Pneumatic-crawler traveling mechanism in pipeline

A traveling mechanism and crawler-type technology, applied in the direction of pipe elements, mechanical equipment, pipes/pipe joints/pipes, etc., can solve problems such as poor climbing ability, and achieve the effect of increasing adhesion coefficient, reducing pressure and large traction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

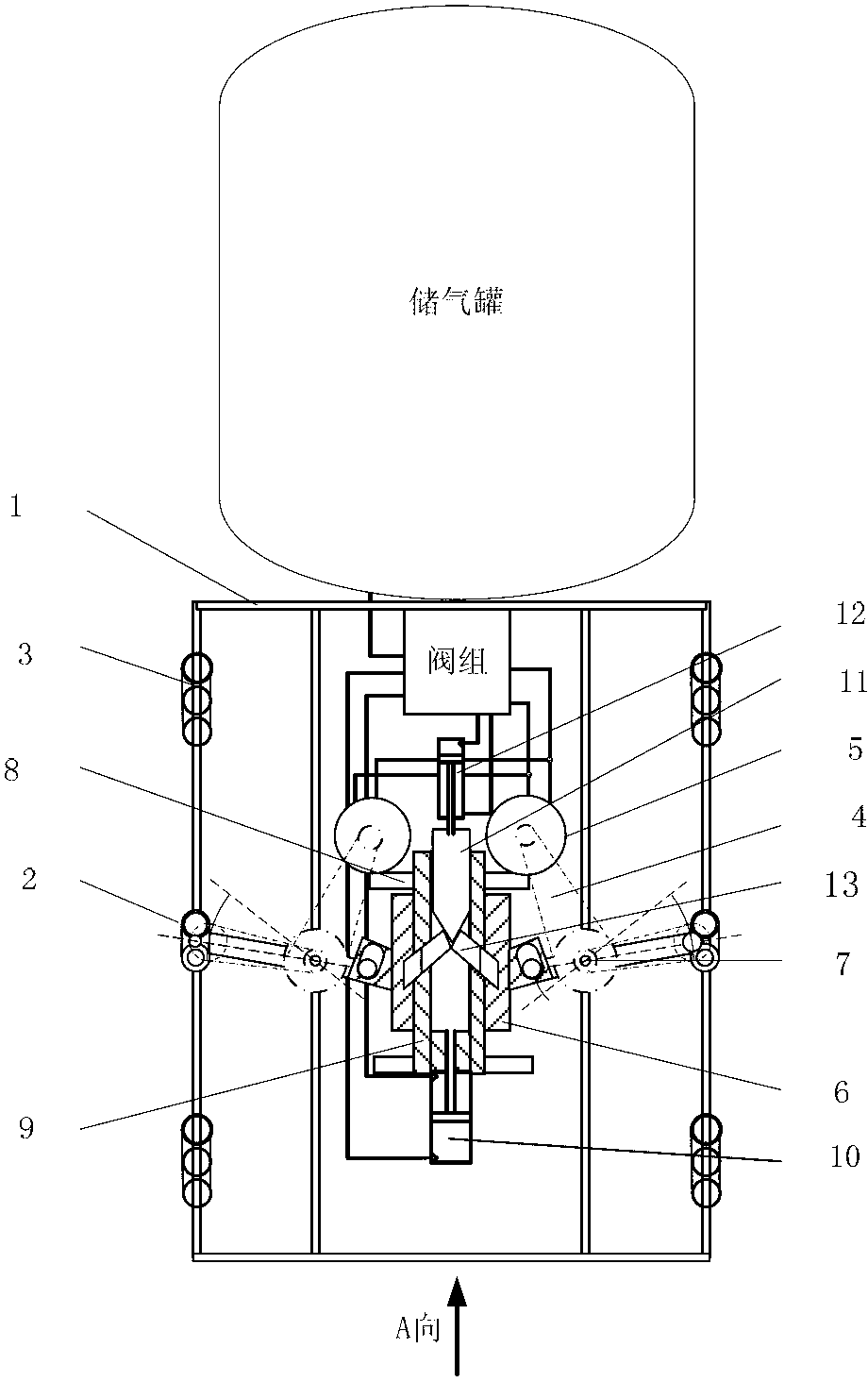

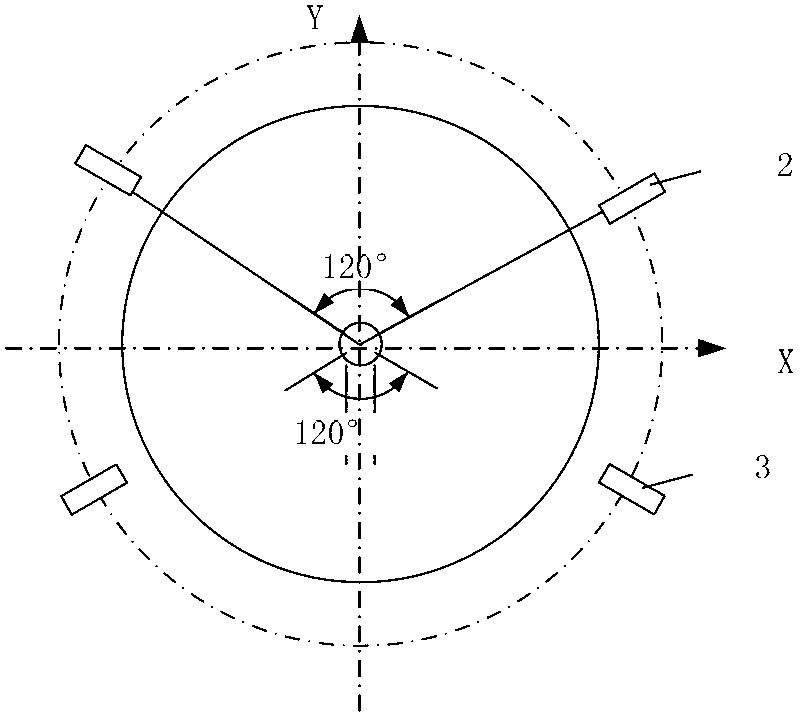

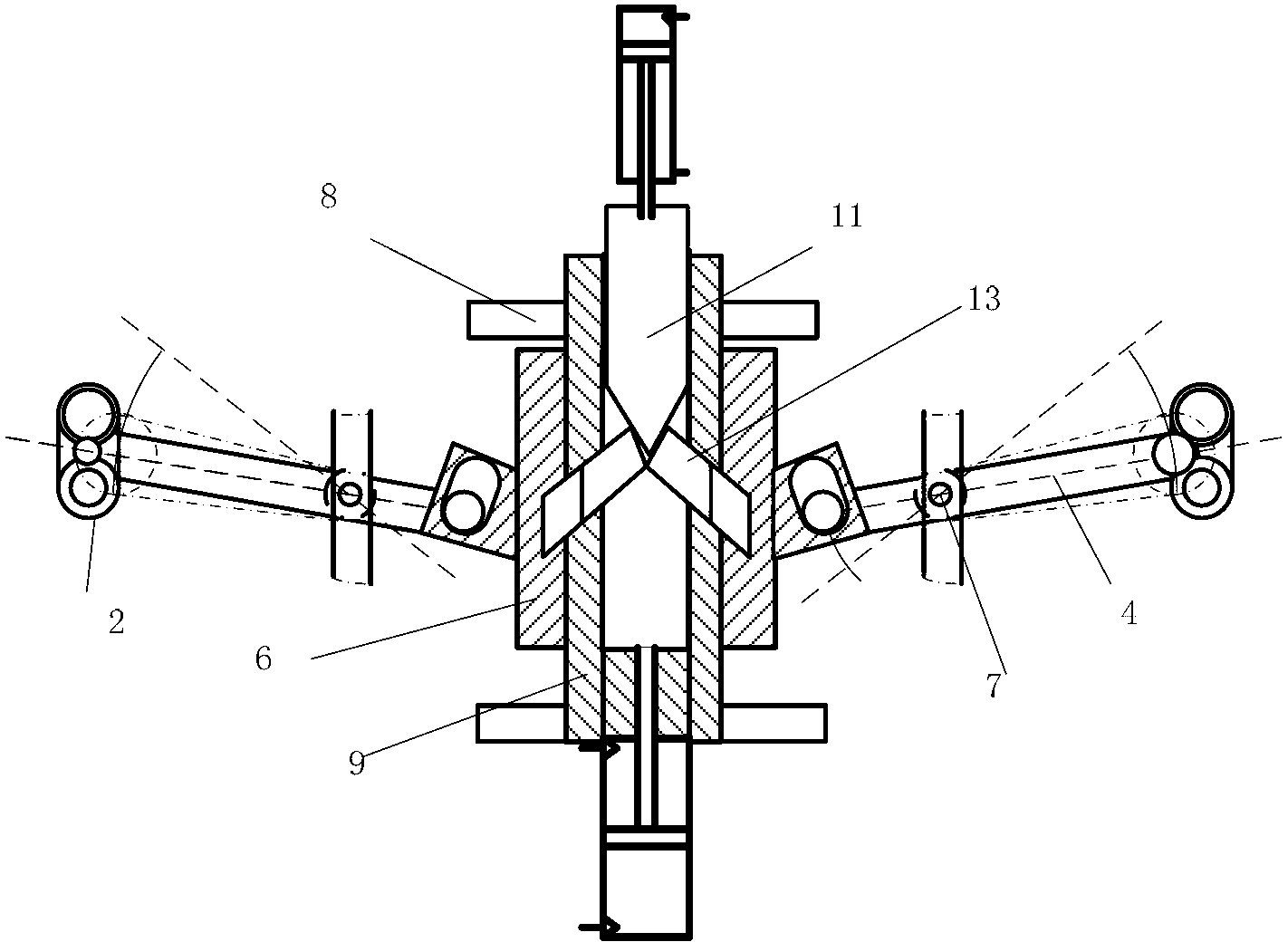

[0033] refer to Figure 1 to Figure 14 , a pneumatic crawler-type pipeline inner walking mechanism, comprising a vehicle frame 1, a driving wheel 2 and a driving wheel 3, two driving wheels 3, a driving wheel 2 and two A walking wheel 3, viewed from the axial direction, the walking wheel 3 is located in the lower semicircle of the vehicle frame, and the driving wheel 2 is located in the upper semicircle of the vehicle frame; the radial distribution is two traveling wheels that are symmetrical about the Y axis, and the traveling wheel 3 is installed on the vehicle frame 1, the drive wheel 2 is connected to the transmission mechanism, and the transmission mechanism includes a support arm 4, a sliding sleeve 6 and a frame center shaft 9. The drive wheel 2 is installed on one end of the support arm 4 through a pin shaft, and the support arm 4 The other end of the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com