High-pressure modular underground centralized refrigeration device and system for mining

A high-pressure module and refrigeration device technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., to achieve stable operation, reduce initial investment, and facilitate transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

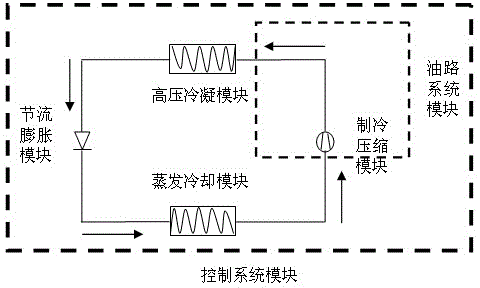

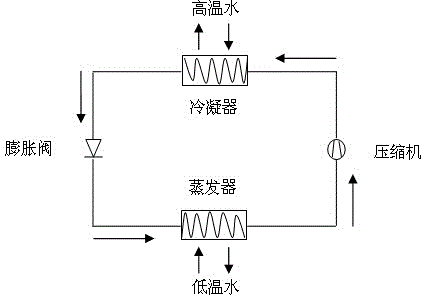

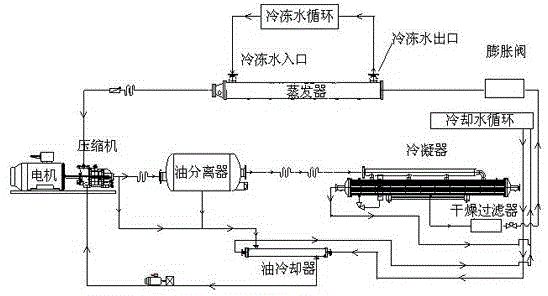

[0043] like figure 1 As shown, the mining high-pressure modular underground centralized refrigeration device of the present invention includes a refrigeration compression module, a high-pressure condensation module, a throttling expansion module, an evaporative cooling module, an oil circuit system module and a control system module. The composition is described as follows:

[0044] (1) Refrigeration compression module: In this embodiment, the refrigeration compression module is mainly composed of a soft starter, an explosion-proof motor and a screw compressor. The explosion-proof motor is connected with the screw compressor to provide power for the operation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com