On-line monitoring device and monitoring method for motor equipment status

A technology of equipment status and monitoring devices, applied in the field of detection, can solve problems such as quantitative analysis and failure to predict failures in advance, and achieve the effect of solving hidden troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

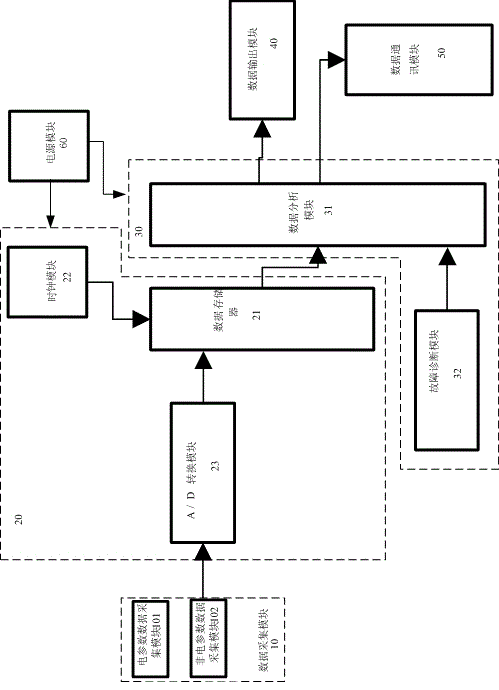

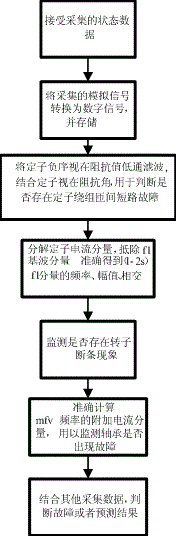

[0008] Specific embodiments of the present invention are described with reference to the above drawings.

[0009] The motor is composed of several parts such as stator, rotor, bearing and air gap. Due to the long-term operation of the motor, its performance will gradually deteriorate, which will lead to various failures of the motor. Generally, according to the location of the fault, common faults can be divided into stator faults, rotor faults, and bearing faults. In order to prevent various faults of the motor, real-time state monitoring is required to prevent the occurrence of faults.

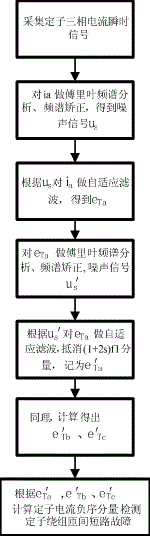

[0010] Stator winding faults mainly include inter-turn short circuit, overheating, and insulation faults. Among them, inter-turn short circuit faults account for 50% of stator winding faults, overheating faults account for about 20%, and insulation faults account for about 25%. By monitoring the stator three-phase current spectrum, voltage, temperature, etc., the specific fault of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com