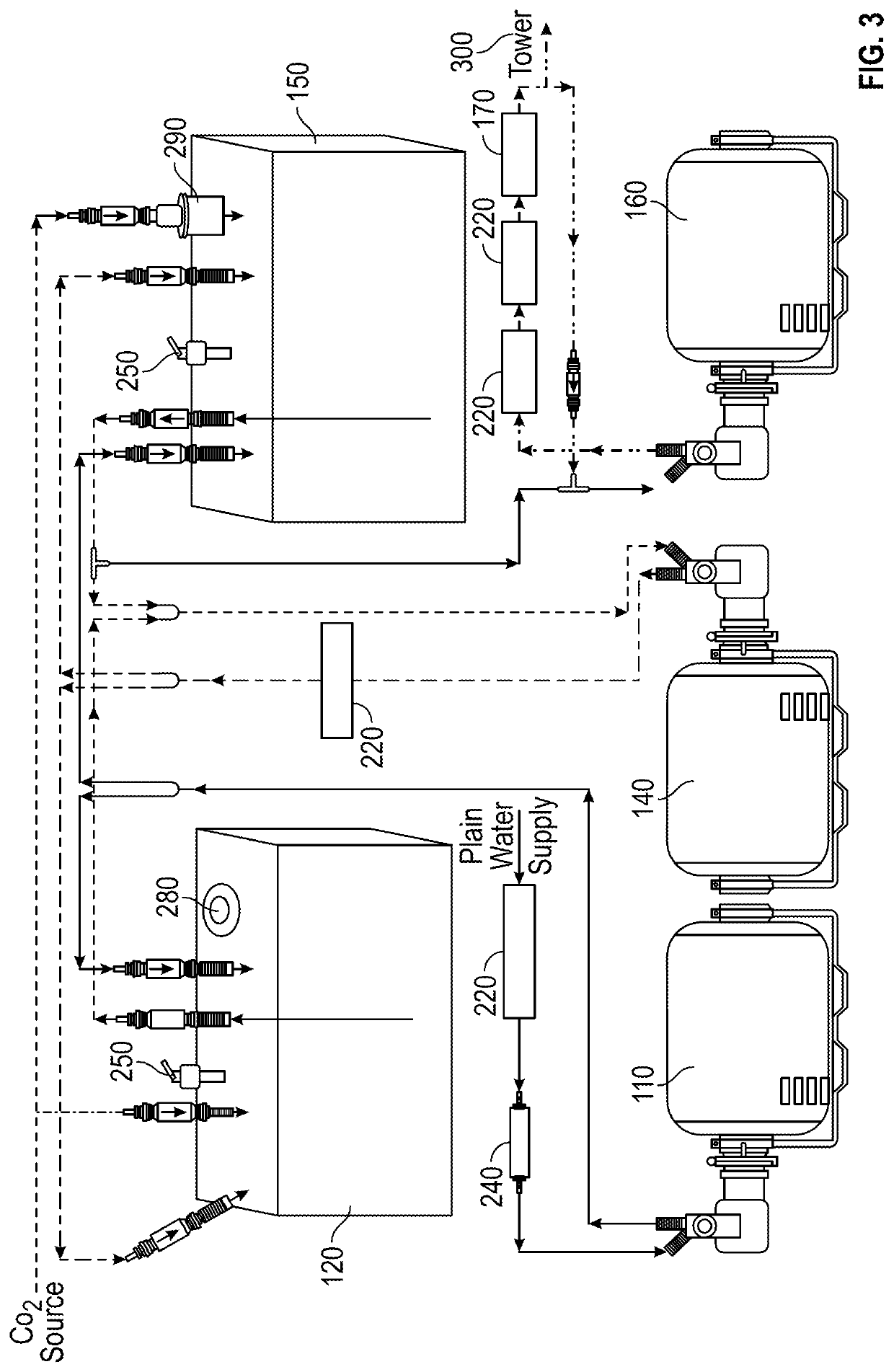

Soda Carbonation and Dispensation System and Method

PendingUS20210214209A1Easy to createRapid carbonation lossMixing methodsLiquid flow controllersBrixCarbonization

