Power tool

A technology of electric tools and tools, applied in the direction of manufacturing tools, portable mobile devices, metal processing equipment, etc., can solve the problem that the nut parts cannot be prevented from loosening, and achieve the effect of preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

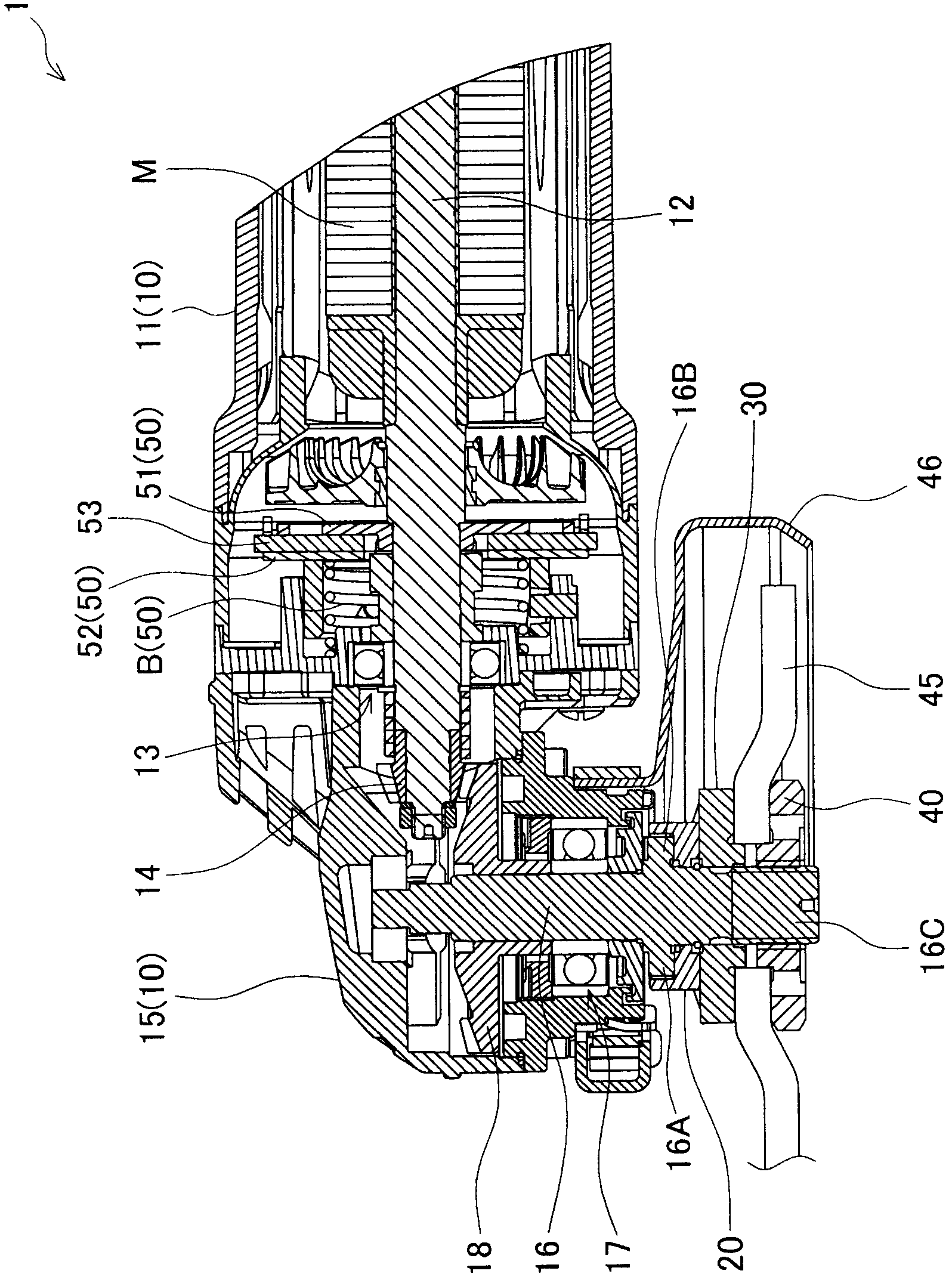

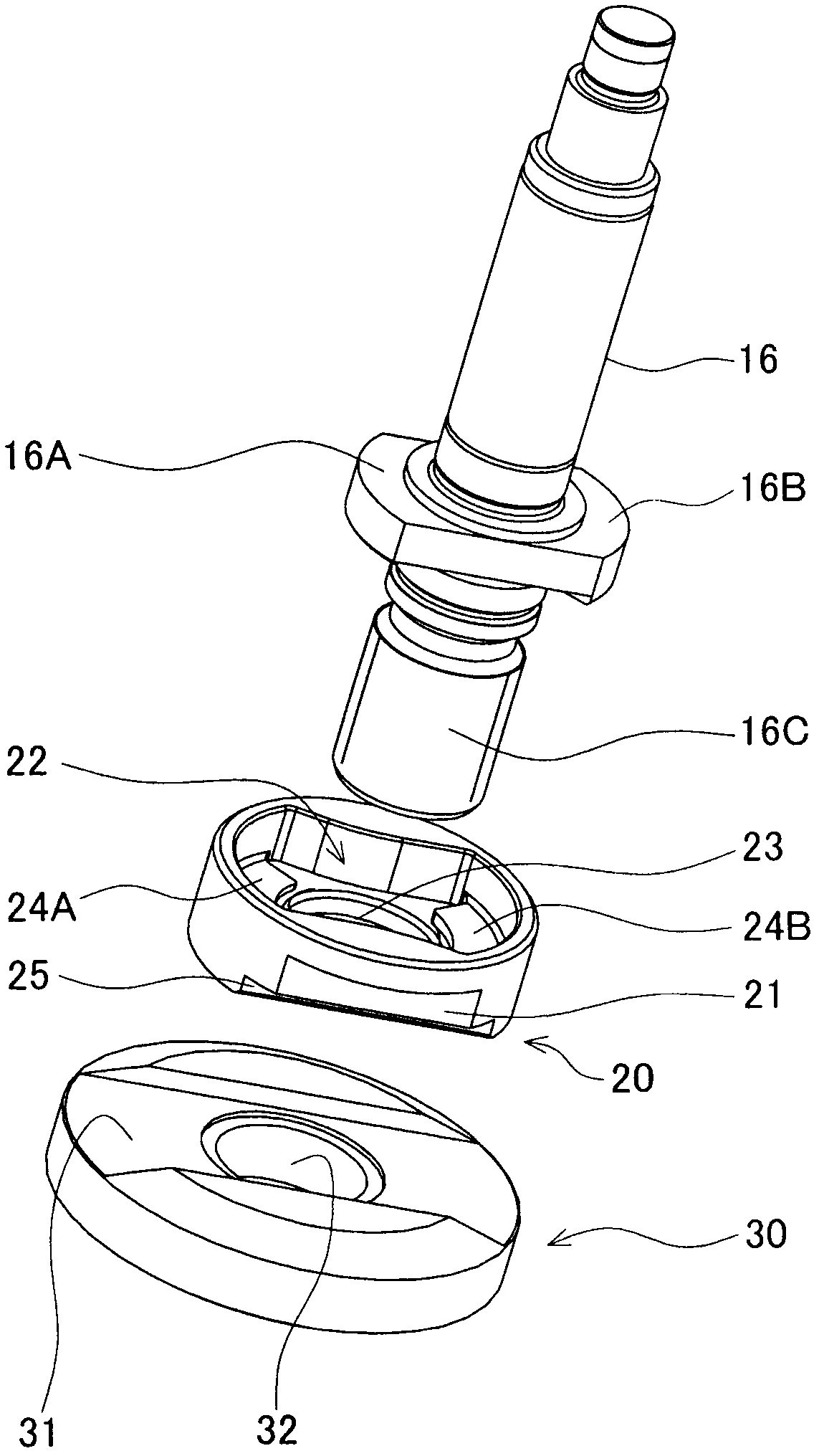

[0026] Refer below Figure 1 to Figure 6 Specific embodiments of the present invention will be described. Such as figure 1 As shown, the grinder 1 has a housing 10 , an anti-loosening component 20 , an inner flange 30 , a lock nut 40 , and a braking device 50 . In addition, the grinder 1 is an example of the electric tool of this invention.

[0027] The housing 10 is composed of a cylindrical motor housing 11 and a transmission mechanism housing 15 . The motor M is accommodated in the motor case 11 . A shaft 12 of the motor M is rotatably supported in the motor housing 11 via a bearing 13 . A first bevel gear 14 is provided at the head end of the rotating shaft 12 .

