Operating process for the production of an insole for footwear and insole thus obtained

A processing technology and shoe insole technology, applied in the field of shoe insoles, can solve problems such as high hardness and poor elasticity of shoe insoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

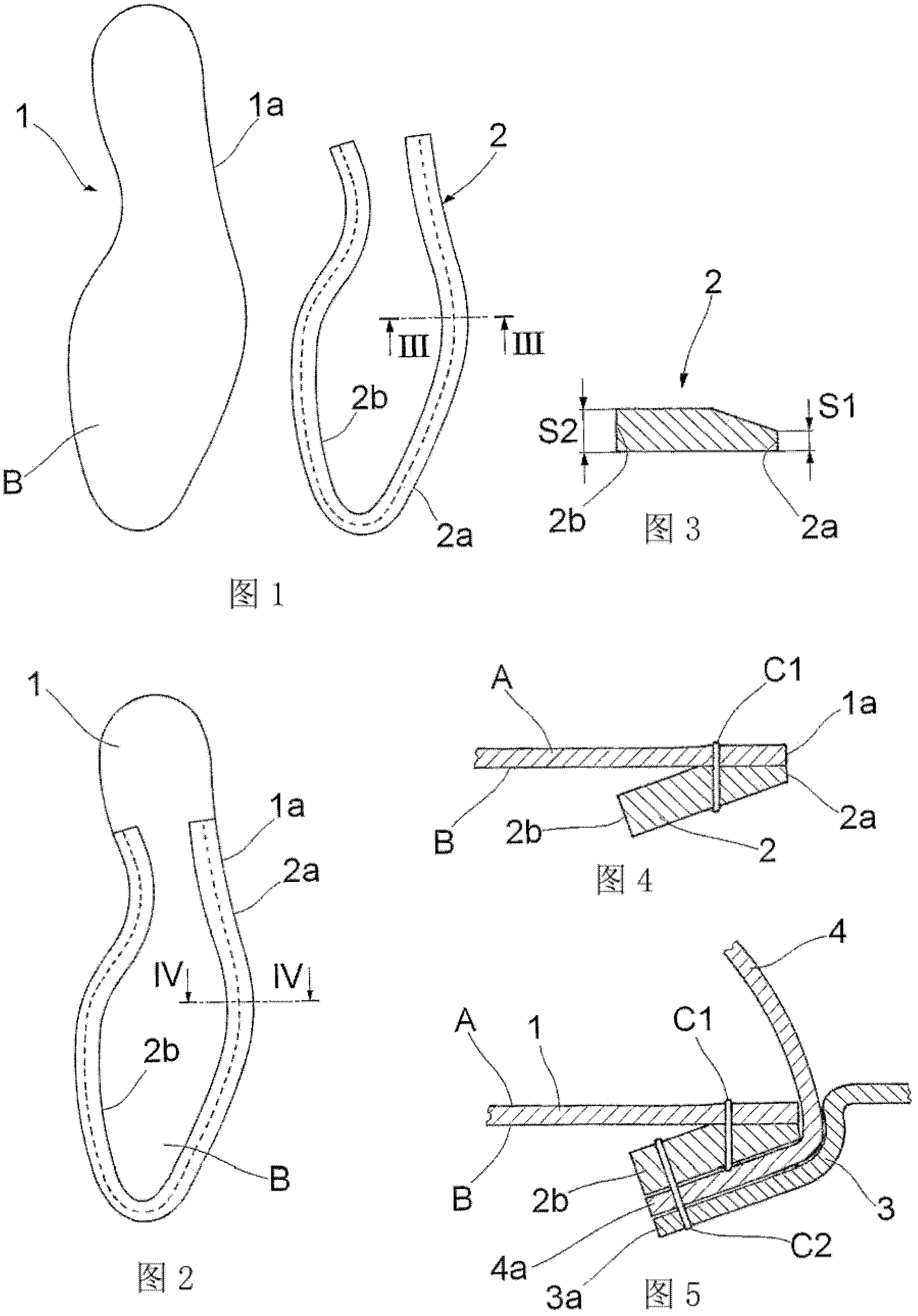

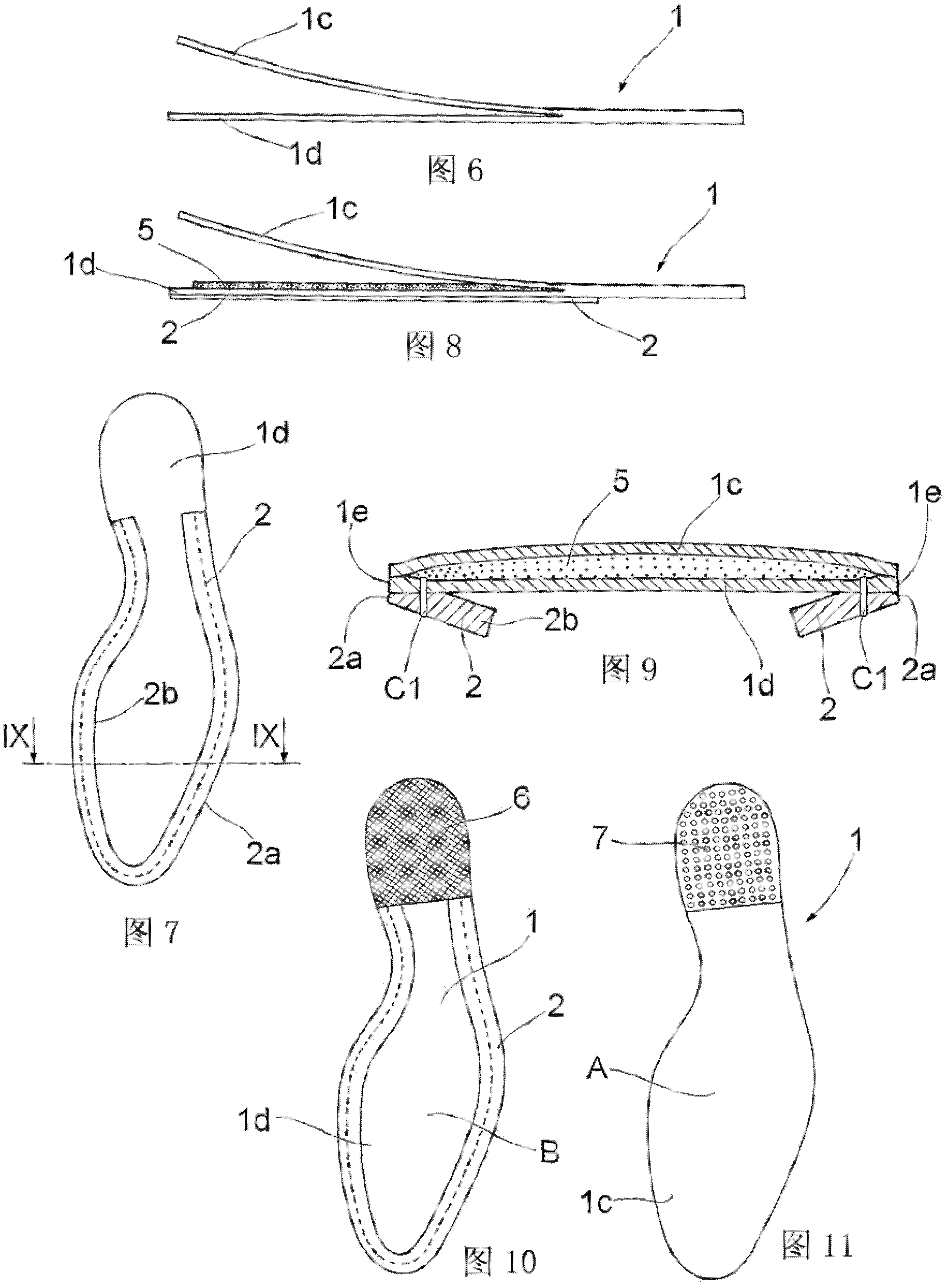

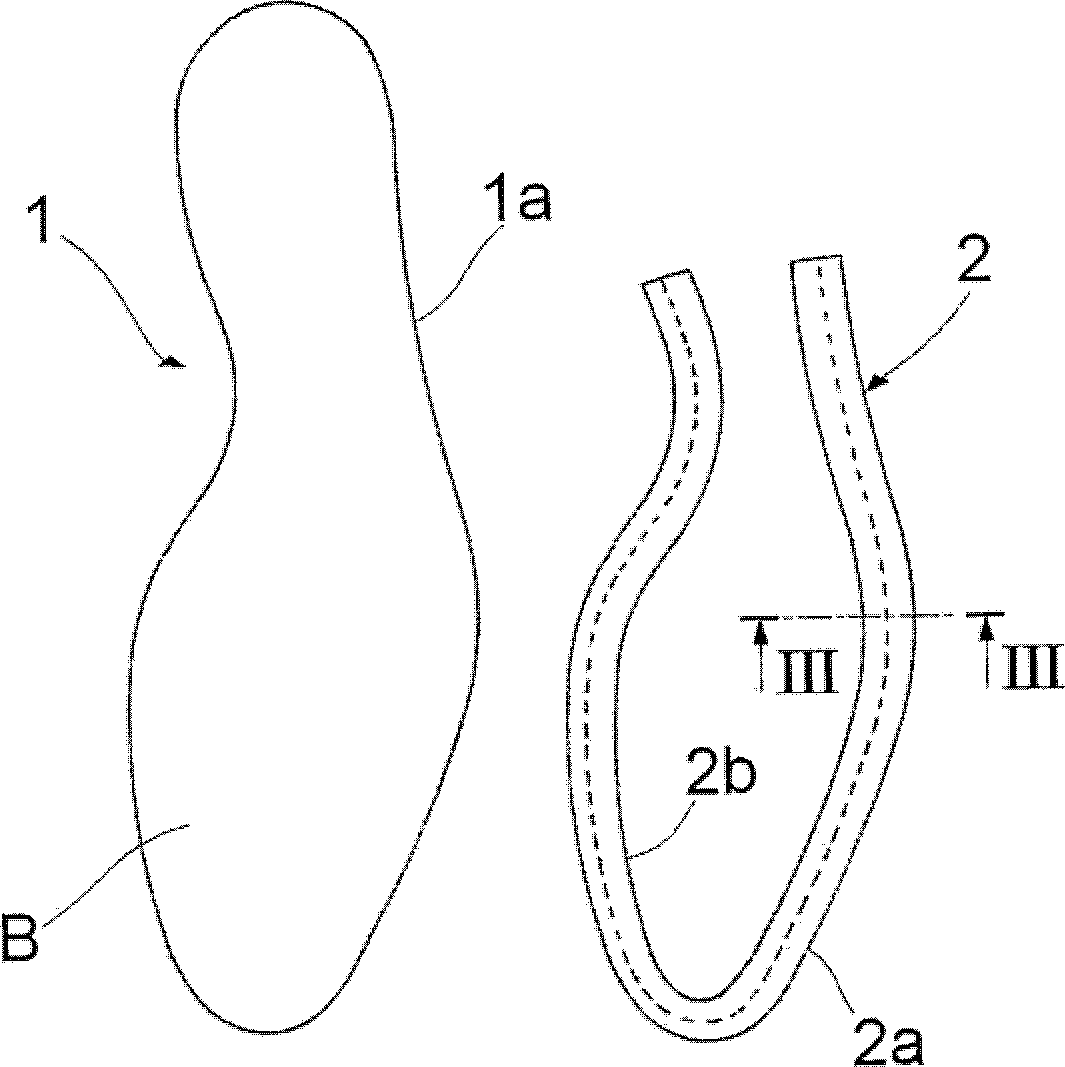

[0031] like Figure 1-5 As shown, the process of the present invention firstly involves the preparation of a novel shoe insole 1, which has the characteristics of light weight, softness and high elasticity.

[0032] Preferably, said insole 1 is made of a piece of thin leather or soft thin tanned leather or even fabric or cloth. The insole 1 has a top surface A and a bottom surface B. A strip 2 is sewn onto the bottom surface B along the entire edge of said insole 1, except for the horseshoe arched sole, whose edge wraps around the heel. Wherein the rubber strip 2 is also made of a piece of thin leather or soft thin tanned leather.

[0033] More specifically, the rubber strip 2 is fixed on the lower inner sole 1 by at least one edge stitch C1, wherein the stitch C1 is close to the outer edge 2a of the rubber strip 2. By setting the outer edge 2a at a position flush with the edge 1a of the insole 1, the inner edge 2b of the rubber strip 2 is freely closed and separated from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com