A soda carbonation and dispensation system and method are provided. The system includes a carbonated water pump and motor assembly operable to draw fresh water into carbonator tanks and circulate the water through a chiller system. A carbon dioxide source is connected to the carbonator tanks to produce carbonated water. The system also includes a water level sensor connected to a controller, a plurality of syrup containers, a syrup pump, syrup regulator valves, a brix capacitor, a dispensing tower and faucets connected to the dispensing tower housing. The controller operates the water pump and motor assembly to maintain a water level within a predetermined range and to maintain continuous flow and refrigeration of the carbonated water, which optimizes carbonation. The brix capacitor receives chilled carbonated water and chilled syrup in separate lines. Carbonated water is circulated to the faucets through a manifold in the brix capacitor and then circulated back into the carbonator tanks. Valves are provided in the brix capacitor to manipulate carbonated water and syrup flow rates and pressures into the faucets. The system maintains the carbonated water and syrup at a refrigerated temperature and a predetermined maximum pressure. When a faucet is opened, the carbonated water and syrup mix as they flow laminarly into a container. The result is consistently optimum carbonation when the beverage is dispensed.

Owner:ABRAHAM HUNTER

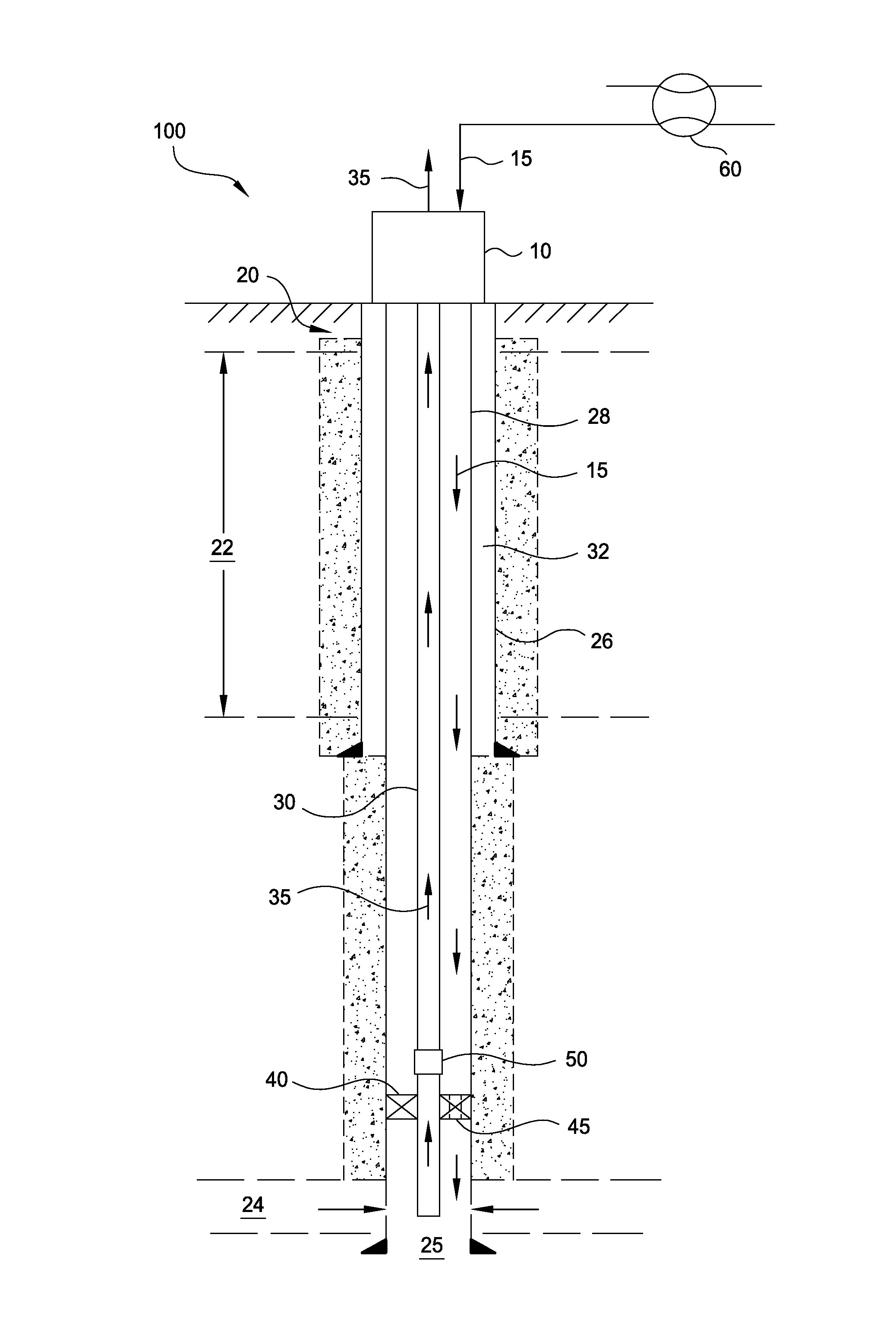

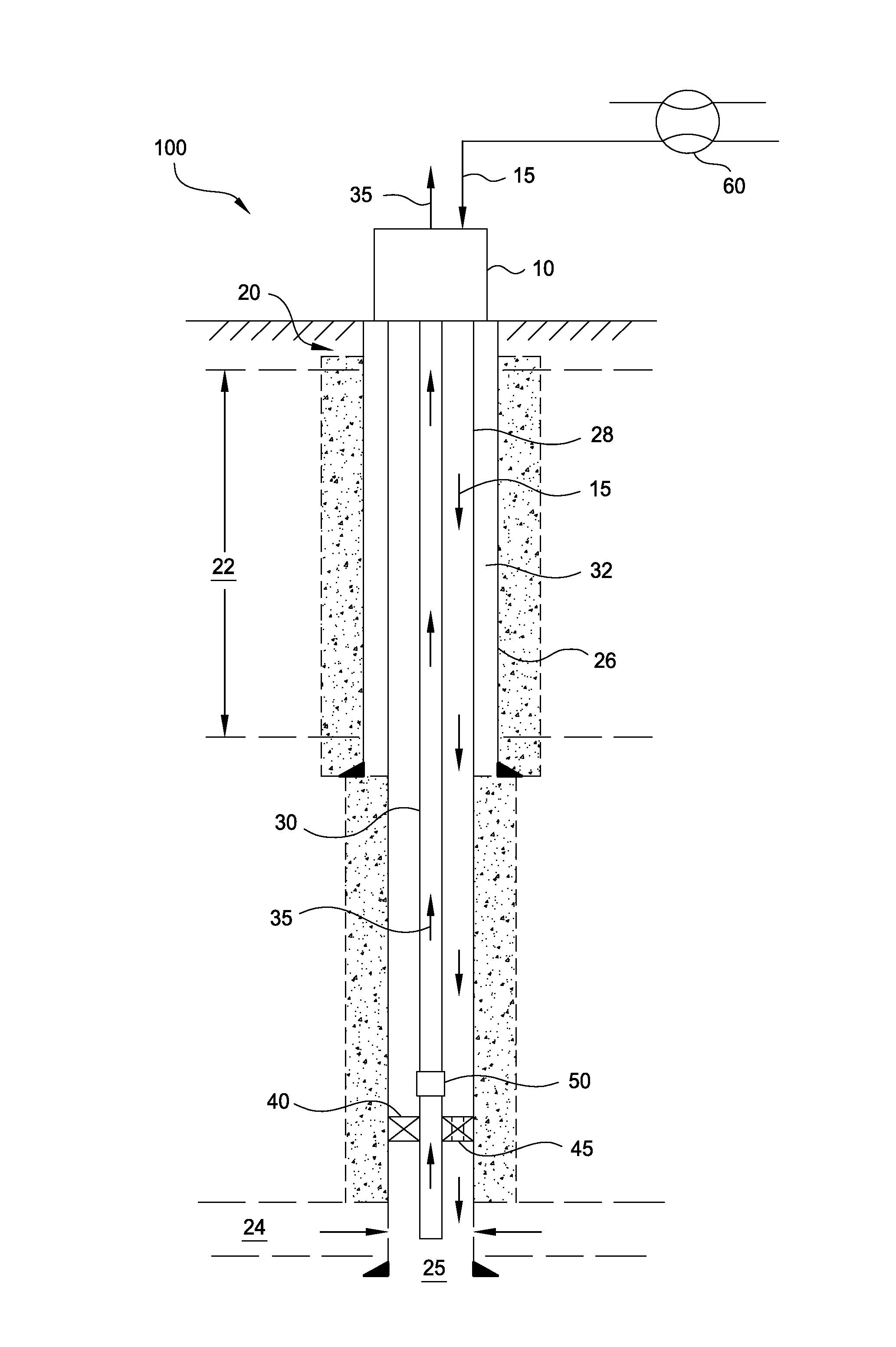

Method and system for controlling wellbore production temperature

ActiveUS9194214B2Avoid overall overheatingLower fluid temperatureInsulationFluid removalEngineeringReservoir fluid

Owner:WORLD ENERGY SYST

A heavy oil recovery method integrating thermal injection recovery and mechanical recovery

ActiveCN109854217BReduce the temperatureSolve temperature resistanceFluid removalThermodynamicsCoiled tubing

The present invention is a heavy oil recovery method integrating heat injection recovery and mechanical oil recovery. The specific steps are: S1, preparatory work; S2, running a combined heat injection string in the wellbore; S3, after running the heat injection string, Install the christmas tree, and after the christmas tree is installed, implement the heat injection process; S4, self-spray production, measure the temperature of the output fluid, and provide a basis for the subsequent selection of the temperature resistance level of the mechanical mining tool; S5, lower the mechanical mining tool; S6, Machine mining. In the present invention, the large-diameter wellbore and the heat injection string are lowered first, and then heat injection is performed; after the heat injection and self-spraying production are completed, no dynamic heat injection string is required, and the oil tree is not required to be dismantled, only the coiled tubing is needed to connect The mechanical mining tools are sent to the predetermined position in the heat injection pipe string for sealing, and then the mechanical mining can be realized, which solves the contradiction between the resistance of the mechanical mining tools and the high temperature of the thermal injection oil production under the existing technical conditions. Oil development provides an important technical means.

