A heavy oil recovery method integrating thermal injection recovery and mechanical recovery

A mining method and mechanical oil recovery technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem that the high temperature resistance of mechanical mining equipment cannot meet the requirements, the heating temperature is high, and the production effect is not ideal, etc. problems, to achieve the effect of solving the contradiction between high temperature resistance and thermal injection oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

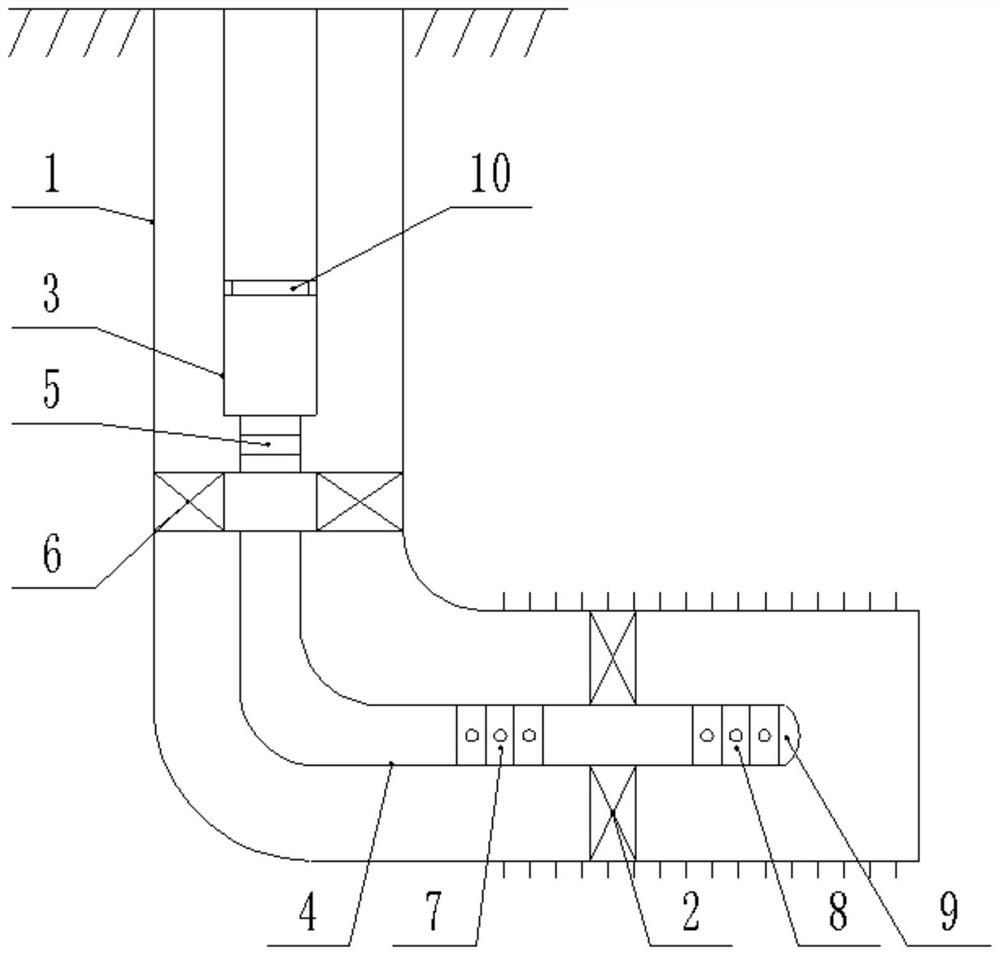

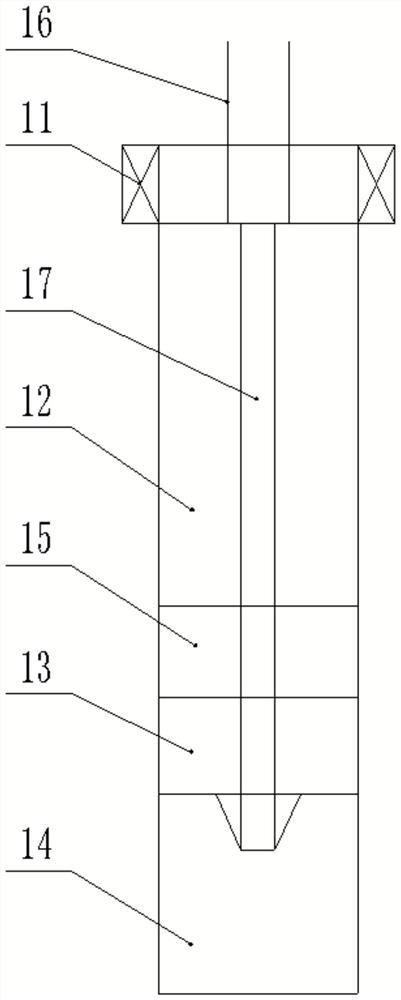

[0040] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0041] Such as Figure 1 to Figure 2 As shown, a heavy oil recovery method integrating thermal oil recovery and mechanical oil recovery, the specific steps are:

[0042] S1. Preparations

[0043] Design a high-temperature isolation packer 2 for deep setting in the wellbore 1;

[0044] S2, down into the heat injection column

[0045] Run the combined heat injection pipe string in the wellbore 1;

[0046] The heat injection string includes a casing / insulated oil pipe 3 and an oil pipe 4, a deep well safety valve 5 is provided between the casing / insulated oil pipe 3 and the oil pipe 4, and an insertion seal 6 is provided at the head end of the oil pipe 4 , the tail end of the oil pipe 4 passes through the high temperature isolation packer 2 in step S1, the oil pipe 4 is provided with an injection valve 7 at the front end of the high temperature isolation pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com