Centrifugal pulp pump

A slurry and pump casing technology, which is applied in the combined structure of centrifugal pump impeller and shaft seal, can solve the problems of rubber lip ring wear, rapid temperature rise of fluid and sealing components, poor fluid fluidity, etc., to reduce impact and friction, improve Operational safety, effect of lowering fluid temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

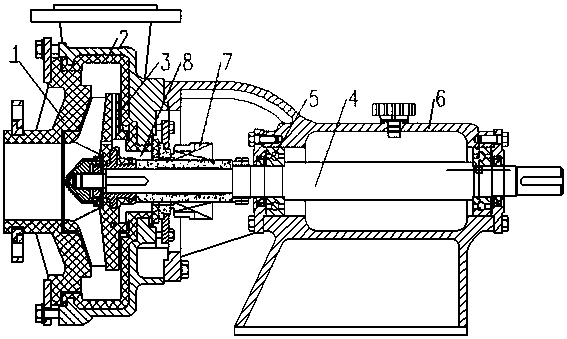

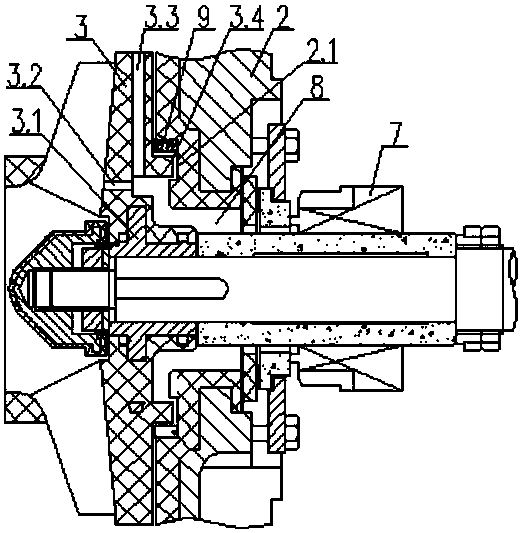

[0032] Embodiment 1: as figure 1 , 2 As shown, a centrifugal slurry pump includes a pump casing 2, a pump cover 1, a bearing 5 and a bearing bracket 6, a main shaft 4, an impeller 3, and a shaft seal 7 in the pump casing 2, the shaft seal 7 is a mechanical seal, and the impeller 3 It is a semi-open impeller with a mouth ring. The impeller 3 includes the impeller web 3.1, the impeller blade 3.7 on the front of the impeller web 3.5, and several decompression channels are opened radially from the outer side wall to the inner side of the impeller web 3.1. 3.3, the back of the impeller panel 3.5 is convexly arranged with the inner surface of the pump casing 2, specifically, the back of the impeller panel 3.5 is provided with an annular convex portion 9, and the corresponding inner wall of the pump casing 2 is provided with a matching annular concave portion 2.1, so that The back of the impeller web 3.1 is surrounded by the inner wall of the pump casing 2, the front end of the shaf...

Embodiment 2

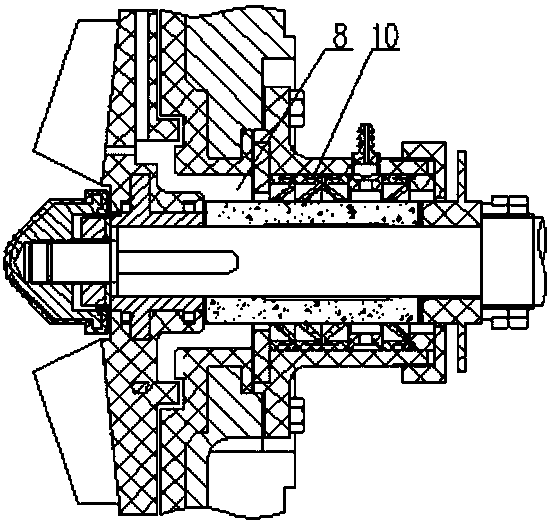

[0033] Embodiment 2: as image 3 As shown, other features remain unchanged, the impeller 3 is an open impeller, and the shaft seal 10 is a plurality of lip-shaped sealing rings.

Embodiment 3

[0034] Embodiment 3: as Figure 4 , 5 , 6, other features remain unchanged, the impeller 3 is a closed impeller, the shaft seal 7 is an assembly of the front lip seal and the mechanical seal, the impeller 3 is made of metal, and the decompression in the web 3.5 of the metal impeller The processing of flow channel 3.3 is to process radial grooves on the impeller panel 3.1 first, and then cover the impeller panel with a convex ring cover plate 3.6. After being strengthened with fasteners, it becomes the impeller panel with built-in radiation. Through-hole metal impeller, this impeller can also effectively isolate the liquid in the cavity from the pump cavity, make the sealing part form a negative pressure, and make the fluid in the sealing part circulate and replace, reducing the temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com