LED light bar and side-entry backlight module using the light bar

A technology of LED light bar and side-type backlight, which is applied in the light guide, optics, light guide and other directions of the lighting system, which can solve the problems of affecting the display effect and lengthening of the dark area, and achieve the effect of increasing the light irradiation range and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

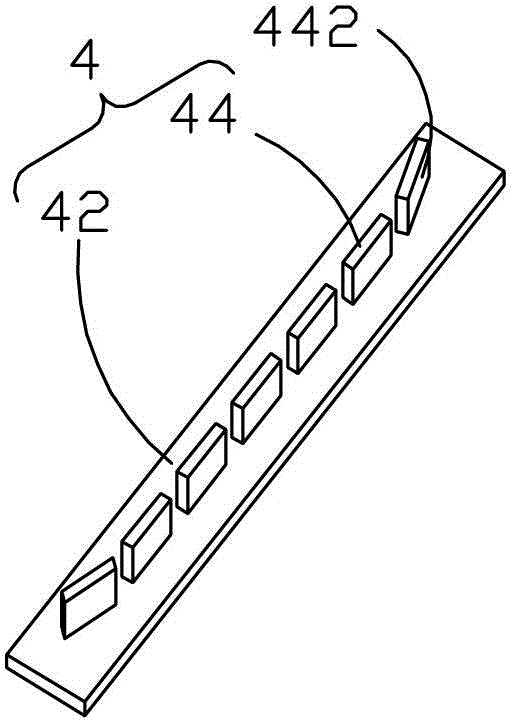

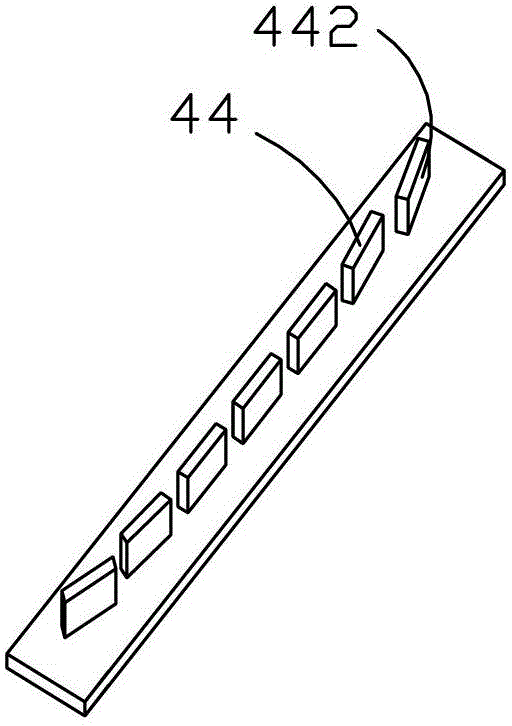

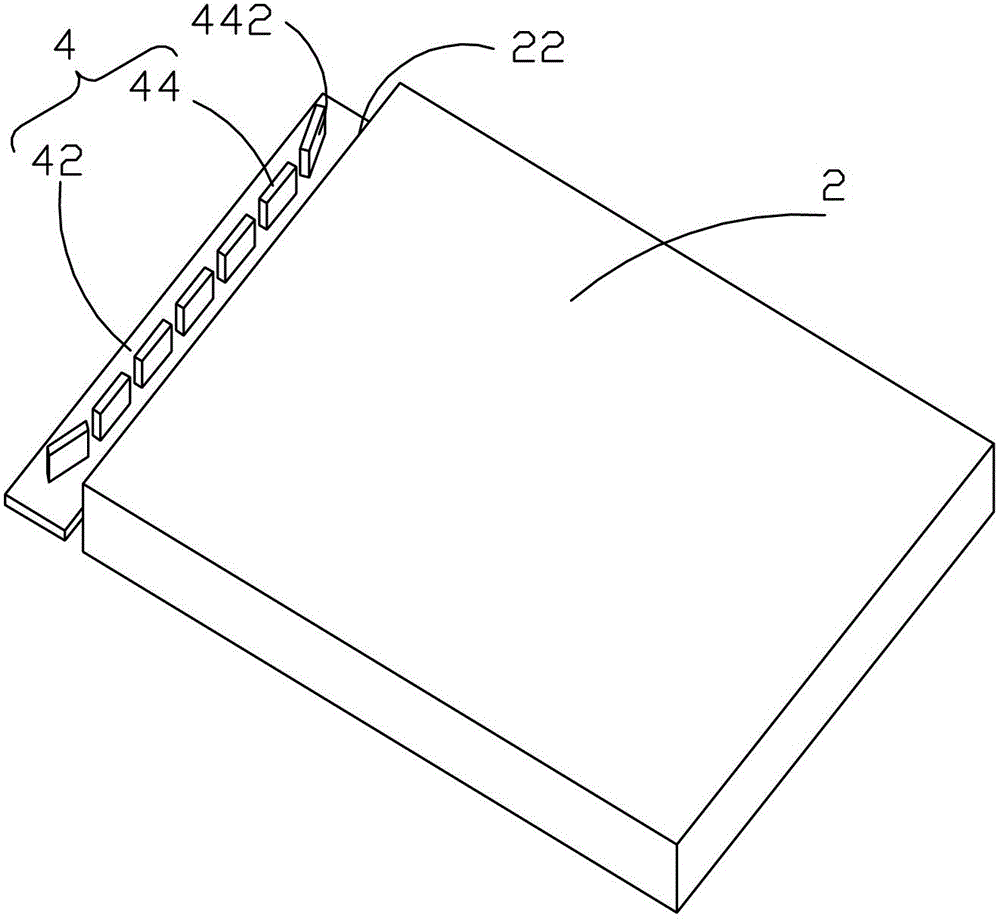

[0025] Such as figure 1 As shown, the present invention provides an LED light bar 4, comprising: a PCB board 42 and several LED lamps 44 installed and electrically connected to the PCB board 42, each LED lamp 44 has a light-emitting surface 442, the The light-emitting surface 442 is perpendicular to the PCB board 42, the several LED lights 44 are arranged in sequence and their light-emitting surfaces 442 are located on the same side of the PCB board 42, the light-emitting surfaces 442 of the middle LED lights 44 are arranged in a straight line, and the LED lights 44 at both ends The light-emitting surface 442 is deflected in a direction away from the light-emitting surface 442 of the middle LED lamp 44 to increase the light irradiation range o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com