Owner:天津克睿特维科技发展有限公司

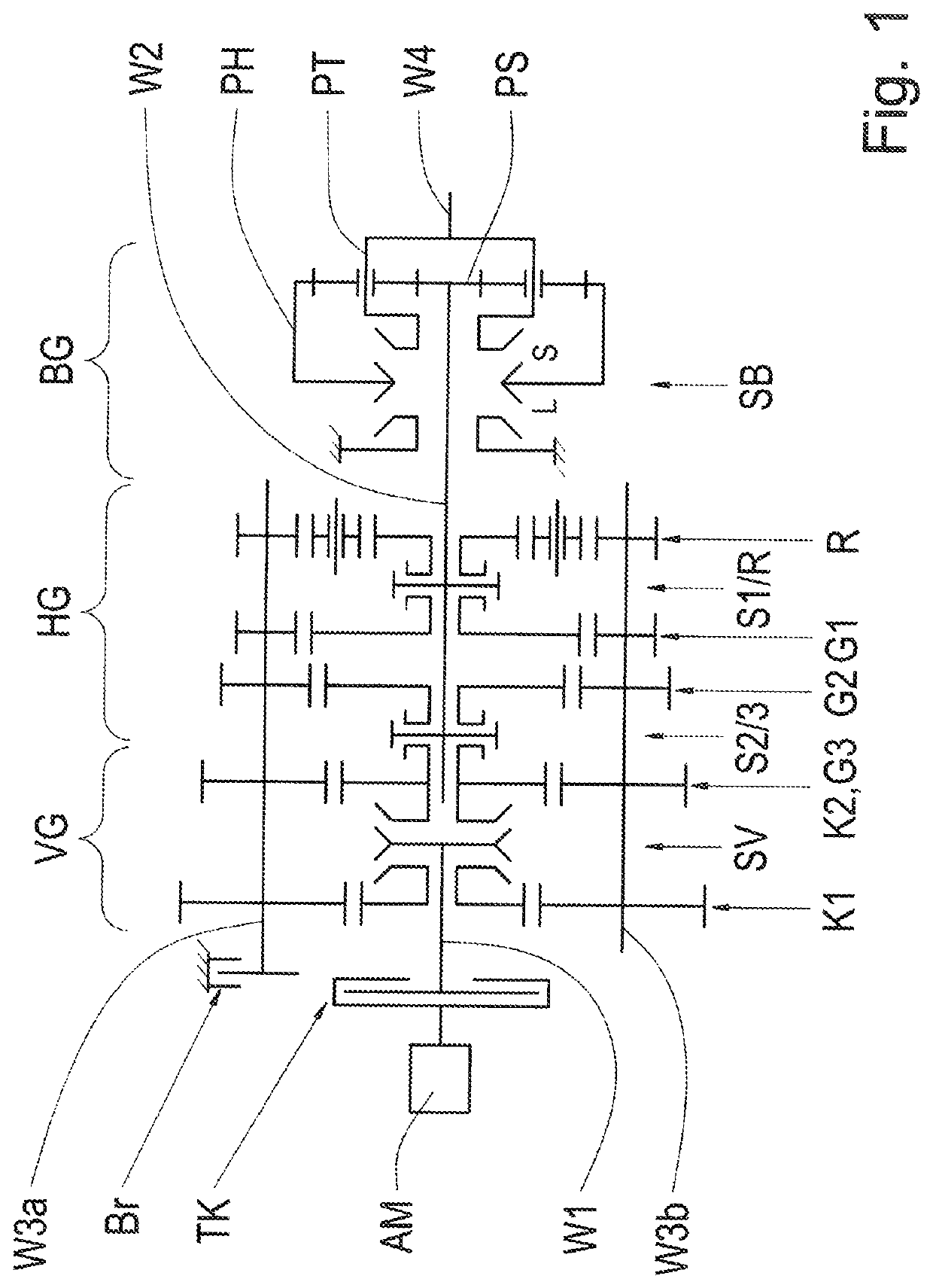

Shift control method for an automated range-change transmission

ActiveUS10648555B2Reduce wearReduce the numberInternal combustion piston enginesGearing controlTransmission brakeReduction drive

Owner:ZF FRIEDRICHSHAFEN AG

a condensation injector

ActiveCN104190572BRelieve pressureReduce the temperatureLiquid spraying apparatusEngineeringMixing chamber

The invention discloses a condensation ejector which comprises an accepting chamber, a throat chamber, a mixing chamber, a dispersion chamber, a condensing chamber and an atomizing mechanism, wherein the accepting chamber is provided with a first inlet and a second inlet; one end of the throat chamber is communicated with the accepting chamber, and the throat chamber is located on the down stream of the second inlet; one end of the mixing chamber is communicated with the other end of the throat chamber, one end of the dispersion chamber is communicated with the other end of the mixing chamber, and a first outlet is formed in the other end of the dispersion chamber; the condensing chamber is arranged close to the outer side of the down stream of the mixing chamber in a surrounding mode and comprises a third inlet formed in the down stream end of the condensing chamber, a second outlet formed in the upstream of the condensing chamber, a plurality of main condensing pipes and a plurality of branch condensing pipes, one end of each of the condensing pipes extends into the mixing chamber, the extending directions of the branch condensing pipes are different, the other end of each of the branch condensing pipes is communicated with a main condensing pipe, one end of the main condensing pipe is sealed, and the other end of the main condensing pipe is communicated with the dispersion chamber through a fourth inlet in the dispersion chamber; the atomizing mechanism is provided with a plurality of nozzles formed in the position of the fourth inlet, and the atomizing mechanism is used for atomizing fluid in the main condensing pipe and spraying the fluid in the dispersion chamber.

Owner:广西海岛生态投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com