Electric rotating machine

A technology for rotating electrical machines and rotor coils, applied in the direction of measuring electricity, electrical components, measuring electrical variables, etc., can solve problems such as difficult to detect ground faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

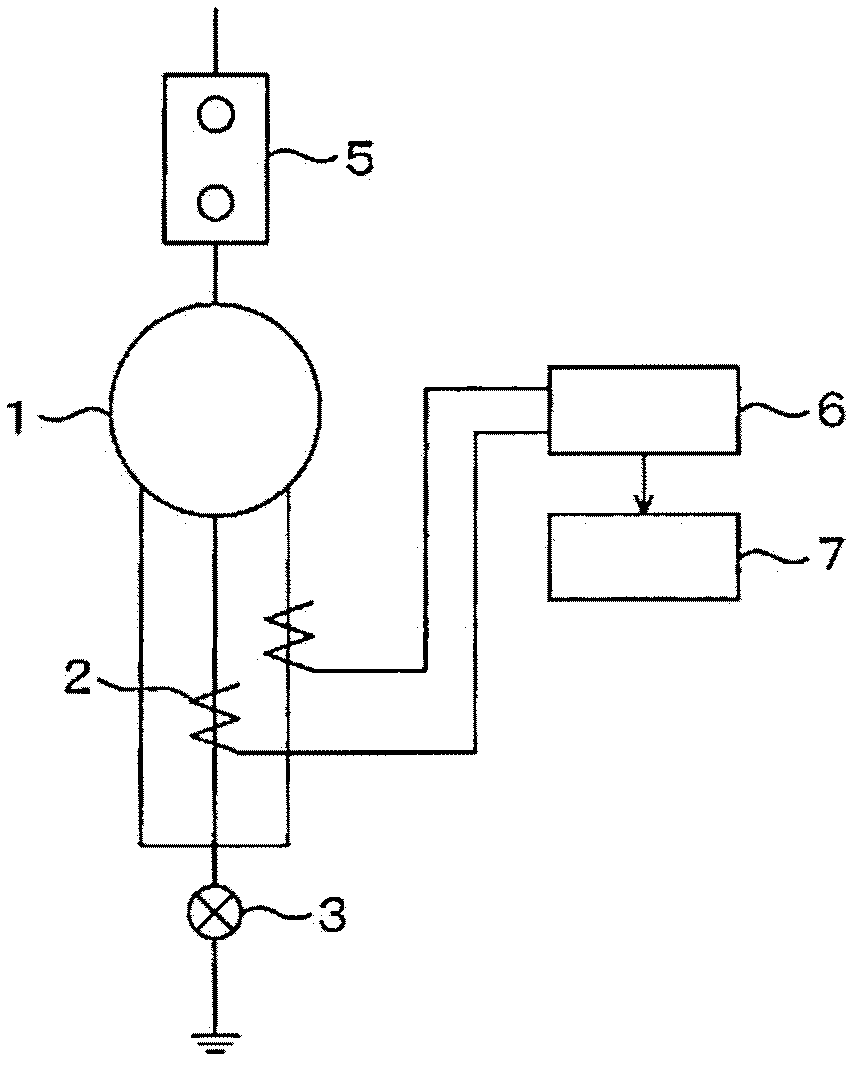

[0055] figure 1 It is a configuration diagram showing Embodiment 1 of the present invention. The neutral point side of the rotor coil of the rotating electric machine 1 is ground-faulted via the circuit breaker 3 after three phases are short-circuited. The current measurement unit 2 is arranged in two of the three phases of the rotor coil to measure the current. The measured two-phase currents are detected by the current detection device, and the calculation device 7 compares the harmonic components of the two-phase currents, and if there is a difference in the harmonic components between the two phases, it is determined that the coil ground fault.

[0056] Figure 10 The coil ground fault detection flow of Embodiment 1 is shown. Current detection 21 is performed by the current detection device 6, and periodic waveform extraction 22 and higher harmonic component calculation 24 are carried out in the calculation device 7 based on the information thereof, and the result base...

