Backward flow type air separation system and method based on cold energy utilization of LNG (Liquefied Natural Gas) satellite station

An air separation and satellite station technology, applied in refrigeration and liquefaction, liquefaction, solidification and other directions, to avoid low-temperature compression, simplify the process, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

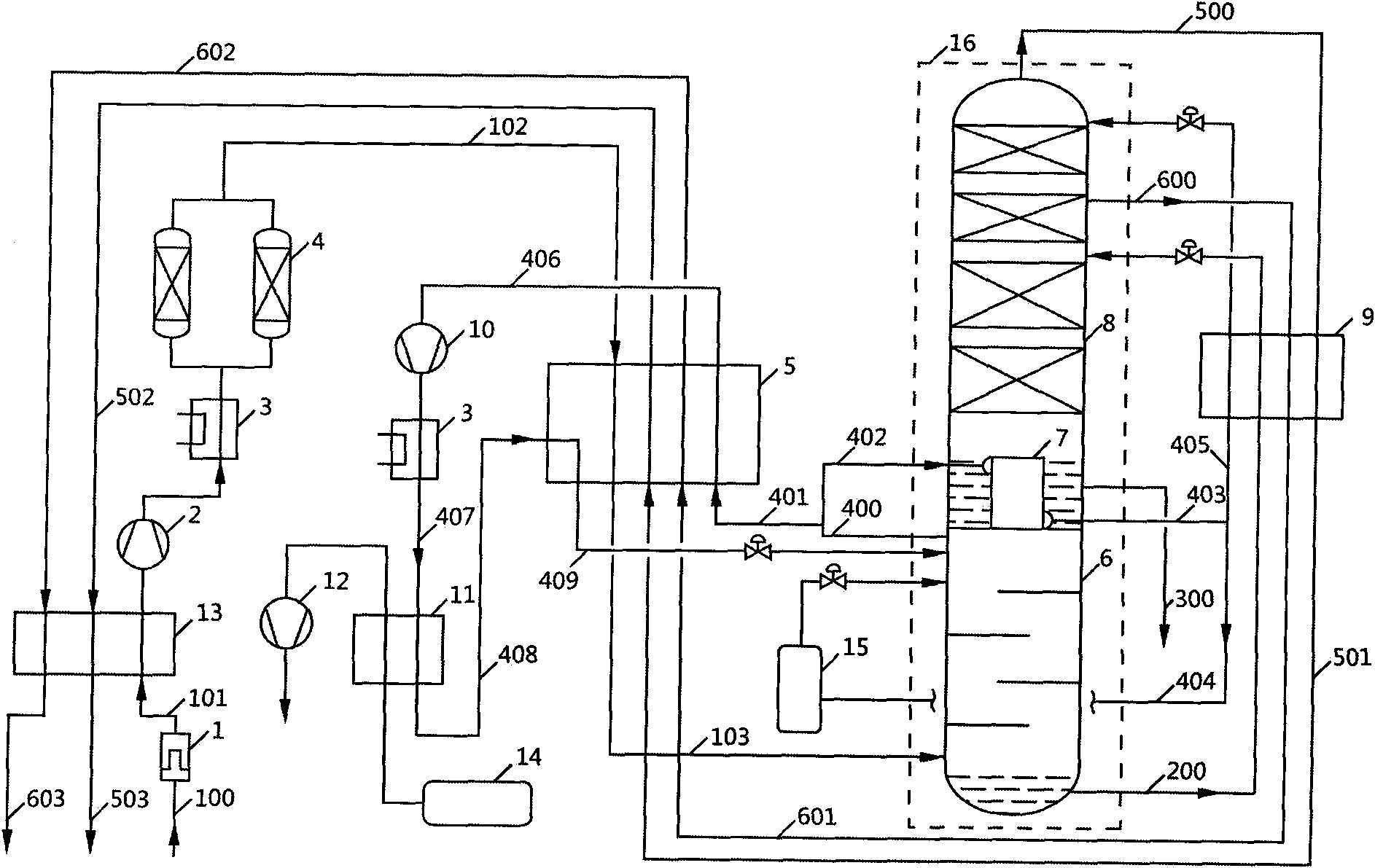

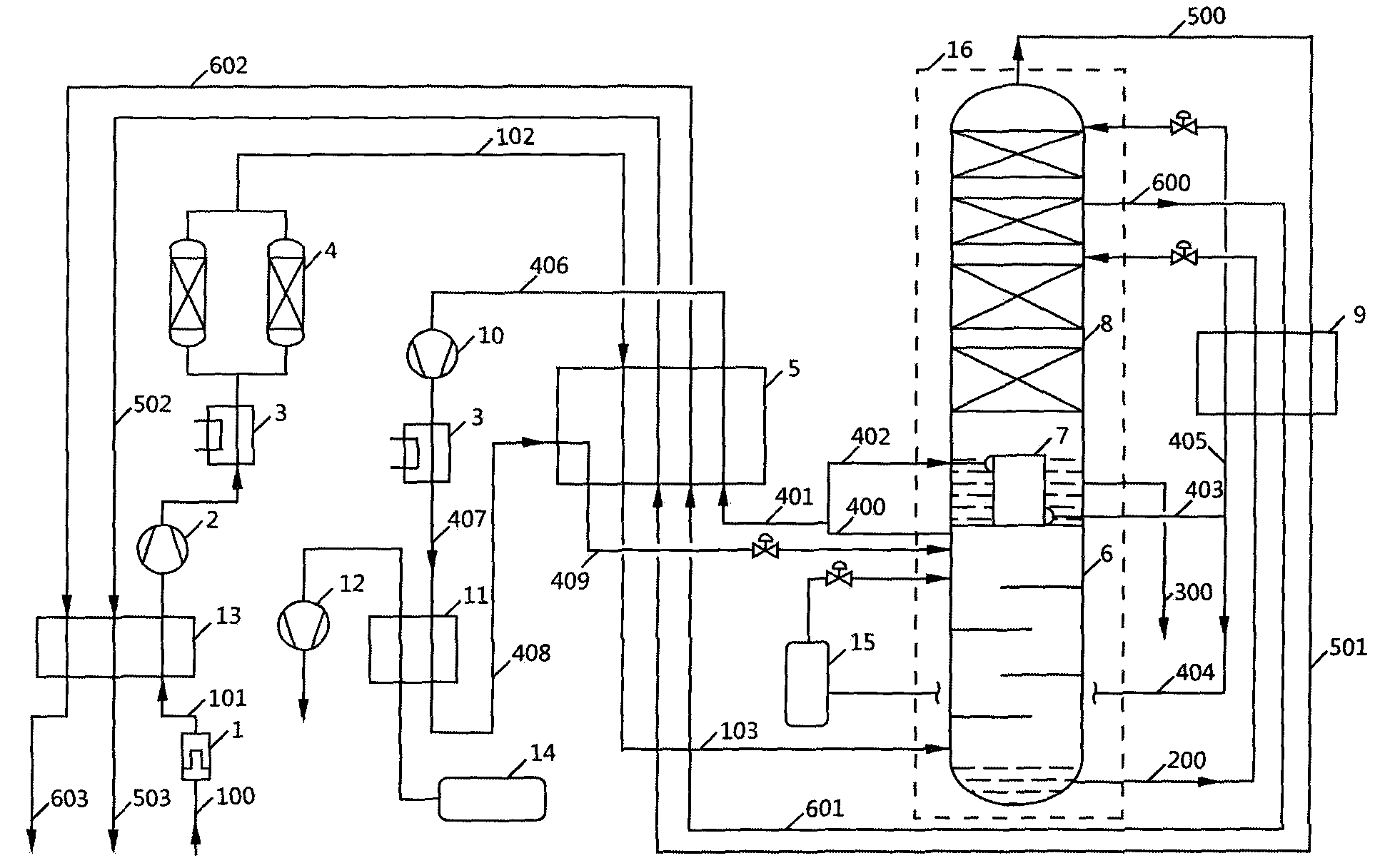

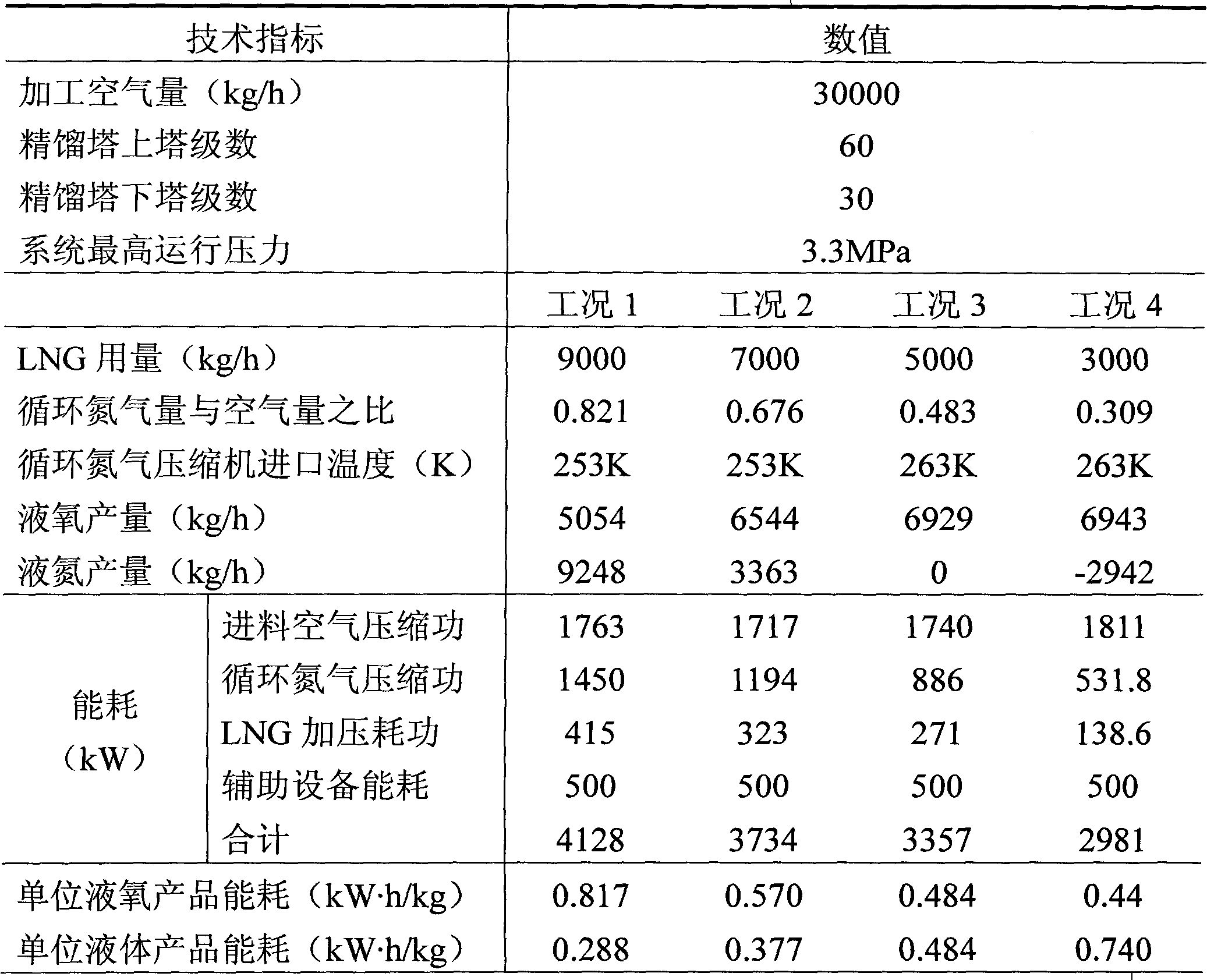

[0009] Such as figure 1 As shown, the inverted air separation system based on cold energy utilization of LNG satellite station includes air filter 1, air compressor 2, water cooling unit 3, air purifier 4, main heat exchanger 5, subcooler 9, nitrogen compressor 10. LNG heat exchanger 11, natural gas compressor 12, air precooler 13, LNG storage tank 14, liquid nitrogen storage tank 15, rectification system 16, rectification system 16 includes a lower tower 6, a condensing evaporator 7, an upper Tower 8; air filter 1 is connected in sequence with air precooler 13, air compressor 2, water cooling unit 3, air purifier 4, feed air channel of main heat exchanger 5, and lower feed air inlet of lower tower 6 , the product nitrogen outlet at the top of the upper tower 8 is connected to the subcooler 9, the product nitrogen flow channel of the main heat exchanger 5, and the air precooler 13 successively, and the circulating nitrogen outlet at the upper end of the lower tower 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com