Aluminum alloy pressure casting workpiece multi-medium air cooling device

An air-cooling device and die-casting technology, which is applied in the field of cooling devices, can solve problems such as inability to adjust, workpiece deformation, and low efficiency, and achieve the effects of simple structure, rapid cooling, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

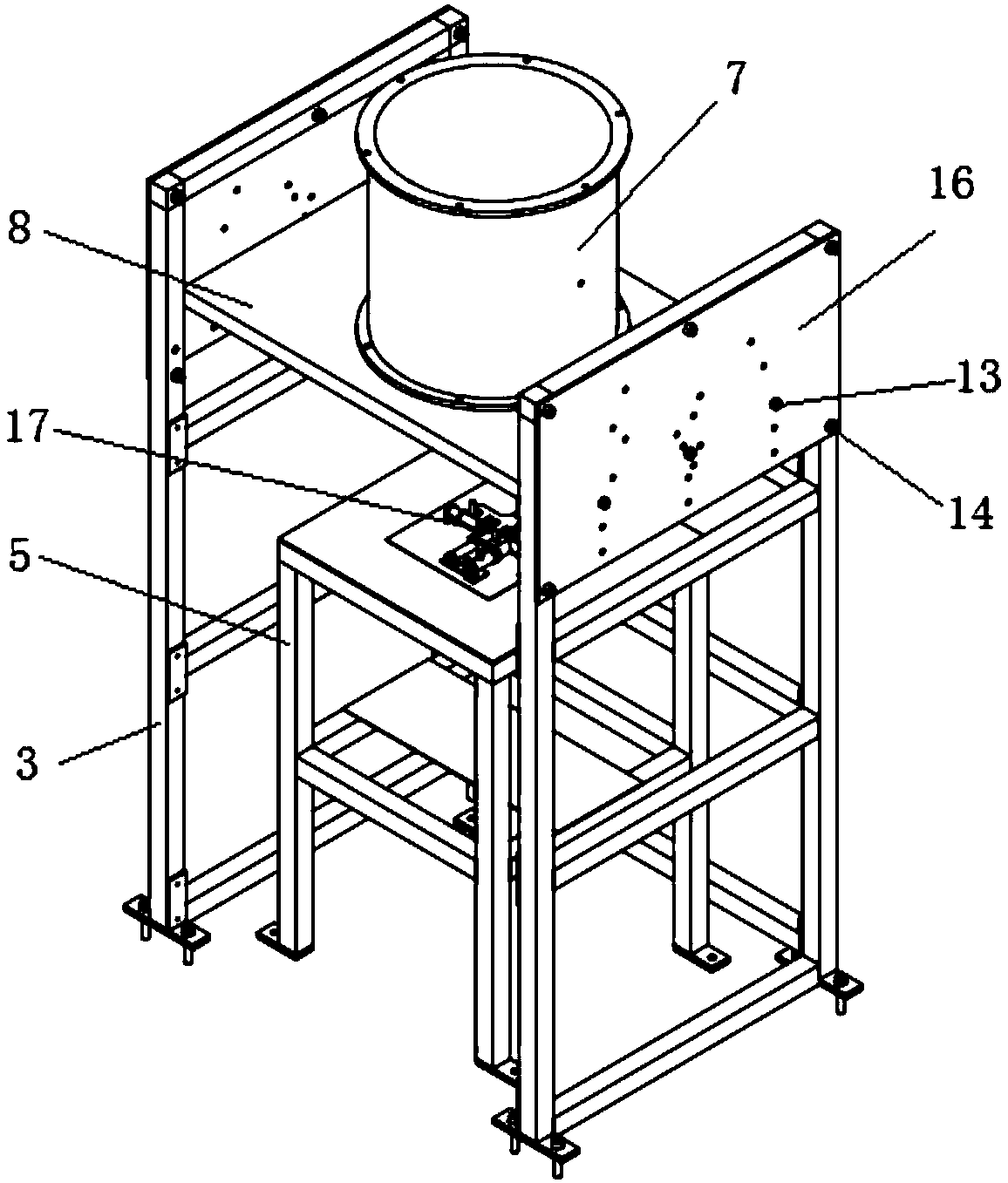

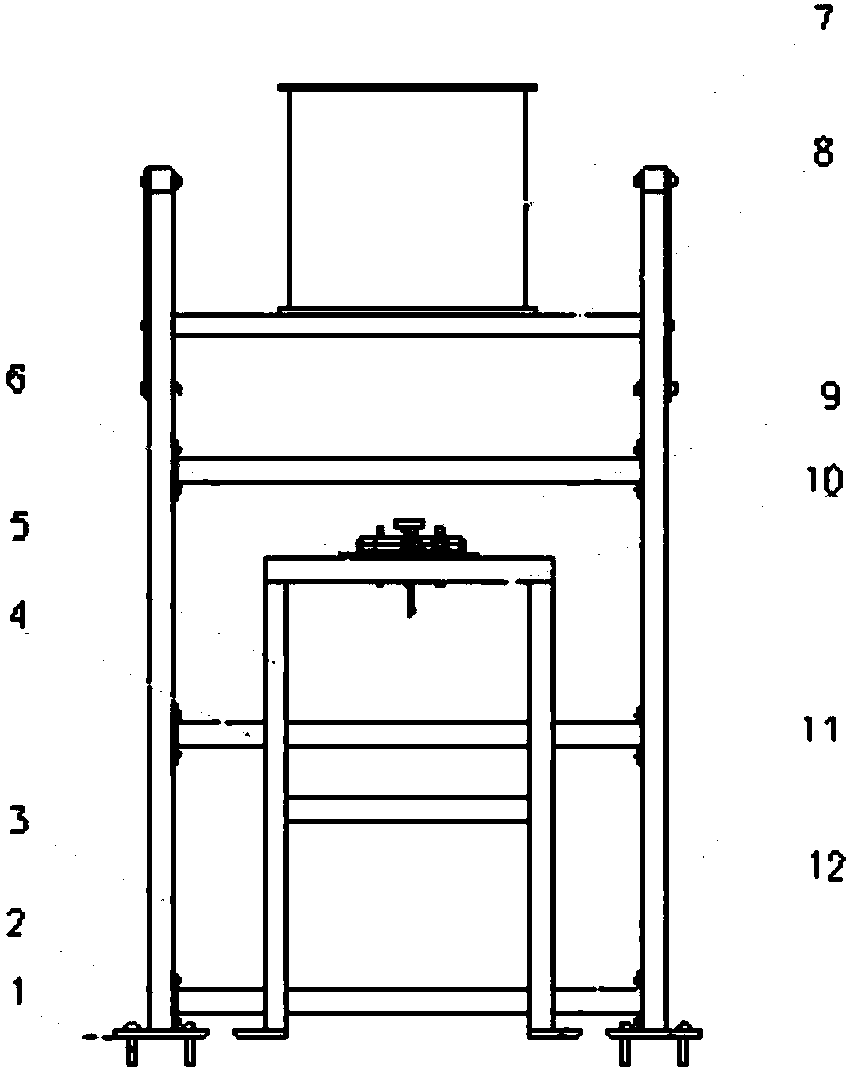

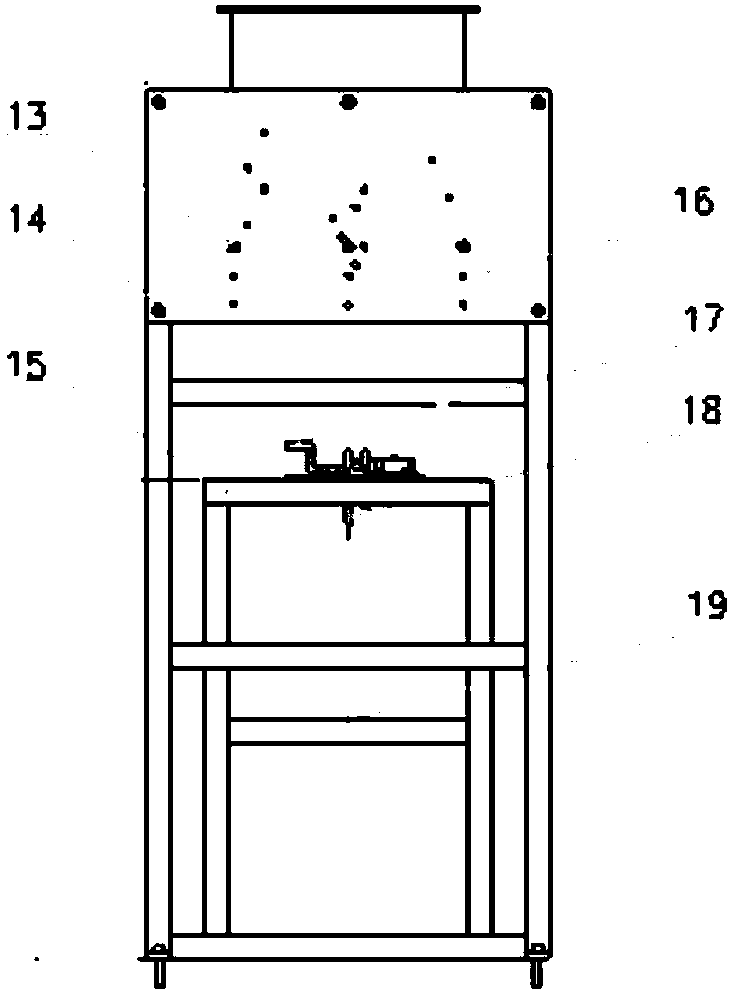

[0027] like Figure 1 to Figure 3 As shown, a multi-media air-cooling device for aluminum alloy die-casting parts, including anchor bolts 1, connecting plate 2, fan support frame 3, detachable reinforcing beam 4, workpiece table 5, fireproof cloth 6, axial flow fan 7, fan Support plate 8, positioning rod 9, thermocouple wire 10, workpiece table corner code 11, support frame corner code 12, M10*20 hexagon socket bolt 13, M12*60 socket head bolt 14, workpiece table skeleton 15, multi-station can Adjust the working panel 16, the die casting 17, the thermocouple fixing device 18, and the workpiece resting table 19.

[0028] The axial flow fan 7 is fixed on the fan support plate 8, and the two sides of the fan support plate 8 are connected to the multi-station adjustable work panel 16 through M10*20 hexagon socket bolts 13, and the multi-station adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com