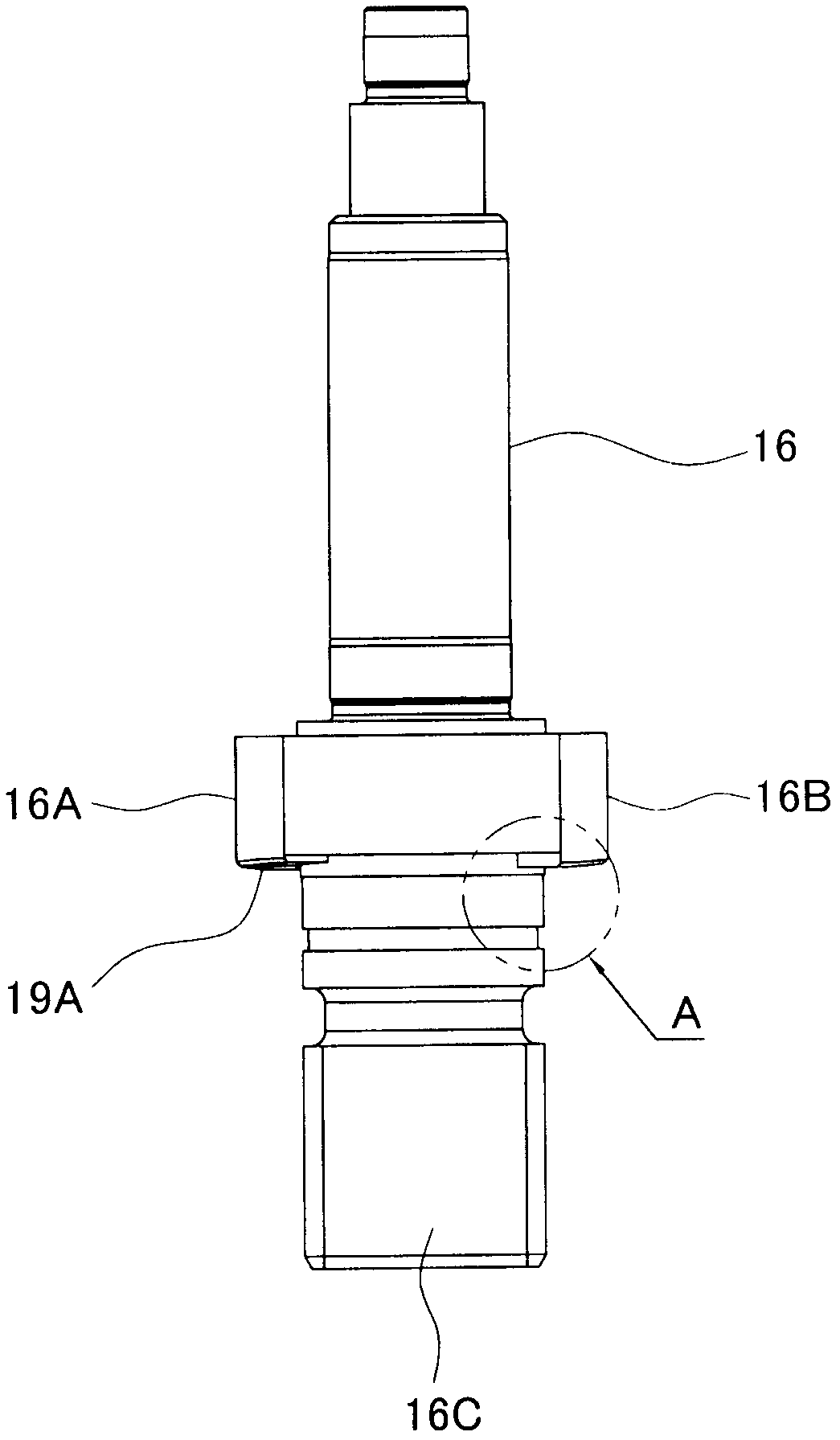

[0028] The transmission case 15 is assembled in front of the motor case 11 . The above-mentioned rotating shaft 12 extends from the motor housing 11 into the transmission mechanism housing 15 . A main shaft 16 is rotatably supported by a bearing 17 in the transmission case 15 , and the main shaft 16 is per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com