Embodiment 2

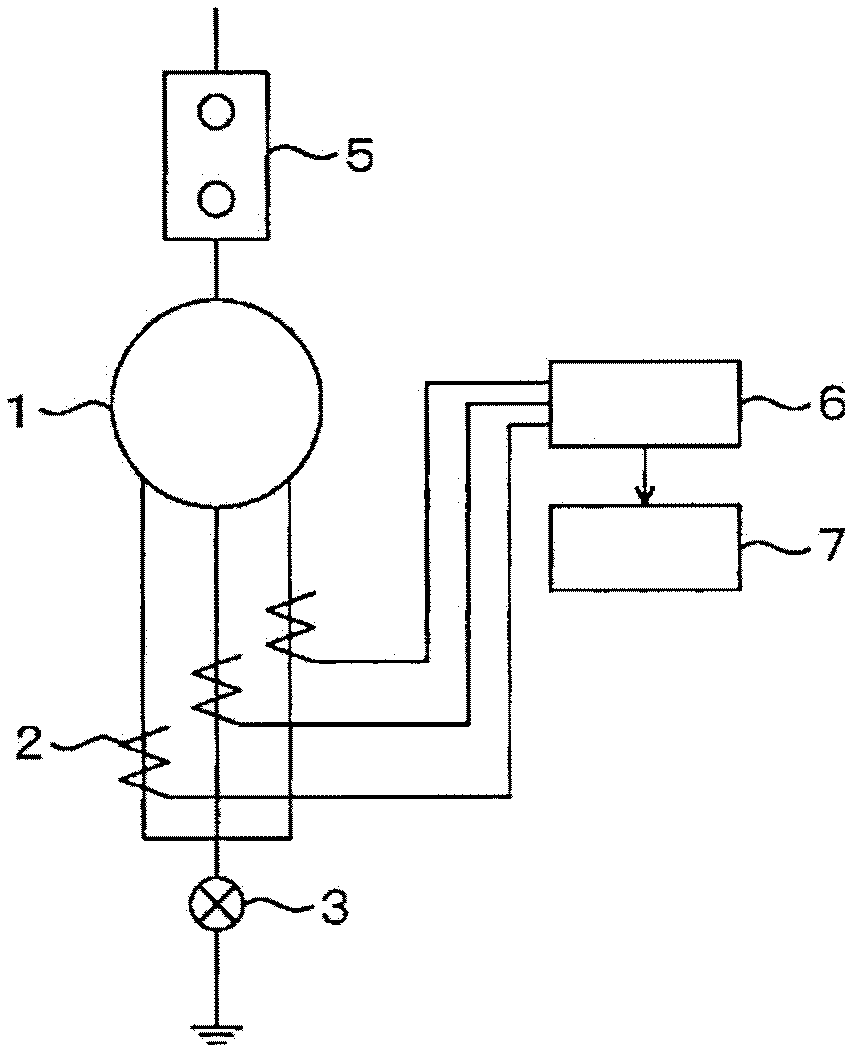

[0064] figure 2 It is a configuration diagram showing Embodiment 2 of the present invention. In Embodiment 1, an example of comparing currents of two phases was shown, but all three phases can be compared in the rotor coil which is the target of current measurement.

Embodiment 3

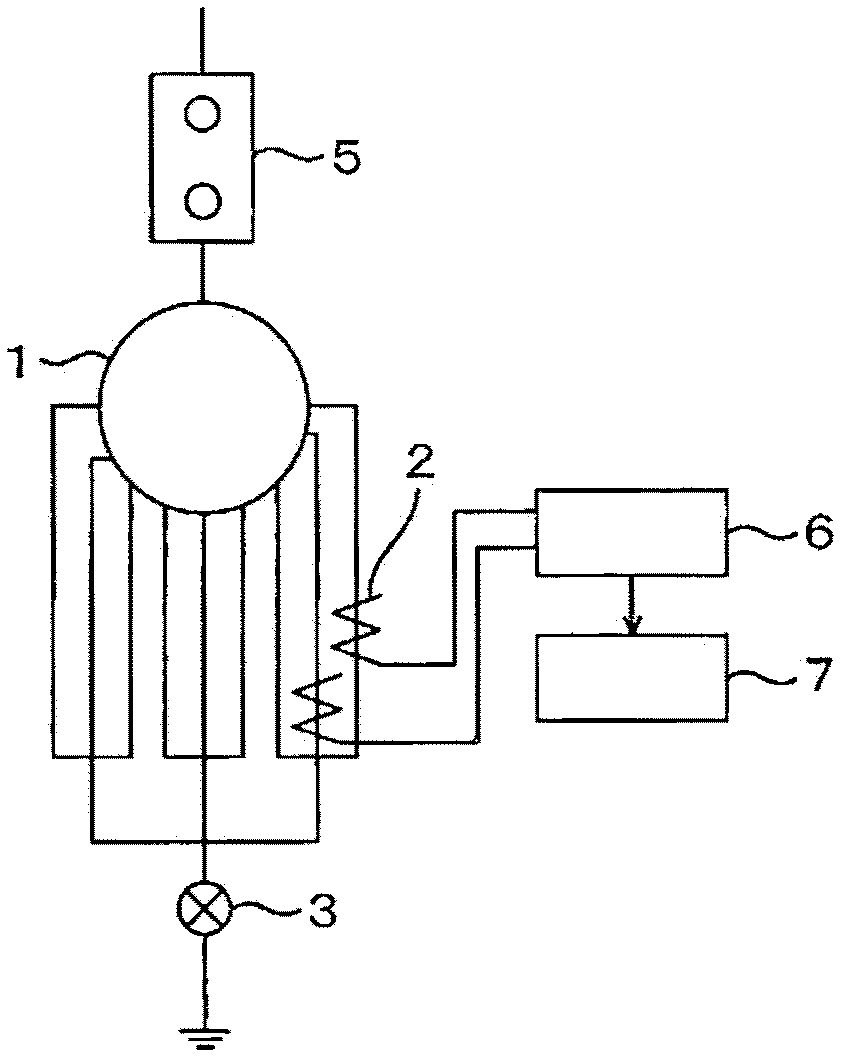

[0066] image 3 It is a configuration diagram showing Embodiment 3 of the present invention. A three-phase rotor coil composed of three parallel circuits is implemented in the rotating electric machine 1 , current measuring means 2 are provided in two parallel circuits of one phase, and current measuring means 2 are provided in one circuit of the other phase. The computing device 7 compares the harmonic components based on the currents of two parallel circuits of the same phase or the current of one circuit of another phase detected by the current detecting device 6, and when there is a difference in the harmonic components between the circuits , it is determined that there is a coil ground fault.

[0067] In a circuit in which a coil ground fault has occurred, the current waveform is different from that of other parallel circuits due to superimposition of the ground fault current. Therefore, coil ground fault detection can be performed by comparing current components betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com